SMT assembly helps you make electronic devices with tiny, light parts. First, you print solder paste. Then, you put the components in place. Next, you heat them to make strong connections. After that, you check if everything works well. SMT is used in 72% of PCB assembly around the world. This shows it is very important in electronics. SMT gives you smaller designs and quick production. This is because SMT can use machines to help. The parts in SMT are much smaller than in old ways. So, your devices can be lighter and more advanced.

Key Takeaways

- SMT assembly helps make electronic devices faster by using machines to put small parts on circuit boards. This technology makes products smaller, lighter, and more dependable. It is great for things like smartphones and medical devices. The SMT process has important steps like solder paste printing, putting parts in place, and reflow soldering. Each step is important for good quality. Automated inspection, like AOI and X-ray, checks for problems early in the process. This helps keep the quality high. SMT has many good points, but it needs special machines and careful work with tiny parts to stop damage.

Surface Mount Technology Overview

What Is Surface Mount Technology

Surface-mount technology helps you make modern electronics. You put small parts right on the top of a printed circuit board. You do not need to make holes for each part. You just place and solder the parts on the board’s surface. This way, you can build things faster and easier. Machines can put thousands of parts on boards every hour. This saves money on workers and lets you make more devices quickly.

Surface-mount technology helps you make smaller and lighter products. You see it in things like smartphones and computers. It is also used in medical tools. The short connections help the electronics work better. Your products are more reliable and have better quality.

Here is a table that shows how surface-mount technology changed electronics manufacturing:

| Benefit | Impact on Electronics Manufacturing |

|---|---|

| Faster Assembly | Machines can place many parts each hour, so work is quicker. |

| Reduced Labor Costs | Using machines means you spend less on workers. |

| Improved Product Quality | Electronics work better and stay the same each time. |

| Compact Designs | Small parts make boards light and save space. |

| Industry Applications | Used in cars, hospitals, and phone companies. |

SMT vs. Through-Hole Technology

You might wonder how surface-mount technology is different from old ways. Through-hole technology needs you to put each part through a hole in the board. Then, you solder it on the other side. This can be done by hand or with machines, but it takes longer and uses more space.

Here is a table that highlights the differences:

| Aspect | Surface Mount Technology (SMT) | Through Hole Technology (THT) |

|---|---|---|

| Assembly Process | Parts go on top of the board and are soldered by machines. | Parts go through holes and are soldered on the back. |

| Reliability | Good for most things but not as strong if bent or pulled. | Stronger for tough jobs and lasts in hard places. |

- SMT parts work well for most things, but they are not as strong if you bend or shake them.

- Through-hole technology is better when you need strong parts that can handle rough use, like in the army or space.

Surface-mount technology helps you make small and fast electronics. You use SMT when you want speed and small size. You use through-hole when you need extra strength.

SMT Assembly Process

The smt assembly process has many steps. Each step helps you make good electronic products. All the steps work together for fast and correct pcb assembly.

| Step Number | Step Name | Contribution to Quality |

|---|---|---|

| 1 | Solder Paste Printing | Ensures the correct amount of solder paste is applied, which is critical for effective soldering. |

| 2 | Solder Paste Inspection (SPI) | Helps catch defects early, reducing potential issues later in the process and improving overall product quality. |

| 3 | Chip Mounting | Core step where components are placed accurately, affecting the reliability of the final assembly. |

| 4 | Visual Inspection | Ensures that components are correctly placed before soldering, reducing defects in the final product. |

| 5 | Reflow Soldering | Melts solder paste to create strong connections, essential for the electrical performance of the assembly. |

| 6 | AOI (Automated Optical Inspection) | Verifies that components are correctly soldered, ensuring the integrity of the assembly. |

| 7 | ICT or Function Test | Tests for circuit integrity and component functionality, crucial for ensuring the final product works as intended. |

Solder Paste Application

You begin smt assembly by putting solder paste on the board. Most factories use a stencil for this job. The stencil helps you put paste on each pad. Even layers of paste are very important. Too much or too little paste can cause weak joints or short circuits.

Tip: Keep the stencil clean and in good shape. This helps stop problems like missing paste or solder bridges.

