Comparing Aluminum, Copper, and Ceramic LED PCBs for Lighting Applications

Choosing the right LED Lighting PCB is very important. It affects how well your lighting works, lasts, and saves energy. Aluminum, copper, and ceramic PCBs each have their own strengths and weaknesses.

- Aluminum PCBs: These are also called Metal Core PCBs. They handle heat well, so they are great for powerful LED lights.

- Copper PCBs: These are super good at carrying electricity. They work best when top electrical performance is needed.

- Ceramic PCBs: These resist heat and are great in very hot places.

Studies show that picking the right LED Lighting PCB helps spread heat better. This makes LED lights last longer and keeps their brightness steady. For example, Metal Core PCBs stay cooler, work more efficiently, and protect parts from heat damage. Knowing these differences helps you choose the best PCB for long-lasting, high-performing LED lights.

Key Takeaways

- Pick aluminum PCBs because they handle heat well and are cheap. They work great for regular lighting tasks.

- Use copper PCBs when you need strong electrical power. They carry more electricity and last longer in tough situations.

- Go for ceramic PCBs in very hot or rough places. They are super strong and reliable.

- Knowing what each PCB type does helps you choose better for your lights.

- Think about cost and performance. Aluminum is affordable, copper is powerful, and ceramic is for special jobs.

Aluminum LED PCBs

Key Features of Aluminum LED PCBs

Aluminum LED PCBs are great at handling heat. They use an aluminum core, which spreads heat better than regular materials like FR4. This helps keep LEDs cool and makes them last longer.

They are also very strong. Aluminum PCBs don’t bend or warp easily, so they work well in tough conditions. They also improve electrical performance by lowering electromagnetic interference (EMI) and keeping signals steady at high speeds.

Here’s a simple look at their strengths:

| Feature | Description |

|---|---|

| Thermal Conductivity | Aluminum spreads heat well, keeping parts cool. |

| Mechanical Strength | Strong and durable, they resist bending and breaking. |

| Cost-Effectiveness | Aluminum is affordable, making it a good choice for LEDs. |

| Heat Management | Good heat control helps LEDs last longer and work better. |

These features make aluminum LED PCBs a solid choice for projects needing good heat control and strength.

Pros and Cons of Aluminum LED PCBs

Aluminum LED PCBs have many benefits but also some downsides. Knowing both can help you decide if they’re right for your needs.

Pros:

- High Thermal Conductivity: They handle heat better than FR4 PCBs.

- Durability: They are strong and resist bending or breaking.

- Improved Electrical Performance: They lower EMI and keep signals steady.

- Environmentally Friendly: Aluminum can be recycled, making it eco-friendly.

- Cost-Effective: They save money over time by lasting longer and needing less cooling.

Cons:

- Higher Cost: They cost more than FR4 PCBs upfront.

- Limited Flexibility: They are stiff and not good for flexible designs.

- Machining Challenges: Aluminum is softer than copper, making it harder to shape.

| Feature | Aluminum PCB | FR4 PCB |

|---|---|---|

| Core Material | Aluminum metal | Fiberglass-reinforced resin |

| Heat Dissipation | Excellent | Limited |

| Mechanical Strength | High | Moderate |

| Flexibility | Rigid | Supports multi-layer design |

| Cost | Higher | Lower |

| Weight | Lightweight | Lightweight |

By looking at these pros and cons, you can decide if aluminum LED PCBs fit your project’s needs.

Best Applications for Aluminum LED PCBs

Aluminum LED PCBs are used where heat control and strength are important. They work well in high-power LED systems.

Here are some common uses for aluminum LED PCBs:

- Consumer and Commercial Lighting: Used in LED bulbs and spotlights. They save energy and spread heat well, making lights last longer.

- Automotive Lighting Systems: Found in car headlights and brake lights. They resist heat, improving safety and reliability.

- Medical Imaging and Diagnostic Tools: Power surgical lamps and endoscopes. They reduce flicker for clear imaging during surgeries.

- Aerospace and Aviation Lighting: Used in airplane landing lights and cockpit displays. They handle extreme heat and vibrations.

