Top 10 tips about PCB stiffeners for complex multilayer rigid flex PCB

Rigid flex PCBs combine flexible and rigid layers to create versatile circuits for demanding applications. A PCB stiffener provides essential reinforcement in these designs. It ensures the flexible sections remain intact during mechanical stress and enables precise component placement on rigid areas. Selecting the right stiffener becomes critical when dealing with complex multilayer designs. You must consider factors like material compatibility, thickness, and environmental conditions to achieve optimal performance.

Key Takeaways

- PCB stiffeners give support and stop flexible parts from breaking.

- Picking the right material, like FR4 for strength or polyimide for bending, is very important.

- Think about how much flexibility or stiffness your design needs to last long and fit in small spaces.

- Using good lamination methods and lining up drill holes correctly keeps your PCB strong.

- Work with skilled manufacturers to get advice and create better, more reliable rigid flex PCBs.

Purpose of PCB Stiffeners

PCB stiffeners play a vital role in ensuring the durability and functionality of rigid flex PCBs. They provide structural reinforcement, protect flexible sections from damage, and improve the placement of components. Understanding their purpose helps you design more reliable and efficient multilayer PCBs.

Mechanical Support

A PCB stiffener adds mechanical strength to your design. It prevents the flexible sections from bending excessively, which could lead to cracks or breaks. This is especially important in applications where the PCB faces constant mechanical stress.

For example:

- In an automotive engine control unit (ECU), a PCB stiffener helped maintain thermal stability at 150°C, ensuring the engine performed reliably.

- Industrial sensors operating in harsh environments also benefited from stiffeners. These sensors faced high humidity and temperatures of up to 130°C, but the stiffeners prevented delamination and extended their lifespan.

- A 5G communication router required a PCB that could handle high-frequency signals and thermal stress. The stiffener provided the necessary support, ensuring consistent performance under demanding conditions.

Preventing Flex Damage

Repeated bending or flexing can weaken the flexible sections of your PCB. A stiffener minimizes this risk by limiting movement in critical areas. This is particularly useful in designs where the PCB must endure frequent handling or vibration. By using a PCB stiffener, you can prevent damage and maintain the integrity of your circuit over time.

Enhancing Component Placement

Placing components on flexible sections can be challenging. A PCB stiffener creates a stable, rigid surface for mounting components. This ensures accurate placement and reduces the risk of misalignment during assembly. It also improves solder joint reliability, which is crucial for maintaining electrical connections in complex multilayer designs.

Types of PCB Stiffeners

Choosing the right type of PCB stiffener is essential for ensuring the performance and durability of your rigid flex PCB. Each material offers unique benefits depending on your design requirements and operating conditions.

