Steps to ensure RoHS compliance in PCB manufacturing

Ensuring RoHS compliance in PCB manufacturing involves several critical steps. You need to start by understanding the specific requirements outlined in the RoHS directive. This knowledge helps you identify restricted substances and avoid non-compliance risks. Next, prioritize selecting materials that meet RoHS standards. Reliable supplier verification ensures that all components align with compliance goals. Testing and certification further validate adherence, while process controls maintain consistency during production. Finally, keeping detailed documentation supports audits and long-term compliance.

📊 The global electrical compliance market, valued at $4.6 billion in 2023, is expected to grow to $7.9 billion by 2032, with a CAGR of 6.1%. This highlights the increasing importance of compliance in the electronics industry.

Key Takeaways

- Learn RoHS rules to prevent breaking the law. Know banned substances like lead and mercury.

- Use materials that follow RoHS, like solder without lead. This improves product safety and meets rules.

- Check suppliers often with audits and paperwork. This makes sure parts follow RoHS rules.

- Test products carefully and get certificates to prove they are safe from harmful substances.

- Keep clear records of materials and steps. This helps with checks and shows you follow the rules.

Understanding RoHS Compliance

What is RoHS compliance?

RoHS compliance refers to adhering to the European Union’s directive that restricts the use of specific hazardous materials in electrical and electronic products. These restrictions aim to minimize environmental harm and improve the safety of electronic waste disposal. By meeting RoHS standards, you ensure that your products are free from substances like lead, mercury, and cadmium, which pose risks to ecosystems and human health.

🌱 Tip: RoHS compliance isn’t just about meeting regulations; it also demonstrates your commitment to sustainability and responsible manufacturing.

Importance of RoHS compliance in PCB manufacturing

Understanding RoHS compliance is essential for PCB manufacturing. Non-compliance can prevent your products from entering the European market, limiting your business opportunities. Moreover, RoHS-compliant manufacturing reduces pollution caused by hazardous substances, contributing to a cleaner environment. It also ensures safer handling and disposal of electronic components, protecting workers and communities.

| Aspect | Description |

|---|---|

| Regulatory Requirement | Compliance with the RoHS Directive is essential for market access in the EU. |

| Environmental Impact | RoHS aims to reduce pollution from hazardous substances in electronic waste. |

| Market Access | Non-compliance can lead to restrictions in selling products within the European market. |

