Top Tips for Choosing the Best One-Stop PCB Assembly Service

Selecting the right PCB assembly company is critical to ensuring your project’s success. A one-stop PCB service simplifies the process by handling everything from design to production. This approach can reduce project management costs by up to 40% and shorten development cycles by 20-40%. Additionally, you can achieve 15-20% overall cost savings while improving product reliability. However, choosing poorly can lead to delays, substandard quality, or even intellectual property theft. By partnering with reliable PCB assembly services, you secure efficiency, quality, and peace of mind for your projects.

Key Takeaways

- Explain your project needs clearly to prevent expensive errors and match goals with others.

- Pick a PCB assembly company that follows industry rules for safety and good quality.

- Check what the company can do, like their tools and modern assembly methods.

- Think about long-term benefits instead of quick savings to keep your project strong and dependable.

- Look at customer reviews and examples to make sure the company is trustworthy.

Define Your Needs

Understand Your Project Requirements

Defining your project requirements is the first step in selecting the right printed circuit board assembly service. A clear understanding of your needs ensures alignment with stakeholders and prevents costly mistakes. For example, specifying the scope of your project helps avoid scope creep, while SMART goals establish measurable success criteria to track progress effectively.

| Key Aspect | Description |

|---|---|

| Clearly Defined Scope | Ensures alignment with stakeholders and communicates essential project values, preventing scope creep in critical areas. |

| Change Control | Maintains focus on core best practices and prevents erosion of key project values during project execution. |

| SMART Goals | Establishes measurable success criteria, which helps in tracking project progress and ensuring that requirements are met effectively. |

Additionally, identifying potential roadblocks early in the process allows you to create mitigation plans that address risks throughout the project lifecycle. This proactive approach reduces delays and ensures your one-stop PCB service provider can meet your unique needs efficiently.

