How to Choose the Best PCB Assembly Manufacturer for Your Project in 2025

Choosing the right PCB assembly manufacturer is very important. It can help your project succeed or fail. Whether you’re making one model or many, you need a partner who understands your needs. The best PCB assembly manufacturer offers more than just assembly; they bring skill, good quality, and trust.

Each PCB assembly manufacturer is unique. Some excel with new technology, while others are better for saving money. Your task is to select one that aligns with your goals. Consider factors like price, quality, and support. This will contribute to your project’s success.

Key Takeaways

- Know what your project needs before picking a PCB maker. Understanding how complex the design is helps you choose better.

- Check manufacturers for their skills and certifications. Look for updated tools and standards like ISO 9001 for good results.

- Make a clear budget and think about all costs. Include design, materials, and hidden fees to avoid problems later.

- Focus on communication and support. A helpful manufacturer can fix issues fast and keep your project moving.

- Visit or check manufacturers to see their workspaces and methods. This makes sure they can meet your needs and make good products.

Know What Your Project Needs

Before picking a PCB assembly company, figure out your project needs. This helps you choose a manufacturer that matches your goals and delivers good results.

Check Design Complexity and Technical Needs

Look at how complex your PCB design is. Does it have tricky layouts or use advanced technology? Manufacturers with modern machines and strong skills are better for hard designs. For example:

| Feature | What It Means |

|---|---|

| Machines | High-tech tools handle tough designs and strict requirements. |

| Flexible Production | Companies should make both small and big batches of products. |

| Quality Certifications | Certifications like ISO 9001 ensure good processes and top-quality products. |

Think about future changes too. Will your product need updates? A flexible manufacturer can save you time and money later.

Set Deadlines and Delivery Goals

Deadlines matter for every project. Pick a manufacturer who can finish on time without lowering quality. Find companies with fast production and reliable delivery. Use key performance indicators (KPIs) to check their dependability:

| KPI | What It Shows | Why It Matters |

|---|---|---|

| Yield Rates | Shows how many good products are made. | High rates mean fewer mistakes and better profits. |

| Lead Times | Tells how fast products are delivered. | Short times avoid delays and keep your project moving. |

Ask manufacturers about their delivery times and how they handle problems. Clear communication about deadlines avoids surprises later.

Plan a Smart Budget

Budgeting takes careful planning. PCB assembly costs depend on design, labor, and materials. Simple designs cost less, but detailed ones cost more. Usually, PCB assembly makes up 30% to 60% of total costs. Here are ways to save money:

- Use simple designs when possible to cut costs.

- Add shipping and delivery fees to your budget.

- Order in bulk to lower the cost per item.

- Work with skilled vendors who know how to save money.

Knowing your project’s money needs early helps you stay on budget while keeping quality high.

Evaluate the PCB Assembly Manufacturer’s Capabilities

When picking the best PCB manufacturer, check their skills carefully. This helps ensure they meet your needs and deliver good results. Let’s look at the key things to review.

