Safety is at the core of KING FIELD as a mover and shaker in the electronics market. That’s why we received our UL (Underwriters Laboratory) certification, a non-profit developing sustainability, safety, and quality standards.

How UL Certification Impacts PCB Safety and Reliability

You rely on printed circuit boards every day, whether you use a smartphone or a home appliance. UL certification for PCBs gives you confidence that your electronics meet strict safety and reliability standards. The underwriters laboratory tests these boards using third-party methods. This process protects you from risks like fire or electrical failure and helps manufacturers deliver products you can trust.

Tip: Choosing products with UL certification means you invest in safer, more reliable technology.

Key Takeaways

- UL certification ensures that printed circuit boards (PCBs) meet strict safety and reliability standards, protecting you from risks like fire and electrical failure.

- Choosing products with the UL mark means you invest in safer technology, as it indicates thorough testing for fire resistance and electrical performance.

- Regular audits and inspections keep UL certification active, ensuring that your electronics remain safe and reliable over time.

- UL certification opens doors to international markets, allowing manufacturers to sell their products globally without facing additional testing barriers.

- Stay informed about updates in UL standards to ensure your products use the latest technology and maintain safety.

What Is UL Certification for PCBs

Definition and Role of UL

You see the UL mark on many electronic products. This mark shows that the product meets strict safety standards. UL certification for PCBs means that your circuit boards have passed tests for fire resistance, electrical performance, and material quality. UL acts as an independent organization. It checks if your PCBs follow industry standards and safety rules. When you choose a product with UL listed or UL recognized components, you know it has gone through careful testing and evaluation.

Here is a table that explains the main functions of UL in PCB certification:

| Function | Description |

|---|---|

| Testing and Evaluation | UL certification for PCBs is determined through testing and evaluation of components for compliance with UL safety standards. |

| Safety Compliance | UL checks components for compliance with safety requirements and provides labeling indicating that the product has passed necessary tests. |

| Component Recognition | UL recognized components are used in larger products and systems, ensuring they meet safety standards before installation. |

Types of UL Certification

You will find two main types of UL certification for PCBs. UL listed means the entire product has passed all required safety tests. UL recognized applies to individual components, such as the PCB itself. Manufacturers use UL recognized PCBs in their devices to meet safety and industry standards. Both types help you identify products that have met strict requirements.

- UL certification ensures that PCBs have been tested for compliance with UL safety standards.

- The UL mark indicates that the product has undergone necessary safety evaluations.

Industry and Global Relevance

UL certification plays a key role in the electronics industry. You benefit from safer products, and manufacturers gain access to more markets. Many countries accept UL certification as proof of quality and safety. When you see the UL mark, you know the product meets global industry standards. This certification helps companies build trust with customers and meet legal requirements in different regions.

Note: UL certification for PCBs supports both local and international safety regulations. You can rely on products with the UL mark for consistent performance and protection.