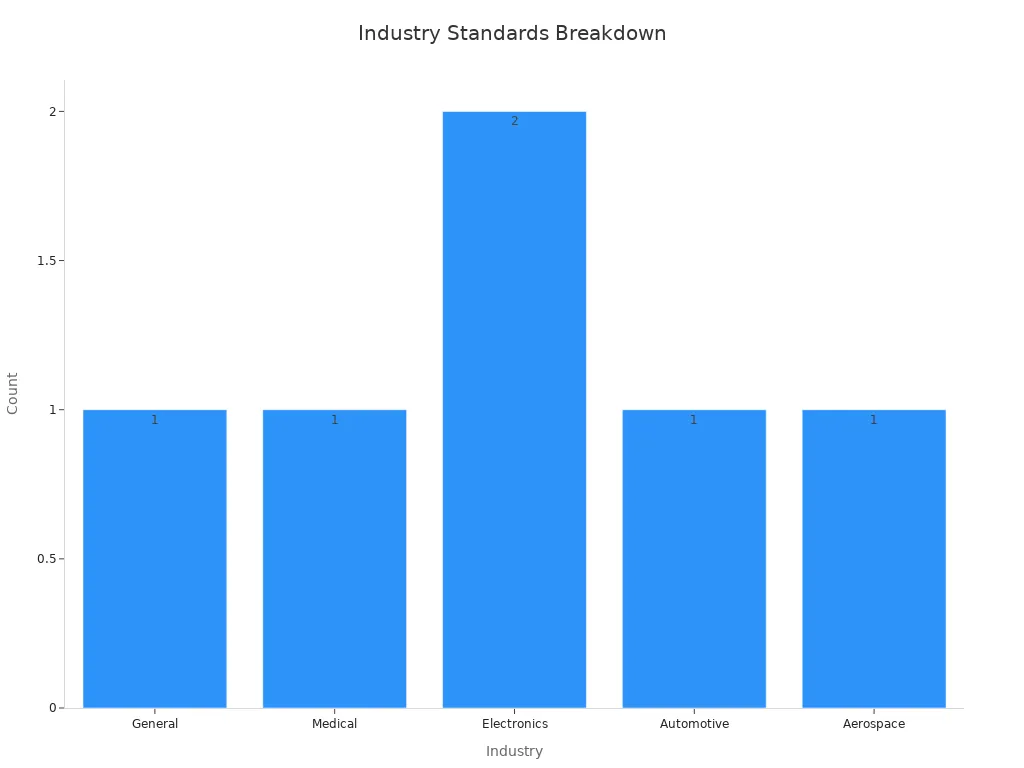

Consider Industry-Specific Standards

Matching your project requirements with industry-specific standards is crucial for ensuring compliance and quality. Different industries demand adherence to unique benchmarks, such as IPC-A-610 for electronics or ISO 13485 for medical devices. These standards guarantee that your printed circuit board assembly meets regulatory requirements and performs reliably in its intended application.

For example:

- Aerospace and Defense require high-reliability PCBs for extreme conditions.

- Medical devices demand safe and reliable PCBs that meet strict regulatory standards.

- Consumer electronics prioritize cost-effective and high-quality PCBs for various devices.

By ensuring your provider adheres to these standards, you safeguard your project against compliance issues and quality failures.

Determine Volume and Complexity Needs

Your project’s volume and complexity directly influence the choice of a PCB assembly service. High-volume production requires providers with advanced manufacturing capabilities, while low-volume prototyping demands flexibility and precision. Complexity factors, such as multilayer boards or specialized materials, necessitate providers with expertise in handling intricate designs.

| Requirement Type | Description |

|---|---|

| PCB Specifications | Key details such as board size, number of layers, material type, thickness, copper weight, etc. |

| Design Rules and Constraints | Specific design rules like minimum trace width, spacing, drill sizes, and impedance control. |

| Signal and Power Integrity Requirements | Information regarding high-speed signals and sensitive analog circuits that require special attention. |

| Compliance and Regulatory Requirements | Industry-specific standards (e.g., IPC, UL, RoHS) that the design must comply with. |

| Test and Validation Requirements | Requirements for design verification and validation testing. |

| Timeline and Milestones | Desired project timeline, including major milestones and deadlines. |

Understanding these requirements ensures your provider can deliver solutions tailored to your unique needs. This alignment minimizes risks and maximizes efficiency throughout the production process.

Evaluate Capabilities of PCB Assembly Companies

Assess Manufacturing Equipment and Technology

When evaluating a PCB assembly company, you must assess its manufacturing equipment and technological capabilities. Advanced equipment ensures precision, efficiency, and scalability, which are critical for meeting your project’s requirements. Modern trends in manufacturing emphasize several key advancements:

- Integration and connectivity between systems streamline production processes.

- Robotic advancements enhance efficiency and reduce human error.

- Localization and customization allow tailored solutions for unique project needs.

- Modular and distributed setups provide flexibility for diverse production demands.

- Autonomous and synchronized manufacturing leverages AI for optimized workflows.

These innovations demonstrate how PCB assembly manufacturers are evolving to meet industry demands. To gauge a company’s technological expertise, consider performance metrics such as technical capabilities, service quality, and cost-effectiveness.

| Metric Type | Description |

|---|---|

| Technical Capabilities | Evaluates the technology level, equipment, and production capacity of manufacturers. |

| Service Quality | Assesses the reliability and responsiveness of the manufacturer in meeting customer needs. |

| Cost-Effectiveness | Analyzes the cost relative to the quality and efficiency of the manufacturing process. |

| Quality Control | Ensures that products meet established quality standards through rigorous testing and management. |

| Supply Chain Management | Evaluates the efficiency and reliability of the supply chain in delivering materials and components. |

By focusing on these metrics, you can identify a PCB assembly company with the expertise and infrastructure to handle your project effectively.

