Circuit Board Components

Circuit board components form the foundation of every electronic device you use daily. These components ensure the smooth flow of electricity and enable devices to perform complex tasks. Without them, smartphones, laptops, and countless other technologies would not function. Each part on a circuit board serves a unique purpose, from managing power to facilitating communication between different sections. Understanding these components helps you appreciate the engineering behind modern electronics and their role in shaping technology.

Key Takeaways

- Circuit board parts are important for devices like phones and laptops. Knowing about them helps you understand modern gadgets better.

- Active parts, like transistors and diodes, need power to work. They manage electrical signals and handle tough tasks in electronics.

- Passive parts, such as resistors and capacitors, don’t need extra power. They control and store energy, keeping circuits safe and working well.

- Connectors join circuit board parts, letting them share power and data. Their design is key to keeping connections strong and secure.

- Picking the right circuit board—single, double, or multi-layer—depends on how complex your project is and what it needs to do.

Overview of Circuit Board Components

Circuit boards rely on a variety of components to function effectively. These components fall into distinct categories based on their roles in electronic devices. Understanding these categories helps you identify how each part contributes to the overall operation of a circuit board.

Active Components

Active components are the driving force behind electronic circuits. They control the flow of electricity and amplify signals, enabling devices to perform complex tasks. Transistors, diodes, and integrated circuits (ICs) are common examples. For instance, transistors act as switches or amplifiers, while ICs combine multiple functions into a single chip. These components require external power to operate, making them essential for dynamic processes in electronic devices.

