What Are Electronic Manufacturing Services and Their Uses?

Electronic manufacturing services (EMS) refer to specialized companies that design, manufacture, test, and manage the supply chain for electronic components and finished products. These services streamline the production of electronic devices, ensuring efficiency and quality.

The global demand for EMS highlights their critical role in modern electronics. For instance:

- In 2024, the EMS market was valued at USD 609.79 billion, with projections to reach USD 1,033.17 billion by 2032.

- The market is expected to grow at a compound annual growth rate (CAGR) of 6.9% from 2025 to 2032.

- Rising consumer electronics and advancements in industrial automation fuel this growth, emphasizing the need for high-speed, cost-effective production.

Key Takeaways

- Electronic Manufacturing Services (EMS) help make electronic devices faster and better.

- Working with EMS companies lowers costs and speeds up product launches.

- EMS providers use advanced tools and skills to help businesses create new ideas without spending too much money.

- Giving manufacturing jobs to EMS lets companies focus on what they do best, improving work and success.

- The EMS industry is expected to grow a lot because more people want good and affordable electronic products.

What Are Electronic Manufacturing Services?

Definition and Scope of EMS

Electronic manufacturing services (EMS) encompass a wide range of activities that support the production of electronic devices. These services include design, assembly, manufacturing, and post-production support for electronic components and finished products. EMS providers play a vital role in the electronics industry by offering specialized expertise and infrastructure that streamline production processes.

Recent market research studies emphasize the importance of EMS in the electronics supply chain. They define EMS as a critical component that serves industries such as consumer electronics, automotive, healthcare, and industrial automation. The studies also highlight the segmentation of the EMS market by service types, showcasing its broad applicability. With a projected compound annual growth rate (CAGR) of 6.9% by 2032, the EMS market is expected to grow significantly. This growth reflects the increasing demand for innovative, cost-effective, and high-quality electronic products.

Key Components of EMS

EMS providers offer several essential components that contribute to the efficient production of electronic devices. These components include:

- Design Services: EMS companies assist in creating electronic designs that meet specific requirements. They use advanced tools to ensure functionality and reliability.

- Manufacturing and Assembly: Providers handle the production and assembly of electronic components, including printed circuit boards (PCBs).

- Testing and Quality Assurance: Rigorous testing ensures that products meet industry standards and perform as expected.

- Supply Chain Management: EMS providers manage the procurement and logistics of materials, ensuring timely delivery and cost efficiency.

These components enable EMS providers to deliver high-quality products while maintaining flexibility and scalability.

Role of EMS in the Electronics Supply Chain

EMS providers serve as a backbone for the electronics supply chain. They integrate advanced technologies and efficient processes to meet the demands of modern production. The role of EMS can be understood through key supply chain metrics:

| Metric | Description |

|---|---|

| Manufacturing Flexibility | The ability to adapt production processes to meet changing demands and specifications. |

| Cost Management | Strategies employed to minimize production costs while maintaining quality and efficiency. |

| Technology Integration | The incorporation of advanced technologies like AI and digital twins to enhance production processes. |

By leveraging these metrics, EMS providers ensure seamless operations across the supply chain. Their expertise in electronic contract manufacturing helps businesses reduce costs, improve product quality, and accelerate time-to-market.

Types of Services Offered by EMS Providers

Design and Prototyping

Design and prototyping services form the foundation of electronic manufacturing. EMS providers assist businesses in transforming ideas into functional designs. They use advanced tools and techniques to create prototypes that meet specific requirements. This process allows companies to identify potential issues early and refine their products before mass production.

Several case studies highlight the advantages of these services:

- Flex’s Sketch-to-Scale® solution enabled a smartphone manufacturer to reduce its product development cycle by 30% while increasing production yield by 15%.

- Jabil’s global network of additive manufacturing facilities helped a medical device company produce custom surgical guides 60% faster than traditional methods.

These examples demonstrate how EMS providers streamline the design process, saving time and improving efficiency for their clients.