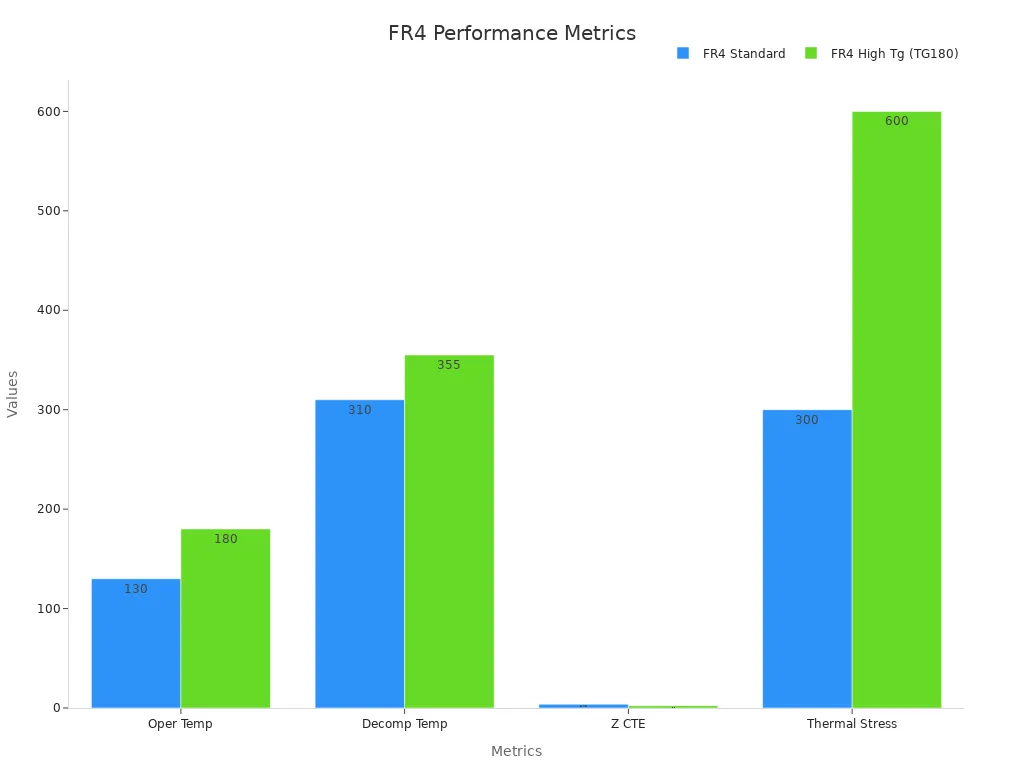

FR4

FR4 is one of the most commonly used materials for PCB stiffeners. It is a glass-reinforced epoxy laminate that provides excellent mechanical strength and thermal stability. You can choose between standard FR4 and high Tg (TG180) variants, depending on your application. High Tg FR4 offers superior thermal resistance, making it ideal for high-temperature environments.

| Metric | FR4 Standard | FR4 High Tg (TG180) |

|---|---|---|

| Maximum Operating Temp (°C) | 130 | 180 |

| Decomposition Temp (Td) | 310 | 355 |

| Z-axis CTE (%) | 3.75 | 2.3 |

| Thermal Stress Resistance (s) | 300 | 600 |

High Tg FR4 also minimizes warping and expansion, which is crucial for high-density multilayer designs. Its enhanced mechanical strength and moisture resistance extend the lifespan of your PCB.

Polyimide

Polyimide stiffeners are lightweight and flexible, making them ideal for applications requiring a balance between rigidity and flexibility. They perform well in extreme temperatures and resist chemical degradation. If your design involves tight spaces or dynamic bending, polyimide is an excellent choice. Its low thermal expansion ensures dimensional stability, even in harsh environments.

Metal Options (Stainless Steel, Aluminum)

Metal stiffeners, such as stainless steel and aluminum, provide unmatched rigidity and durability. Stainless steel offers superior strength, while aluminum is lightweight and corrosion-resistant. These materials are perfect for applications requiring high mechanical support, such as aerospace or industrial equipment. However, their higher weight and cost may not suit all designs.

Tip: Use metal stiffeners for designs exposed to heavy vibration or mechanical stress to ensure long-term reliability.

Design Requirements

When designing a rigid flex PCB, you must carefully balance several factors to ensure optimal performance. The interplay between flexibility, rigidity, layer count, thickness, and space constraints significantly impacts the final design.

Flexibility vs. Rigidity

Finding the right balance between flexibility and rigidity is crucial. Flexible sections allow your PCB to bend and fit into compact spaces, while rigid sections provide the stability needed for component placement. You should determine which areas require flexibility and which need reinforcement. For example, if your design involves frequent bending, prioritize flexibility in those sections. However, for areas with heavy components, a rigid structure supported by a PCB Stiffener ensures durability and reliability.

Tip: Use flexible materials like polyimide for dynamic sections and rigid materials like FR4 for areas requiring mechanical support.

