Comparing PCB Types for Beauty Instruments

When making beauty tools, the Beauty Instrument PCB type affects performance. The right Beauty Instrument PCB keeps the device working well and reliably. It also helps the device last longer and stay cool.

Choosing the best Beauty Instrument PCB is not only about how it works. It also helps control costs while maintaining good quality. Picking the right Beauty Instrument PCB lets you create devices that users like and that compete well in the market.

Key Takeaways

- Picking the right PCB improves how beauty tools work and last.

- FR4 PCBs are cheap and good for simple beauty tools.

- Flexible PCBs are great for wearable gadgets with creative shapes.

- Metal Core PCBs handle heat well in powerful beauty devices.

- Choose strong PCBs that manage heat to make tools reliable.

Overview of Beauty Instrument PCB Types

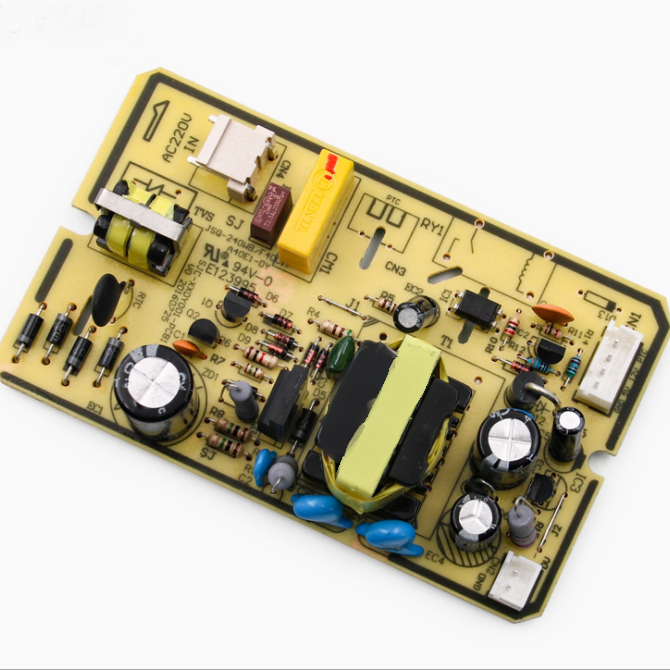

FR4 PCBs

FR4 PCBs are very common in beauty tools. They are made from strong fiberglass and epoxy, which makes them tough and good at stopping electricity from leaking. These boards can be single-layer, double-layer, or multi-layer, so they work for many devices. FR4 PCBs are affordable and dependable, making them great for beauty tools that need steady performance. But they might not be the best for devices needing flexibility or handling a lot of heat.

Tip: FR4 PCBs are best for simple beauty tools with average heat needs.

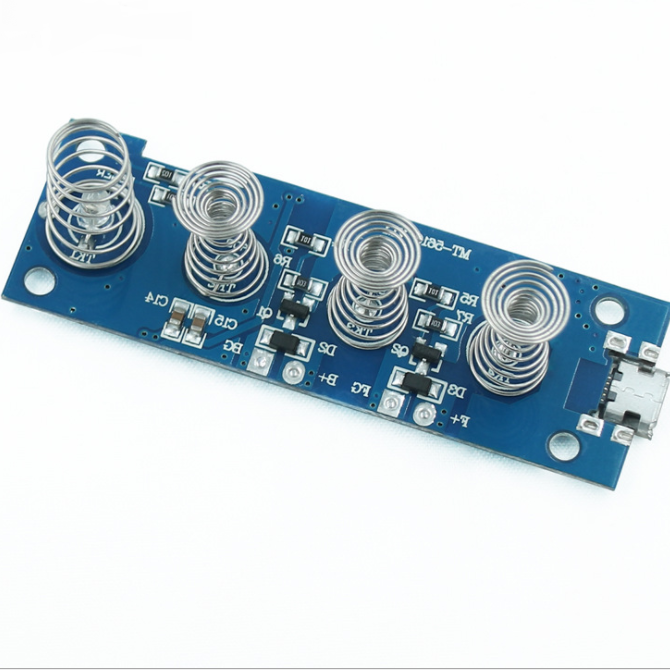

Flexible PCBs

Flexible PCBs are special because they can bend and fit curved designs. They use materials like polyimide, which let them twist without breaking. These boards are great for small beauty tools where space is tight. They also make assembly easier by reducing the need for connectors. Flexible PCBs are adaptable but can cost more than FR4 PCBs, especially if they have many layers.