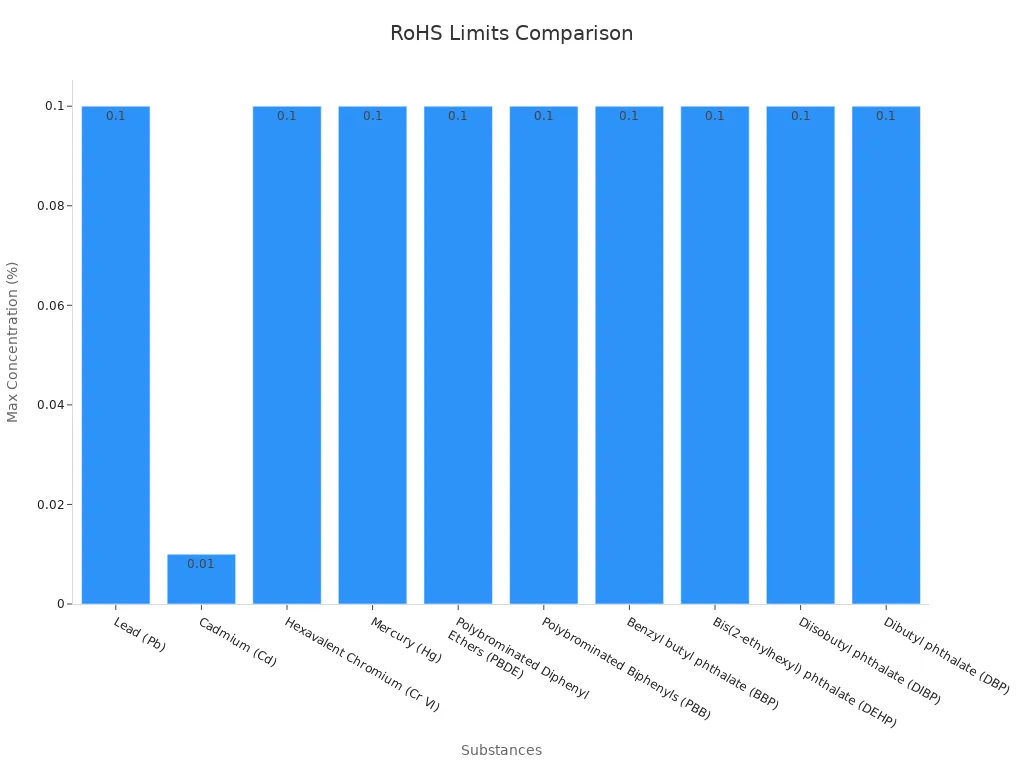

Substances restricted under RoHS

The RoHS directive limits the concentration of ten hazardous substances commonly found in electronic products. These substances include heavy metals and flame retardants, which can harm the environment and human health. Below is a table outlining the maximum allowable concentrations for each substance:

| Substance | Maximum Allowable Concentration |

|---|---|

| Lead (Pb) | 0.1% |

| Cadmium (Cd) | 0.01% |

| Hexavalent Chromium (Cr VI) | 0.1% |

| Mercury (Hg) | 0.1% |

| Polybrominated Diphenyl Ethers (PBDE) | 0.1% |

| Polybrominated Biphenyls (PBB) | 0.1% |

| Benzyl butyl phthalate (BBP) | 0.1% |

| Bis(2-ethylhexyl) phthalate (DEHP) | 0.1% |

| Diisobutyl phthalate (DIBP) | 0.1% |

| Dibutyl phthalate (DBP) | 0.1% |

By ensuring your PCB manufacturing processes comply with these limits, you protect the environment and align with global standards.

Key Steps to Ensure RoHS Compliance

Understanding RoHS requirements

To ensure RoHS compliance, you must first familiarize yourself with the directive’s specific requirements. The RoHS directive restricts the use of hazardous substances in electrical and electronic equipment. These substances include lead, mercury, cadmium, and others that pose risks to human health and the environment. Understanding these restrictions helps you avoid costly mistakes during manufacturing.

You should also focus on three critical areas to meet RoHS requirements:

- Materials: Use compliant materials, such as lead-free solder, to meet RoHS standards.

- Processes: Implement procedures to prevent contamination with non-RoHS substances.

- Documentation: Maintain traceable records of all materials to ensure compliance.

🛠️ Tip: Create a checklist of restricted substances and their allowable limits. This ensures you stay on track during the design and production phases.

Selecting RoHS-compliant materials

Choosing the right materials is crucial for RoHS compliance. You need to ensure that every component in your PCB meets the directive’s technical specifications. For instance, using lead-free printed circuit boards and solder paste with specific compositions like SAC305 or SN100C ensures compliance. Below is a table summarizing the key material requirements:

| Specification Type | Details |

|---|---|

| Lead-Free Materials | RoHS-compliant products must use lead-free printed circuit boards. |

| Substrate/Laminate Materials | Common materials include FR370HR, IS410, Polyclad370HR, IsolaFR415. |

| Solder Paste Requirements | Must consist of lead-free solder and flux, with specific compositions like SAC305 and SN100C. |

| Compliance with RoHS Directive | All materials and processes must adhere to the RoHS directive prohibiting six hazardous substances. |

Selecting these materials not only ensures compliance but also enhances the quality and reliability of your PCBs. Always verify the technical specifications of materials before integrating them into your manufacturing process.

🌟 Note: Partnering with suppliers who specialize in RoHS-compliant materials can simplify this step and reduce the risk of non-compliance.

Verifying supplier compliance

Your suppliers play a significant role in maintaining RoHS compliance. Verifying their adherence to the directive ensures that the components you source meet the required standards. Conducting regular audits and assessments can help you identify potential risks and address them proactively. The table below outlines the key types of audits and their purposes:

| Type of Audit | Purpose | Components Involved |

|---|---|---|

| Compliance Audit | Verify adherence to RoHS requirements | Review of documentation, inspection of products and processes |

| Risk Assessment Audit | Identify potential non-compliance and assess impact | Review of documentation to identify issues, assessment of operational impact |

| Documentation Requirements | Ensure all necessary documentation is in place for compliance verification | Comprehensive review of all relevant documents and preparation of compliance report |

| Certification Requirements | Obtain certification from recognized bodies | Assessment by certification body against international and national standards |

When working with suppliers, request detailed documentation, including material certifications and test reports. This ensures traceability and provides evidence of compliance during audits.