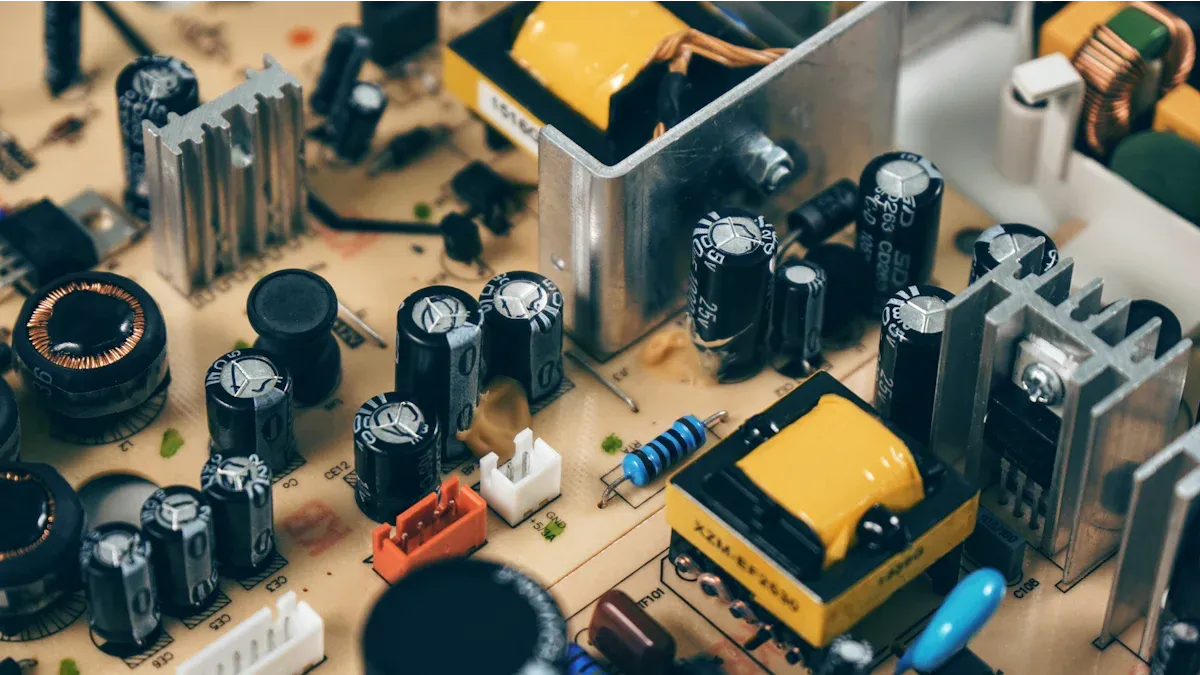

Passive Components

Passive components play a supporting role by storing, regulating, or dissipating energy. Unlike active components, they do not require external power to function. Resistors, capacitors, and inductors are key examples. Resistors limit the flow of current, ensuring circuits operate safely. Capacitors store electrical energy and release it when needed, while inductors manage magnetic fields. These components contribute to the stability and efficiency of a circuit board.

Connectors

Connectors serve as the bridge between different parts of a circuit board. They enable communication and power transfer between components. You’ll find connectors in various forms, such as pin headers, sockets, and cable connectors. Their design ensures secure connections, minimizing the risk of interruptions. As electronic devices become more compact, connectors are evolving to meet the demand for smaller and more efficient designs.

The growing demand for compact and lightweight electronic components, especially in consumer electronics like smartphones, has driven innovation in circuit board design. Flexible Printed Circuit Boards (FPCBs), for example, are projected to reach $48.7 billion by 2030, growing at a compound annual rate of 10.5%. This trend highlights the importance of connectors and other components in enabling miniaturization and flexibility.

Power Management Components

Power management components ensure that your electronic devices receive the right amount of power to function efficiently. These components regulate, distribute, and sometimes store electrical energy, making them essential for the stability and longevity of a circuit board.

Key Types of Power Management Components

- Voltage Regulators

Voltage regulators maintain a consistent output voltage, even when the input voltage fluctuates. They protect sensitive components from damage caused by voltage spikes or drops. For example, linear regulators are simple and reliable, while switching regulators offer higher efficiency for devices with varying power demands. - Batteries

Batteries store electrical energy and supply it to the circuit when needed. Rechargeable batteries, like lithium-ion, are common in portable devices such as smartphones and laptops. They ensure uninterrupted operation, especially during power outages. - Power Inductors

Power inductors store energy in a magnetic field and release it when required. They help filter noise and stabilize current flow in power supply circuits. You’ll often find them in devices that require smooth and consistent power delivery. - Transformers

Transformers adjust voltage levels to match the requirements of different components. They step up or step down voltage, ensuring compatibility between the power source and the circuit.

Tip: When designing or troubleshooting a circuit board, always check the power management components. Proper regulation and distribution of power can prevent overheating and extend the lifespan of your device.

Power management components are the unsung heroes of electronics. They ensure your devices operate safely and efficiently, no matter the conditions. By understanding their roles, you can appreciate the engineering that keeps your gadgets running smoothly.

Common Electronic Components on Circuit Boards

Circuit boards consist of various electronic components that work together to ensure functionality. Among these, resistors, capacitors, and diodes are some of the most common components. Each plays a unique role in managing electrical signals and maintaining the stability of the circuit.

Resistors

Resistors are essential for controlling the flow of electrical current in a circuit. They limit current to prevent damage to sensitive components and ensure the circuit operates safely. You can find resistors in almost every electronic device, from smartphones to industrial machinery.

Resistors come in different types, such as fixed, variable, and surface-mount resistors. Fixed resistors have a constant resistance value, while variable resistors allow you to adjust the resistance. Surface-mount resistors are compact and ideal for modern, space-saving circuit board designs.

Failures in resistors can occur due to various reasons. The table below highlights some common failure modes and their descriptions:

| Failure Mode | Description |

|---|---|

| Open or Short Failure | Resistors can fail by becoming an open circuit or a short circuit. |

| Manufacturing Defects | Issues like improperly crimped caps can lead to intermittent problems. |

| Delamination | Surface-mount resistors may delaminate at material junctions. |

| Corrosion | Nichrome thin-film resistors can corrode due to phosphorus in passivation. |

| Environmental Failure | Sulfur-rich environments can cause silver sulfide buildup in SMD resistors. |

| Copper Dendrites | Growth of copper dendrites can bridge connections and cause failures. |

Tip: When selecting resistors for your circuit board, consider their power rating and tolerance to ensure reliable performance.