Check Advanced Manufacturing Technologies

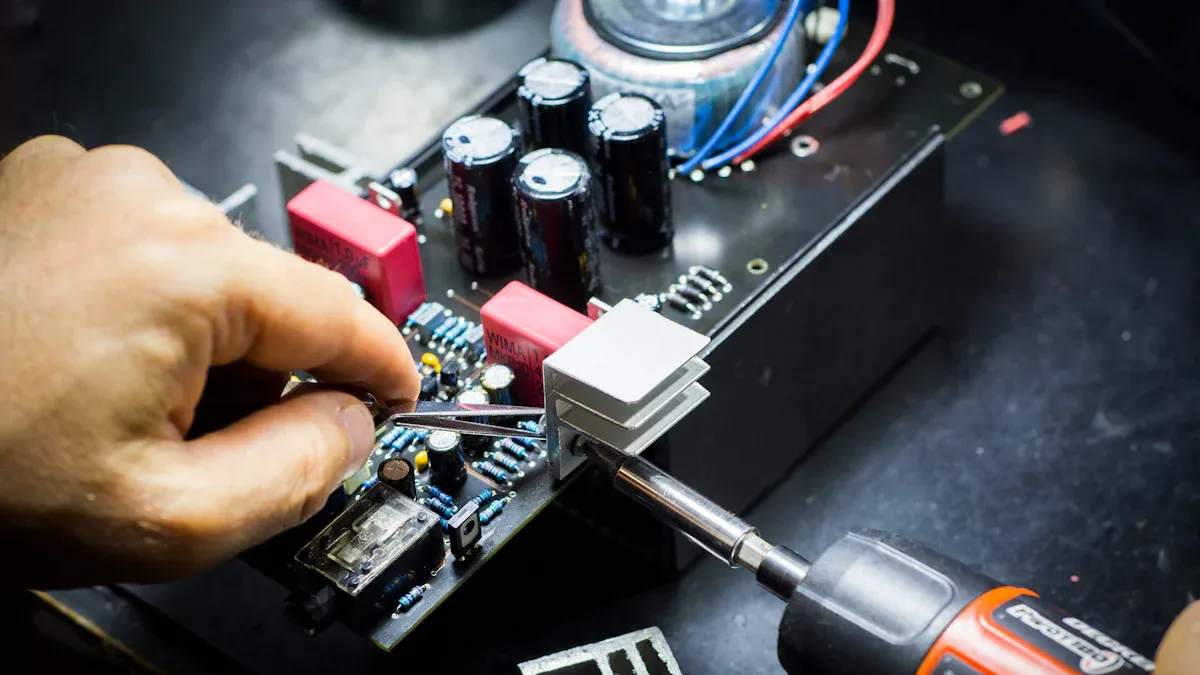

Technology is very important in PCB assembly. Companies with modern tools can handle tricky designs and keep quality high. Look for manufacturers using tools like automated optical inspection (AOI), surface-mount technology (SMT), and X-ray systems. These tools make work precise and reduce mistakes.

Ask if they can handle both small and big orders. A flexible company can adjust as your project changes. For example, if your design needs tiny parts or multilayer boards, make sure they have the right tools and skills.

Tip: Ask if they invest in new tools. Companies that follow trends often give better solutions for your project.

Check Certifications and Standards

Certifications show a company cares about quality and rules. They prove the company follows industry standards and makes reliable products. When choosing a PCB manufacturer, look for certifications like ISO 9001, IPC-A-610, and J-STD-001. These prove their processes are good and ensure top results.

Here’s a quick guide to key standards:

| IPC Standard | What It Means | Why It Matters |

|---|---|---|

| IPC-A-610 Class X | Rules for good electronic assemblies | Needed for contracts |

| J-STD-001 | Rules for soldered parts | Lowers solder mistakes |

| IPC-6012 | Rules for making circuit boards | Reduces hidden problems |

| IPC Class 3 | High standard for critical uses | Needed for long-lasting and safe products |

These certifications mean the company follows strict rules, lowering risks of mistakes. Always check their certifications before deciding.

Match Your Design Needs

Your design must fit the manufacturer’s process for smooth production. This includes matching their machines, parts, and methods to your project. If their tools and processes don’t match, it can cause delays.

Studies show using smart setups improves results. Companies using Group Technology or Cellular Manufacturing organize work better. This reduces downtime and speeds up production.

Note: It’s not just about tools. Communication matters too. Pick a company that understands your goals and helps improve your design.

Ask if they’ve worked on similar projects before. Experienced companies can spot problems early and offer fixes. This keeps your project on track from start to finish.

Importance of Experience and Quality Assurance

Picking a PCB assembly manufacturer with experience and quality checks is key. These factors help your project succeed and ensure good results.

Why Experience Matters

A company with years of experience knows how to handle tough jobs. They’ve worked with hard designs, tricky materials, and tight schedules. Their knowledge helps avoid problems before they happen. Here’s why experience is important:

- Skilled workers know materials and methods, making fewer mistakes.

- They finish tasks faster, saving time and cutting costs.

- They use new tools and ideas to keep your project up-to-date.

For example, one client had only 25% good boards with a 4-layer design. An experienced company fixed the design and raised the success rate to 92%. This shows how helpful expertise can be!

