Understanding Hardware Assembly and Its Role in Manufacturing

- Hardware assembly puts parts together to make working systems or products.

- It is a key part of modern manufacturing and helps industries work better.

- It makes production faster and more accurate, saving time and effort.

- Industries like cars, electronics, and airplanes depend on well-made parts.

The market for precision parts will grow a lot.

In 2024, it will be worth $181.51 billion.

By 2034, it will reach $434.48 billion, growing 9.1% each year.

This shows how important hardware assembly is for making good products.

- From new car designs to advanced airplane technology, hardware assembly is essential.

- It helps create the future of manufacturing.

Key Takeaways

- Hardware assembly is key to making parts into full products.

- It ensures all parts fit and work well together.

- Modern methods can save time, cut costs, and meet needs fast.

- Tools like robots, IoT, and digital twins make assembly better.

- Planning products for easy assembly saves money and time.

- It also helps factories adjust quickly to new changes.

- Car and tech industries need assembly for safety and quality.

What Is Hardware Assembly and Why Is It Important?

Definition of Hardware Assembly

Hardware assembly means putting parts together to make products work. It’s like the heart of manufacturing, turning raw parts into finished items. Whether it’s a car, phone, or plane, assembly makes sure all pieces fit right. This process uses methods like fastening, welding, or riveting, depending on the product’s needs.

In short, hardware assembly connects making parts to creating final products. Without it, you’d only have loose parts, not a complete system.

Importance of Hardware Assembly in Manufacturing

Hardware assembly is key to making strong and reliable products. For instance, industrial electronics face tough conditions like heat and shocks. To handle this, makers use special resins and cooling systems during assembly. This ensures parts like sensors and controllers work well, avoiding costly delays.

Also, partial assembly helps companies stay flexible. By shipping parts separately, they can make some items themselves and outsource others. This saves money and speeds up production. Techniques like riveting and welding also improve efficiency, helping create quality products faster.

Tip: When designing, follow “design for manufacturing and assembly” rules. This makes assembly easier, lowers costs, and improves how products work.