Layer Count and Thickness

The number of layers and their thickness directly affect your PCB’s performance. A higher layer count increases complexity but allows for more intricate circuits. Thicker layers provide better mechanical strength but reduce flexibility. You should evaluate your design’s electrical and mechanical requirements to determine the ideal balance. For instance, a multilayer PCB with eight layers may require a thinner stiffener to maintain flexibility while still providing adequate support.

| Design Factor | Impact on PCB |

|---|---|

| High Layer Count | Increased complexity |

| Thick Layers | Reduced flexibility |

| Thin Layers | Lower mechanical strength |

Space Constraints

Space limitations often dictate your design choices. Compact devices like smartphones or wearables require PCBs that fit into tight enclosures. You must consider the stiffener’s thickness and placement to avoid interfering with other components. For tight spaces, opt for lightweight and thin materials like polyimide. This ensures your PCB remains functional without compromising the overall design.

Note: Always verify the dimensions of your PCB and stiffener during the prototyping phase to avoid assembly issues.

Operating Environment

Temperature Tolerance

PCB stiffeners must endure a wide range of temperatures to ensure your rigid flex PCB performs reliably. High temperatures can cause delamination, while low temperatures may lead to brittleness. Selecting materials with excellent thermal stability is essential for long-term durability. For instance, stiffeners with a glass transition temperature (Tg) of 170°C or higher resist heat effectively. A decomposition temperature (Td) above 300°C ensures the material withstands soldering processes without degradation.

| Metric | Value |

|---|---|

| Coefficient of thermal expansion (CTE) | X/Y axis: 12-16 ppm/°C, Z-axis: 25-50 ppm/°C |

| Reliability standard | 300 thermal cycles (-55℃~125℃) without delamination |

| Heat resistance index | Tg point: ≥170℃, Td point: ≥300℃, Delamination time: >60min (288℃ solder test) |

By choosing stiffeners with these properties, you can prevent thermal damage and maintain the structural integrity of your PCB in extreme environments.

Moisture Resistance

Moisture can compromise the performance of your PCB by causing short circuits or delamination. Stiffeners with low water absorption rates protect your design from humidity and water exposure. For example, materials with saturated water absorption below 0.2% after 24 hours of immersion offer excellent moisture resistance. This feature is particularly important for applications in humid climates or devices exposed to water, such as outdoor sensors or wearable electronics.

| Metric | Value |

|---|---|

| Saturated water absorption | <0.2% (24h immersion) |

Using moisture-resistant stiffeners ensures your PCB remains functional and reliable, even in challenging conditions.

Vibration and Shock

Vibration and mechanical shock can damage your PCB, especially in high-stress environments like automotive or aerospace applications. Stiffeners enhance the mechanical stability of your design, reducing the risk of cracks or component displacement. Materials that pass a 30G/0.5ms mechanical shock test demonstrate excellent impact strength. This level of durability ensures your PCB withstands sudden impacts or continuous vibrations without failure.

| Metric | Value |

|---|---|

| Mechanical shock (Impact strength) | Pass 30G/0.5ms test |

By incorporating stiffeners with proven vibration and shock resistance, you can extend the lifespan of your PCB and maintain consistent performance in demanding applications.

Material Compatibility

When selecting a PCB stiffener, you must ensure it is compatible with the materials in your rigid flex PCB. Material compatibility affects the performance, durability, and reliability of your design. Here are three critical factors to consider.

Thermal Expansion Matching

Thermal expansion mismatch between the stiffener and the PCB can cause warping, delamination, or cracks. Each material expands at a different rate when exposed to heat. You should choose a stiffener with a coefficient of thermal expansion (CTE) similar to the PCB material. For example, FR4 stiffeners pair well with rigid PCB layers due to their matching CTE values. This reduces stress during thermal cycling.

| Material | CTE (ppm/°C) |

|---|---|

| FR4 | 12-16 |

| Polyimide | 20-50 |

| Aluminum | 23 |

Tip: Always check the CTE values of your materials to prevent thermal stress in high-temperature applications.

Adhesion Properties

Strong adhesion between the stiffener and the PCB ensures structural integrity. Poor adhesion can lead to delamination, especially in environments with high humidity or vibration. You should select adhesives that bond well with both the stiffener and the PCB materials. For instance, epoxy-based adhesives work effectively with FR4 and polyimide stiffeners. Surface preparation, such as cleaning and roughening, also improves adhesion.