- Advantages of Flexible PCBs:

- Lightweight and saves space.

- Allows creative designs for new products.

- Less chance of breaking due to bending.

Rigid-Flex PCBs

Rigid-Flex PCBs mix the benefits of rigid and flexible boards. They have stiff parts joined by bendable layers, making them strong and adaptable. These boards are good for beauty tools that need both strength and flexible designs. They work well for devices with many features packed into a small space. But making Rigid-Flex PCBs is tricky, which can raise costs.

| Feature | Rigid-Flex PCBs |

|---|---|

| Durability | Very strong |

| Design Flexibility | Good to Excellent |

| Cost Efficiency | Average |

Note: Rigid-Flex PCBs are perfect for high-tech beauty tools with complex designs.

Metal Core PCBs

Metal Core PCBs (MCPCBs) are great at handling heat. Unlike regular PCBs, they have a metal base, usually aluminum or copper. This design helps them cool down faster, making them perfect for beauty tools that get hot during use.

Key Features of Metal Core PCBs:

- Superior Thermal Conductivity: The metal base pulls heat away from parts.

- Enhanced Durability: These boards stay strong, even in high heat.

- Improved Electrical Performance: The metal layer keeps electricity flowing smoothly.

Tip: Use Metal Core PCBs for devices with high-power LEDs or heaters.

Advantages for Beauty Instruments

Metal Core PCBs work well in LED masks, hair removers, and skin tools. These devices need good heat control to work safely and last longer.

- Longer Lifespan: They stop overheating, helping devices last longer.

- Compact Design: Better cooling means smaller, sleeker beauty tools.

- Cost-Effective in High-Heat Applications: They cost more upfront but save on cooling parts.

| Feature | Benefit for Beauty Devices |

|---|---|

| Thermal Management | Stops overheating and damage |

| Durability | Handles high heat without breaking |

| Compactness | Makes portable, slim designs easier |

Note: Metal Core PCBs are stiff, so they fit rigid designs best.

If your beauty tools need to handle heat and stay durable, Metal Core PCBs are a smart choice. They keep devices working well, even in tough conditions.

Key Factors for Choosing Beauty Instrument PCBs

When picking PCBs for beauty tools, think about key factors. These factors affect how well your devices work and last. They also impact how good your devices look. Below are the main things to consider.

Size and Compactness

Beauty tools often need to be small and easy to use. The PCB size is important for this. Single-layer, double-layer, and multi-layer PCBs each have benefits. Single-layer PCBs work for simple tools with few parts. Multi-layer PCBs are better for complex designs in tight spaces.

Smaller PCBs make devices easier to carry and more stylish. A compact PCB helps create slim and lightweight tools. These tools are more appealing and user-friendly. Focusing on size and compactness improves both function and looks.

Tip: Use multi-layer PCBs for advanced tools needing high performance in small sizes.

Flexibility and Design Adaptability

Flexibility matters for tools with unique shapes or curved designs. Flexible PCBs let you make devices that bend without losing performance. This is key for creating high-quality and stylish products.

Rigid-flex PCBs combine strength and flexibility. They are great for tools needing durability and creative designs. These PCBs allow multiple features in one design, cutting down extra parts. This makes assembly easier and tools more attractive.

Note: Flexible PCBs are best for wearable tools or detailed designs.

Thermal Management

Good heat control is crucial for keeping beauty tools safe and lasting longer. Tools with high-power LEDs or heaters need PCBs that handle heat well. Metal core PCBs are perfect for this. Their metal base moves heat away from key parts.