PCB Assembly and Manufacturing

Printed Circuit Board (PCB) assembly and manufacturing are core services offered by EMS providers. These services involve assembling electronic components onto PCBs and ensuring their functionality. A contract manufacturer often employs automated processes to achieve precision and consistency in production.

Performance metrics illustrate the effectiveness of these services:

| Metric | Description |

|---|---|

| Overall Equipment Effectiveness (OEE) | Measures the percentage of planned manufacturing time that is productive, calculated as Availability x Performance x Quality. An OEE of 100% indicates optimal performance. |

| Production Attainment | Represents the ratio of units manufactured to target production output, expressed as a percentage. It indicates how well a manufacturer meets production goals. |

| On-time Delivery | The percentage of shipments delivered on time, reflecting the reliability of the manufacturing process and its impact on customer satisfaction. |

These metrics highlight how EMS providers ensure high-quality production while meeting deadlines and maintaining cost efficiency.

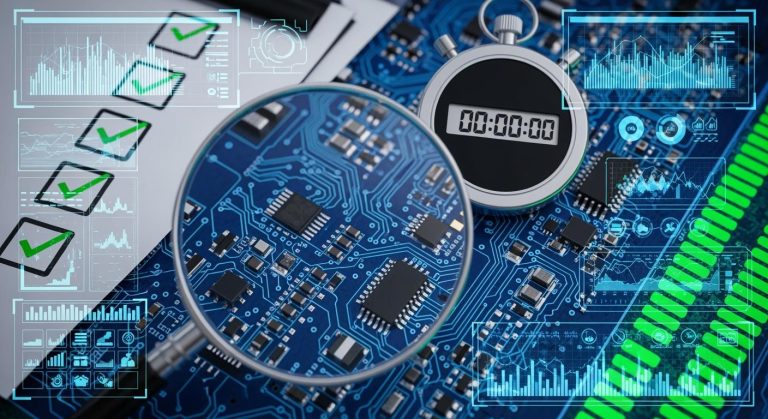

Testing and Quality Assurance

Testing and quality assurance are critical to delivering reliable electronic products. EMS providers conduct rigorous testing to validate product performance and compliance with industry standards. This ensures that only high-quality products reach the market.

Key processes in testing and quality assurance include:

- Factory Acceptance Testing (FAT): Validates product quality and compliance before equipment leaves the factory.

- Problem Identification and Resolution: Identifies and resolves non-conformities during FAT to maintain high standards.

- Reporting and Approval: Consolidates test data into structured reports for stakeholder approval, ensuring compliance.

These practices help EMS providers maintain their reputation as reliable partners in the electronics supply chain.

Supply Chain Management

Supply chain management plays a pivotal role in electronic manufacturing services. It ensures the seamless flow of materials, components, and finished products across the production process. EMS providers leverage advanced tools and strategies to optimize supply chain operations, reducing costs and improving efficiency.

Modern supply chain management often incorporates AI-driven tools. These tools enhance demand planning and scheduling, enabling companies to predict and meet production needs effectively. For example:

- Two-thirds of companies now use advanced planning and scheduling systems to streamline operations.

- AI implementation can reduce inventory levels by 20 to 30 percent, logistics costs by 5 to 20 percent, and procurement expenses by 5 to 15 percent.

These improvements highlight the transformative impact of technology on supply chain management. EMS providers also focus on maintaining strong relationships with suppliers and ensuring timely delivery of materials. This approach minimizes production delays and enhances overall efficiency. A contract manufacturer often relies on these strategies to meet client demands while maintaining cost-effectiveness.

Circuit Board Components Purchasing

Purchasing circuit board components is a critical aspect of EMS. It involves sourcing high-quality parts that meet the specifications of the design. EMS providers work closely with suppliers to procure components at competitive prices while ensuring reliability and compliance with industry standards.

The purchasing process requires careful planning and coordination. Providers evaluate supplier performance, negotiate contracts, and monitor market trends to secure the best deals. A contract manufacturer may also leverage bulk purchasing to reduce costs and pass the savings on to clients. Additionally, providers ensure that all components meet regulatory requirements, reducing the risk of product recalls or failures.