- Horticultural and Aquarium Lighting: Help LED systems give the right light for plants or aquariums.

| Application Area | Role | Advantage |

|---|---|---|

| Consumer and Commercial Lighting | Used in bulbs and spotlights | Saves energy and spreads heat for longer-lasting lights |

| Automotive Lighting Systems | Found in car headlights and brake lights | Stops overheating, improving safety and durability |

| Telecommunications Equipment | Used in routers and servers for displays | Keeps signals steady and spreads heat |

| Medical Imaging and Diagnostic Tools | Powers surgical lamps and endoscopes | Reduces flicker for clear imaging |

| Aerospace and Aviation Lighting | Powers landing lights and cockpit displays | Handles vibrations and extreme heat |

| Industrial and Machinery Displays | Used in control panels for machines | Stays strong in high heat and tough conditions |

| Entertainment and Stage Lighting | Powers LED lights for theaters and concerts | Keeps cool during long performances |

| Horticultural and Aquarium Lighting | Gives the right light for plants or aquariums | Customizable for specific light needs |

These examples show how aluminum LED PCBs are useful in industries needing strong and heat-resistant materials.

Copper LED PCBs

Key Features of Copper LED PCBs

Copper LED PCBs are known for their excellent performance. They use copper as the core material, which manages heat and electricity well. Copper spreads heat quickly, keeping LED lights cool even when very bright. This helps prevent overheating and makes LEDs last longer.

These PCBs are also great at handling electricity. They carry more current with less energy loss, making lights work better. Their strong build resists bending and damage, even in tough conditions. Copper doesn’t rust easily, so these PCBs stay durable in harsh environments.

Here’s a simple breakdown of their features:

| Feature | Description |

|---|---|

| Thermal Management | Spreads heat well, keeping LEDs cool and safe. |

| Electrical Conductivity | Carries more current with less energy loss. |

| Mechanical Strength | Strong and resists bending, great for tough conditions. |

| Lifespan and Reliability | Lasts longer due to better heat control and strength. |

| Corrosion Resistance | Doesn’t rust easily, staying durable in harsh places. |

These qualities make copper LED PCBs a top pick for high-performance lighting needs.

Pros and Cons of Copper LED PCBs

Copper LED PCBs have many benefits but also some downsides. Knowing both helps you decide if they’re right for your project.

Pros:

- Great Heat Control: Copper spreads heat well, lowering LED temperatures by 25°C.

- Better Energy Use: Carries more current with less power loss.

- Very Durable: Resists bending, warping, and rust, even in tough spots.

- Longer Lifespan: LEDs on copper PCBs last 40% longer with less dimming.

- Precise Design: Parts are placed accurately for reliable performance.

Cons:

- Higher Cost: Copper PCBs cost more than aluminum or FR4 ones.

- Heavier Weight: They weigh more, which isn’t ideal for portable designs.

- Harder to Make: Making copper PCBs takes more time and effort.

| Metric | Value |

|---|---|

| Thermal conductivity | 200W/m·K |

| Junction temperature reduction | 25°C |

| Light output degradation | < 5% over 50,000 hours |

| Product lifespan increase | 40% longer |

| Solder void rates | < 3% |

| Component placement accuracy | ±0.1mm |

| Thermal cycles withstand | 1000+ |

| Hot spot temperature | > 150°C (standard aluminum) |

| Lumen depreciation rate | 30% faster with aluminum |

Copper LED PCBs perform very well, but their cost and weight need careful planning.

Best Applications for Copper LED PCBs

Copper LED PCBs are perfect for demanding lighting jobs. They handle high heat and heavy electrical loads, making them great for special uses.

Here are some examples:

- Industrial Lighting: Used in factories and warehouses for strong, reliable lighting.

- Automotive Lighting: Found in car headlights and taillights, resisting vibrations and heat.

- Aerospace and Defense: Used in planes and military tools, working well in extreme conditions.

- Medical Devices: Powers surgical lights and tools, keeping light steady and clear.

- Telecommunications: Helps routers and servers stay cool and work efficiently.

- Outdoor Lighting: Used in streetlights and floodlights, handling all kinds of weather.

| Application Area | Role | Advantage |

|---|---|---|

| Industrial Lighting | Powers strong LED systems | Works well in tough conditions |

| Automotive Lighting | Found in headlights and taillights | Handles vibrations and heat for safety |

| Aerospace and Defense | Used in planes and military tools | Reliable in extreme environments |

| Medical Devices | Powers surgical lights and tools | Keeps light steady and clear |

| Telecommunications | Supports routers and servers | Stays cool and keeps signals strong |

| Outdoor Lighting | Used in streetlights and floodlights | Works well in all weather |

Copper LED PCBs are the best choice for jobs needing strong, reliable, and efficient lighting.