Managing heat properly keeps devices working safely for a long time. It stops overheating, which can harm parts and shorten lifespan. Choosing PCBs with great heat control ensures your tools meet user needs.

Tip: Pick metal core PCBs for tools like LED masks or hair removers that get hot.

Durability and Longevity

When picking PCBs for beauty tools, durability is very important. Devices need to handle daily use without breaking or losing function. Strong PCBs lower the chance of failure, even in tough conditions like heat or frequent use. This makes products last longer and more attractive to users.

Different PCBs have different levels of strength. FR4 PCBs work well for basic beauty tools. For high-end devices needing extra toughness, rigid-flex or metal core PCBs are better. These types resist damage and keep working over time. Metal core PCBs are especially good in hot conditions, keeping devices running smoothly under heat.

Durability also affects how people see your brand. Reliable products build trust, leading to repeat buyers and good reviews. Choosing the right PCB not only makes devices last longer but also helps your brand stand out in the market.

Tip: Use durable PCBs for premium beauty tools to ensure they last longer.

Cost Considerations

Cost is another key factor when choosing PCBs for beauty tools. While saving money upfront is tempting, think about long-term value too. Cheaper PCBs might cost less now but could need more repairs later. High-quality PCBs work better and last longer, saving money over time.

Each PCB type has its own price range. FR4 PCBs are the cheapest and good for simple tools. Flexible and rigid-flex PCBs cost more but offer better designs and durability. Metal core PCBs are expensive but great for handling heat, making them worth it for hot-running devices.

Balancing cost and performance is important. Spending more on advanced PCBs can improve user satisfaction and device life for high-end tools. For simpler tools, FR4 PCBs are a good, affordable choice.

Note: Match your product’s needs with your budget to pick the right PCB.

Comparing Beauty Instrument PCB Types

Performance Comparison

When looking at PCB performance for beauty tools, think about how well they help the devices work. FR4 PCBs are steady and reliable for simple tools. They are great for devices that don’t need special features or high power. But they aren’t the best for handling heat or bending.

Flexible PCBs work well for tools with tricky designs. They can bend and fit curved shapes, making them perfect for wearable beauty gadgets. These PCBs also cut down on connectors, making devices more efficient. Rigid-flex PCBs mix the strengths of rigid and flexible boards. They are strong and adaptable, ideal for complex devices needing both features.

Metal core PCBs are the best for high-power tools. They handle heat well, keeping devices like LED masks or hair removers from overheating. This makes them perfect for high-end products. Picking the right PCB ensures your beauty tools work great and meet user needs.

Durability and Reliability

Durability is key to making beauty tools last longer. FR4 PCBs are tough enough for basic devices. They resist damage, making them good for entry-level products. But they might not hold up in very hot or bending conditions.

Flexible PCBs are great for devices that need to move or bend. They don’t break easily, which helps them last longer. Rigid-flex PCBs are even stronger, combining the toughness of rigid boards with the flexibility of bendable ones. These are perfect for high-end tools needing both strength and flexibility.

Metal core PCBs are the strongest for handling heat. Their metal base keeps them stable, even in very hot conditions. This makes them a smart choice for tools that get hot during use. Choosing durable PCBs helps devices last longer and perform well over time.

Cost Efficiency

Cost is important when picking PCBs for beauty tools. FR4 PCBs are the cheapest option, great for simple and budget-friendly devices. But their limits in bending and heat control might lead to higher repair costs later.

Flexible and rigid-flex PCBs cost more upfront but are worth it. They are durable and allow creative designs, cutting down on extra parts. These PCBs also make products look better, which attracts buyers.

Metal core PCBs cost the most at first but save money over time. They handle heat well, so you don’t need extra cooling parts. They are also very durable, reducing repair and replacement costs. For high-end tools that need top performance, metal core PCBs are a smart investment. Balancing cost and quality keeps your beauty tools competitive.