Capacitors

Capacitors store and release electrical energy, making them vital for stabilizing voltage and filtering noise in circuits. They are commonly used in power supply systems, signal processing, and timing applications. You’ll encounter various types of capacitors, including ceramic, electrolytic, and tantalum capacitors, each suited for specific purposes.

To ensure reliability, capacitors undergo rigorous burn-in testing under elevated voltage and temperature. These tests help identify defects and improve performance. Some key testing specifications include:

- MIL-C-55681, MIL-C-123, and MIL-C-49467 standards.

- Testing conditions with voltages twice the working rating at temperatures of 85°C or 125°C.

- Durations of 96, 100, or 168 hours.

Despite their reliability, capacitors can fail due to loss of resistivity, degradation of capacitance, or changes in the dissipation factor. Proper selection and testing of capacitors can significantly enhance the durability of your circuit board.

Note: Always choose capacitors with a voltage rating higher than the circuit’s operating voltage to prevent premature failure.

Diodes

Diodes are semiconductor devices that allow current to flow in one direction while blocking it in the opposite direction. They are crucial for rectification, signal modulation, and voltage regulation. Common types of diodes include rectifier diodes, Zener diodes, and light-emitting diodes (LEDs).

The performance of diodes depends on several parameters. The table below provides key metrics for diodes used in circuit boards:

| Parameter | Value |

|---|---|

| Breakdown Voltage (Bv) | 7.0 V |

| Threshold Voltage (Vth) | 0.25–0.35 V |

| Non-linear Resistance (Rs) | 5 Ω |

| Junction Capacitance (Cj0) | 0.18 pF |

| Reverse Saturation Current (Is) | 5 × 10⁻⁸ A |

| M Factor | 0.5 |

| N Factor | 1.08 |

Diodes are highly reliable but can fail due to overheating, excessive current, or reverse voltage. Proper heat dissipation and circuit design can help prevent these issues.

Tip: When designing circuits with diodes, ensure they are rated for the maximum current and voltage they will encounter.

Transistors

Transistors are among the most versatile electronic components on circuit boards. They act as switches or amplifiers, controlling the flow of electrical signals. Their ability to regulate current makes them indispensable in modern electronics, from smartphones to industrial machinery.

Types of Transistors

Transistors come in several types, each suited for specific applications:

- Bipolar Junction Transistors (BJTs): These transistors amplify current and are commonly used in audio devices and signal processing.

- Field-Effect Transistors (FETs): FETs control voltage and are ideal for high-speed switching in digital circuits.

- Metal-Oxide-Semiconductor FETs (MOSFETs): MOSFETs are widely used in power management systems due to their efficiency and reliability.

Market Trends

The demand for transistors continues to grow as electronic devices become more advanced. Key market insights include:

- The global surface mount technology market divides into active components, including transistors, and passive components like capacitors and resistors.

- Active components are projected to grow at a compound annual growth rate (CAGR) of 13.23%, driven by the increasing need for sophisticated electronic devices.

- Passive components dominate with a projected market share of 75.34% by 2035, highlighting the balance between active and passive components in circuit board assemblies.

Tip: When selecting transistors for your circuit board, consider their switching speed and power rating to ensure optimal performance.

Integrated Circuits (ICs)

Integrated circuits (ICs) revolutionized electronics by combining multiple functions into a single chip. These compact components house thousands or even millions of transistors, resistors, and capacitors, enabling complex operations in a small footprint.

Applications of ICs

ICs are the backbone of modern technology. You’ll find them in:

- Microprocessors: These ICs serve as the brain of computers and smartphones, executing instructions and processing data.

