How to Pick the Perfect PCB Manufacturer

Choosing the right PCB manufacturer plays a pivotal role in the success of your project. You must evaluate key factors like quality, certifications, and cost to ensure the final product aligns with your expectations. Consider lead time and customization options to meet your specific needs. Strong customer support ensures smooth collaboration and quick issue resolution. A reliable manufacturer not only guarantees high-quality PCB production but also helps you achieve your goals efficiently. By prioritizing these aspects, you can secure a partner that supports your vision and delivers excellence.

Key Takeaways

- Know what your PCB needs are. Match them to your project.

- Check if manufacturers have quality certifications like ISO 9001. This shows they follow rules.

- Ask for samples or test pieces first. This lets you check quality early.

- Get prices from different manufacturers. Make sure there are no hidden fees.

- Choose a company with good customer support. Clear communication solves problems fast.

Define Your PCB Needs

Determine PCB Specifications

Understanding your project’s requirements is the first step in selecting the right PCB. You need to define the specifications based on the application. For example:

- Medical devices: PCBs are used in monitors, imaging machines, and implants for testing.

- Consumer electronics: Phones, tablets, and smartwatches rely on PCBs for early-stage testing.

- Industrial equipment: Robots and power tools use PCBs during pre-production testing.

- Automotive: Safety sensors and navigation systems depend on PCBs for functionality.

Additionally, consider the type of PCB you need, such as single-layer, multi-layer, or flexible boards. The materials, like glass fiber-epoxy resin or ceramic, also play a role in determining product quality. Referencing standards like IPC-A-610 or IPC J-STD-001 can help ensure your PCB meets industry benchmarks for quality and reliability.

Identify Budget and Volume Requirements

Budget planning is crucial for any PCB project. Factors like location, facility setup, and technology significantly impact costs. Urban locations often have higher lease rates, while choosing between new or existing facilities can alter expenses by 30-50%. To optimize your budget, consider sourcing used machinery or negotiating leases, which can reduce initial investments by up to 40%.

Volume requirements also affect costs. High-volume production may lower the per-unit cost, while smaller batches might incur higher expenses. Planning for raw materials, such as copper-clad laminates and solder masks, is essential. Fluctuations in material pricing can influence your overall costs, so strategic planning ensures you stay within budget.

Address Unique Needs and Special Requirements

Every project has unique needs that require attention. For instance, if your design involves intricate layouts or advanced technology, you may need a PCB assembly company with specialized equipment. Some projects demand specific testing methods, like UV etching or laser etching, to achieve precision.

Customization options are another factor to consider. Whether you need flexible PCBs or specific soldering techniques, ensure the manufacturer offers services that align with your requirements. Strong customer support is vital for addressing challenges and ensuring your unique needs are met throughout the production process.

Evaluate Manufacturer Quality and Capabilities

Assess Quality Standards and Certifications

When selecting a PCB manufacturer, you must evaluate quality standards and certifications to ensure the final product meets your expectations. Certifications like ISO 9001 and IPC-A-610 demonstrate adherence to industry benchmarks. These certifications reflect a commitment to high quality and consistent production processes. You should also verify if the manufacturer integrates advanced digital quality platforms, such as Empower QLM, which link real-time capability analysis to quality plans. This ensures better control over assembly processes.

Another critical factor is process capability evidence. Manufacturers should provide dimensional data supported by Statistical Process Control (SPC) studies or capability indices. A lack of these can be a red flag for quality. Capability validation, including Gage R&R studies, should also be part of their launch readiness planning. These measures help you evaluate quality and ensure the manufacturer can meet your unique needs.

| Evidence Type | Description |

|---|---|

| Process Capability Evidence | Submitting dimensional data without SPC studies or capability indices is a red flag for quality. |

| Capability Validation | Integrate capability validation into launch readiness planning, including Gage R&R studies. |

| Digital Quality Platforms | Platforms like Empower QLM link real-time capability analysis to quality plans for better control. |