Suitability for Specific Applications

When picking a PCB for a beauty tool, think about what the tool needs. Each PCB type has special benefits that fit certain devices better. Below, we’ll explain how different PCBs work for various beauty tools.

1. LED-Based Beauty Devices

LED masks and light therapy tools need good heat control. These devices create a lot of heat from high-power LEDs, which can harm parts if not managed.

- Best PCB Type: Metal Core PCBs

- The metal base helps remove heat, keeping LEDs safe and lasting longer.

- These PCBs handle high temperatures well, making them great for long use.

Tip: Use Metal Core PCBs for devices with high-power LEDs to improve safety and performance.

2. Wearable Beauty Gadgets

Wearable tools like skin patches or microcurrent masks need to be light and flexible. These devices must fit the body for comfort and better results.

- Best PCB Type: Flexible PCBs

- They bend and twist without breaking, perfect for wearable tools.

- They also cut down on bulky connectors, making designs sleeker.

| Feature | Why It Matters for Wearables |

|---|---|

| Flexibility | Makes tools comfy and easy to use |

| Lightweight Design | Improves user experience |

Note: Flexible PCBs are key for making wearable beauty tools that are easy to use.

3. Compact, Multi-Functional Devices

Small tools like facial brushes or portable analyzers often have many features. These tools need PCBs that save space and handle complex circuits.

- Best PCB Type: Rigid-Flex PCBs

- They mix rigid strength with flexible layers for tough, compact designs.

- These PCBs support detailed layouts while staying durable.

Callout: Rigid-Flex PCBs make assembly easier and reduce extra parts, saving space and boosting reliability.

4. Basic Beauty Tools

Simple tools like massagers or low-power cleansers don’t need fancy features. These devices work best with affordable and reliable PCBs.

- Best PCB Type: FR4 PCBs

- These boards are cheap but dependable for tools with low heat and simple designs.

- They offer a good balance of cost and performance.

Tip: FR4 PCBs are a smart choice for budget-friendly beauty tools.

5. High-Heat Applications

Tools like hair removers or heated rollers run at high temperatures. These devices need PCBs that can handle heat without breaking down.

- Best PCB Type: Metal Core PCBs

- Their metal base moves heat away, keeping the device stable and safe.

- They also help tools last longer by stopping heat damage.

| Application | Recommended PCB |

|---|---|

| LED Masks | Metal Core PCBs |

| Heated Rollers | Metal Core PCBs |

Reminder: Always pick PCBs with great heat control for hot tools to keep users safe and devices lasting longer.

6. Innovative and Custom Designs

For brands creating unique beauty tools, flexible designs are important. These tools often need PCBs that fit unusual shapes or advanced features.

- Best PCB Type: Flexible or Rigid-Flex PCBs

- Flexible PCBs bend to fit creative shapes.

- Rigid-Flex PCBs add strength for tools needing both flexibility and durability.

Pro Tip: Choose flexible or rigid-flex PCBs to make standout designs that attract attention.

By matching the PCB type to your beauty tool’s needs, you can improve how it works, lasts, and satisfies users. Knowing these uses helps you make better choices for successful products.

Recommendations for Beauty Instrument PCB Types

Best PCB Types for Compact Beauty Devices

Small beauty tools need PCBs that save space but work well. Multi-layer PCBs are great for this because they stack circuits. This design lets devices have advanced features without taking up much room.

These PCBs also make products look better. They help create slim and lightweight designs, which are perfect for portable tools like facial analyzers or small cleansing brushes.

Tip: Choose multi-layer PCBs for tools that need to be small and work efficiently.

| Feature | Benefit for Compact Devices |

|---|---|

| Space Efficiency | Fits advanced features in small spaces |

| Lightweight Design | Makes tools easy to carry and use |

Best PCB Types for High-Heat Applications

Tools like LED masks or heated rollers get very hot. They need PCBs that handle heat well to stay safe and last longer. Metal core PCBs are the best choice for these tools. Their metal base moves heat away from parts, keeping them cool.