You can change the pressure and speed of the printer. For example, 7 kgf pressure and 20 mm/s speed work well. Automated smt assembly uses machines to make this step fast and correct.

Component Placement

Next, you put small parts on the board. This step is called component placement. Pick-and-place machines do this job in automated smt assembly. These machines can put thousands of parts on boards every hour.

How well parts are placed depends on many things:

- The design and quality of your board

- The type and size of the parts

- Where the feeder holds the parts

- The force used to press the parts down

- How well the placement head is set up

You need to check all these things for the best results. Machines help you place parts quickly and very accurately. This makes your smt assembly strong and repeatable.

Reflow Soldering

After placing the parts, you heat the board in a reflow oven. This melts the solder paste and connects the parts to the board. The oven uses a special heat plan. It starts slow, then gets hotter to melt the solder, and then cools down.

| Stage | Importance |

|---|---|

| Solder Paste Application | Ensures solder is deposited only on designated pads, critical for joint quality. |

| Component Placement | Automated machines ensure high precision in component alignment. |

| Preheating | Activates flux and minimizes thermal shock, essential for component integrity. |

| Soaking | Stabilizes flux activity and ensures even preparation of solder paste. |

| Reflow | Creates strong bonds; precise temperature control avoids defects like cold joints and bridging. |

| Cooling | Gradual cooling solidifies solder into strong, reliable joints, preventing thermal stress. |

Flux in the solder paste cleans the metal. This helps the solder stick better. Good reflow soldering gives you strong and safe connections.

Inspection and Testing

You need to check your work after soldering. Inspection and testing help you find and fix problems before you finish the product.

Here are common inspection methods:

| Inspection Method | Description |

|---|---|

| Visual Inspection | You check the board with your eyes for obvious problems. |

| Automated Optical Inspection (AOI) | Machines use cameras to find missing parts or bad solder joints. |

| X-ray Inspection | X-rays let you see under parts to find hidden solder problems. |

| In-Circuit Testing (ICT) | Machines test each part and connection for electrical problems. |

| Functional Testing | You test the finished board to see if it works in real life. |

- AOI checks the board fast and finds most mistakes.

- X-ray inspection helps you see under big chips.

- Manual checks are still good for small details.

- ICT and function tests make sure your board works right.

Automated smt assembly uses these tools to keep quality high and lower mistakes. If you follow these steps, your pcb assembly will work well.