By managing the procurement process effectively, EMS providers help businesses focus on innovation and product development. This approach not only saves time but also ensures the consistent quality of electronic devices.

Applications of EMS Across Industries

Electronic manufacturing services (EMS) play a pivotal role in various industries, enabling the production of innovative and reliable electronic devices. The applications of EMS span across sectors such as consumer electronics, automotive, and healthcare, where they drive efficiency, quality, and scalability.

Consumer Electronics

The consumer electronics industry relies heavily on EMS to meet the growing demand for high-quality devices. EMS providers assist in designing, assembling, and testing products like smartphones, laptops, and smart home devices. Their expertise ensures that these products meet market expectations for performance and reliability.

The global EMS market for consumer electronics was valued at USD 495.58 billion in 2024. It is projected to grow to USD 742 billion by 2033, with a compound annual growth rate (CAGR) of 4.60% from 2025 to 2033. This growth reflects the increasing adoption of EMS in producing advanced gadgets and appliances.

The emergence of the Internet of Things (IoT) has further expanded the scope of EMS in consumer electronics. IoT-enabled devices, such as smart thermostats and wearable fitness trackers, require precise manufacturing and testing to ensure seamless connectivity and functionality. EMS providers play a crucial role in meeting these technical requirements, enabling the rapid development of IoT products.

Tip: Companies in the consumer electronics sector can leverage EMS to reduce production costs and accelerate time-to-market, gaining a competitive edge in a fast-paced industry.

Automotive and Transportation

The automotive and transportation industry has witnessed a surge in the adoption of EMS due to the increasing integration of electronics in vehicles. Modern vehicles rely on electronic systems for functions such as navigation, safety, and entertainment. EMS providers contribute by manufacturing components like sensors, control units, and infotainment systems.

The global electronics contract manufacturing services market is projected to grow to approximately $32.05 billion by 2025, up from $18.63 billion in 2018. This growth, driven by a CAGR of over 8% from 2019 to 2025, highlights the rising demand for EMS in automotive applications.

Electric vehicles (EVs) and autonomous driving technologies have further amplified the need for EMS. EVs require complex battery management systems and power electronics, while autonomous vehicles depend on advanced sensors and processors. EMS providers ensure the production of these critical components with precision and reliability.

Note: By partnering with EMS providers, automotive companies can focus on innovation while outsourcing the complexities of electronic manufacturing.

Healthcare and Medical Devices

The healthcare industry depends on EMS for the production of medical devices that meet stringent regulatory standards. These devices include diagnostic equipment, wearable health monitors, and surgical instruments. EMS providers ensure that these products are manufactured with high precision and undergo rigorous testing to guarantee safety and effectiveness.

The adoption of EMS in healthcare has grown significantly due to advancements in medical technology. For example, IoT-enabled medical devices, such as remote patient monitoring systems, require specialized manufacturing processes. EMS providers play a key role in producing these devices, ensuring their reliability and compliance with healthcare regulations.

The global EMS market’s growth across industries, including healthcare, underscores its importance. By 2025, the market is expected to reach $32.05 billion, driven by demand in sectors like medical and healthcare. This trend highlights the critical role of EMS in supporting the development of innovative medical solutions.

Callout: EMS providers help healthcare companies bring life-saving technologies to market faster, improving patient outcomes and advancing medical care.

Industrial and Manufacturing Equipment

Electronic manufacturing services (EMS) play a vital role in the production of industrial and manufacturing equipment. These industries rely on EMS providers to deliver high-quality electronic components that enhance operational efficiency and reliability. EMS providers support the development of equipment such as robotics, automation systems, and heavy machinery, which are essential for modern manufacturing processes.

One of the key advantages of EMS in this sector is its ability to integrate advanced technologies like predictive maintenance. By analyzing real-time data, EMS providers help manufacturers predict equipment breakdowns and schedule timely repairs. This reduces downtime and ensures uninterrupted production. Additionally, demand forecasting tools enable better inventory management. Manufacturers can plan their supply chains more effectively, avoiding overstocking or shortages.