📋 Pro Tip: Establish long-term relationships with trusted suppliers who have a proven track record of meeting RoHS standards. This reduces the need for frequent re-verifications.

Conducting RoHS testing and certification

Testing and certification are essential steps to ensure your products meet RoHS compliance standards. These processes verify that your PCBs are free from restricted substances and align with regulatory requirements. Here’s how you can approach this:

- Testing: Use advanced techniques like X-ray fluorescence (XRF) to detect the presence of restricted substances. For phthalates, apply solvent extraction testing in a certified lab.

- Process Audit: Evaluate critical manufacturing processes to confirm they comply with RoHS regulations. This includes reviewing production workflows and identifying potential risks.

- Documentation Review: Examine essential documents such as bills of materials and test reports. Ensure all records clearly demonstrate compliance with RoHS standards.

- RoHS Certification: After completing the audits and tests, obtain a certification from an authorized body. This certification serves as proof of compliance and builds trust with your customers.

🛡️ Tip: Always work with accredited testing labs and certification bodies to ensure accurate results and reliable documentation.

By following these steps, you can confidently certify your PCBs and meet global regulatory compliance certifications.

Implementing process controls

Strong process controls are vital for maintaining RoHS compliance throughout the PCB assembly process. These measures help you prevent contamination and ensure consistent quality. Consider implementing the following controls:

- Material Selection: Choose only RoHS-compliant materials for your PCBs. Verify their compliance before use.

- Supplier Verification: Establish a zero-tolerance policy for non-compliance. Regularly audit your suppliers to ensure they meet RoHS standards.

- Periodic Testing: Conduct routine chemical testing of PCB components to detect restricted substances.

- Continuous Quality Control: Monitor every stage of the PCB assembly process to identify and address issues promptly.

- Employee Training: Train your staff on RoHS regulations and safe handling practices. This ensures everyone understands their role in maintaining compliance.

🔍 Note: Implementing these controls not only ensures compliance but also improves the overall efficiency of your manufacturing process.

By integrating these measures, you can maintain a high level of compliance and reduce the risk of errors during production.

Maintaining documentation and records

Proper documentation is the backbone of RoHS compliance. It provides evidence of your efforts to meet regulatory requirements and simplifies the audit process. Below is a table outlining key documentation practices for each phase of the PCB assembly process:

| Phase | Task | Action Items | Tools/Documents |

|---|---|---|---|

| Design | Component Selection & Sourcing | Obtain material declarations (e.g., SDS, RoHS, CoC); maintain a preferred parts list; document alternatives. | Component DB, PLM, Altium 365 |

| Fabrication | Fabrication Drawings | Specify materials and stackup; include compliance instructions in the drawings. | Fabrication drawings |

| Testing & Certification | Test Reports | Maintain detailed reports on RoHS testing and certification outcomes. | Test reports |

📋 Pro Tip: Use digital tools like PLM (Product Lifecycle Management) software to organize and store your compliance records. This makes it easier to retrieve documents during audits.

Maintaining accurate and up-to-date records ensures you can demonstrate compliance at any time. It also helps you stay prepared for changes in RoHS regulations.

Common Challenges and Solutions

Identifying compliant materials

Finding materials that meet RoHS compliance standards can be challenging. You must navigate evolving regulations and ensure that every material used in your PCB manufacturing process adheres to the directive. Staying updated on changes in RoHS requirements is essential, as non-compliance risks increase with outdated practices. Managing complex supply chains adds another layer of difficulty, especially when verifying the accuracy of material declarations.

| Challenge | Description |

|---|---|

| Evolving Regulations | Staying up-to-date with changing regulations requires constant monitoring and adaptation. |

| Complex Supply Chains | Managing intricate supply chains to ensure all materials are compliant is resource-intensive. |

| Accuracy of Material Declarations | Ensuring the correctness of material declarations is crucial for compliance verification. |

| Lead-Free Soldering | Transitioning to lead-free soldering involves technical adjustments and affects component selection. |

| Alternative Materials | Finding substitutes for restricted substances while maintaining performance is challenging. |

To overcome these challenges, focus on building strong relationships with suppliers who specialize in RoHS-compliant materials. Regular audits and documentation reviews can help ensure accuracy and traceability. Using compliance management tools can also streamline the process and reduce errors.

Ensuring supplier compliance

Suppliers play a critical role in maintaining RoHS compliance. You need to verify that every component sourced meets the directive’s standards. This requires conducting regular audits and risk assessments to identify potential issues. Complex supply chains often make this process resource-intensive, but proactive measures can mitigate risks.

