What is BGA Assembly and How Does It Work in 2025

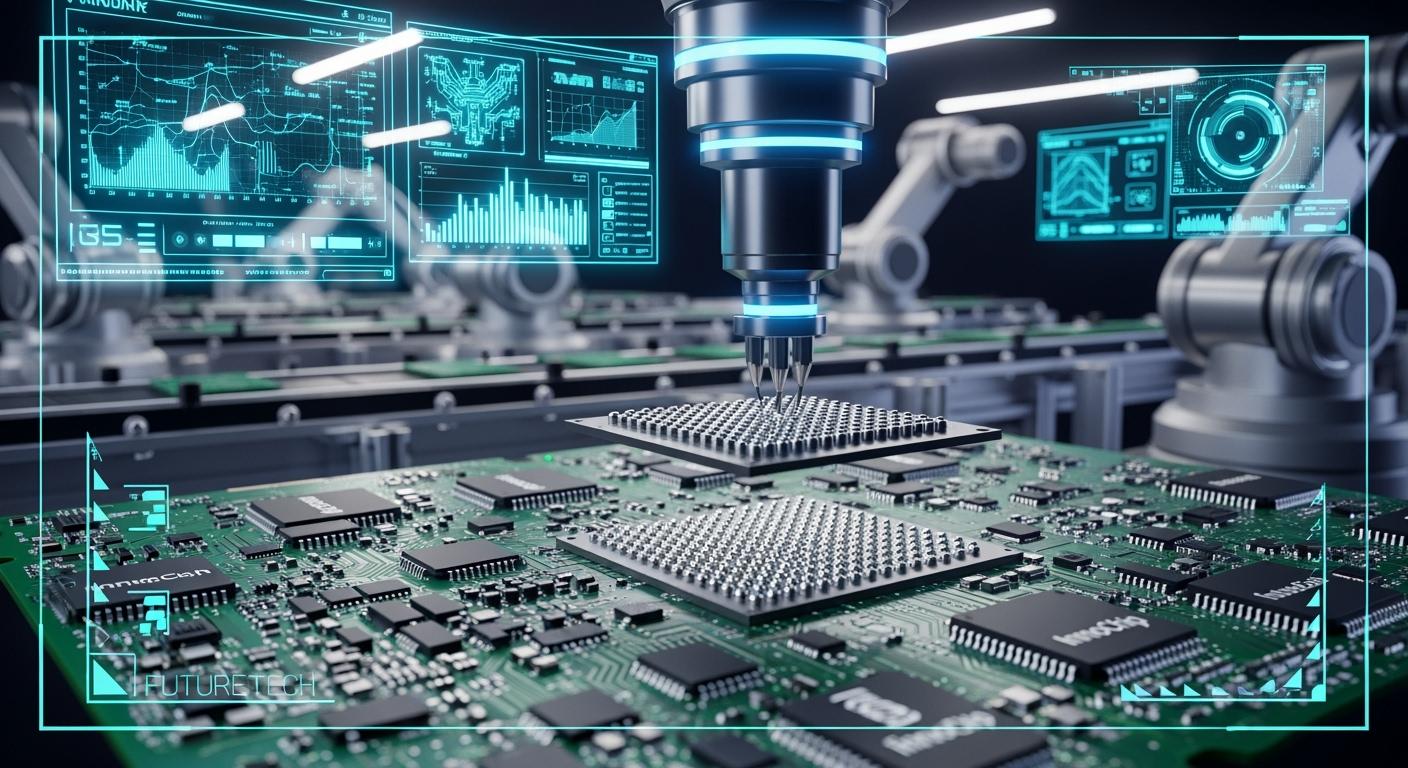

You use bga assembly to put small parts on a board. These parts have tiny solder balls in a grid shape. Heat is used to stick the parts to the printed circuit board. This is called reflow soldering. Bga helps make devices faster and smaller. You can see bga in many new gadgets. The table below explains why bga assembly is still important in 2025.

| Market Growth | The global BGA packaging market grows as devices get smaller and need more power. | | Industry Drivers | Consumer electronics and car systems help more people use BGA. | | Telecommunications Impact | 5G networks make people need strong, high-density packaging. |

Key Takeaways

- BGA assembly uses a grid of solder balls to connect chips to circuit boards. This lets more connections fit in a small space.

- The assembly process has careful steps. First, the board is prepared. Next, workers place the components. Then, they use reflow soldering. Last, they check for quality.

- BGA technology makes devices work better. It helps electricity move well and keeps things cool. This makes gadgets faster and cooler.

- X-ray inspection is very important for BGA assembly. It finds hidden problems with solder joints. These problems cannot be seen with just your eyes.

- BGA is used a lot in electronics, cars, and new technology. It helps make devices smaller and smarter.