Why Quality Control Is Important

Quality checks make sure your PCB assembly works well. Without them, even great designs can fail. You should check how a company ensures quality. Here are some ways they do it:

| Quality Check Method | What It Does |

|---|---|

| X-ray Inspection | Finds hidden problems like cracks in small parts. |

| In-Circuit Testing (ICT) | Tests if circuits work properly in big batches. |

| Functional Testing | Checks if the board works in real-life situations. |

| Environmental Stress Tests | Adds stress to find hidden issues and improve durability. |

These checks make sure your boards are strong and reliable.

Testing and Inspection Services

Testing finds problems early and fixes them fast. Issues like rust, bad solder joints, or dirt can cause failures. Good companies use advanced tests to catch these problems. Here are some examples:

| Test Type | What It Finds |

|---|---|

| Optical Inspection | Spots surface problems like bad solder or shorts. |

| Microsection Analysis | Looks at layers to check strength and reliability. |

| Contamination Testing | Finds harmful dirt left during assembly. |

| Thermal Imaging | Detects overheating parts to improve cooling. |

Choosing a company with strong testing ensures your boards work well in real life.

Tip: Ask about their testing tools. Companies with good quality checks save you time and money later.

Cost and Material Sourcing Considerations

Picking the right PCB assembly partner means knowing costs and materials. These things affect your budget, product quality, and project success. Let’s break it into simple steps.

Compare Prices and Hidden Costs

Not all pricing is the same. Turnkey PCB assembly includes many costs like buying parts, making boards, assembling, and testing. Each part can change your budget. For example, part costs depend on where they’re bought, how many you need, and the type of parts. Also, making PCBs costs more if they have more layers or special materials.

Here’s a simple table of what affects prices:

| Factor | What It Means |

|---|---|

| Board Complexity and Size | Bigger or harder boards cost more to make. |

| Component Types and Quantity | Rare or fancy parts raise costs. |

| Production Volume | Big orders lower the cost per board. |

| Turnaround Time | Faster delivery costs more; slower saves money. |

| Quality Requirements | Extra tests cost more but make better boards. |

Tip: Ask for a clear price list. This helps you compare costs and avoid surprises. Be careful with very cheap prices—they might mean bad parts or poor work.

Check Material Sourcing and Supply Chain

Getting good materials on time is very important. A strong supply chain ensures you get the right parts when needed. Here’s how to check if a manufacturer is reliable:

- Work with several suppliers to avoid problems during shortages.

- Pick quality over cheap prices. Bad parts can cost more later if they fail.

- Make sure the manufacturer checks parts to avoid fake ones.

Good manufacturers also watch their supply chain using these methods:

| Method | What It Does |

|---|---|

| Key Performance Indicators (KPIs) | Tracks things like delivery times and sourcing success. |

| Bottleneck Identification | Finds and fixes slow parts of the process. |

| Proactive Communication | Talks with suppliers to solve problems fast. |

Balance Cost with Quality and Performance

Finding the right mix of cost and quality is key. Cheap boards might save money now but cost more later if they fail. High-quality boards last longer and need fewer repairs.

Here are ways to get the best value:

| Strategy | What It Does |

|---|---|

| Collaborative Design and Development | Work with the manufacturer early to save money without losing quality. |

| Preventive Quality Measures | Use checks to catch problems early and avoid fixing mistakes later. |

| Lifecycle Costs | Think about all costs, like repairs and downtime, not just the price now. |

Note: A good PCB assembly company helps you balance cost and quality. They guide you to smart choices that fit your budget and goals.

Customer Support and Communication

Working with a PCB assembly company needs good support and clear communication. A helpful partner listens, answers fast, and works well with you. Let’s see how to check these qualities.

Check Responsiveness and Communication Options

Clear communication keeps your project on track. Companies with easy contact options make updates and problem-solving simple. Look for manufacturers offering email, phone, or online tools to stay connected.

Here are ways to measure their responsiveness:

- Open Rates and Click-Through Rates (CTR): Show how often they read your emails.

- Survey Responses: Reveal how their team feels about internal communication.

- Feedback Volume and Sentiment: Help find areas where communication can improve.

A responsive partner keeps you updated and solves issues quickly. This saves time and avoids extra costs.