Role in Streamlining Production Processes

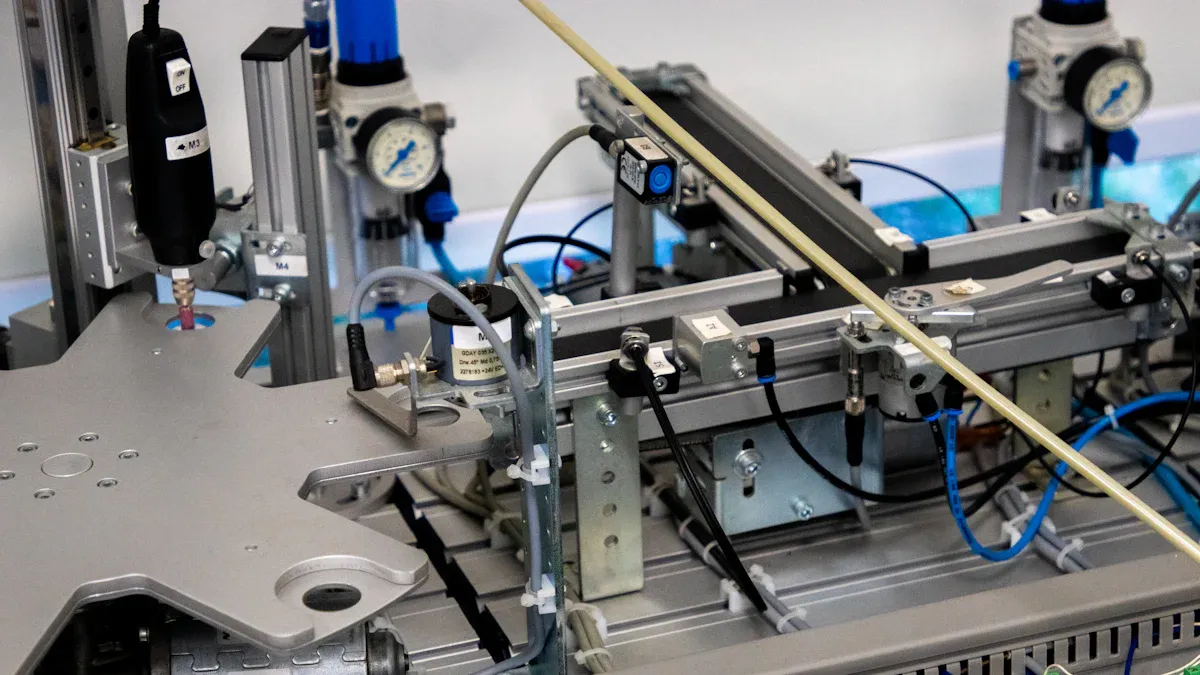

Hardware assembly makes production smoother and faster. Using advanced methods and automation, companies can work more efficiently. For example, BC Machining cut waste and reduced tool change times, saving money. These changes show how better assembly boosts production and cuts waste.

Automation is also very important. For instance, document automation stops delays caused by missing or wrong paperwork. This keeps production running smoothly, increasing output without needing extra workers or tools. Key metrics like cycle time, throughput, and labor use show how hardware assembly improves manufacturing:

| Metric | Description |

|---|---|

| Cycle Time | Tracks how long it takes to finish one product. |

| Throughput | Measures how many products are made in a set time. |

| Labor Utilization | Checks how well workers are used in the production process. |

By focusing on these metrics, you can find problems and fix them to improve production. Whether creating new hardware or increasing output, hardware assembly ensures every step works well for success.

Types of Hardware Assembly

Partial Assembly

Partial assembly means putting together some parts first. Other parts are added later. This method is useful in industries like cars and electronics. Modular designs make it easier to change or add parts. Building only the needed parts at first saves money and time.

For example, TiMEG is a model used in partial assembly. It has pros and cons:

| Advantages of TiMEG | Limitations of TiMEG |

|---|---|

| Works well with missing data | Harder to use with many SNPs |

| Finds weak signals in omics | Trouble filling in missing data |

| Keeps strong statistical power | May lose details with some data types |

Partial assembly helps companies stay flexible. It meets different needs without slowing down production.

Rivet Assembly

Rivet assembly joins materials using rivets for strong connections. It works well in tough conditions like cars and airplanes. Rivets make sure parts stay together and work correctly.

New riveting methods, like orbital forming, improve quality. They use data to check force and movement during assembly. This is important for safety in car parts.

Rivet assembly creates durable connections that make products last longer.

Weld Assembly

Weld assembly connects materials by melting them together. This makes strong bonds that are often tougher than the original parts. It’s used in industries like cars and airplanes for reliable results.

| Feature | Details |

|---|---|

| Strong Connections | Welded parts are stronger than separate materials. |

| Works with Many Materials | Can join metals, plastics, and composites easily. |

| Saves Resources | Welding wastes less material than other methods. |

| Car Use | Welding makes car parts stronger and safer. |

| Airplane Use | Welding meets strict rules for airplane safety and performance. |

Weld assembly is dependable and important for making high-quality products.

Mechanical Assembly

Mechanical assembly means joining parts with screws, bolts, or nuts. It is a common and flexible method in manufacturing. Industries like cars and electronics often use it. This method keeps parts secure but allows easy disassembly. It’s great for products needing repairs or upgrades.

One big benefit of mechanical assembly is its flexibility. It works with many materials like metals, plastics, and composites. Modular designs let you replace parts without changing the whole system. This makes production faster and saves money.

Precision is very important in mechanical assembly. Misaligned parts can cause damage or failure. Automated tools and quality checks help ensure accuracy. Accurate assembly makes products meet standards and satisfy customers.

Specialized Types (e.g., Adhesive Bonding, Press-Fit Assembly)

Special methods like adhesive bonding and press-fit assembly have special uses. Adhesive bonding uses glue to join parts. It’s good for lightweight materials and smooth finishes. Industries like aerospace and electronics use it to reduce weight and improve looks.

Press-fit assembly uses friction to connect parts tightly. One part is pressed into another without extra fasteners. It’s used in precise work like making circuits or car parts. This method skips welding or riveting, saving time and materials.

Both methods follow design-for-assembly rules. They make production simpler and faster. Picking the right method improves product strength and lowers costs.

Key Processes in Hardware Assembly

Joining Methods (e.g., Welding, Riveting, Fastening)

Joining methods are how parts are securely connected. They help parts work together as one system. Common methods include welding, riveting, and fastening, each with its own benefits.