Ceramic LED PCBs

Key Features of Ceramic LED PCBs

Ceramic LED PCBs are special because they handle heat and electricity very well. They are made with ceramic materials like aluminum oxide (Al₂O₃) or aluminum nitride (AlN). These materials help spread heat and stop electrical problems, making them great for powerful and fast devices.

Key features include:

- Thermal Management: Ceramic materials spread heat quickly, keeping high-power LEDs cool.

- Electrical Insulation: They block electricity from leaking, preventing short circuits.

- Mechanical Strength: Ceramic PCBs are tough and resist breaking or bending.

- High Power Handling: They can handle strong currents and fast signals without issues.

- High-Temperature Resistance: They work well in very hot places like engines or airplanes.

| Metric | Description |

|---|---|

| Thermal Conductivity | High, spreads heat quickly and efficiently. |

| Electrical Insulation | Excellent, prevents electrical problems. |

| CTE Mismatch | Low, protects LED parts from stress. |

| Applications | Perfect for aerospace, military, and car industries. |

Pros and Cons of Ceramic LED PCBs

Ceramic LED PCBs have many good points but also some downsides. Knowing both helps you decide if they fit your needs.

Pros:

- Great at spreading heat, so LEDs stay cool longer.

- Block electricity leaks, making them reliable for sensitive uses.

- Protect LED parts from stress, making them last longer.

- Work well in hot and shaky environments.

Cons:

- Cost more than aluminum and copper PCBs.

- Can crack easily if too much force is applied.

- Harder to make, which increases production time.

Best Applications for Ceramic LED PCBs

Ceramic LED PCBs are best for tough jobs where heat and reliability matter most. Their special features make them perfect for specific uses.

- Aerospace and Military: Used in planes and defense tools, they handle heat and shaking.

- Automotive Electronics: Found in electric cars, they manage power and improve safety.

- Medical Devices: Power surgical tools, keeping them steady and accurate.

- High-Frequency Communication: Reduce signal loss in advanced communication systems.

- Renewable Energy Systems: Help manage energy in solar panels and wind turbines.

Ceramic LED PCBs are the top choice for industries needing strong and heat-resistant materials.