Look for Design Help and Support Services

Good manufacturers do more than just build boards—they improve designs. Talking to their team early ensures your design is easy to make and affordable. Regular reviews catch problems before production starts.

| Service Type | Benefit |

|---|---|

| Clear Communication | Makes sharing updates and feedback simple during the project. |

| Early Consultation | Confirms your design works and avoids expensive errors. |

| Design Reviews | Spots issues early, making production smoother and faster. |

Pick a manufacturer offering these services. Their advice can make your design better and improve results.

Think About Location and Logistics

Where your manufacturer is located affects your project’s flow. A nearby company can deliver faster and make shipping easier. If they’re overseas, check their inventory and shipping systems.

Important things to consider:

- Lead times and how they affect your schedule.

- Inventory management to prevent delays or missing parts.

- Working with contract manufacturers to improve shipping plans.

Good logistics ensure quality and on-time delivery. Whether close by or far away, choose a partner focused on being reliable and efficient.

Tip: Building a strong relationship with your manufacturer can help you get faster support when needed.

Step-by-Step Guide to Choosing a PCB Assembly Partner

Picking a PCB assembly partner can seem hard, but simple steps help. By following a clear plan, you can find a manufacturer that fits your needs and delivers good results. Let’s look at the steps to choose the right partner.

Research and Make a Shortlist

Start by learning about different manufacturers. Look for companies with experience in PCB assembly and your industry. Check their certifications, reviews, and case studies. This helps you find manufacturers who meet your quality and technical needs.

When making a shortlist, focus on how well they perform. Here are key things to check:

| Key Factors | What It Means |

|---|---|

| Supplier Evaluation and Selection | Important for smooth operations and good results. |

| Design Simplification and Modular Design | Makes manufacturing faster and more effective. |

| IT Infrastructure and Systems | Helps track and improve performance. |

| Open Communication | Makes teamwork and sharing information easier. |

Keep these tips in mind while shortlisting:

- Measuring performance helps keep results consistent.

- A rating system shows how reliable and good a supplier is.

- Updates with failure data improve how products are made.

By focusing on these points, you’ll find the best PCB manufacturer for your project.

Tip: Avoid companies with bad communication, no certifications, or poor reviews. These are warning signs of future problems.

Ask for Proposals and Compare Them

After shortlisting, ask for detailed proposals from the manufacturers. These should include their skills, prices, delivery times, and testing options. Comparing them side by side helps you see what each company offers.

Here’s how to review proposals step by step:

- Take Your Time: Carefully read each proposal.

- Check Experience: Look for companies with work in your field.

- Review Quality: See if they have good tools, certifications, and feedback.

- Look at Testing: Make sure they offer strong testing to avoid problems.

- Ask About Support: Check how quickly they respond and help.

- Compare Costs: Focus on value, not just low prices.

- Spot Red Flags: Be careful with unclear proposals or very cheap prices.

Following these steps helps you understand each company’s strengths and weaknesses. This way, you can pick a partner that matches your goals and timeline.

Note: Don’t only look at price. Spending a bit more can mean better quality and support, saving money later.