- Technical Challenges:

- Shift to lead-free soldering affects component selection and manufacturing processes.

- Finding alternatives for restricted substances can impact reliability and performance.

- Economic Challenges:

- Initial investments in new equipment and training are often substantial.

- Higher costs of compliant materials can increase production expenses.

Establishing long-term partnerships with trusted suppliers simplifies compliance verification. Request detailed documentation, such as material certifications and test reports, to ensure traceability. Embedding compliance into your core business processes fosters a culture of adherence and reduces the likelihood of non-compliance.

Managing compliance costs

RoHS compliance often comes with increased production expenses. Compliant materials, lead-free soldering, and alternative substances can be more expensive than traditional options. Additionally, upfront investments in new equipment and staff training add to the financial burden. Salaries for compliance staff and regulatory reporting costs further contribute to overall expenses.

To manage these costs effectively, consider the following strategies:

- Invest in technologies that streamline compliance processes and reduce manual errors.

- Conduct regular risk assessments to identify and address potential issues early.

- Implement a compliance management system to automate routine tasks and improve efficiency.

- Educate employees on compliance requirements to foster a culture of adherence.

- Embed compliance into everyday activities to integrate it into your core operations.

By adopting these strategies, you can reduce compliance-related expenses while maintaining high standards in PCB manufacturing.

Solutions to overcome compliance challenges

Overcoming compliance challenges in PCB manufacturing requires a proactive and strategic approach. Here are some effective solutions to help you address these obstacles:

- Build a Reliable Supplier Network

Partner with suppliers who specialize in RoHS-compliant materials. Conduct regular audits to verify their adherence to regulations. Request detailed documentation, such as material declarations and test reports, to ensure traceability. A strong supplier relationship reduces risks and simplifies compliance management. - Invest in Compliance Training

Educate your team about RoHS requirements and best practices. Training ensures that everyone understands their role in maintaining compliance. Focus on areas like material selection, process controls, and documentation. Well-trained employees can identify potential issues early and take corrective actions. - Leverage Technology

Use compliance management tools to streamline your processes. Software solutions can help you track materials, monitor supplier compliance, and maintain accurate records. Automation reduces manual errors and saves time during audits. - Adopt Alternative Materials

Transition to lead-free solder and other RoHS-compliant materials. Research and test substitutes for restricted substances to maintain product performance. Collaborate with material experts to find cost-effective alternatives that meet regulatory standards. - Stay Updated on Regulations

Monitor changes in RoHS directives and related standards. Subscribe to industry newsletters or join compliance forums to stay informed. Being aware of updates helps you adapt quickly and avoid non-compliance risks.

💡 Tip: Create a compliance checklist to track your progress. This ensures you address every requirement and stay on top of regulatory changes.

By implementing these solutions, you can overcome compliance challenges and maintain a competitive edge in the market.

Best Practices for Maintaining RoHS Compliance

Staying updated on RoHS regulations

Keeping up with RoHS regulations ensures your manufacturing processes remain compliant. Regulatory updates often introduce new restrictions or modify existing ones. Staying informed helps you avoid non-compliance risks, such as product recalls or legal penalties. By designing for environmental compliance from the start, you can enhance your brand reputation and improve product safety.

| Best Practices | Benefits |

|---|---|

| Design for environmental compliance | Minimize recalls, avoid legal issues, and boost brand reputation. |

| Maintain compliance in manufacturing | Gain a competitive edge through safer, more reliable, and marketable products. |

| Adhere to stringent standards | Build trust with customers by demonstrating reliability and safety. |

You can stay updated by subscribing to industry newsletters, attending compliance seminars, or joining professional forums. These resources provide insights into regulatory changes and best practices for maintaining compliance.

Conducting regular audits

Regular audits are essential for identifying and addressing compliance gaps. These audits evaluate your materials, processes, and documentation to ensure they meet RoHS standards. By conducting audits, you can detect potential issues early and take corrective actions before they escalate.

Focus on these key areas during audits:

- Material Compliance: Verify that all materials used in your pcb manufacturing meet RoHS requirements.

- Supplier Verification: Assess supplier documentation and certifications to ensure traceability.

- Process Evaluation: Review manufacturing workflows to identify contamination risks.

Using compliance management tools like MatCheck by Rumzer or Source Intelligence can simplify the audit process. These tools provide features such as material tracking, supplier reminders, and full material disclosure, ensuring thorough and efficient audits.