What is BGA Assembly

BGA Definition and Features

Bga assembly connects ball grid array parts to a printed circuit board. You put a chip with small solder balls in a grid on the board. Then you heat the board so the solder balls melt. This makes strong connections between the chip and the board. Electronics rules say bga assembly means putting ball grid array packages on boards with careful placement and soldering. These packages are chips with solder balls under them. This way gives you lots of connections in a small space. You see bga assembly in devices that need to be small and fast.

Tip: Picking bga assembly helps your device work better and fit more things in a small space.

You can look at this table to compare bga assembly and other surface-mount technologies:

| Feature | BGA Assembly | Other SMT Technologies |

|---|---|---|

| Pin Count | High | Varies, often lower |

| Electrical Efficiency | High | Moderate to High |

| Soldering Structure | Grid of solder balls | Varies, typically leads |

| Space Utilization | Better due to compact design | Less efficient |

| Performance | Enhanced connectivity and performance | Varies, often less effective |

Bga assembly is different because it uses a grid of solder balls, not pins or leads. You get better electrical work and more connections in less space. That is why bga is a top pick for new electronics.

How BGA Assembly Works

First, you get the printed circuit board ready. You put solder paste on the spots for the bga. Next, a machine puts the ball grid array part on the board. Then you put the board in a reflow oven. The oven heats the board and melts the solder balls. The melted solder makes strong links between the bga and the board. After the board cools, you check it for problems. You might use machines or X-rays because the solder joints are under the part.

Bga assembly is not like old ways such as pin-through-hole or QFP. Those use pins that go through the board. Bga uses solder balls under the chip. This lets you have more connections in a smaller space. You need special tools to check the solder joints because you cannot see them. Reflow soldering in bga assembly depends on how well the board handles heat. Old ways heat the pins right on the board.

Here are the main steps for bga assembly:

- PCB Preparation: Put solder paste on the pads for the bga.

- Placement of BGAs: Use machines to put the bga on the board.

- Reflow Soldering: Heat the board in an oven to melt the solder and make connections.

- Cooling and Inspection: Cool the board and check for problems with machines.

- Secondary Processes: Clean and test the board if needed.

Bga assembly helps you make devices that are smaller, faster, and work better. You find bga in smartphones, computers, and many other electronics in 2025.

Ball Grid Array Components

Package Structure

When you look at a bga package, you see several important parts working together. The main part is the semiconductor die. This is the chip that does all the work inside your device. The die sits on a layer called die attach. This layer holds the chip in place and helps connect it to other parts. You also find wire bonding or flip-chip bonding. Wire bonding uses thin wires to link the chip to the substrate. Flip-chip bonding connects the chip directly to the substrate with tiny solder bumps. The substrate is a special board that routes signals between the chip and the solder balls. The solder balls sit in a grid under the package. They connect the bga to printed circuit boards.

Here is a table showing the main components and what they do:

| Component | Function |

|---|---|

| Semiconductor Die | The chip that runs your device. |

| Die Attach | Holds the chip and helps make connections. |

| Wire Bonding | Links the chip to the substrate with thin wires. |

| Flip-Chip Bonding | Connects the chip directly to the substrate with solder bumps. |

| Substrate | Routes signals between the chip and solder balls. |

| Solder Balls | Connect the bga to printed circuit boards. |

The structure of a bga package helps your device work faster and stay cool. Short and uniform connections between solder joints improve signal transmission. The substrate uses materials that spread heat well, so your device does not overheat. You get reliable performance because the design reduces the risk of solder joint failures.

Solder Balls and PCB Interface

You see solder balls arranged in a grid on the bottom of the bga package. These tiny balls create strong electrical connections between the bga and printed circuit boards. When you heat the package during assembly, the solder balls melt and join the bga to the board. This method gives you many connections in a small space.

The design of the PCB interface matters a lot. High-density interconnects let you fit more connections on printed circuit boards. Good PCB design helps signals move without interference and makes the board easier to manufacture. If you design the routing poorly, you may face problems like solder bridges or signal loss. You want to minimize defects and keep your device reliable.

Tip: Always check your PCB layout before assembly. Careful planning helps you avoid costly mistakes and keeps your bga working well.

You use bga packages in devices that need high speed and high power. The spherical solder balls help spread heat and keep your device cool. You get better performance and longer life for your electronics.

BGA Assembly Process Steps

You have to do several steps to finish bga assembly. Each step helps you make electronics that work well and last long. You need to check quality at every step. This makes sure your pcb assembly is strong and does not break easily.

Solder Paste Application

First, you put solder paste on the pads of your printed circuit board. This step is very important for making strong links between the bga and the board. You use a stencil to put the paste in the right places. The paste has tiny solder balls mixed with flux. The flux helps the solder melt and stick during soldering.