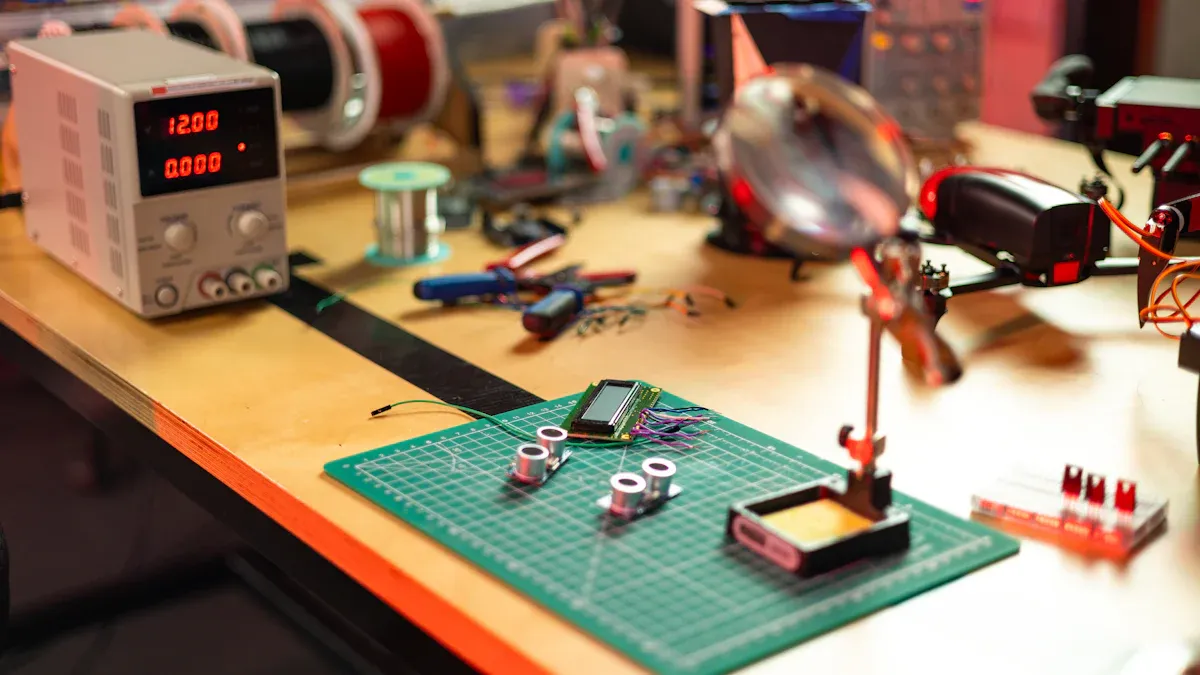

SMT Equipment

Solder Paste Printer

You begin pcba with a solder paste printer. This machine puts solder paste on each pad. Modern printers use machines to place the paste in the right spot. 3D solder paste inspection systems check the paste. They look at the height and area to find mistakes early. If you use new solder paste and keep it cool, you get better results. Let the paste warm up before printing. This stops water drops and keeps the print good.

| Feature | Description |

|---|---|

| 3D Solder Paste Inspection (SPI) | Checks solder paste with 3D pictures for accuracy. |

| Automated Solder Paste Printing | Uses machines for perfect paste and fits many part sizes. |

| Consistent Quality | Gives you good solder and fewer mistakes. |

| Impact on Thermal Management | Good solder helps your pcb stay cool and work well. |

Pick and Place Machine

Next, you use a pick and place machine for smt. This machine puts small parts on the pcb fast and very accurately. Vision systems help the machine see each part and put it in the right place. You can place up to 50,000 parts every hour with few mistakes. Some machines use many nozzles to move lots of parts at once. You get fast placement and good alignment, which is important for pcba.

Pick and place machines use cameras and smart programs to check each part. You get good placement even for tiny parts.

Reflow Oven

After placing the parts, you use a reflow oven. This oven heats the board in steps. First, it warms up the pcb. Then, it holds a set heat. Next, it gets hot enough to melt the solder and make strong joints. Last, it cools down to make the joints solid. You must use the right heat steps to stop bad joints or broken parts. Good ovens help you get strong and safe solder joints in your pcba.

- Good solder joints come from using the right heat at each step.

- You can stop problems like tombstoning and voids by using the right heat plan.

Inspection Systems

You finish smt by checking your work with inspection systems. Automated Optical Inspection (AOI) machines look at every pcb for mistakes. Some systems use 3D AOI to check solder joints and part placement. You also use SPI to measure solder paste. For hidden joints under big chips, you use X-ray checks. These systems help you find mistakes before your pcba leaves the factory.

| Inspection System | Description |

|---|---|

| AOI | Checks every pcb fast for mistakes. |

| 3D AOI | Looks at solder joints and placement closely. |

| SPI | Measures solder paste to stop problems. |

| X-ray Analysis | Finds hidden mistakes under parts. |

Tip: Keep your parts in dry bags and take care of your smt machines. This keeps your pcb assembly working well and helps you avoid problems.

SMT Assembly Advantages and Disadvantages

Benefits of SMT Assembly

SMT assembly gives you lots of good things. It helps you make smaller and faster electronics. Machines put parts on boards very quickly. This means you can make many products in less time. You do not need as many workers, so you save money. You also use less material. Short connections on the board help your devices work better.

Here is a table that shows the main advantages of smt:

| Advantage | How It Helps You |

|---|---|

| Miniaturization | You can design compact and lightweight devices. |

| High Speed & Volume | Machines let you produce many boards quickly and efficiently. |

| Cost-Effective | You lower your manufacturing costs and save on labor. |

| Performance | Shorter paths improve signal quality and device reliability. |

Tip: Use automated machines and keep your process steady. This helps you get good results with smt.

You can find smt in phones, computers, and medical tools. This way, you can fit more parts on each board. Your products can do more things.