- Memory Chips: ICs store data in devices like laptops, cameras, and gaming consoles.

- Analog ICs: These chips process continuous signals, making them essential for audio and video equipment.

Benefits of ICs

ICs offer several advantages:

- Miniaturization: They reduce the size of electronic devices, enabling portability.

- Efficiency: ICs consume less power compared to discrete components.

- Reliability: Their integrated design minimizes the risk of component failure.

Note: When designing with ICs, ensure compatibility with other electronic components on the circuit board to avoid performance issues.

Inductors

Inductors are passive electronic components that store energy in a magnetic field when current flows through them. They play a crucial role in filtering noise, stabilizing current, and managing power in circuits.

Key Parameters

Modern circuit board designs rely on inductors with specific characteristics. The table below highlights important parameters:

| Parameter | Description |

|---|---|

| Inductance | Measures the ability of the inductor to store energy in a magnetic field. |

| Resistance (DC and AC) | Indicates the opposition to current flow, affecting efficiency and heat generation. |

| Temperature Rise | Assesses how much the inductor heats up under operating conditions, impacting reliability. |

| Total Harmonic Distortion | Evaluates the inductor’s effectiveness in filtering out unwanted harmonics in high-frequency signals. |

| Efficiency | Represents the ratio of useful power output to total power input, crucial for performance assessment. |

Applications

Inductors are essential in various electronic devices:

- Power Supplies: They filter out voltage spikes and ensure smooth power delivery.

- RF Circuits: Inductors manage high-frequency signals in communication devices.

- Transformers: They enable voltage conversion in power systems.

Tip: Choose inductors with low resistance and high efficiency to enhance the performance of your circuit board.

Switches

Switches are essential components on circuit boards that control the flow of electricity. They allow you to open or close a circuit, enabling or disabling the operation of electronic devices. By toggling a switch, you can manage the functionality of a device with ease.

Types of Switches

Switches come in various forms, each designed for specific applications. Understanding the different types helps you choose the right one for your circuit board.

- Toggle Switches

Toggle switches are among the most common types. They feature a lever that you flip to open or close a circuit. These switches are durable and often used in industrial equipment and household appliances. - Push-Button Switches

Push-button switches operate when you press them. They can be either momentary (returning to their original position after release) or latching (staying in the pressed position). You’ll find these switches in calculators, keyboards, and doorbells. - Slide Switches

Slide switches use a small slider to change the circuit’s state. They are compact and ideal for devices like remote controls and toys. - Rotary Switches

Rotary switches allow you to select between multiple circuits by rotating a knob. These switches are common in audio equipment and multi-speed fans. - DIP Switches

Dual Inline Package (DIP) switches consist of a series of small toggle switches mounted on a single unit. They are used for configuring settings on circuit boards, such as setting device modes or addresses. - Micro Switches

Micro switches are highly sensitive and activate with minimal physical force. They are often used in safety devices, vending machines, and control panels.

How Switches Work

Switches function by creating or breaking a connection in an electrical circuit. When you close a switch, it completes the circuit, allowing current to flow. Opening the switch interrupts the flow, stopping the operation of the connected device. This simple mechanism makes switches indispensable in electronics.

Applications of Switches

Switches play a vital role in various electronic devices and systems. Here are some common applications:

- Consumer Electronics: Power buttons on TVs, computers, and smartphones rely on switches.

- Industrial Machinery: Switches control heavy machinery, ensuring safe and efficient operation.

- Automotive Systems: Cars use switches for headlights, wipers, and ignition systems.

- Home Automation: Smart switches enable remote control of lights and appliances.

Tip: When selecting a switch for your circuit board, consider factors like size, current rating, and durability to ensure optimal performance.