Check for Advanced Assembly Techniques

Advanced assembly techniques set top-tier PCB assembly companies apart from the competition. Techniques like surface-mount technology (SMT), ball grid arrays (BGA), and through-hole assembly ensure high-quality results for complex designs. Companies that adopt fast-turn PCB assembly can significantly reduce development cycles. For instance, a start-up in wearable technology launched its product months ahead of competitors by leveraging rapid assembly processes. Similarly, a medical device company met urgent healthcare demands by expediting production with advanced techniques.

When selecting a provider, prioritize those with experience in cutting-edge methods. Their expertise ensures your printed circuit board assembly meets the highest standards of quality and performance.

Look for Prototyping and High-Volume Production Options

A reliable PCB assembly company should offer both prototyping and high-volume production capabilities. Prototyping allows you to test and refine your design before committing to large-scale manufacturing. This step minimizes risks and ensures your product functions as intended. High-volume production, on the other hand, requires robust infrastructure and streamlined processes to meet tight deadlines without compromising quality.

Choose a provider with the flexibility to scale production based on your needs. Their ability to handle both small and large orders demonstrates their experience and adaptability. This versatility ensures your project remains on track, regardless of its complexity or volume.

Quality Assurance in PCB Assembly Services

Verify Certifications (e.g., ISO, IPC Standards)

Certifications serve as a benchmark for the reliability and professionalism of a PCB assembly company. When evaluating providers, look for certifications such as ISO 9001, which ensures adherence to quality management systems, or IPC-A-610, which sets the standard for electronic assembly acceptability. These certifications demonstrate that the company complies with globally recognized quality standards.

For industries like aerospace or medical devices, additional certifications may be necessary. For instance, ISO 13485 ensures compliance with medical device manufacturing requirements. By verifying these certifications, you can trust that the provider meets stringent quality control standards and delivers consistent results.

Review Quality Control Processes

Effective quality control processes are essential for ensuring excellent quality inspections and minimizing defects. Leading PCB assembly companies implement a range of methods to maintain high standards. These include:

| Quality Control Method | Purpose |

|---|---|

| Process Review | Assess and inspect the PCBA manufacturing process to improve quality from the technology. |

| Incoming Quality Control (IQC) | Check component values and quantities to ensure correctness before production. |

| Solder Paste Inspection (SPI) | Detects issues with solder paste application to prevent quality problems. |

| Online AOI Inspection | Identifies soldering errors post-reflow to ensure quality of solder joints. |

| First Sample Test | Verifies parameter values against specifications to ensure correctness. |

| Off-line AOI Inspection | Inspects soldered surfaces for errors according to IPC610D standards. |

| X-Ray Welding Inspection | Ensures reliability of solder joints for hidden components. |

| QC Manual Inspection | Visual inspection of finished boards to ensure all products meet quality standards. |

These processes ensure that every stage of production aligns with quality standards. A PCB assembly manufacturer with robust quality control processes will deliver reliable and high-performing products.

Ensure Comprehensive Testing Protocols

Comprehensive testing is vital for identifying and resolving potential issues in printed circuit board assembly. Top-tier PCB assembly companies employ a variety of testing methods to ensure product reliability.

- FCT vs. ICT: Functional Circuit Testing (FCT) evaluates overall functionality, while In-Circuit Testing (ICT) focuses on individual components.

- FCT vs. AOI: Automated Optical Inspection (AOI) detects visual defects, whereas FCT identifies functional issues not visible through optical inspection.

| Testing Method | Description | Advantages |

|---|---|---|

| Burn-in Testing | Applies extreme conditions to identify weak points in PCB design. | Ensures durability under heavy stress. |

| Functional Circuit Test (FCT) | Evaluates overall functionality and component interactions. | Identifies component imperfections and assesses performance accurately. |

| Automated Optical Inspection | Uses high-resolution cameras to detect visual defects. | Detects issues at multiple assembly stages, ensuring quality control. |

| In-Circuit Testing (ICT) | Focuses on individual component testing and connection verification. | Offers high fault coverage for manufacturing defects. |

Comprehensive testing protocols reduce costs, improve safety, and ensure that your product meets performance requirements. Regular testing also minimizes the risk of returned goods, enhancing customer satisfaction and trust in your chosen PCB assembly services.