UL Certification and PCB Safety

Fire and Flammability Standards

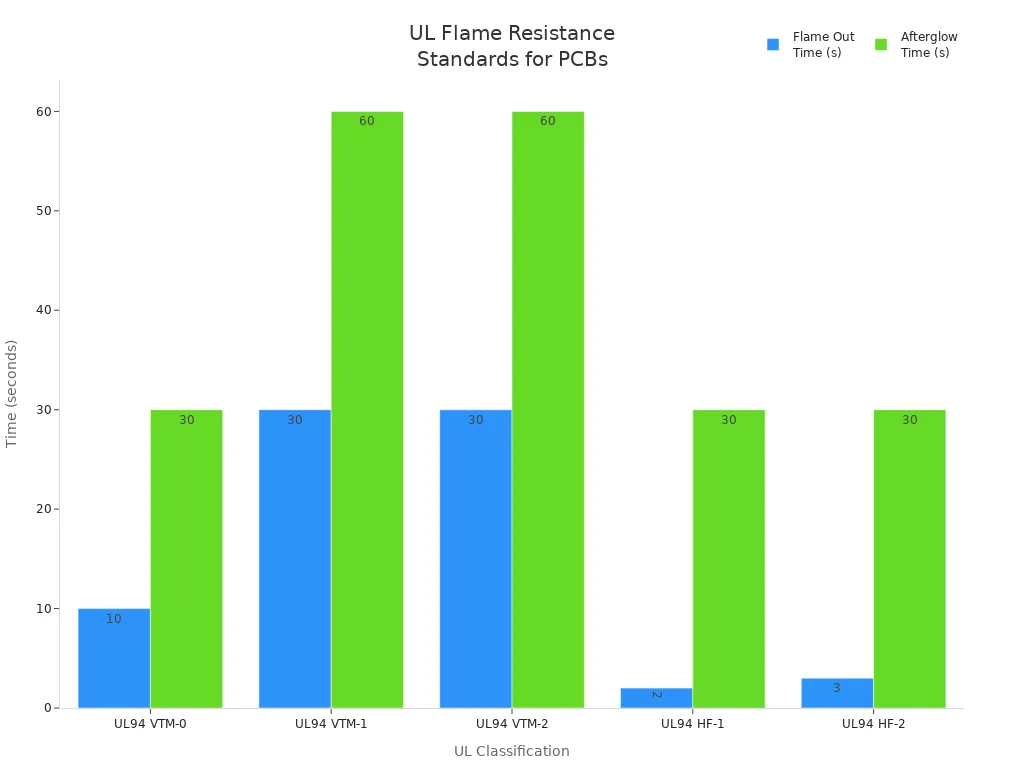

You want your electronics to stay safe even in tough conditions. UL certification for PCBs sets strict fire and flammability standards that protect you from hazards. UL uses tests like UL94 to measure how quickly materials stop burning and how long they glow after the flame goes out. These tests help you avoid risks like fire spreading inside your devices.

Here is a table that shows the main UL classifications for flammability in PCBs:

| Classification | Flame Out Time (s) | Afterglow Time (s) | Dripping Allowed |

|---|---|---|---|

| UL94 VTM-0 | ≤ 10 | ≤ 30 | No |

| UL94 VTM-1 | ≤ 30 | ≤ 60 | No |

| UL94 VTM-2 | ≤ 30 | ≤ 60 | Yes |

| UL94 HF-1 | ≤ 2 | ≤ 30 | No |

| UL94 HF-2 | ≤ 3 | ≤ 30 | Yes |

| UL94 HBF | ≤ 40 mm/min | N/A | N/A |

You see that UL certification helps you choose PCBs that meet safety and quality standards. These flammability ratings show how well your circuit boards resist fire and prevent dangerous situations. When you select products with UL certification, you lower the risk of fire damage in your electronics.

Electrical and Material Integrity

UL certification also protects you from electrical hazards. You need PCBs that can handle voltage and heat without failing. UL tests the electrical strength and material quality of every board. These tests make sure your devices work safely under stress.

The table below lists important UL standards for electrical and material integrity:

| Standard | Application |

|---|---|

| UL 796F | Covers electrical and thermal safety for flexible printed circuits (FPC). |

| UL 94 (V-0, VTM-0) | Fire safety standards for plastic materials, applicable to flexible materials under UL 94 VTM category. |

| UL Recognized | Materials must be certified for use in UL-marked devices. |

You benefit from these standards because they keep your electronics reliable. UL certification checks that the materials in your PCBs do not break down or cause short circuits. You get products that meet industry standards for safety and performance.

Ongoing Compliance

You want your devices to stay safe over time, not just when they leave the factory. UL requires regular audits and inspections to keep certification active. Manufacturers must follow strict rules and update their processes to maintain safety certification.

Here are some ways ongoing compliance helps you:

- You receive products that meet current safety rules.

- Manufacturers fix problems quickly if UL finds issues.

- Your electronics stay reliable for years.

Tip: Always look for the UL mark on PCBs and electronic devices. This mark means the product meets ongoing safety and quality standards.

UL certification for PCBs gives you peace of mind. You know your devices meet high safety standards and stay reliable through regular checks. This process protects you and helps manufacturers build trust in the market.

Key UL Standards for PCBs

UL 796 and UL 94

You need to understand two of the most important standards for PCBs. UL 796 covers the safety requirements for printed circuit boards. This standard checks how your PCBs perform under heat, moisture, and electrical stress. UL 94 focuses on the flammability of plastic materials. It tests how quickly a material burns and if it stops burning when the flame is removed. When you see a PCB that meets these standards, you know it has passed tough safety tests.

Note: UL 796 and UL 94 help you choose PCBs that resist fire and work safely in many environments.

UL 746E and Related Standards

UL 746E sets the rules for polymeric materials used in electrical equipment. This standard checks how materials react to heat, chemicals, and electrical stress. You want your PCBs to last a long time and stay safe. UL 746E makes sure the materials in your boards do not break down or cause failures. Other related standards, like UL 746C, test how materials handle UV light and weather. These standards protect your devices from damage over time.

- UL 746E: Tests for material strength and safety.

- UL 746C: Checks resistance to sunlight and weather.

Trace Spacing and HiPot Testing

Trace spacing is the distance between conductive paths on your PCB. UL sets minimum spacing rules to prevent short circuits and electrical arcing. HiPot testing checks if your board can handle high voltages without breaking down. You want your PCBs to pass these tests so your devices stay safe and reliable. Meeting these requirements shows that your boards follow industry standards and pass strict certification.

Tip: Always ask if your PCBs have passed HiPot testing and meet UL trace spacing rules. This step helps you avoid electrical hazards.

The UL Certification Process

Understanding how UL certification works helps you see why your PCBs are safe and reliable. The process includes several important steps. Each step ensures that only high-quality boards reach the market.