Key Parameters to Consider

Switches vary in design and specifications. The table below highlights some important parameters to evaluate when choosing a switch:

| Parameter | Description |

|---|---|

| Voltage Rating | Maximum voltage the switch can handle without failure. |

| Current Rating | Maximum current the switch can carry safely. |

| Contact Resistance | Resistance at the contact points, affecting efficiency and heat generation. |

| Actuation Force | Amount of force required to operate the switch. |

| Lifespan | Number of cycles the switch can perform before wearing out. |

Maintenance and Troubleshooting

Switches are generally reliable, but they can fail due to wear and tear, dirt accumulation, or corrosion. Regular cleaning and inspection can extend their lifespan. If a switch stops working, check for loose connections or damaged contacts. Replacing a faulty switch is often straightforward and restores functionality quickly.

Note: Always disconnect power before inspecting or replacing a switch to avoid electrical hazards.

Switches may seem simple, but they are crucial for controlling and managing electronic circuits. By understanding their types, functions, and applications, you can make informed decisions when designing or repairing circuit boards.

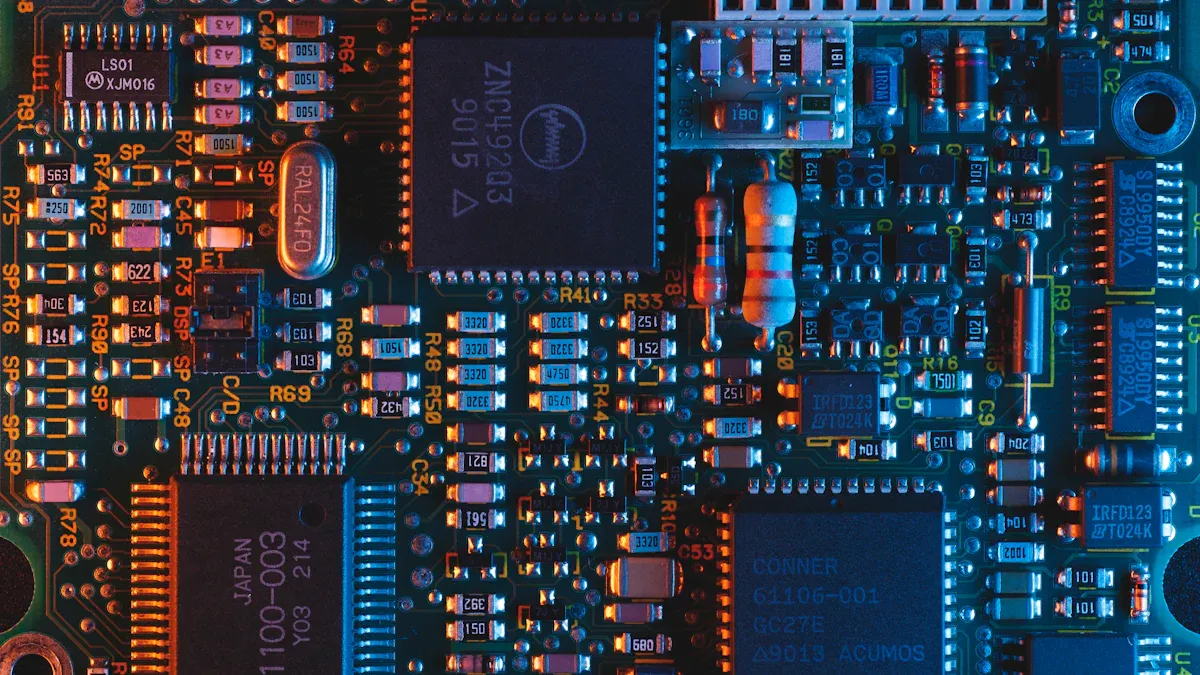

Identifying Circuit Board Components

Identifying electronic components on a circuit board can seem challenging at first. However, with the right techniques and tools, you can quickly learn to recognize and understand these components. This section will guide you through visual identification methods, the role of component designators, and the tools that make the process easier.

