Turnkey PCB assembly is a one-stop way to build circuit boards. You send your design to one company. They do everything from getting parts to testing. This method saves you time and money. It also makes managing your project easier. Many managers and engineers pick turnkey because it is faster. It gives better quality checks and flexible production. When you work with KING FIELD, you get quick service. You also get great results at every step.

Key Takeaways

- Turnkey PCB assembly makes your project easier. One company does everything from getting parts to testing.

- Turnkey services help you save time and make fewer mistakes. You can spend more time on your design and new ideas.

- You can pick full or partial turnkey solutions. This depends on how much control you want and what your project needs.

- Turnkey assembly helps you save money with bulk orders. You pay one price for the whole process, so there are no hidden costs.

- Quality checks happen at every step. This makes sure you get PCBs that work well and meet top standards.

Turnkey PCB Assembly Overview

What Is Turnkey PCB Assembly?

Turnkey pcb assembly gives you everything you need to build your pcb boards. You send your design files to one company. That company does every step for you. They get the parts, put the boards together, and test them. You get a pcb that is ready to use, called a box build. This way is different from other services. You do not have to talk to many vendors or handle each stage by yourself.

Here are some important things about turnkey pcb assembly:

- One company does all the pcb assembly work.

- You get a finished pcb that you can use right away.

- You do not have to do extra work or worry about mistakes.

- The company gets the parts, builds the boards, tests them, and packs everything for you.

- Quality checks are better because one team does every step.

You get a simple process that saves time and helps you feel less stressed. Turnkey pcb assembly works for easy and hard projects. You can use it for testing ideas or making lots of pcbs.

How It Simplifies PCB Projects

Turnkey pcb assembly makes your project easier in many ways. You do not need to talk to different suppliers or keep track of parts from many places. The company does everything, so you can focus on your design and what you want to do.

Tip: If you pick turnkey pcb assembly, you make your supply chain easier and your work less complicated.

You also save time because the company can do many jobs at once. They can make pcbs, buy parts, and start building all at the same time. This way can make your wait time shorter, from eight weeks to five weeks. You spend less time talking to people and more time working on your project.

- You get your pcb projects done faster.

- You make fewer mistakes because one team does all the work.

- You get better quality and your boards work well.

- You make your work steps easier.

Turnkey pcb assembly helps you make better products with less trouble. You can control your time and money more easily.

Turnkey PCB Assembly Process

The turnkey pcb assembly process covers every step. It starts with your idea and ends with delivery. Each stage works together to give you a finished pcb. At KING FIELD, you get advanced machines and automated lines. We use strict quality checks at every step. You can trust us with all types of pcb. We handle rigid, flex, metal core, and rigid-flex boards. Our team helps with small and big projects. You can order one prototype or thousands of units.

Note: Turnkey pcb assembly lets you focus on your design. Experts take care of everything else.

Here is a table that shows the main stages in the process:

| Stage Number | Stage Description |

|---|---|

| Stage 1 | Painless PCB Prototyping |

| Stage 2 | Turnkey PCB Manufacturing |

| Stage 3 | Turnkey Circuit Card Assembly |

| Stage 4 | Inventory Storage and Management |

| Stage 5 | Integrated Fulfillment |

| Stage 6 | System Integration |

You can follow these steps to see how it works:

- Send your design files.

- Get a quote and feedback.

- The team buys the parts.

- Your pcb gets made.

- The board is put together and soldered.

- Testing and quality checks happen.

- You get your boards packed and delivered.

Component Sourcing

First, you send your design files. The team checks your files and gives a quote. After you say yes, they start finding parts. KING FIELD uses trusted distributors for real parts. We check every part to make sure it is real. We keep the supply chain clear and honest. Our global network helps us find good prices and strong parts. If a part is hard to get, we suggest other options.

- We keep common parts in stock to stop delays.

- Sourcing can take as little as 2 days. Some special chips may take up to 12 weeks.