Pricing and Value in Selecting the Right PCB Assembly

Balance Cost with Quality

Balancing cost and quality is essential when selecting a one-stop PCB service. While cost-effective solutions may seem appealing, sacrificing quality can lead to expensive rework or product failures. PCB assembly manufacturers often offer materials tailored to specific applications, allowing you to optimize both cost and performance.

| Application | Recommended Material | Cost per m² | Max Temp Rating | Best Use Case |

|---|---|---|---|---|

| Automotive ECU | FR-4 Tg170 | $18.50 | 170°C | High-reliability systems |

| Home IoT Devices | CEM-3 | $12.80 | 130°C | Cost-sensitive electronics |

| LED Controllers | CEM-1 | $9.20 | 110°C | Non-critical applications |

To achieve competitive pricing without compromising quality, consider negotiating tiered pricing for bulk orders. For example, discounts of 10-20% are often available for orders exceeding 500 panels. Additionally, maintaining a three-month material buffer can help you avoid costly emergency purchases.

Consider Long-Term Value Over Short-Term Savings

Prioritizing long-term value over short-term savings ensures the sustainability of your project. A PCB assembly manufacturer with robust capabilities and a proven track record can deliver consistent results, reducing the risk of defects and delays. While upfront costs may be higher, the long-term benefits include fewer product recalls, enhanced reliability, and improved customer satisfaction.

For instance, partnering with distributors offering free cutting services can reduce material waste and streamline production. Similarly, selecting a provider with advanced testing protocols ensures your product meets stringent quality standards, minimizing future expenses. By focusing on long-term value, you safeguard your investment and enhance your project’s success.

Request Transparent Pricing and Quotes

Transparent pricing is a hallmark of reliable PCB assembly manufacturers. Requesting a detailed quote allows you to evaluate costs comprehensively, including material expenses, labor charges, and testing fees. This approach helps you avoid hidden costs and ensures alignment with your budget.

When assessing quotes, consider factors such as delivery timelines, scalability, and service quality. A provider offering competitive pricing and clear communication demonstrates professionalism and reliability. Selecting a one-stop PCB service with transparent pricing ensures you receive value for your investment while maintaining control over project costs.

Communication and Support from PCB Assembly Companies

Evaluate Responsiveness and Customer Service

Responsiveness and customer service play a pivotal role in selecting a PCB assembly company. You need a provider that promptly addresses inquiries and resolves issues efficiently. Key performance metrics such as response times, customer satisfaction scores, and communication effectiveness can help you evaluate a company’s responsiveness. For instance, companies that improve customer retention by just 5% often see profit increases of up to 25%. This highlights the importance of prioritizing customer satisfaction and retention.

To assess a company’s customer service, consider metrics like:

- Customer satisfaction scores and feedback loops.

- Response times to inquiries and issues.

- Net promoter scores (NPS) for service evaluation.

- Repeat order rates and customer loyalty indicators.

These metrics reflect how well a company supports its clients, ensuring your project stays on track in the fast-paced electronics industry.

Look for Design Collaboration and Feedback

Effective design collaboration ensures your PCB assembly provider aligns with your project goals. A reliable company should offer constructive feedback during the design phase, helping you optimize your PCB for manufacturability and performance. For example, they might suggest adjustments to improve signal integrity or reduce production costs.

You should also look for providers that use advanced design tools and simulation software. These tools enable them to identify potential issues early, saving you time and resources. Open communication during the design process fosters innovation and ensures your final product meets industry standards.

Ensure Clear Communication Channels

Clear communication channels are essential for a smooth partnership with your PCB assembly provider. You should expect regular updates on project milestones, timelines, and any potential challenges. Transparent communication minimizes misunderstandings and keeps you informed throughout the production process.