Other benefits include price optimization. EMS providers use accurate cycle times and cost models to help manufacturers set competitive pricing strategies. This balance between profitability and demand ensures sustainable growth.

Tip: Companies in the industrial sector can leverage EMS to adopt cutting-edge technologies and improve their production capabilities.

The emergence of the internet of things (IoT) has further expanded the applications of EMS in industrial equipment. IoT-enabled devices, such as smart sensors and connected machinery, require precise manufacturing and testing. EMS providers ensure these devices meet industry standards and function seamlessly within automated systems.

Aerospace and Defense

The aerospace and defense industries demand the highest levels of precision and reliability in electronic manufacturing. EMS providers play a critical role in producing components for aircraft, satellites, and defense systems. These components include avionics, communication systems, and radar equipment, all of which must meet stringent safety and performance standards.

In aerospace, EMS providers contribute to the development of lightweight and durable electronic systems. These systems improve fuel efficiency and reduce operational costs for airlines. For example, advanced avionics systems rely on EMS providers to manufacture circuit boards that withstand extreme conditions, such as high altitudes and temperature fluctuations.

In defense, EMS providers support the production of mission-critical equipment. This includes navigation systems, surveillance devices, and electronic warfare tools. Rigorous testing ensures these components perform reliably in challenging environments.

The applications of EMS in aerospace and defense also extend to unmanned aerial vehicles (UAVs) and space exploration. EMS providers manufacture the electronic systems that power drones and satellites, enabling advancements in these cutting-edge technologies.

Note: By partnering with EMS providers, aerospace and defense companies can focus on innovation while ensuring compliance with strict regulatory standards.

Benefits of Using EMS

Cost Efficiency and Scalability

Electronic manufacturing services (EMS) provide businesses with significant cost savings and scalability. By automating routine tasks, EMS providers reduce manual labor, which lowers administrative expenses and minimizes human errors. This approach improves operational efficiency and allows employees to focus on higher-value activities.

- Data-driven operations help manufacturers cut unnecessary expenses.

- Companies transitioning to integrated data environments save 5–10% within six months. Over three years, these savings can grow to 10–30%, freeing up capital for innovation.

- Robotic process automation (RPA) systems scale to handle increased workloads without requiring additional staff.

| Evidence Description | Key Points |

|---|---|

| Outsourced IT services lower operational costs by replacing outdated tech. | Reduces downtime and eliminates internal IT overhead, leading to cost efficiency. |

| IT solutions automate tasks and connect systems. | Fewer errors and faster decision-making, enhancing scalability as the business grows. |

| Scalable, cloud-based services align investment with return. | Allows small to mid-sized manufacturers to avoid heavy upfront costs while growing their tech. |

These benefits make EMS an ideal solution for businesses seeking to optimize costs while maintaining flexibility to scale operations.

Access to Advanced Technology and Expertise

EMS providers offer access to cutting-edge technology and specialized expertise. They invest in advanced tools and equipment, enabling businesses to leverage innovations like IoT and artificial intelligence without incurring high upfront costs.

For example, EMS providers use state-of-the-art testing equipment to ensure product quality and compliance with industry standards. Their expertise in areas such as PCB assembly and supply chain management allows businesses to focus on core competencies while outsourcing complex manufacturing tasks.

By partnering with EMS providers, companies gain a competitive edge through access to resources and knowledge that would otherwise require significant investment. This collaboration fosters innovation and accelerates the development of high-quality products.

Faster Time-to-Market

EMS providers streamline production processes, helping businesses bring products to market faster. Centralized procurement, inventory management, and distribution eliminate inefficiencies caused by fragmented supply chains.

“Businesses are increasingly realizing they can no longer afford to rely on fragmented networks of suppliers, logistics providers, and service partners. What they need is a trusted partner who can manage it all. By centralizing procurement, distribution, inventory management, obsolescence planning, and a range of value-added services under one roof, we help our clients streamline operations, cut costs, and accelerate time-to-market.”