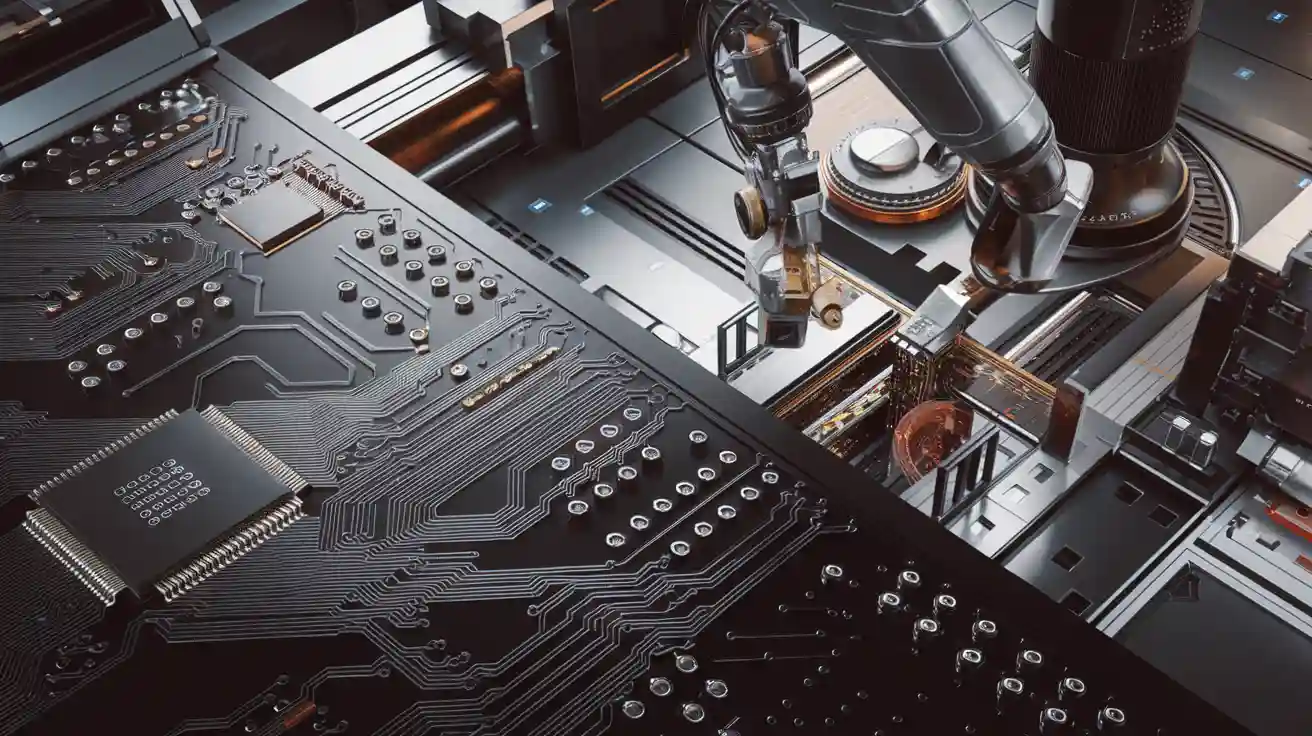

Review Manufacturing Capabilities and Equipment

The manufacturer’s production capabilities and equipment play a vital role in delivering high-quality PCBs. Advanced technology, such as automated pick-and-place machines and precision soldering tools, ensures accurate assembly. You should ask about customer support and whether the manufacturer offers prototyping and testing services. These services help identify potential issues early in the production process.

A reliable PCB assembly company should also have the flexibility to handle various assembly types, including single-layer, multi-layer, and flexible PCBs. This versatility ensures they can meet your unique needs. Additionally, explore testing options like UV etching or laser etching to confirm the manufacturer’s ability to deliver precise results. By reviewing their equipment and capabilities, you can determine if they are the right partner for your project.

Examine Cost and Pricing Transparency

Transparent pricing is essential when choosing a PCB assembly company. You should compare costs across multiple manufacturers to ensure you receive fair pricing. Look for detailed quotes that outline material, labor, and testing costs. Hidden fees or vague pricing structures can indicate potential issues. A trustworthy manufacturer will provide clear cost breakdowns and explain any additional charges.

Volume requirements also impact costs. High-volume production often reduces per-unit costs, while smaller batches may incur higher expenses. Discuss your budget and production needs with the manufacturer to find the best options. By understanding their pricing structure, you can make informed decisions and avoid unexpected expenses.