Note: Test the adhesive’s performance under operating conditions to ensure long-term reliability.

Electrical Insulation

Stiffeners must not interfere with the electrical performance of your PCB. Materials like FR4 and polyimide provide excellent electrical insulation, making them ideal for multilayer designs. Metal stiffeners, however, require an insulating layer to prevent short circuits. You should verify the dielectric strength of the stiffener material to ensure it meets your design’s requirements.

Reminder: Use insulating coatings or films when working with conductive stiffeners like aluminum or stainless steel.

By considering these factors, you can select a stiffener that enhances your PCB’s performance and reliability.

Manufacturing Considerations

Lamination Techniques

The lamination process plays a critical role in ensuring the durability and performance of your rigid flex PCB. Proper lamination techniques help bond the stiffener to the PCB layers, preventing issues like delamination or warping. You should prioritize precision during this step to maintain the structural integrity of your design.

Leading manufacturers rely on advanced tools like automated roll-to-roll laminators to achieve consistent results. These systems apply uniform pressure and heat, ensuring the stiffener adheres seamlessly to the PCB. For high-stress areas, polyimide stiffeners are often laminated to prevent cracking and delamination. This approach enhances the reliability of your PCB, especially in demanding applications.

Tip: Always verify the lamination temperature and pressure settings to match the materials used in your design.

Drill Hole Alignment

Accurate drill hole alignment is essential for maintaining the functionality of your PCB. Misaligned holes can lead to connectivity issues, such as poor signal transmission or mechanical instability. You should ensure that the stiffener and PCB layers align perfectly during the drilling process.

Laser drilling systems are widely used to achieve precise hole placement. These systems offer high accuracy, reducing the risk of errors. Before drilling, double-check the alignment of all layers, including the stiffener. This step minimizes the chances of defects and ensures a smooth assembly process.

Reminder: Use alignment pins during manufacturing to keep all layers in place and avoid shifting.

Cost Factors

Manufacturing costs can vary depending on the materials and techniques you choose. High-quality stiffeners like polyimide or metal may increase costs but offer better performance and durability. Similarly, advanced processes like laser drilling or automated lamination add to the expense but improve reliability.

To optimize costs, evaluate your design requirements carefully. For instance, use FR4 stiffeners for standard applications where budget constraints exist. Reserve premium materials for designs requiring exceptional performance in harsh environments.

Note: Collaborate with your manufacturer to identify cost-effective solutions without compromising quality.

Weight and Thickness Optimization

Lightweight Design

Reducing the weight of your PCB stiffener can improve the overall design of your rigid flex PCB. Lightweight stiffeners, such as polyimide or aluminum, are ideal for applications where weight is a critical factor. Devices like drones, wearables, and portable medical equipment benefit from lighter designs. These materials maintain structural integrity while minimizing the burden on the PCB.

To achieve a lightweight design, focus on selecting materials with a low density. For example, aluminum stiffeners weigh less than stainless steel but still provide excellent mechanical support. Polyimide stiffeners offer flexibility and durability without adding unnecessary weight.

Tip: Use lightweight stiffeners to reduce transportation costs and improve device portability.

Stiffener Thickness Impact

The thickness of your stiffener directly affects the mechanical properties of your PCB. Thicker stiffeners provide greater rigidity, which is essential for designs with heavy components or high mechanical stress. However, they reduce flexibility and may increase the overall weight of your PCB.

You should evaluate the trade-offs between thickness and performance. For instance, a stiffener with a thickness of 0.5 mm may work well for compact devices, while a 1.5 mm stiffener offers better support for industrial applications.

| Thickness | Application |

|---|---|

| 0.5 mm | Compact devices, wearables |

| 1.0 mm | General-purpose electronics |

| 1.5 mm | Industrial and automotive use |

Note: Always test the impact of stiffener thickness on flexibility and assembly during prototyping.