- Welding melts materials to join them into one piece. This creates very strong connections, perfect for cars and airplanes. Automated welding makes the process faster and more accurate, reducing mistakes and saving materials.

- Riveting is a fast way to join different materials. Rivets are not as strong as welds but are easier to use and fix. This method works well for simple designs or when materials don’t match.

- Fastening uses screws, bolts, or nuts to hold parts together. It allows easy repairs and upgrades. This method is popular in electronics and products with replaceable parts.

The best joining method depends on the product’s needs, materials, and balance between strength and ease of use.

Assembly Line Evolution and Automation

Assembly lines have changed a lot over time. Early ideas, like Ransom Olds’ car assembly line in 1901, made production faster. Henry Ford’s moving assembly line in 1913 cut the time to build a Model T from 12 hours to just 93 minutes.

In the 1960s, robots were added to assembly lines. General Motors used the first industrial robots to make work safer and more consistent. By the 1970s, programmable machines became common, improving manufacturing even more.

Today, Industry 4.0 tools like the Industrial Internet of Things (IIoT) share data instantly. This makes production faster and more accurate. Using automation helps companies stay ahead in a competitive market.

| Year | Milestone | Impact |

|---|---|---|

| 1901 | First automotive assembly line by Ransom Olds | Increased production from 425 to 2,500 cars in one year. |

| 1913 | Moving assembly line by Henry Ford | Cut production time and costs, making cars affordable. |

| 1962 | First industrial robots by General Motors | Made repetitive tasks safer and more consistent. |

| 2000s | Industry 4.0 technologies emerge | Allowed instant data sharing and better operations. |

Quality Control in Hardware Assembly

Quality control ensures products meet standards and satisfy customers. It includes testing and checking at every step of assembly. Rules like ISO 9001 and IATF 16949 help companies make fewer mistakes and keep quality high.

Modern tools use automation to catch errors quickly. For example, CNC machines are very precise, making sure parts are made correctly. This stops bad parts from moving forward in production.

Mistake-proofing is also important. Designing processes to avoid human errors improves accuracy and reduces waste. These steps make products better, keep customers happy, and build trust in your brand.

| Quality Standard | Description |

|---|---|

| ISO 9000 and 9001 | Ensures companies follow quality management rules. |

| IATF 16949 | Focuses on cutting defects in car manufacturing. |

| IAQG 9100 | Sets quality goals for airplane manufacturing. |

| GMP | Makes sure products are made consistently and safely. |

By focusing on quality control, companies can earn customer trust and succeed in the long run.

Applications of Hardware Assembly in Manufacturing

Industrial Solutions (e.g., Automotive, Aerospace)

Hardware assembly is very important in industries like cars and airplanes. These industries need safe and reliable products to work well. Assembly makes sure every car or plane part fits perfectly. This helps them handle tough conditions. For example, in cars, welding and riveting make strong frames. They also secure parts like engines and suspensions. In airplanes, precise assembly ensures safety and top performance.

Research shows how important hardware assembly is. Check out this data:

| Evidence Type | Description |

|---|---|

| Market Size Estimation | Car equipment market size is calculated using different methods. |

| Primary Research Methodology | Experts are interviewed to collect useful data. |

| Data Triangulation | Data is checked and confirmed using multiple sources. |

| Role of Hardware Components | Assembly improves efficiency and flexibility in making products. |

This data proves how assembly helps industries work better. Whether driving a car or flying, you rely on assembly for safety and quality.

Sheet Metal Fabrication

In sheet metal work, assembly makes production easier and better. This process shapes and joins metal sheets into things like panels and frames. These are used in buildings, electronics, and more. Assembly ensures parts are joined tightly, making strong and useful designs.

Here’s why assembly is so helpful in sheet metal work:

- It makes production faster and simpler.

- It improves the quality of finished products.

- It helps move from small to large-scale production easily.

Designing for easy assembly lowers costs and boosts accuracy. Quick assembly also reduces mistakes. This means products are cheaper, stronger, and last longer.