Analyze Lead Times and Delivery Reliability

Lead times and delivery reliability are critical factors when selecting a pcb assembly company. You need to ensure the manufacturer can meet your project deadlines without compromising quality. Delays in production can disrupt schedules and increase costs, so evaluating this aspect thoroughly is essential.

Start by asking the manufacturer about their average lead times for different types of pcb assembly. Some projects may require faster turnaround times, especially if you’re working on prototypes or urgent production runs. Manufacturers with streamlined processes and advanced technology often deliver quicker results. Automated systems, such as pick-and-place machines, can enhance efficiency and reduce delays.

Reliability in delivery is equally important. You should assess whether the manufacturer has a proven track record of meeting deadlines. Look for reviews or testimonials from other clients to gauge their experience with delivery reliability. Consistent delays or missed deadlines are red flags that could indicate operational inefficiencies.

Consider the manufacturer’s ability to handle unexpected challenges. For example, disruptions in supply chains or equipment malfunctions can impact production timelines. A reliable partner will have contingency plans to address these issues and ensure your project stays on track. By analyzing lead times and delivery reliability, you can minimize risks and ensure smooth project execution.

Evaluate Customer Support and Communication

Strong customer support and effective communication are vital when working with a pcb assembly company. You need a manufacturer that listens to your unique needs and provides timely assistance throughout the production process. Poor communication can lead to misunderstandings, delays, and compromised quality.

Ask about customer support services offered by the manufacturer. Do they provide dedicated account managers or technical support teams? These resources can help you address challenges quickly and ensure your project runs smoothly. A manufacturer with responsive support will make collaboration easier and more efficient.

Evaluate the communication channels available. Manufacturers that offer multiple options, such as email, phone, and live chat, provide flexibility for addressing concerns. Regular updates on production progress are also important. You should receive clear and detailed reports on milestones, testing results, and delivery schedules.

Transparency in communication is another key factor. A trustworthy manufacturer will openly discuss costs, services, and any potential issues. They should be willing to answer your questions and provide detailed explanations. Lack of transparency can be a red flag, indicating potential problems down the line.

By prioritizing customer support and communication, you can build a strong partnership with your manufacturer. This ensures your unique needs are met and your project achieves the desired outcomes.

Compare PCB Manufacturers

Read Reviews and Testimonials

Reading reviews and testimonials is a great way to gauge the reliability and quality of a PCB assembly company. These firsthand accounts provide valuable insights into the experiences of other clients. Look for reviews that highlight the manufacturer’s ability to meet deadlines, deliver high-quality products, and provide excellent support. For example, one client shared, “I made numerous errors in the files that I submitted, but the support staff at PCBWay did an excellent job sorting through all of it, and when my boards finally arrived, they worked perfectly.” Another customer praised their assembly services, stating, “Their assembly services are A+++ and I consider them part of our team.”

You can also explore testimonials from clients in different regions to understand the manufacturer’s global reputation. For instance:

| Customer Location | Comment |

|---|---|

| Canada | “From the genuine feelings of all buyers, it is a trustworthy choice.” |

| UK | “Excellent service and quality, highly recommended for all PCB needs.” |

| Germany | “Professional team and excellent communication throughout the process.” |

These reviews can help you identify a partner that aligns with your needs and expectations.

Request Samples or Prototypes

Requesting samples or prototypes is an essential step in evaluating a PCB assembly company. Samples allow you to assess the quality of their work and ensure it meets your project’s requirements. Prototypes also help you test the functionality of your design before committing to full-scale production. Many manufacturers offer this service to demonstrate their capabilities and build trust with potential clients.

When reviewing samples, pay attention to details like soldering precision, component placement, and overall assembly quality. Testing these prototypes can reveal potential issues early, saving you time and costs in the long run. A reliable manufacturer will provide clear communication and support throughout this process, ensuring your unique needs are addressed.

Compare Quotes and Services

Comparing quotes and services from multiple manufacturers helps you find the best fit for your project. Request detailed quotes that break down costs for materials, labor, assembly, and testing. Transparent pricing ensures you understand what you’re paying for and helps you avoid hidden fees. For example, some manufacturers may include additional charges for expedited production or specialized testing.