Providers with dedicated customer support teams often excel in maintaining effective communication. They ensure you have a single point of contact for all inquiries, streamlining the process and enhancing your overall experience. Strong communication builds trust and ensures your project progresses without unnecessary delays.

Logistics and Location of the PCB Assembly Company

Consider Proximity to Your Business

The location of your PCB assembly provider plays a significant role in the efficiency of your project. Choosing a company close to your business can reduce lead times, improve communication, and enhance overall coordination. Proximity allows for quicker delivery of components, which is especially critical in industries like semiconductors, where high demand requires rapid response times.

| Evidence Point | Description |

|---|---|

| Shorter Lead Times | Faster delivery of components ensures timely production and project success. |

| Efficient Stock Turnover | Nearby warehouses enable rapid replenishment, maintaining supply chain efficiency. |

| Better Synchronization | Close proximity improves coordination between suppliers and manufacturers. |

By selecting a provider near your location, you can streamline logistics, minimize delays, and maintain better control over your supply chain.

Assess Delivery Timelines and Reliability

Reliable delivery timelines are essential for meeting project deadlines and avoiding costly delays. Evaluate a PCB assembly company’s track record for on-time delivery and responsiveness. Companies that excel in logistics often provide rapid prototyping and maintain accurate documentation to ensure smooth operations.

| Category | Examples |

|---|---|

| Technology | Electrical (thick copper), Thermal (low CTE), Dimensional (flexible circuits), Assembly (tolerances). |

| Responsiveness | On-time delivery, rapid prototyping, short lead times. |

| Quality | Conformance to industry standards, order completeness, and documentation accuracy. |

| Cost and Price | Competitive pricing and efficient supplier management. |

| Other Services | Design support and locally-based technical staff. |

A company with a proven history of meeting delivery commitments ensures your project stays on schedule, reducing risks and enhancing reliability.

Review Supply Chain Management Practices

Effective supply chain management is critical for ensuring smooth PCB assembly operations. Look for providers that optimize inventory levels, collaborate with contract manufacturers, and plan ahead to mitigate risks. Key performance indicators can help you assess their logistics efficiency:

- Supplier lead time: Measures the duration from order placement to delivery, ensuring responsiveness.

- Inventory management: Balances stock levels to prevent shortages or overstocking.

- Assembly schedule: Tracks timelines for production processes to meet deadlines.

- Intermediate shipment duration: Monitors the time taken for shipments between supply chain stages.

Additionally, strategies like using common board materials and diversifying supplier sources can reduce delays and improve flexibility. A provider with robust supply chain practices ensures your project runs smoothly, even in the face of unexpected challenges.

Confidentiality and IP Protection in PCB Assembly Services

Ensure NDAs and Confidentiality Agreements

Protecting your intellectual property begins with establishing robust confidentiality agreements. These agreements safeguard sensitive information shared during PCB assembly projects. They can take the form of standalone NDAs or be embedded within broader contracts. Written agreements clarify what constitutes confidential information and set clear expectations for its handling.

- Confidentiality agreements are essential for protecting trade secrets and proprietary designs.

- They ensure compliance with upstream agreements involving third-party stakeholders.

- Structured NDAs help avoid misunderstandings and provide legal recourse in case of breaches.

To strengthen confidentiality, you should also consider additional measures:

- Limit access to sensitive data based on employee roles.

- Train staff on their confidentiality obligations.

- Require suppliers and partners to adhere to strict confidentiality standards.

By implementing these practices, you create a secure foundation for your PCB assembly project.

Verify Secure Data Handling Practices

Data security is a critical component of intellectual property protection. You should evaluate how a PCB assembly provider manages sensitive information. Look for companies that employ secure information systems, robust cybersecurity measures, and physical security protocols. For example, providers with encrypted data storage and restricted access policies demonstrate a commitment to safeguarding your designs.

Additionally, assess whether the company conducts regular audits of its security practices. These audits ensure compliance with industry standards and help identify vulnerabilities. A provider with strong data handling practices not only protects your intellectual property but also enhances the overall quality of their services.