Training staff on compliance requirements

Educating your team about RoHS compliance is crucial for maintaining adherence. Well-trained employees can identify risks, follow proper procedures, and ensure consistent compliance. Training programs tailored to PCB manufacturing provide practical knowledge and skills.

| Training Program | Description | Price (Member/Nonmember) |

|---|---|---|

| IPC J-STD-001 for Operators | Introduction to IPC J-STD-001 standard for operators. | $50.00 / $65.00 |

| IPC-A-610 for Operators | Overview of IPC-A-610 standard for operators. | $50.00 / $65.00 |

| WHMA/IPC 620 for Operators | Basics of IPC/WHMA-A-620 standard for operators. | $50.00 / $65.00 |

| Electronics Assembly for Operators | Key concepts and processes for electronics assembly. | $200.00 |

Investing in these programs equips your staff with the knowledge to handle compliance challenges effectively. This proactive approach reduces errors and strengthens your overall compliance strategy.

Using compliance management tools

Compliance management tools simplify the process of ensuring RoHS compliance in PCB manufacturing. These tools help you track materials, monitor supplier certifications, and maintain accurate records. By automating repetitive tasks, they save time and reduce the risk of human error.

Benefits of Compliance Management Tools

Using these tools offers several advantages:

- Streamlined Documentation: Store and organize all compliance-related documents in one place. This makes it easier to retrieve records during audits.

- Real-Time Monitoring: Track supplier compliance and material certifications in real time. This ensures you stay updated on any changes.

- Error Reduction: Automation minimizes manual errors, improving the accuracy of your compliance processes.

- Time Efficiency: Focus on critical tasks while the tool handles routine compliance checks.

💡 Tip: Choose a tool that integrates with your existing systems, such as ERP or PLM software. This ensures seamless data sharing and reduces setup time.

Popular Compliance Management Tools

Here’s a comparison of some widely used tools:

| Tool Name | Key Features | Best For |

|---|---|---|

| MatCheck by Rumzer | Material tracking, supplier reminders | Small to medium-sized businesses |

| Source Intelligence | Full material disclosure, risk analysis | Large-scale operations |

| Assent Compliance | Supply chain data management, reporting | Enterprises with global suppliers |

How to Choose the Right Tool

When selecting a compliance management tool, consider your specific needs. Evaluate the size of your operation, the complexity of your supply chain, and your budget. Look for tools that offer scalability, user-friendly interfaces, and robust customer support.

📋 Pro Tip: Test the tool with a free trial or demo before committing. This helps you assess its compatibility with your workflow.

By leveraging compliance management tools, you can simplify RoHS compliance and focus on delivering high-quality PCBs.

RoHS compliance plays a vital role in ensuring the safety and sustainability of your pcb manufacturing processes. By adhering to the directive, you protect the environment, meet market requirements, and enhance product reliability. Following key steps like selecting compliant materials, verifying suppliers, and maintaining documentation simplifies compliance and reduces risks. Adopting best practices, such as regular audits and staff training, ensures long-term success. Staying proactive in compliance not only strengthens your operations but also builds trust with customers.

FAQ

What does RoHS stand for?

RoHS stands for “Restriction of Hazardous Substances.” It is a directive from the European Union that limits the use of specific hazardous materials in electrical and electronic equipment to protect the environment and human health.

How can you identify RoHS-compliant components?

Look for certifications or labels like “RoHS Compliant” on components. Request material declarations or test reports from suppliers. Use compliance management tools to verify the status of materials and ensure traceability.

🛠️ Tip: Always double-check supplier documentation to avoid non-compliance risks.

Is RoHS compliance mandatory for all countries?

No, RoHS compliance is mandatory in the European Union. However, many other countries have adopted similar regulations. If you plan to sell products globally, adhering to RoHS standards ensures broader market access.

What happens if your product fails RoHS compliance?

Non-compliance can lead to product recalls, fines, or bans from the European market. It can also damage your brand reputation. Regular audits and testing help you avoid these consequences.

⚠️ Note: Non-compliance can also increase production costs due to rework or redesign.

Can RoHS compliance improve product quality?

Yes, RoHS compliance often leads to better product quality. Using lead-free solder and other compliant materials enhances reliability and safety. It also aligns your manufacturing process with global environmental standards.

🌱 Pro Tip: Highlight your compliance efforts to attract eco-conscious customers.