- Our team handles inventory so you do not worry about shortages.

| Sourcing Strategy | Description |

|---|---|

| Authorized Distributors | Use only trusted sources for genuine components. |

| Authenticity Verification | Check every part for quality and origin. |

| Supply Chain Transparency | Keep you informed about sourcing and delivery. |

| Strategic Inventory Management | Store common parts to speed up your project. |

| Substitution Expertise | Offer alternatives if a part is unavailable. |

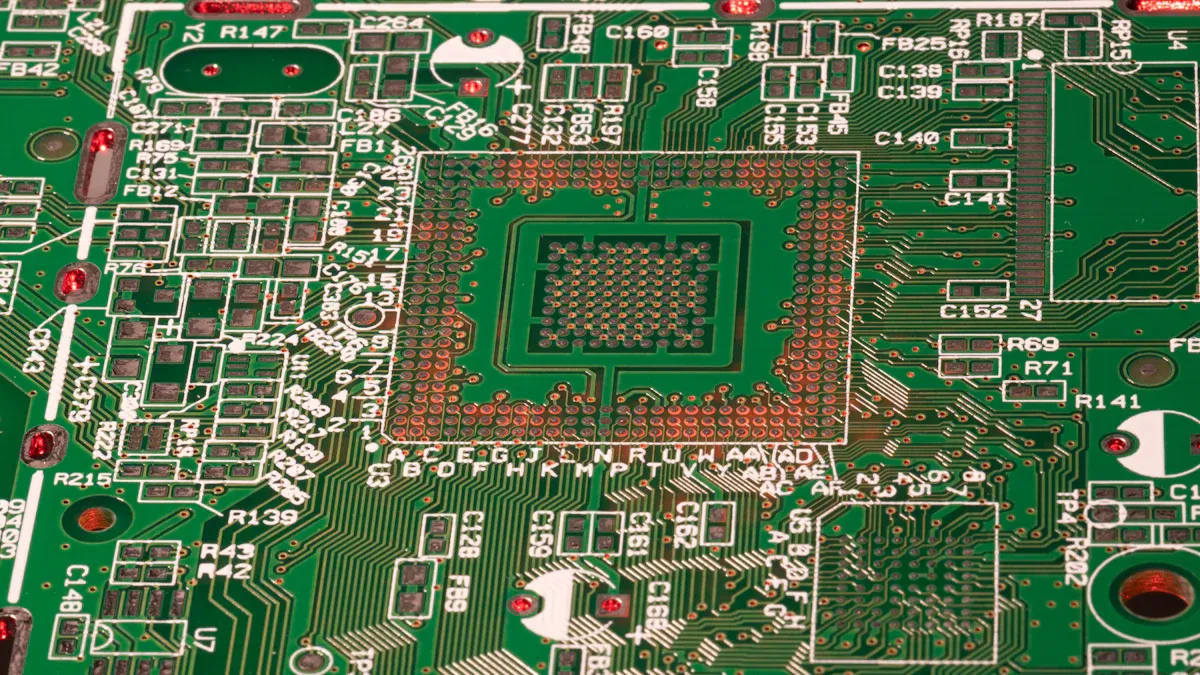

PCB Fabrication

After we have the parts, we start making your pcb. KING FIELD uses automated machines and smart systems. Our team builds many types of pcb. We make rigid, flex, metal core, and rigid-flex boards. We use SMT assembly, DLP insertion, and full machine assembly. This makes sure every board fits your needs.

- Automated inspection checks for mistakes.

- We use strict quality control at every step.

- Regular checks keep the process running well.

Tip: Automated systems help us make boards faster. They also help us make fewer mistakes.

Assembly and Soldering

The assembly stage brings your pcb to life. We use Surface Mount Technology (SMT) and Plated Through-Hole (PTH) assembly. SMT puts small parts on the board. PTH puts bigger parts through holes and uses wave soldering. Our machines handle big orders. Our skilled team works on special or tricky boards.

- Selective soldering helps with sensitive spots.

- Laser soldering is very precise for tiny parts.