Evaluate the range of services offered by each manufacturer. Look for options like flexible PCB assembly, advanced testing methods, and customization capabilities. A manufacturer with diverse services can adapt to your specific requirements and provide better value. Additionally, consider their technology and equipment, as these factors influence the quality and efficiency of their assembly processes.

By comparing quotes and services, you can make an informed decision and choose a manufacturer that aligns with your budget, timeline, and project goals.

Avoid Common Pitfalls in PCB Selection

Identify Hidden Costs

Hidden costs can derail your budget if you don’t address them early. When evaluating a pcb assembly company, ask for a detailed breakdown of expenses. Manufacturers often include charges for materials, labor, and testing, but additional fees may lurk in areas like expedited production, shipping, or specialized services. These costs can inflate your budget unexpectedly.

To avoid surprises, request a transparent quote that outlines every expense. Compare quotes from multiple manufacturers to identify discrepancies. For example, some companies may charge extra for advanced assembly techniques or customizations. Understanding these charges helps you make informed decisions and ensures your project stays within budget.

Tip: Always clarify whether the quote includes costs for prototyping, testing, and delivery. These elements often carry hidden fees that can impact your overall expenses.

Verify Certifications and Claims

Certifications validate a manufacturer’s commitment to quality and industry standards. Before partnering with a pcb assembly company, verify their certifications, such as ISO 9001 or IPC-A-610. These certifications ensure the manufacturer follows rigorous processes and delivers reliable products.

Don’t rely solely on claims made on their website or marketing materials. Ask for documentation or evidence of compliance. Manufacturers should provide proof of their certifications and testing protocols. For instance, they might share results from quality audits or testing reports that demonstrate adherence to standards.

Note: If a manufacturer hesitates to provide certification details, consider it a red flag. Transparency in this area reflects their credibility and reliability.

Prioritize Customer Support

Customer support plays a crucial role in the success of your project. A manufacturer with strong support ensures smooth communication and quick resolution of issues. Evaluate their responsiveness and willingness to address your concerns. For example, do they offer dedicated account managers or technical support teams?

Effective communication channels are equally important. Look for manufacturers that provide multiple options, such as email, phone, or live chat. Regular updates on production progress help you stay informed and reduce uncertainties. A reliable partner will prioritize your needs and maintain transparency throughout the process.

Tip: Test their customer support by asking questions about their assembly services or technology. Their response time and quality of answers can reveal their commitment to supporting your project.

Choosing the right PCB manufacturer is essential for your success. Start by defining your project requirements to ensure clarity. Evaluate manufacturers based on quality, certifications, and capabilities. Avoid common pitfalls like hidden costs or unverified claims. Thorough research helps you find a reliable partner who meets your expectations. Prioritize quality and unique needs to achieve the best results. By taking these steps, you can make an informed decision that aligns with your goals and ensures a smooth production process.

FAQ

What certifications should a reliable PCB manufacturer have?

Look for certifications like ISO 9001 for quality management and IPC-A-610 for assembly standards. These certifications ensure the manufacturer follows industry best practices and delivers high-quality products.

Tip: Always verify the authenticity of certifications by requesting documentation.

How can you ensure the manufacturer meets your project deadlines?

Ask about their average lead times and delivery reliability. Manufacturers with automated systems and streamlined processes often deliver faster. Check reviews or testimonials to confirm their track record for meeting deadlines.

Note: Reliable manufacturers often provide regular updates on production progress.

Why is prototyping important before full-scale production?

Prototyping helps you test your design for functionality and quality. It identifies potential issues early, saving time and costs. A good manufacturer will offer prototyping services to ensure your project’s success.

What should you check in a manufacturer’s equipment and technology?

Ensure they use advanced tools like automated pick-and-place machines and precision soldering equipment. These technologies improve accuracy and efficiency in PCB assembly.

Tip: Ask if they offer specialized testing methods like UV or laser etching for added precision.

How do you avoid hidden costs when choosing a PCB manufacturer?

Request a detailed quote that breaks down material, labor, and testing costs. Clarify if additional fees apply for expedited production, shipping, or customizations. Comparing quotes from multiple manufacturers helps you spot discrepancies.

Emoji Reminder: 💡 Transparency in pricing reflects a trustworthy manufacturer.