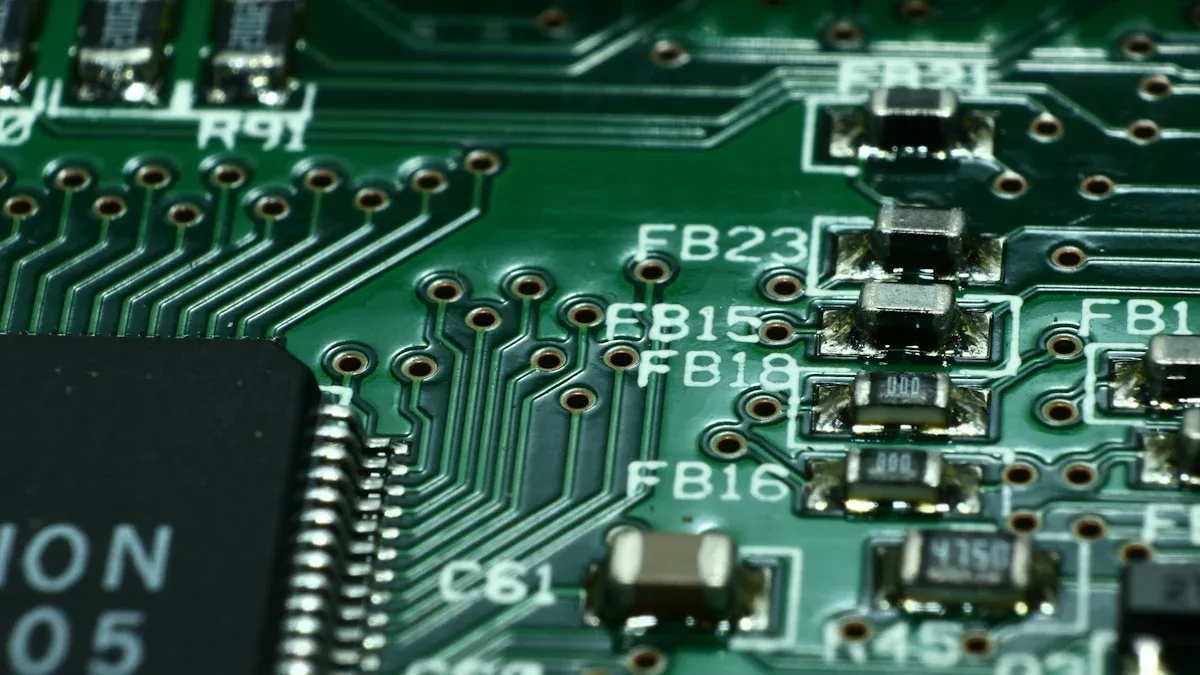

Electronics and Consumer Goods

Hardware assembly is key in making electronics and everyday items. From phones to appliances, you use these products daily. Processes like PCB assembly connect electronic parts correctly. This makes devices like phones work smoothly. For example, assembly combines the screen, battery, and circuits into one compact phone.

Consumer goods also use modular assembly. This makes fixing or upgrading products easier. For instance, in appliances, you can replace broken parts instead of throwing them away. This saves money and reduces waste, helping the environment.

Assembly is crucial for making high-quality electronics and goods. Whether using a laptop or washing machine, you benefit from precise and efficient assembly.

Custom Manufacturing and Prototyping

Custom manufacturing and prototyping help make special products for specific needs. Whether creating new gadgets or improving old ones, hardware assembly is key. It ensures accuracy, speed, and growth, keeping you ahead in the market.

Why Custom Manufacturing Matters

Custom manufacturing helps design unique products. It lets you follow trends and meet customer needs. For example, in electronics, modular designs allow easy upgrades for devices like phones and watches. You can swap old parts without rebuilding the whole product. This saves time, money, and keeps products updated.

Prototyping is just as important. It lets you test ideas before full production. By building prototypes, you can find problems early and fix designs. This lowers risks and ensures the final product is high quality.

Benefits of Hardware Assembly in Prototyping

Hardware assembly makes prototyping faster and more accurate. Tools like digital twins and 3D printing speed up the process. For example:

- Digital twins copy real-world conditions to test designs virtually. This saves time and money.

- Caldwell Manufacturing used 3D printing for metal parts. Costs dropped from $300-$5,000 to $30 per part. Production time went from eight weeks to three days.

These tools let you test ideas quickly and learn from mistakes. You can improve products faster and smarter.

Real-World Success Stories

Custom manufacturing and prototyping have changed industries. Here are some examples:

- A company cut cycle times by 63% during prototype production.

- Prototype data was linked to company databases, improving tracking.

- Factory tests were done within four months of the order.