Research the Provider’s Reputation for IP Protection

A provider’s reputation speaks volumes about their reliability in protecting intellectual property. Start by reviewing customer testimonials and case studies that highlight their track record in confidentiality. Online reviews and ratings can also provide insights into their trustworthiness.

You should also inquire about their history with NDAs and confidentiality breaches. A company with a clean record and a proactive approach to IP protection is more likely to meet your expectations. By choosing a provider with a strong reputation, you minimize risks and ensure your project remains secure.

Testimonials and Reputation of PCB Assembly Companies

Review Customer Testimonials and Case Studies

Customer testimonials and case studies provide valuable insights into the performance of pcb assembly companies. By reviewing these resources, you can gauge how well a provider meets client expectations. Testimonials often highlight key strengths, such as timely delivery, quality assurance, or exceptional customer service. Case studies, on the other hand, offer a deeper look into specific projects, showcasing how the company overcame challenges or delivered innovative solutions.

When analyzing testimonials, focus on recurring themes. For example, consistent praise for technical expertise or problem-solving skills indicates a reliable partner. Case studies can also reveal whether the company has experience in your industry, which is crucial for meeting specialized requirements. These resources help you make an informed decision and build confidence in your choice.

Check Online Reviews and Ratings

Online reviews and ratings are another essential tool for evaluating pcb assembly companies. Platforms like Google Reviews, Trustpilot, or industry-specific forums often feature honest feedback from previous clients. High ratings and positive comments reflect a company’s commitment to quality and customer satisfaction.

Pay attention to how the company responds to negative reviews. A professional response that addresses concerns and offers solutions demonstrates accountability and a customer-focused approach. Look for patterns in the feedback. Frequent complaints about delays or quality issues may signal potential risks. By leveraging online reviews, you can assess a company’s reputation and reliability effectively.

Request References from Past Clients

Requesting references from past clients allows you to verify a company’s claims directly. Speaking with previous customers provides firsthand insights into their experience with the provider. Ask specific questions about project timelines, communication, and the quality of the final product.

References can also shed light on how the company handles unexpected challenges. For instance, did they resolve issues promptly? Were they transparent about delays or additional costs? This information helps you determine whether the company aligns with your expectations and project needs. A provider willing to share references demonstrates confidence in their services and track record.

Choosing the right PCB assembly services requires careful evaluation of multiple factors. You should define your project needs, assess the provider’s capabilities, and verify their quality assurance processes. A systematic approach ensures you make informed decisions that align with your goals. Prioritize providers offering one-stop PCB solutions to streamline production and reduce costs. Matching the service to your industry-specific requirements guarantees compliance and reliability. By taking these steps, you secure a trusted partner who delivers high-quality results tailored to your project.

FAQ

What is a one-stop PCB assembly service?

A one-stop PCB assembly service handles all aspects of PCB production, including design, prototyping, assembly, and testing. This approach simplifies your workflow, reduces costs, and ensures faster delivery times. It’s ideal for projects requiring streamlined processes and consistent quality.

How can you verify the quality of PCB assembly services?

Check certifications like ISO 9001 and IPC standards. Review the company’s quality control processes, including testing protocols like AOI and ICT. Customer testimonials and case studies also provide insights into their reliability and performance.

What factors affect PCB assembly pricing?

Pricing depends on factors like material selection, production volume, and complexity. Transparent quotes help you evaluate costs, including labor, testing, and delivery. Balancing cost with quality ensures long-term value for your project.

Why is confidentiality important in PCB assembly services?

Confidentiality protects your intellectual property and proprietary designs. Ensure your provider uses NDAs, secure data handling practices, and robust cybersecurity measures. A trusted partner safeguards your sensitive information throughout the production process.

How do logistics impact PCB assembly projects?

Efficient logistics ensure timely delivery and reduce delays. Proximity to your business improves coordination and minimizes lead times. Providers with strong supply chain management practices enhance reliability and keep your project on schedule.