These PCBs work well for high-end tools that need to perform under heat. Using metal core PCBs lowers the chance of overheating and helps devices last longer. They are a smart choice for tools that run hot.

Reminder: Pick PCBs with good heat control for tools that get hot.

| Application | Recommended PCB |

|---|---|

| LED Masks | Metal Core PCBs |

| Heated Rollers | Metal Core PCBs |

Best PCB Types for Flexible Designs

Wearable beauty tools need PCBs that can bend and fit unique shapes. Flexible PCBs are perfect for this. They can twist and bend without breaking, making them great for skin patches, masks, and other wearable devices.

For tools needing both flexibility and strength, rigid-flex PCBs are a great option. They combine stiff and bendable layers, allowing for durable and creative designs. These PCBs are ideal for high-end tools with multiple features.

Pro Tip: Use flexible PCBs for wearable tools and rigid-flex PCBs for strong, creative designs.

| Feature | Why It Matters for Flexible Designs |

|---|---|

| Flexibility | Helps create wearable and unique tools |

| Durability | Keeps tools working for a long time |

General Recommendations for Beauty Instruments

Choosing PCBs for beauty tools means balancing how they work, last, and cost. Each tool has its own needs, so knowing these helps you pick the right PCB. Below are some tips to help you decide.

- Think About How the Tool Works

Look at what your tool does. Simple tools like massagers or cleansers can use FR4 PCBs. These are cheap and work well. For advanced tools, rigid-flex or metal core PCBs are better. They handle heat and complex designs. - Pick the Right PCB for the Job

Flexible PCBs are great for small or bendable tools. Rigid-flex PCBs are strong and flexible, perfect for tools with many features. Metal core PCBs are best for tools that get hot, like LED masks or heated rollers. - Choose Quality Over Price

Spending more on good PCBs makes tools last longer. High-quality PCBs stop tools from breaking, making users happy. They cost more upfront but save money by needing fewer repairs. - Plan for New Trends

Beauty tools are always changing. Flexible and rigid-flex PCBs help you make cool new designs. These PCBs keep your tools modern and popular with buyers.

Pro Tip: Work with a trusted PCB maker to ensure your tools meet standards and work great.

Following these tips helps you make beauty tools that work well, last long, and look good. This makes users happy and helps your brand succeed in the market.

Picking the right PCB for beauty tools is very important. It helps devices work well, last longer, and make users happy. Different PCBs have different benefits. FR4 PCBs are cheap and good for simple tools. Flexible and rigid-flex PCBs are great for creative designs. Metal core PCBs are best for high-end tools that need to handle heat.

Focus on quality and match the PCB to your tool’s needs. Working with a trusted maker like King Field PCB gives you certified production and expert help. They offer custom solutions and help you avoid mistakes, ensuring great results for your beauty tools.

FAQ

What is the cheapest PCB for beauty tools?

FR4 PCBs are the least expensive choice. They work well for simple tools that don’t get too hot. If your device doesn’t need special features, FR4 PCBs are a good mix of low cost and solid performance.

Can flexible PCBs handle a lot of heat?

Flexible PCBs can handle some heat but not very high temperatures. For tools like LED masks or heated rollers, metal core PCBs are better because they manage heat much better.

How do I pick the best PCB for my beauty tool?

Think about what your tool needs. Use multi-layer PCBs for small designs. Pick metal core PCBs for tools that get hot. Flexible PCBs are great for wearable or curved tools. Match the PCB to your tool’s design and purpose.

Are rigid-flex PCBs worth the extra money?

Yes, rigid-flex PCBs are strong and flexible. They are great for tools with many features. They also need fewer connectors, making them easier to build and more reliable, which makes the higher cost worth it.

Do metal core PCBs help tools last longer?

Yes, metal core PCBs handle heat well, stopping parts from overheating. This keeps high-power tools like LED devices and heated rollers working longer and in better shape.