Limitations of SMT Assembly

SMT has some problems you should know about. You need special machines, and they cost a lot at first. The small parts can break if you are not careful. It is hard to check for mistakes because the joints are tiny. If you want to change your design, it takes more time and work.

Here are some common limitations of smt:

- Equipment and setup cost a lot at the start.

- Small solder joints make inspection and testing hard.

- Parts are fragile and need gentle handling.

- Repairs are harder because parts are close together.

- It is not easy to make changes for small batches.

- You need skilled workers and strict controls to stop mistakes.

You should plan well and use good machines for smt assembly. If you know the good and bad sides, you can pick the best way for your project.

SMT Applications

Consumer Electronics

You can find smt in many electronics you use every day. This technology helps make devices smaller and lighter. Tiny parts can be placed close together on a pcb. This lets you make things that fit in your pocket or on your wrist. Smt lets you design gadgets that do more but use less space. Machines can put thousands of parts on a pcb each hour. This makes production faster and more efficient.

Some products that use smt assembly are:

- Smartphones and tablets

- Wearable devices like fitness trackers and smartwatches

- Laptops and computers

Smt lets you use small parts and pack them tightly. This saves space and helps your devices work better.

Automotive

You will see smt in almost every new car. Smt lets you put parts right on the pcb. This is important for making small and reliable car systems. You can add features like navigation, music, and safety systems. Smt helps you build these systems quickly and with fewer mistakes.

- Smt lets you fit more circuits in a small space.

- You get better reliability and faster production.

- Each pcb batch must be tracked, and strict rules keep car electronics safe.

Car smt assemblies must meet high standards like ISO/TS 16949 and IATF 16949. These rules make sure your car’s electronics work well and last long.

Medical Devices

Smt is very important in medical devices. You can use smt to make assembly faster and cheaper. Smaller pcb sizes let you make small and easy-to-carry devices. Smt also helps signals stay clear and reduces interference. This is important for getting correct medical readings.

Some medical devices that use smt are:

- Electrocardiographs

- Blood glucose meters

- X-ray equipment

You must follow strict rules like ISO 9000, ISO 13485, and IEC 60601 when making medical pcbs. These standards help keep your devices safe and reliable.

Industrial Uses

Smt helps you make strong and efficient industrial electronics. You can build smaller, lighter, and more reliable devices for factories and machines. Smt lets you skip drilling holes in the pcb, which saves time and money. You can use smt for fast and complex jobs in places like aerospace, defense, and industrial controls.

| Benefit | Description |

|---|---|

| Compact Design | Lets you make smaller and lighter pcb assemblies. |

| High Speed and Efficiency | Automated smt lines make production faster. |

| Cost-Effective Manufacturing | Smt processes help lower your costs. |

| Enhanced Reliability | Strong solder joints help your devices last longer. |

| Versatility | Works with many types of parts for complex designs. |

Tip: Smt gives you the freedom to create advanced industrial systems for today’s needs.

You now know that smt assembly helps you make electronics fast and well. Machines put tiny parts on PCBs. This helps you build smaller and lighter devices. SMT makes electronics cheaper and quicker to produce. You can start a project with basic tools. Use tweezers, solder paste, and a magnifying glass. As technology gets better, new things like 5G and IoT will make smt assembly even more useful.

FAQ

What does SMT stand for?

SMT stands for Surface Mount Technology. You use this method to place electronic parts directly onto the surface of a printed circuit board.

Why do you use SMT instead of through-hole?

You use SMT because it lets you make smaller, lighter, and faster devices. Machines can place many parts quickly. SMT also helps you save space on your circuit boards.

Can you repair SMT boards at home?

You can repair SMT boards at home with the right tools. Use tweezers, solder paste, and a magnifying glass. Small parts make repairs tricky, so work slowly and carefully.

What is a pick and place machine?

A pick and place machine helps you put tiny parts on a circuit board. The machine uses cameras and suction nozzles to move and place each part in the right spot.

How do you check SMT assembly quality?

You check SMT assembly quality with Automated Optical Inspection (AOI), X-ray machines, and manual checks. These tools help you find missing parts, bad solder joints, or other problems before you finish your product.