Ultra-Thin Applications

Ultra-thin stiffeners are essential for designs with strict space constraints. These stiffeners, often made from polyimide, fit seamlessly into compact enclosures without compromising performance. They are ideal for applications like smartphones, tablets, and miniaturized sensors.

When working with ultra-thin stiffeners, prioritize materials with high tensile strength and low thermal expansion. This ensures your PCB remains stable under mechanical and thermal stress.

Reminder: Verify the dimensions of ultra-thin stiffeners to avoid interference with other components during assembly.

Assembly and Testing

Placement Accuracy

Accurate placement of components ensures your PCB performs as intended. Misaligned components can cause electrical failures or mechanical instability. You should use automated assembly systems to achieve precise placement. These systems rely on advanced vision technology to detect and correct alignment errors during the assembly process.

For example, pick-and-place machines offer high-speed and accurate component placement. They reduce human error and improve consistency. You should also verify alignment during testing to catch any issues early. This step prevents costly rework and ensures your PCB meets design specifications.

Tip: Use fiducial markers on your PCB to guide automated systems and improve placement accuracy.

Avoiding Warping

Warping can compromise the structural integrity of your PCB. It occurs when uneven thermal expansion or mechanical stress distorts the board. You should select stiffeners with matching thermal expansion properties to minimize this risk. Materials like FR4 and polyimide work well because they expand at similar rates to PCB layers.

During assembly, monitor lamination pressure and temperature settings. Excessive heat or pressure can cause warping. You should also use proper storage conditions to prevent moisture absorption, which can lead to deformation.

| Testing Protocol | Description |

|---|---|

| Thermal Cycling Tests | Simulates extreme environments by subjecting connectors to rapid temperature shifts. |

| Mechanical Vibration Testing | Applies vibration profiles to assess pin loosening and housing integrity. |

| Humidity and Corrosion Resistance | Accelerates oxidation to measure insulation resistance and visualize contact surfaces. |

These tests help identify potential warping issues and ensure your PCB remains stable under operating conditions.

Performance Testing

Testing validates the reliability and functionality of your PCB. You should conduct multiple tests to assess its performance under real-world conditions. Thermal cycling tests simulate rapid temperature changes to evaluate durability. Mechanical vibration testing checks for pin loosening and housing integrity.

For flexible PCBs, flexural endurance tests measure signal integrity during dynamic bending. These tests ensure your PCB withstands repeated flexing without failure. You should also verify current-carrying capacity to monitor temperature rise during operation.

Reminder: Always test your PCB against industry standards to ensure compliance and reliability in harsh environments.

Manufacturer Collaboration

Collaborating with a reliable PCB manufacturer is essential for achieving the best results in your rigid flex PCB design. Manufacturers bring expertise, resources, and innovative solutions to help you overcome design and production challenges.

Expert Guidance

Experienced manufacturers provide valuable insights into material selection, design optimization, and manufacturing techniques. They understand the complexities of multilayer rigid flex PCBs and can guide you in choosing the right stiffeners for your application.

Tip: Share your design requirements and operating conditions with your manufacturer early in the process. This ensures they can recommend materials and processes that align with your goals.

Manufacturers also help you navigate industry standards and compliance requirements. Their expertise ensures your PCB meets performance expectations while adhering to safety and quality regulations.

Custom Solutions

Every PCB design is unique, and manufacturers can offer tailored solutions to meet your specific needs. Whether you require a lightweight stiffener for a wearable device or a high-strength option for industrial equipment, they can customize materials, thicknesses, and finishes to suit your application.

Examples of Customization:

- Adding cutouts or slots in stiffeners to accommodate connectors or components.

- Using hybrid stiffeners that combine materials like FR4 and polyimide for balanced performance.

- Applying specialized coatings for enhanced moisture resistance or thermal stability.

Collaborating on custom solutions allows you to create a PCB that performs optimally in its intended environment.

Prototyping

Prototyping is a critical step in the PCB development process. Manufacturers can produce prototypes to test your design before full-scale production. This helps you identify potential issues, such as misaligned stiffeners or inadequate adhesion, and make necessary adjustments.