Here are the main steps for putting on solder paste in bga assembly:

- Solder Paste Printing: Use a stencil printer to put paste on the pcb assembly pads.

- SPI (Solder Paste Inspection): Check the paste with a 3D system to measure how much is there.

- Chip Mounting: Get the board ready for the bga.

- Reflow Soldering: Heat the board so the solder melts.

- AOI (Automated Optical Inspection): Look at the solder joints.

- AXI (X-ray Inspection, optional): Check hidden joints if you need to.

- Rework (optional): Fix any problems you find.

Note: Checking quality when you put on solder paste stops weak joints, solder bridges, and open circuits. Always make sure the paste is in the right spot and the right amount.

Component Placement

Special machines put the bga on the pcb assembly. These machines pick up the bga and place it very carefully. Good placement is needed for soldering to work well. If you put the bga in the wrong spot, you can get bad links or short circuits.

Here is a table that shows tools used for placing parts:

| Equipment Type | Description |

|---|---|

| Automated Placement Machines | Put bga parts on the board fast and very accurately. |

| Automatic Solder Dispensing Machine | Spread solder paste evenly to stop bridging and make strong joints. |

| Reflow Oven | Heats the board in a careful way for soldering. |

| X-ray and AOI Inspection Systems | Check where parts are and look at solder joints, even ones you can’t see. |

| Specialized Inspection Systems | Measure how high solder balls are and how much they cover for good connections. |

You need to use quality control tools like cameras to check if the bga lines up with the pads on the pcb assembly.

Reflow Soldering

Reflow soldering melts the solder paste and makes strong joints between the bga and the board. You put the pcb assembly in a reflow oven. The oven heats the board in different steps. Each step has its own temperature and time.

You must control some things for good soldering:

| Parameter | Ideal Value | Impact on BGA Connections |

|---|---|---|

| Solder Mask Thickness | 0.8–1.2 mils (20–30 micrometers) | Stops paste from spreading and keeps the paste amount the same. |

| Stencil Thickness | 0.12–0.15 mm (for 0.5–1.0 mm BGA pitch) | Too thin makes weak joints; too thick causes bridging. |

| Paste Volume per Pad | 0.08–0.12 mm³ (for 0.5 mm pitch BGAs) | Makes sure solder balls and pads join well. |

| Slump Rate | < 15% (after 1 hour at 25°C/50% RH) | Stops short circuits between pads. |

You also need to watch these things during soldering:

- Ramp Rate: Raise the heat by 1–3°C each second. Too fast can break things. Too slow dries out the flux.

- Peak Temperature: Keep the hottest part 18–33°C above the solder’s melting point (217°C for lead-free). Too hot can hurt the bga. Too cool means the solder does not melt.

- Time Above Liquidus (TAL): Keep the board hotter than 217°C for 30–60 seconds. Too short makes cold joints. Too long makes solder balls or lifts pads.

Tip: Use sensors and thermal tools to watch the soldering process. This helps you stop mistakes and make better boards.

Inspection and Testing

After soldering, you need to check and test the pcb assembly. Inspection finds problems you cannot see with your eyes. Testing checks if the bga works right.

Here is a table of ways to check and what they find:

| Inspection Method | Description | Defects Detected |

|---|---|---|

| Visual/Optical Inspection | Use a microscope to look at bga placement and see problems. | Misalignment, damage, solder bridges, dirt. |

| Automated Optical (AOI) | Use cameras and computers to check solder joints and placement. | Missing parts, misalignment, solder balls. |

| X-Ray Inspection | Use 2D or 3D X-ray to see solder joints under the bga. | Voids, open circuits, shorts, head-in-pillow. |

| Electrical Testing | Check for open and short circuits in the pcb assembly. | Open and short circuits. |

| Boundary Scan Inspection | Check every solder joint on the edge connector for opens and shorts. | Open and short circuits. |

Automated X-ray inspection is great for finding hidden problems like holes and bubbles. Electrical testing and boundary scan inspection help you find open and short circuits. You need to check quality at this step to catch problems before the product leaves the factory.

Note: Checking quality at every step of bga assembly makes your final product work better. Careful checking and testing help you make great electronics.

You must do each step with care. Good quality checks at every stage of pcb assembly make sure your bga assembly meets the rules and works well in new electronics.

BGA Assembly Benefits and Challenges

Main Advantages

BGA technology gives your devices many good things. It lets you put more integrated circuits in a small space. You can make fast and powerful circuits with it. Here is a table that lists the main good things about bga technology:

| Advantage | Description |

|---|---|

| Increased Packaging Density | You save space and add more complex circuits to your board. |

| Enhanced Thermal Performance | BGA helps your device stay cool and last longer. |

| Improved Electrical Performance | You get better signals and less noise in your circuits. |

| Mechanical Stability | Your device stays stable and works well, even with heat or cold. |

| Higher Pin Counts | You can connect more integrated circuits in a small area, which helps advanced chipsets. |

BGA uses many solder balls in a grid. This design lets you add more connections without making the package bigger. Ultra-fine pitch technology helps you fit even more circuits on your board. BGA can use only one-third of the space that other packages need.