- Hot bar soldering works for flexible circuits. Direct chip attach helps boards work better.

Some soldering problems are cold joints, solder bridges, and tombstoning. We stop these by using the right heat and good pad designs. Careful checks help us keep defects low. Our team follows strict rules and checks every step.

Testing and Quality Control

Testing and quality control are very important. KING FIELD uses smart tools like ICT, X-ray, and functional testing. We check every board for safety and performance. Our process follows top standards like ISO 9001:2015, UL Listing, RoHS, IPC, and MIL-STD.

| Certification/Standard | Description |

|---|---|

| UL Listing | Makes sure pcb manufacture and assembly are safe. |

| ITAR | Protects sensitive technology and checks parts are real. |

| MIL-STD | Sets high rules for performance and environment. |

| ISO 9001:2015 | Promises good quality management. |

| RoHS | Limits dangerous substances in electronics. |

| IPC | Sets quality rules for pcb assemblies. |

Almost all boards pass the first test. The first-pass yield is about 99.5%. This means you get boards that work well and need almost no fixing.

Delivery and Support

After testing, we pack your boards safely. We deliver them to you fast. KING FIELD offers quick delivery choices. For simple projects, you can get boards in 72 hours. For harder orders, it takes 5 to 7 business days. Our team helps you even after delivery. If you have questions, we are ready to help.

- You get updates at every step.

- We handle small and big orders.

- Our support team helps you fix problems fast.

Note: With turnkey pcb assembly, you save time and avoid stress. You get high-quality boards quickly. You can focus on your next big idea.

Full vs. Partial Turnkey PCB Assembly

Full Turnkey Explained

When you choose a full turnkey solution, you let one provider handle every step of your PCB project. You send your design files and bill of materials. The provider takes care of sourcing all parts, making the boards, assembling them, and testing each one. You only need to talk to one company. This makes your project simple and fast.

Here is a table that shows what you get with each service:

| Item | Full Turnkey PCB Assembly | Partial Turnkey PCB Assembly |

|---|---|---|

| Material procurement | Provider sources all components and arranges PCB fabrication based on your files. | You supply some components, provider buys the rest and makes the PCBs. |

| Vendor management | Single point of contact – provider manages all vendors for you. | Shared responsibility – you manage your own vendors for supplied parts. |

| Control over key parts | Provider follows your list, but handles all purchasing and logistics. | You keep control over selected or special parts. |

| Impact on lead time | Lead time depends on provider’s speed and part availability. | Lead time also depends on how fast you send your parts. |

| Cost structure | Easier to see total cost in one quote. | Possible savings if you already have parts, but more work for you. |

| Typical use cases | Best for startups, design houses, and OEMs who want a one-stop solution. | Good for customers with their own parts or strict sourcing rules. |

A full turnkey solution works best when you want speed, less stress, and clear costs.

Partial Turnkey Explained

A partial turnkey solution lets you stay involved in your project. You supply some or all of the parts you want to control. The provider handles the rest, including making the boards and assembling them. This option gives you more control over special or hard-to-find parts.

You might pick a partial turnkey solution if you already have some parts in stock or want to use your own suppliers. This can help you save money if you get better prices. You also keep control over important or custom parts.

Tip: A partial turnkey solution can make your project more complex. You need to manage your parts and make sure they arrive on time.

Choosing the Right Option

You should think about your project needs before you choose between a full turnkey solution and a partial turnkey solution. If you want a simple process, fast results, and less work, a full turnkey solution is the best choice. This works well for rapid prototyping, small runs, and when you have tight deadlines.

A partial turnkey solution fits projects where you already have some parts or need to follow strict sourcing rules. You might use this if you have special chips or want to save money by using your own inventory.

Here are some points to help you decide:

- Use a full turnkey solution for speed, simplicity, and reliability.

- Pick a partial turnkey solution if you want more control or already have parts.

- Think about your timeline, budget, and how much work you want to do.

No matter which turnkey option you choose, you can make your project easier and get high-quality results.