This integrated approach reduces delays and ensures that products reach consumers quickly. Companies that adopt EMS can respond to market demands more effectively, gaining a significant advantage in competitive industries.

Enhanced Product Quality and Reliability

Electronic manufacturing services (EMS) enhance product quality and reliability through structured processes and advanced quality tools. Supplier Quality Engineers (SQEs) play a pivotal role in bridging the gap between Original Equipment Manufacturer (OEM) expectations and supplier capabilities. They implement frameworks like Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) to prevent defects and ensure consistent quality.

EMS providers also establish rigorous supplier qualification processes. These processes ensure that only suppliers with proven capabilities are selected. On-site audits further maintain supplier performance, driving continuous improvement across production lines.

Key metrics demonstrate the impact of EMS on product quality:

| Component | Weight | Target Benchmark | Measurement Method |

|---|---|---|---|

| Product/Service Specifications | 40% | ≥98% compliance | Lab tests & audits |

| Defect/Return Rates | 30% | ≤2% defects | Quality control inspections |

| Compliance Standards | 30% | 100% adherence | Audit results |

These metrics highlight how EMS providers ensure products meet stringent specifications and industry standards. By focusing on defect prevention and process consistency, EMS providers deliver reliable electronic devices that exceed customer expectations.

Tip: Companies can leverage EMS to achieve higher compliance rates and reduce defect rates, ensuring their products stand out in competitive markets.

Focus on Core Business Competencies

Outsourcing to EMS providers allows businesses to concentrate on their core competencies. EMS providers handle complex manufacturing tasks, such as PCB assembly and supply chain management, enabling companies to focus on innovation and customer engagement.

Delegating non-core functions leads to measurable productivity gains. Businesses that outsource administrative tasks, like payroll or customer service, report a 25% increase in efficiency. This shift allows them to allocate resources to product development and revenue-driving activities.

EMS providers also ensure cost-effective production of high-quality electronics. Contract Electronics Manufacturers (CEMs) streamline operations, reducing the need for in-house manufacturing infrastructure. This approach frees companies to prioritize strategic goals without being burdened by operational complexities.

Callout: By partnering with EMS providers, businesses can redirect their efforts toward innovation and market expansion, fostering long-term growth.

Outsourcing to EMS providers not only enhances operational efficiency but also strengthens a company’s ability to compete in dynamic industries.

Electronic manufacturing services (EMS) play a crucial role in modern technology. They provide design, assembly, testing, and supply chain solutions, enabling businesses to produce high-quality electronics efficiently. EMS applications span industries like healthcare, automotive, and aerospace, showcasing their versatility. Companies benefit from cost savings, faster production, and access to advanced technologies. As technology evolves, EMS will continue driving innovation and supporting industries in meeting future demands. Their role in shaping the electronics landscape remains indispensable.

FAQ

What is the difference between EMS and OEM?

EMS refers to companies that provide electronic manufacturing services, including design, assembly, and testing. OEMs (Original Equipment Manufacturers) create products under their brand name. EMS providers often work with OEMs to manufacture components or entire products.

How do EMS providers ensure product quality?

EMS providers use advanced testing methods, such as Factory Acceptance Testing (FAT) and quality control inspections. They follow strict industry standards and implement frameworks like APQP and PPAP to prevent defects and maintain consistent quality.

Can small businesses benefit from EMS?

Yes, EMS providers offer scalable solutions that suit small businesses. They reduce production costs, provide access to advanced technology, and streamline operations. This allows small companies to focus on innovation and growth without investing heavily in manufacturing infrastructure.

What industries rely most on EMS?

Industries like consumer electronics, automotive, healthcare, aerospace, and industrial manufacturing depend heavily on EMS. These sectors require precision, scalability, and advanced technology to produce high-quality electronic devices efficiently.

Are EMS providers involved in product design?

Many EMS providers offer design services. They assist clients in transforming ideas into functional prototypes. Their expertise ensures that designs meet technical requirements and are optimized for manufacturing, saving time and reducing costs.