BGA packages give you better signals and less noise, so your device works better.

You also get less stress from heat changes. This means your circuits stay strong and last longer. BGA supports high-density interconnection, which is needed for new integrated circuits.

Common Challenges

BGA technology also has some hard parts. The biggest problem is that the solder joints are under the package. You cannot see these joints with your eyes. Old ways to check for problems do not work well for bga. You need special tools like X-ray machines to find issues.

Here are some problems you might have:

- BGA solder joints are hidden, so you cannot use regular visual checks.

- Automated Optical Inspection cannot find problems under the package.

- You need X-ray inspection to see things like voids or bad soldering.

- Solder joint quality is very important for your circuits. If the reflow process is not right, you can get problems like voids, cold joints, or solder bridges.

- If a void is bigger than 25% of a solder joint, your circuits may not work well or may get too hot.

- Lead-free solder can break more easily when your device heats up or cools down.

Because bga solder joints are hidden, checking and fixing them is harder. You must use special equipment and be careful with your process to keep your circuits working well. Good checking helps you find problems early and stop your circuits from failing.

BGA Assembly Applications 2025

Consumer Electronics

You can find bga technology in almost every new device. Companies pick bga because it is small and works well. This makes your gadgets lighter and faster. It also helps them last longer. The table below shows where bga is used in electronics:

| Product Type | Description |

|---|---|

| Smartphones | Widely use bga technology for compact design and high performance. |

| Tablets | Incorporate bga assemblies for enhanced functionality and miniaturization. |

| Wearable Devices | Utilize bga for efficient space management and performance optimization. |

| High-Performance Computing | Bga packages are favored for their thermal management and power handling. |

| Automotive Electronics | Bga technology is essential for reliability and performance in vehicles. |

| Aerospace Systems | Use bga for critical applications requiring high integration and efficiency. |

Bga helps make phones smaller and batteries last longer. Computers run faster because of bga. Smartwatches use bga to fit more features in a tiny space.

Automotive and Industrial

Bga is found in many car and factory parts. Car makers use bga to make cars safer and smarter. In factories, bga helps machines work better and faster. Here are some ways bga helps these industries:

- Bga parts are used in advanced driver-assistance systems.

- They are important in engine control units.

- Car infotainment systems need bga to work well.

- Bga helps with hard jobs in factory automation.

- It lets control systems be smaller and more powerful.

Bga must be very reliable for these uses. You need to pay attention to how the parts connect. The solder mask pad design and surface finish are important too. These things help your devices last longer and work well, even if you change parts a lot.

Note: Good bga connections keep your car and factory machines safe and working.

Emerging Technologies

Bga is helping new technology grow fast. The market for bga-based solid-state drives is getting bigger. These drives save space and handle heat better. Ultra-thin laptops and small systems use bga SSDs to be faster and smaller.

The Internet of Things also needs bga. IoT connects things like wearables and handhelds to the internet. This makes your devices smarter and more helpful. Companies use IoT to work better and make smart choices.

Bga is also used in new computers and communication tools. For example:

- 5G networks use bga for fast data and good heat control.

- Artificial intelligence systems use bga to do hard jobs and stay cool.

- IoT devices need bga to be small and connect well.

Tip: As technology changes, learning about bga helps you see why your devices get smaller, faster, and smarter.

You now know that bga assembly helps make better electronics. Smaller designs and new materials help with AI, 5G, and IoT. Automation and new packaging make work faster and more exact. When you design, keep these tips in mind:

- Use X-ray inspection to check hidden joints.

- Plan for heat control and good routing.

- Make sure PCB pads and solder paste are just right.

The market will keep growing as devices get smaller and smarter. You will see new ideas in packaging and connections for many years.

FAQ

What does BGA stand for?

BGA stands for Ball Grid Array. You see this term when you work with small chips that use tiny solder balls to connect to a circuit board.

Why do you need X-ray inspection for BGA assembly?

You cannot see the solder joints under a BGA chip with your eyes. X-ray inspection helps you find hidden problems like cracks or missing connections.

Can you repair a faulty BGA connection?

Yes, you can repair a BGA joint. You use special tools to remove the chip, clean the area, and place a new chip. This process is called rework.

What devices use BGA technology in 2025?

You find BGA in smartphones, laptops, cars, and smart home devices. BGA helps these products stay small, fast, and reliable.