Visual Identification Techniques

Visual identification is one of the most straightforward ways to identify components on a circuit board. By observing the physical characteristics of each component, you can often determine its type and function. Features like size, shape, color, and markings provide valuable clues.

For example, resistors typically appear as small cylindrical components with colored bands that indicate their resistance value. Capacitors, on the other hand, may look like small discs or cylinders, often labeled with their capacitance. Integrated circuits (ICs) are rectangular chips with multiple pins, while diodes are small cylindrical components with a stripe indicating polarity.

Advancements in technology have improved the accuracy of visual identification techniques. Studies show that defect detection in circuit boards using image datasets can achieve high accuracy rates. The table below highlights some findings:

| Study Description | Accuracy Rate | Additional Details |

|---|---|---|

| Defect detection accuracy from a dataset of 184 training images and 108 test images. | 89.22% | Focus on defect detection in PCBs. |

| Pyramidal concatenation technique applied to a public dataset, achieving a mean Average Precision (mAP) score. | 98.9% | Addresses challenges in detecting small defects. |

| Supervised learning MLP for solder joint classification with a 10-fold cross-validation test. | 98.8% | Classifies five solder joint conditions. |

These findings demonstrate the effectiveness of visual techniques, especially when combined with advanced imaging methods. By practicing visual identification, you can develop the skills needed to identify components accurately.

Tip: Keep a reference chart of common electronic components nearby. It can help you quickly match physical features to specific components.

Understanding Component Designators

Component designators are alphanumeric codes printed on circuit boards to label individual components. These codes follow a standardized naming convention, making it easier to identify components and understand their roles in the circuit.

For instance, resistors are often labeled with an “R” followed by a number (e.g., R1, R2). Capacitors use the letter “C,” while diodes are marked with “D.” Integrated circuits may have designators like “U” or “IC.” These labels correspond to the circuit diagram, helping you locate and identify components during assembly or troubleshooting.

Here’s a quick guide to common designators:

- R: Resistor

- C: Capacitor

- D: Diode

- Q: Transistor

- U/IC: Integrated Circuit

- L: Inductor

- SW: Switch

Understanding these designators allows you to navigate circuit boards more efficiently. When you see a designator, you can immediately associate it with the corresponding component type, saving time and reducing errors.

Note: Always cross-reference designators with the circuit schematic for a complete understanding of the board layout.

Tools for Identification

While visual techniques and designators are helpful, certain tools can make identifying electronic components even easier. These tools provide precise measurements and additional insights that go beyond what the naked eye can observe.

- Multimeter

A multimeter is an essential tool for measuring electrical properties like resistance, capacitance, and voltage. By testing components directly on the board, you can confirm their functionality and identify faulty parts. - Magnifying Glass or Microscope

Circuit boards often feature tiny components with intricate details. A magnifying glass or microscope helps you examine these components closely, making it easier to read markings and inspect for defects. - Component Tester

A component tester automatically identifies components and measures their properties. It’s especially useful for beginners who may struggle with manual identification. - Reference Manuals and Apps

Manuals and mobile apps provide detailed information about various components. They include diagrams, specifications, and tips for identifying components based on their appearance and markings. - Labeling and Organization Tools

Keeping your workspace organized with labeled containers for components can streamline the identification process. When components are sorted by type and size, you can find what you need quickly.

Tip: Invest in a digital multimeter with advanced features like auto-ranging and component testing. It can save you time and improve accuracy when working with circuit boards.

By combining these tools with visual techniques and an understanding of designators, you can confidently identify components on any circuit board. Practice and familiarity will further enhance your skills, making the process second nature.

Types of Printed Circuit Boards

Printed circuit boards come in various types, each designed to meet specific requirements. Understanding these types helps you choose the right one for your project based on factors like complexity, cost, and application.