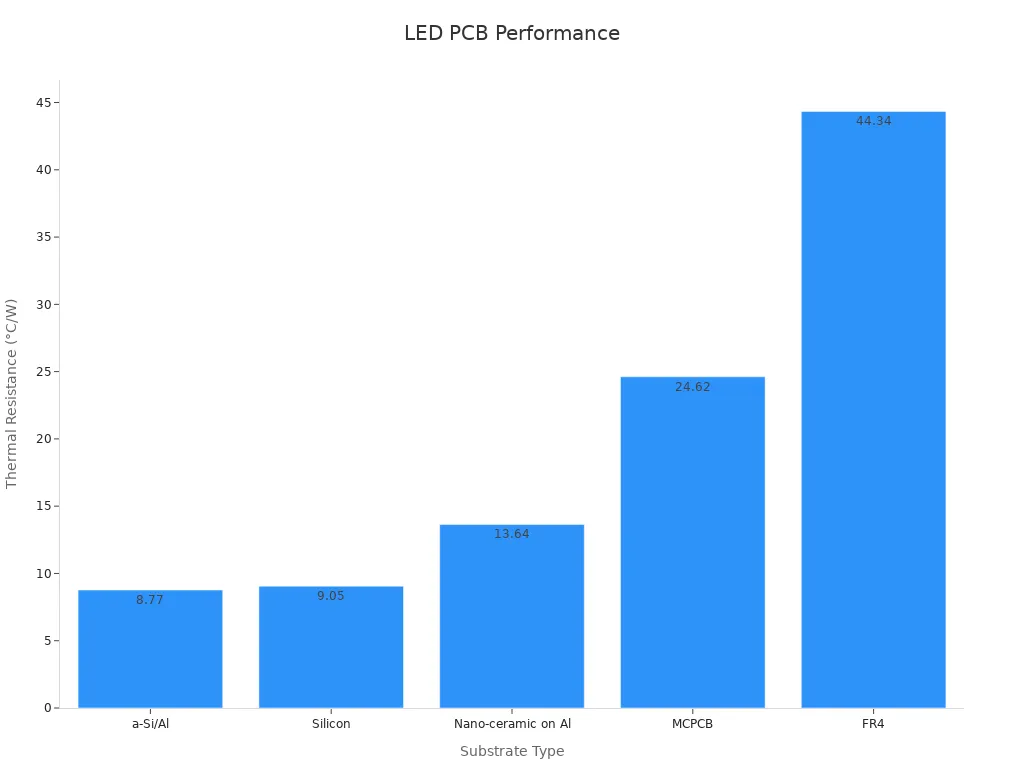

Comparative Analysis of Types of LED PCBs

Performance Comparison of LED PCBs

Different LED PCBs perform well in unique ways. Aluminum PCBs are great at spreading heat. Copper PCBs carry electricity better than others. Ceramic PCBs work best in very hot places because they resist heat.

Here’s a simple table showing how they compare:

| Substrate Type | Thermal Resistance (°C/W) | Light Output Efficacy (%) | Light Output Drop (%) |

|---|---|---|---|

| a-Si/Al | 8.77 | N/A | 1.66 |

| Silicon | 9.05 | N/A | N/A |

| Nano-ceramic on Al | 13.64 | N/A | N/A |

| MCPCB | 24.62 | N/A | N/A |

| FR4 | 44.34 | N/A | 10.66 |

The chart below shows how well these materials handle heat. Aluminum and ceramic options are the most efficient:

This data shows how choosing the right material improves your lighting system’s performance.

Cost Comparison of LED PCBs

Cost is important when picking an LED PCB. Aluminum PCBs are cheaper and good for basic lighting. Copper PCBs cost more but work better for high-performance needs. Ceramic PCBs are the most expensive but last longer in tough conditions.

For example:

- Aluminum PCBs: Affordable for everyday lighting.

- Copper PCBs: Worth it for powerful lighting systems.

- Ceramic PCBs: Best for industries like aerospace or medical tools.

Balancing cost and performance helps you get the best value.

Durability and Heat Management in LED PCBs

Durability and heat control are key for long-lasting LEDs. LEDs turn 80% of energy into heat. Without good heat control, they dim faster and don’t last as long.

Materials like aluminum and ceramic are great at managing heat. Aluminum PCBs use heat sinks to stay cool. Ceramic PCBs handle very high heat without bending. Copper PCBs are strong and resist damage in tough conditions.

Important durability features include:

- Shock Resistance: Strong solder joints prevent damage.

- Heat-Resistant Materials: Aluminum and ceramic handle heat expansion well.

- Rust-Proof Design: Nickel coatings stop rust in harsh places.

Picking the right PCB keeps your lights working well, even in hard conditions.

Knowing how aluminum, copper, and ceramic LED PCBs differ is helpful. Aluminum PCBs are great at handling heat and are affordable. They work well for regular lighting needs. Copper PCBs are strong and carry electricity better. They are best for tough jobs. Ceramic PCBs can handle very high heat and are super reliable. They are used in special industries.

Think about what your lights need before picking a PCB. Aluminum PCBs are a good choice for everyday use because they cost less. Copper PCBs are better for systems needing top performance. Ceramic PCBs are worth it for hot or rough places. Choosing the right PCB helps your lights work well and last longer.

FAQ

What makes aluminum, copper, and ceramic LED PCBs different?

Aluminum PCBs are great at controlling heat. Copper PCBs carry electricity very well. Ceramic PCBs handle extreme heat and are super reliable. Pick one based on your lighting needs and where it will be used.

Which LED PCB works best for outdoor lights?

Aluminum PCBs are a good choice for outdoor lights. They manage heat well and can handle tough weather. Copper PCBs are also good for outdoor systems that need high performance.

Are ceramic LED PCBs worth the extra money?

Yes, if you need them for very hot or demanding jobs. Ceramic PCBs last longer and work better in tough places like airplanes or medical tools.

Can aluminum PCBs be used for powerful LED lights?

Yes, aluminum PCBs are perfect for powerful LEDs. They spread heat well, keeping LEDs cool and bright for a long time.

How do I pick the right LED PCB for my project?

Think about what you need. Aluminum is budget-friendly. Copper is best for strong electrical needs. Ceramic is great for handling extreme heat. Match the PCB to your project’s requirements.