Benefits of Turnkey PCB Assembly

Faster Turnaround

You want your pcb project done fast. Turnkey pcb assembly helps you save time at each step. You send your design to the provider. They do everything, like getting parts and testing. KING FIELD uses smart machines and robots to work faster. You get answers quickly, fast samples, and quick shipping. The table below shows what makes things go faster:

| Factor | Description |

|---|---|

| Design Readiness | Using smart design rules to stop mistakes and delays. |

| In-House Capabilities | All steps happen in one place for better speed and talking. |

| Quick-Turn Services | Fast samples let you try ideas quickly. |

| Testing and Inspection | Quality checks are quick and do not slow down work. |

| Supply Chain Optimization | Good supplier links stop delays from missing parts. |

You can go from an idea to a finished pcb in just days.

Cost Savings

Turnkey pcb assembly helps you keep costs low. You get one price for the whole job, so there are no hidden fees. KING FIELD gives good prices and discounts for big orders. If you order more, each pcb costs less. The table below shows the usual costs:

| Production Volume | Cost per Unit ($) |

|---|---|

| Prototypes (1–10 pcs) | 180 – 400 |

| Low to Mid-Volume (50–500 pcs) | 30 – 85 |

| Mass Production (1,000+ pcs) | 12 – 45 |

- You save money when you order more.

- Buying in bulk and using many services together lowers your cost.

- You do not pay extra for shipping or talking to many vendors.

Quality and Reliability

You want every pcb to work right. Turnkey assembly teams use strong quality checks. KING FIELD tests every board with smart tools. You get boards that pass the first test and have few problems. Quality checks look at solder joints, where parts go, and if the board works. Teams also test for heat, shaking, and wetness. You get boards that meet top rules.

- Visual checks find surface problems and solder issues.

- Electrical tests make sure each pcb works right.

- Environmental tests show your boards last in hard places.

Simplified Supply Chain

Turnkey pcb assembly makes your supply chain easy. You work with one team who does everything. KING FIELD gets parts, keeps track of them, and ships your boards. You do not need to watch parts or talk to many people. This saves time and stops mistakes.

- One deal covers all the work.

- You get easy control of your parts.

- Fewer vendors means less paperwork and faster fixes.

- Experts help you pick good parts and avoid supply problems.

Tip: Turnkey pcb assembly lets you focus on your product, not on handling suppliers.

You get flexible choices, custom help, and fast shipping. KING FIELD helps you stay ahead and grow your business.

Turnkey PCB assembly lets you finish projects faster and with less worry. You get good quality, fast delivery, and help for any project size. KING FIELD gives you service you can trust and many choices. If you want the best provider, follow these steps:

- Check if they have lots of experience.

- See if their machines can make enough boards.

- Make sure they check quality at every step.

- Try out their customer support.

- Compare prices and what you get for your money.

| Criteria | Description |

|---|---|

| Quality Control | Check for certificates and how they test boards. |

| Production Capacity | Be sure they can make as many as you need. |

| Customer Support | Pick a team that answers questions quickly. |

Contact KING FIELD to start your next project and feel sure about your choice.

FAQ

What files do you need to start turnkey PCB assembly?

You need to send your Gerber files, Bill of Materials (BOM), and assembly drawings. These files help KING FIELD understand your design and build your boards correctly.

How fast can you get your finished PCBs?

You can get simple prototypes in as little as 72 hours. Standard orders usually take 5 to 7 business days. KING FIELD works quickly to meet your deadlines.

Can you order both small and large quantities?

Yes, you can order one prototype or thousands of boards. KING FIELD supports low-volume runs for testing and high-volume production for mass market needs.

How does KING FIELD ensure quality?

KING FIELD uses automated inspection, advanced testing tools, and strict quality control at every stage. You get boards that meet top industry standards.

What types of PCBs can you assemble?

You can request rigid, flex, metal core, or rigid-flex PCBs. KING FIELD has the equipment and expertise to handle many board types for different industries.