Single-Sided Boards

Single-sided boards are the simplest type of printed circuit boards. They have only one layer of conductive material, typically copper, on one side of the board. Components are mounted on the opposite side, making these boards easy to design and manufacture.

These boards are ideal for low-density circuits and simple devices like calculators, LED lights, and basic power supplies. Their simplicity keeps production costs low, but they lack the capacity for complex or high-performance systems. According to performance data, single-sided boards have low density, low complexity, and low signal integrity, making them suitable for straightforward applications.

Tip: If you’re working on a beginner electronics project, single-sided boards are a great starting point due to their simplicity and affordability.

Double-Sided Boards

Double-sided boards feature conductive layers on both sides of the board. This design allows components to be mounted on both sides, increasing the circuit’s density and functionality. These boards use vias—small holes plated with conductive material—to connect the two layers electrically.

You’ll find double-sided boards in consumer electronics like televisions, smartphones, and audio equipment. They strike a balance between cost and complexity, offering medium density and signal integrity. While more expensive than single-sided boards, they provide greater flexibility for moderately complex designs.

Note: Double-sided boards are a popular choice for devices requiring compact designs without the need for multi-layer complexity.

Multi-Layer Boards

Multi-layer boards take complexity to the next level by stacking three or more conductive layers separated by insulating material. These layers are interconnected through vias, enabling intricate circuit designs in a compact space. Multi-layer boards are essential for high-performance systems like servers, medical devices, and aerospace equipment.

These boards offer high density, excellent signal integrity, and the ability to handle complex circuits. However, their advanced design and manufacturing process make them more expensive. For example, multi-layer boards are significantly costlier than single-sided boards but are indispensable for applications requiring high-speed data processing and minimal interference.

| Type of PCB | Layers | Density | Complexity | Cost | Signal Integrity | Applications |

|---|---|---|---|---|---|---|

| Single-Sided | 1 | Low | Simple | Low | Low | Simple Devices |

| Double-Sided | 2 | Medium | Moderate | Medium | Medium | Consumer Electronics |

| Multi-Layer | 3+ | High | High | High | High | High-Performance Systems |

Tip: When designing multi-layer boards, consider the trade-off between cost and performance. These boards are ideal for advanced applications but may exceed the budget for simpler projects.

Rigid, Flexible, and Rigid-Flex Boards

Printed circuit boards come in different forms to meet the diverse needs of modern electronics. Among these, rigid, flexible, and rigid-flex boards stand out for their unique properties and applications.

Rigid Boards

Rigid boards are the most common type of printed circuit boards. They feature a solid, inflexible substrate, usually made of fiberglass or epoxy resin. This sturdy design makes them ideal for devices requiring durability, such as desktop computers and televisions. Rigid boards provide excellent support for components and ensure reliable performance over time. However, their lack of flexibility limits their use in compact or dynamic devices.

Flexible Boards

Flexible boards, also known as flex PCBs, are made from bendable materials like polyimide. These boards can twist, fold, or curve to fit into tight spaces. You’ll often find them in wearable devices, smartphones, and medical equipment. Their lightweight and adaptable nature make them perfect for applications where space and weight are critical. Despite their advantages, flexible boards can be more expensive to manufacture due to their specialized materials and processes.

Rigid-Flex Boards

Rigid-flex boards combine the best features of rigid and flexible printed circuit boards. They consist of rigid sections connected by flexible layers, allowing for both stability and adaptability. These boards are commonly used in aerospace, automotive, and military applications, where reliability and compact design are essential. Rigid-flex boards reduce the need for connectors and cables, simplifying assembly and improving signal integrity.

Tip: When choosing a board type, consider the device’s size, environment, and performance requirements. Each type offers unique benefits tailored to specific applications.

By understanding these board types, you can select the right one for your project and optimize your device’s performance.

Applications and Importance of Circuit Boards

Circuit boards are the backbone of modern technology, powering devices and systems across various industries. Their versatility and reliability make them indispensable in consumer electronics, industrial applications, and emerging technologies like IoT.