Reminder: Request multiple prototypes to test different configurations and materials. This approach ensures you select the best option for your final design.

Prototyping also provides an opportunity to evaluate the performance of your PCB under real-world conditions. By working closely with your manufacturer, you can refine your design and ensure it meets all functional and reliability requirements.

Long-Term Reliability

Durability in Harsh Conditions

Your PCB stiffeners must withstand challenging environments to ensure long-term reliability. Extreme temperatures, high humidity, and mechanical stress can degrade materials over time. Selecting stiffeners with proven durability helps your PCB maintain its structural integrity.

Materials like FR4 and polyimide excel in harsh conditions. FR4 offers high thermal stability, while polyimide resists chemical exposure and moisture. Metal stiffeners, such as stainless steel, provide unmatched mechanical strength for applications involving heavy vibration or shock.

Tip: Test your PCB under simulated environmental conditions, such as thermal cycling and vibration tests, to verify its durability.

Delamination Prevention

Delamination weakens your PCB by separating layers, leading to electrical failures and mechanical instability. Preventing this issue starts with choosing stiffeners that bond securely to the PCB. Adhesives with high peel strength and proper surface preparation ensure a strong connection.

Polyimide stiffeners reduce delamination risks due to their excellent adhesion properties. FR4 stiffeners also perform well when paired with epoxy-based adhesives. Avoid materials with high water absorption rates, as moisture accelerates delamination.

| Material | Water Absorption Rate | Adhesion Strength |

|---|---|---|

| Polyimide | <0.2% | High |

| FR4 | <0.5% | Moderate |

Reminder: Regular inspections during assembly help identify early signs of delamination and prevent costly repairs.

Consistent Performance

Your PCB must deliver consistent performance throughout its lifespan. Stiffeners play a key role in maintaining electrical and mechanical stability. Materials with low thermal expansion ensure dimensional accuracy, reducing stress on solder joints and components.

For example, FR4 stiffeners minimize warping during thermal cycling, while polyimide stiffeners maintain flexibility without compromising strength. Metal stiffeners provide stability for high-frequency circuits, ensuring signal integrity.

Callout: Use stiffeners with matching thermal expansion coefficients to avoid performance fluctuations in extreme temperatures.

By prioritizing durability, adhesion, and stability, you can design a PCB that performs reliably in any environment.

PCB stiffeners are essential for ensuring the durability and functionality of complex multilayer rigid flex PCBs. They provide structural support, protect against damage, and enhance component placement. To achieve optimal results, you must carefully balance design requirements, material selection, and manufacturing processes.

Tip: Collaborate with experienced PCB manufacturers to gain expert guidance and access to custom solutions. Their insights can help you refine your design and ensure long-term reliability.

By prioritizing these factors, you can create a PCB that performs consistently, even in the most demanding environments.

FAQ

What is the primary purpose of a PCB stiffener?

A PCB stiffener reinforces your rigid flex PCB. It provides mechanical support, prevents flex damage, and ensures accurate component placement. This improves durability and reliability, especially in complex multilayer designs.

How do you choose the right stiffener material?

Select a stiffener based on your design needs. FR4 offers rigidity and thermal stability. Polyimide provides flexibility and lightweight properties. Metal stiffeners like aluminum or stainless steel deliver unmatched strength for high-stress applications.

Can stiffeners affect PCB flexibility?

Yes, stiffeners reduce flexibility in reinforced areas. Use them strategically to balance rigidity and flexibility. For dynamic sections, opt for thinner stiffeners or flexible materials like polyimide.

Are stiffeners necessary for all rigid flex PCBs?

Not always. Stiffeners are essential for designs requiring mechanical support, precise component placement, or durability in harsh environments. Evaluate your PCB’s application to decide if stiffeners are needed.

How do stiffeners improve long-term reliability?

Stiffeners prevent delamination, warping, and mechanical damage. They enhance structural integrity and ensure consistent performance under thermal, moisture, and vibration stress. Proper material selection and adhesion techniques maximize reliability.