- A prototype system reached nearly 100% efficiency.

These results show how hardware assembly boosts speed and reliability. Using these methods can improve your processes and products.

How It Impacts Consumer Electronics

In the US, electronics depend on custom manufacturing and prototyping. Devices like phones, laptops, and smartwatches need precise assembly to meet customer demands. Modular designs and quick prototyping help follow trends like foldable screens and AI features.

For example, adhesive bonding in prototypes creates sleek designs that stay strong. Press-fit assembly makes small circuits for smartwatches. These methods improve how products look and work, giving them an edge.

Custom manufacturing and prototyping help you create and lead. With hardware assembly, you can make products customers love and succeed in the market.

Benefits and Challenges of Hardware Assembly

Benefits (e.g., Efficiency, Cost-Effectiveness, Scalability)

Hardware assembly has many advantages for manufacturing. It makes designs simpler and speeds up assembly. This improves efficiency and saves money. For example, using Design for Assembly (DFA) can cut product costs by half. DFA focuses on the whole assembly process to keep costs low.

Another benefit is scalability. Whether making phones or smart home gadgets, DFA works well in many industries. It’s used in cars, electronics, and airplanes. This flexibility lets companies grow production without losing quality or speed.

Hardware assembly also reduces waste and speeds up production. Modular designs allow easy part upgrades or replacements. This saves time and materials. These benefits lower costs and help meet market needs faster.

Tip: Keep product designs simple to save money and time.

Challenges (e.g., Labor Costs, Technological Integration)

Hardware assembly has challenges that need solving to stay competitive. Labor costs are a big problem, especially in places with high wages. Automation can lower these costs, but it’s expensive to set up and maintain. Small businesses often struggle with these expenses.

Adding automation to old systems is also hard. Many companies find it tricky to mix new tech with older workflows. This can cause delays and raise costs during the change.

Studies show the assembly automation market faces problems like high startup costs and tech integration issues. Fixing these problems takes careful planning and long-term investments.

Advancements in Hardware Assembly Technology

New technology is changing hardware assembly and solving many problems. Robots and AI tools make assembly faster and more accurate. These tools reduce mistakes and improve efficiency, helping companies make better products quickly.

Digital twins and IoT devices are also improving assembly. Digital twins test designs virtually, saving time and money. IoT devices give live data to monitor and improve assembly lines.

These advancements are especially helpful for electronics. Adhesive bonding creates lightweight phone designs. Press-fit assembly ensures accuracy in small devices like smartwatches. These innovations improve product quality and give companies an edge in the market.

Note: Using advanced assembly tools can solve problems and create growth opportunities.

Hardware assembly turns separate parts into working products. Different methods, like welding, riveting, and mechanical assembly, make production faster and improve quality. These techniques are vital for industries such as cars, airplanes, and electronics.

Why it matters: Hardware assembly boosts efficiency, lowers costs, and helps make more products to meet worldwide needs.

New technologies like automation, IoT, and digital twins are improving hardware assembly. Using these tools can help you stay competitive and create great products.

Take action today: Use advanced assembly methods to grow your manufacturing success!

FAQ

What is the best way to choose a hardware assembly method?

Think about what your product needs. Look at things like material type, how strong it must be, and how fast it should be made. For example, welding is great for strong connections, while adhesive bonding works well for lightweight items.

Tip: Follow “Design for Assembly” rules to make work easier and save money.

How does automation improve hardware assembly?

Automation makes production faster and more accurate. Robots and AI tools help do tasks perfectly, saving time and materials. You can make more products without hiring extra workers.

Why it matters: Automation helps you stay ahead in a fast-moving industry.

Can hardware assembly help reduce manufacturing costs?

Yes! Smart assembly methods cut down on waste and speed up production. Modular designs let you fix or upgrade parts easily, saving money.

Call to Action: Keep designs simple to save money and increase profits.

What industries benefit the most from hardware assembly?

Industries like cars, airplanes, and electronics depend on hardware assembly. It makes products safer, stronger, and more precise.

Example: Rivet assembly keeps airplane parts secure, and PCB assembly powers electronic devices.

How do advancements in technology impact hardware assembly?

New tools like digital twins and IoT devices make work more accurate and faster. They let you test ideas virtually and watch production closely.

Note: Use these tools to stay competitive and make better products.