Consumer Electronics

Circuit boards are at the heart of consumer electronics, enabling the functionality of devices like smartphones, laptops, and smart TVs. These boards support compact designs and advanced processing capabilities, making them essential for modern gadgets. The demand for circuit boards in this sector continues to grow due to advancements in 5G technology and the Internet of Things (IoT).

- The consumer electronics sector, including mobile phones and smart devices, drives significant PCB demand.

- The PCB market is projected to grow by USD 26.8 billion from 2025 to 2029, fueled by the rising need for electronic devices.

- Compact and efficient circuit boards dominate this market, highlighting their critical role in the industry.

As technology evolves, circuit boards will remain vital for creating smaller, faster, and more efficient devices.

Industrial and Automotive Systems

In industrial and automotive systems, circuit boards ensure reliability and performance under demanding conditions. These boards undergo rigorous testing, such as UL and electrical stress tests, to meet industry standards like IPC-6011 and IPC-6012D. This ensures they can handle extreme environments and maintain functionality.

The automotive PCB market is growing rapidly, with projections showing an increase from $10.05 billion in 2024 to $14.88 billion by 2029 at a CAGR of 8.5%. Circuit boards play a crucial role in automotive technologies, including GPS systems, advanced driver-assistance systems (ADAS), and electric vehicles. In industrial applications, they power machinery, robotics, and control systems, ensuring efficiency and precision.

IoT and Emerging Technologies

The rise of IoT and emerging technologies has further emphasized the importance of circuit boards. Flexible printed circuit boards (FPCBs) are particularly significant in this sector due to their adaptability and lightweight design. These boards are essential for smart devices, wearables, and healthcare equipment.

- The FPCB market is expected to grow at an 11.0% CAGR, reaching $33.39 billion by 2025.

- The IoT market is also expanding, with a projected CAGR of 26.1% and a market volume of $1,387 billion.

- Key growth areas include automotive, industrial, and smart finance sectors.

Circuit boards enable seamless connectivity and data processing in IoT devices, making them indispensable for the future of technology.

Circuit board components form the backbone of modern electronics, powering everything from smartphones to industrial machinery. By understanding these components, you can unlock the potential to design and troubleshoot electronic devices effectively. Each component, whether active or passive, plays a critical role in ensuring functionality and reliability. Gaining knowledge about circuit board components not only enhances your technical skills but also deepens your appreciation for the engineering behind today’s technology. Start exploring these essential building blocks to elevate your expertise in electronics.

FAQ

What is the difference between active and passive components?

Active components, like transistors and diodes, require an external power source to function. They control or amplify electrical signals. Passive components, such as resistors and capacitors, do not need external power. They store, regulate, or dissipate energy within the circuit.

How can you identify components on a circuit board?

You can identify components by their physical appearance, markings, or designators (e.g., “R” for resistors, “C” for capacitors). Tools like multimeters and magnifying glasses help with precise identification. Reference charts and manuals also provide valuable guidance for recognizing components.

Why are integrated circuits (ICs) important?

Integrated circuits combine multiple electronic functions into a single chip. They save space, improve efficiency, and enhance reliability. ICs are essential for modern devices like smartphones, computers, and medical equipment, enabling advanced operations in a compact form.

What tools do you need to test circuit board components?

Essential tools include a multimeter for measuring electrical properties, a soldering iron for repairs, and a magnifying glass for inspecting small components. Advanced tools like component testers and oscilloscopes provide detailed insights into functionality and performance.

How do you choose the right circuit board for your project?

Consider the complexity of your design, the required durability, and the available budget. Single-sided boards work for simple projects. Double-sided boards suit medium complexity. Multi-layer boards handle advanced designs. Flexible and rigid-flex boards fit compact or dynamic applications.

Tip: Always match the board type to your device’s performance needs for optimal results.