Preparation and Application

You start the process by gathering all the necessary documents. For serial production, you need technical documentation, standards, and sometimes a quality management system certificate. If you certify a single batch, you also include an operational manual and contract copies. You then submit your application to the certification body. This group reviews your documents and decides if your PCBs can move forward.

Tip: Preparing complete and accurate documents speeds up your certification.

Testing and Inspection

After approval, you work with the certification body to select an accredited lab. The lab tests your PCBs for electrical performance, fire resistance, and material quality. They also analyze your technical documents and may visit your production site. The lab checks if your boards meet all UL requirements. If your PCBs pass, the certification body reviews the results and makes a final decision.

Here is a simple list of what happens during this stage:

- Choose a lab for testing.

- Provide samples and documents.

- Complete all required tests.

- Wait for the lab to review and report results.

Authorization and Marking

When your PCBs pass all tests, you receive official authorization. The certification body issues a certificate and adds your product to the official register. You can now mark your boards with the UL symbol. This mark shows that your PCBs meet strict safety standards. The marking process uses a special photoemulsion and UV light to create a clear, lasting symbol.

Note: The UL mark makes it easy for inspectors and customers to verify your product’s certification.

The UL certification process gives you confidence in the safety and quality of your PCBs. Manufacturers benefit from clear steps and global recognition, but they must keep up with documentation and regular testing to maintain certification.

Benefits, Challenges, and Trends

Benefits for Manufacturers and Customers

You gain many advantages when you choose products with UL certification for PCBs. Manufacturers see their market position improve because customers trust their products more. UL certification confirms that PCBs meet strict safety standards. This trust helps manufacturers build a strong reputation and attract more buyers.

You also benefit as a customer. You know that the PCBs in your devices have passed tough tests for safety and reliability. The table below shows how UL certification helps you:

| Benefit | Description |

|---|---|

| Confidence in Quality and Safety | You can trust the quality and safety of the products you buy. |

| Demonstration of Manufacturer Competence | UL certification shows that manufacturers have the skills to make safe products. |

| Assurance of Durability and Reliability | You get products that last longer and work reliably. |

| Better Insurance Opportunities | Insurance companies may offer better terms for products with UL certification. |

Tip: When you see the UL listed or UL recognized mark, you know the manufacturer values safety and quality.

Compliance and Market Access

You want your products to reach more customers around the world. UL certification helps you do that. When your PCBs meet international safety and quality standards, you can sell them in many countries. You do not face barriers that stop you from entering new markets.

- UL certification confirms that your PCBs follow global safety rules.

- You can ship your products to more regions without extra testing.

- Customers in other countries trust your products because they see the UL mark.

Note: UL certification opens doors to international markets and helps you compete globally.

Challenges and Limitations

You may face some challenges when you work toward UL certification. The process focuses on product safety, so you must follow strict rules for materials and design. Sometimes, these rules limit your choices. You may need to use certain materials or avoid new technologies that do not meet UL standards yet. This can slow down innovation and make it harder to try new ideas.

You also spend time and money on extra testing and documentation. You must keep up with regular audits to maintain safety certification. These steps protect you and your customers, but they can make development slower.

Tip: Plan for extra time and resources when you design PCBs for UL certification. This helps you avoid delays and stay compliant.

Future Trends in UL Certification

You will see changes in UL certification as technology grows. New materials and advanced PCB designs appear every year. UL updates its standards to keep up with these changes. You may find more flexible rules for innovative products in the future. Digital tools and automated testing make the certification process faster and easier.

You should watch for new trends in PCB safety certification. Staying informed helps you use the latest technology and keep your products safe. UL continues to lead the way in setting safety standards for PCBs.

Tip: Follow updates from UL to learn about new standards and testing methods. This helps you stay ahead in the market and protect your customers.

You protect your devices and build trust when you choose PCBs with UL certification. This mark shows your electronics meet strict safety and reliability standards. Manufacturers use automated systems to track updates in UL standards. These systems:

- Monitor key parameters for each change

- Provide documentation for updates

- Include details on mechanical processing

You benefit from safer products and easier market access. Stay informed about UL trends to keep your technology reliable and up to date.

FAQ

What does the UL mark mean on a PCB?

You see the UL mark on a PCB when it meets strict safety and quality standards. This mark shows that the board passed tests for fire resistance and electrical safety.

How often do manufacturers need to renew UL certification?

You need to know that manufacturers must pass regular audits and inspections. These checks help keep the certification active and ensure ongoing safety for all products.

Can you use non-certified PCBs in electronic devices?

You can use non-certified PCBs, but you risk safety and reliability. Many industries require certified boards to meet legal and insurance requirements.

Does UL certification increase the cost of PCBs?

You may pay more for certified PCBs because of extra testing and documentation. This cost gives you better safety and market acceptance.

Is UL certification recognized worldwide?

You benefit from UL certification because many countries accept it as proof of safety. This recognition helps you sell products in global markets.