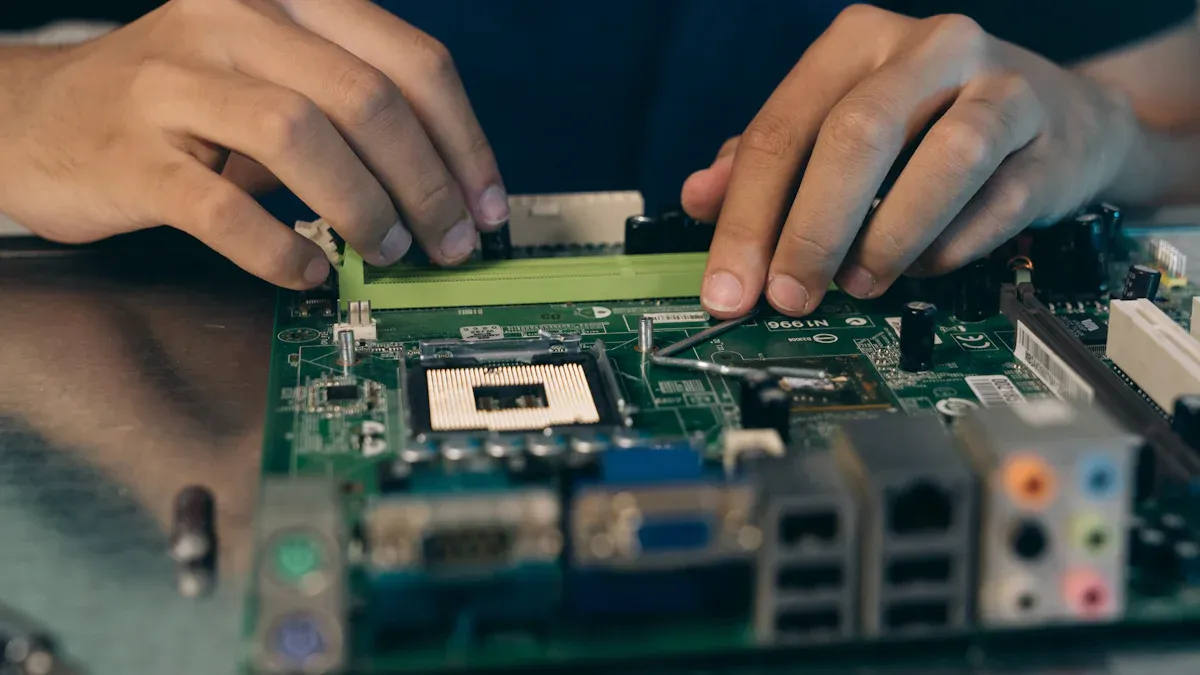

Visit or Audit the Manufacturer

Before deciding, visit or audit the manufacturer to check their abilities. Seeing their workplace shows you their tools, processes, and quality checks. You can also ask questions and solve concerns directly.

During your visit, look at these things:

- Tools and Technology: Do they use modern machines like AOI or X-ray systems?

- Testing Options: Do they offer tests like in-circuit or functional testing?

- Workplace: Is their space clean and well-organized?

- Support: Are they open to answering your questions?

If you can’t visit, ask for a virtual tour or detailed documents about their work. This step ensures the manufacturer can meet your needs and deliver good results.

Tip: Watch out for old tools, messy spaces, or unwillingness to share details. These could mean problems with quality or reliability.

By doing audits, you’ll feel confident in your choice and avoid surprises during the PCB assembly process.

Picking the right PCB assembly manufacturer is very important. It can help your project succeed or fail. Start by knowing what your project needs. Then, check manufacturers based on these points:

- Equipment: Do they have tools to build boards themselves?

- Production Capabilities: Can they handle small or big projects?

- Experience: Have they done similar work before?

- Product Quality: Look for certifications like ISO 9001.

- Customer Support: Do they answer questions quickly?

- Cost: Find a balance between price and quality.

By following these steps, you’ll pick a partner who meets your needs and delivers great results.

FAQ

What certifications should I check for in a PCB manufacturer?

Look for certifications like ISO 9001, IPC-A-610, and J-STD-001. These show the manufacturer follows strict rules for quality. Certifications ensure good processes and reliable products, which are key for your project.

Tip: Always confirm the certifications are valid before choosing.

How can I make sure the manufacturer meets my design needs?

Ask if they’ve worked on similar designs before. Share your design details and ask for advice. A good manufacturer will check your design and suggest ways to improve it.

Note: Clear communication helps avoid mistakes and keeps things on track.

Should I pick a local or overseas PCB manufacturer?

Local manufacturers are quicker to contact and ship faster. Overseas ones may cost less but could have delays or quality problems. Think about your budget, timeline, and shipping needs before deciding.

Tip: If choosing overseas, check if they have a strong supply chain.

What testing should a PCB manufacturer offer?

They should provide tests like X-ray inspection, in-circuit testing (ICT), and functional testing. These tests find problems and make sure the boards work well.

Emoji Reminder: 🛠️ Testing is important for strong and reliable boards!

How do I compare prices between manufacturers?

Ask for detailed quotes that list all costs, like materials and testing. Compare them carefully. Focus on value, not just the cheapest price, to avoid bad quality.

Pro Tip: Be careful of hidden fees or very low prices—they might mean poor work.