How to Select the Best PCB Builder for Your Projects

Choosing the right PCB builder plays a critical role in determining the success of your project. A skilled and reliable manufacturer ensures smooth execution, while a poor choice can derail timelines, inflate costs, and compromise quality. For instance:

- Projects with a first pass yield of 90% or higher are generally successful, with industries averaging 95%.

- Low first pass yields often lead to increased expenses and delays.

Additionally, over 60% of PCB designs face delays during tooling setup due to mismatched requirements. These challenges underline the importance of selecting the best PCB manufacturer for your needs. So, how do you make the right choice?

Key Takeaways

- Know what your project needs, like size and difficulty, to pick the right PCB maker.

- Check if the maker has the tools and skills to handle your project.

- Focus on quality by looking at their certifications and tests to avoid problems.

- Look for clear prices and on-time delivery to prevent surprises or delays.

- Use websites, events, and reviews to learn about and compare PCB makers.

Understanding Your Project Requirements

Complexity and scale of your project

The complexity and scale of your project determine the type of PCB manufacturer you should choose. Projects with higher complexity, such as multi-layer boards or intricate designs, require manufacturers with advanced technology capabilities. For example, first pass yield (FPY) metrics often drop when complexity increases, making it essential to select a builder with proven expertise in handling challenging designs. Similarly, the scale of production impacts your choice. High-volume production demands robust manufacturing capacity, while smaller batches may benefit from manufacturers specializing in prototyping.

To assess your project needs, consider factors like design flexibility, production volume, and the type of board required. Single-layer boards are simpler and cost-effective, while multi-layer boards offer greater functionality but require more sophisticated processes. Matching your project’s complexity and scale with the manufacturer’s capabilities ensures smoother production and higher success rates.

Design rules and technical requirements

Adhering to industry-standard design rules is critical for PCB manufacturing success. Minimum trace widths, proper trace spacing, and via design are essential elements that influence electrical integrity, signal reliability, and heat management. For instance, IPC-2221 guidelines provide benchmarks for trace widths and spacing based on current load and voltage levels. Manufacturers must also support advanced via designs, such as blind or buried vias, to accommodate complex interlayer connectivity.

When evaluating manufacturers, ensure they can meet your technical requirements without compromising quality. A builder with limited technology capabilities may restrict your design scope, leading to suboptimal performance. Collaborating with a manufacturer familiar with your design rules reduces the risk of errors and ensures compatibility with your specifications.

Budget and timeline considerations

Budget considerations play a pivotal role in PCB project planning. Allocating costs effectively requires balancing component quality with affordability. For instance, investing in higher-quality materials may reduce expenses in other areas, such as software development or testing. Manufacturers offering pricing transparency help you manage costs better by providing detailed breakdowns of tooling charges, per-board costs, and additional fees.

Timelines are equally important. Delayed lead times can disrupt your project schedule and increase costs. A good PCB design tool can help identify potential issues early, ensuring your design aligns with the manufacturer’s capabilities. Choosing a builder with reliable delivery schedules minimizes risks and keeps your project on track.

Understanding your project requirements—complexity, design rules, budget, and timelines—lays the foundation for selecting the best PCB builder. A thorough evaluation ensures your manufacturer aligns with your goals, reducing the likelihood of setbacks and maximizing project success.

Key Factors to Choose the Right PCB Manufacturer

Manufacturing capabilities

When selecting a PCB builder, manufacturing capabilities should be your top priority. A manufacturer’s ability to handle your project’s complexity and volume directly impacts the success of your PCB manufacturing service. Assess their production capacity, equipment, and technology to ensure they can meet your current needs and scale for future growth. For example, manufacturers investing in research and development often demonstrate their readiness to tackle emerging requirements and advanced designs.

| Evidence | Explanation |

|---|---|

| Assessing the manufacturer’s production capacity, equipment, and technology. | Crucial for handling project volume and complexity. |

| Manufacturers should have production capacity capable of meeting the project’s current needs and the potential for future growth. | Ensures they can handle projects of different scales and complexities. |

| A strong manufacturing partner will be transparent in their processes and timelines. | Essential for avoiding misunderstandings and ensuring projects run smoothly. |

| Look for manufacturers who are committed to investing in research and development. | Indicates capability to handle complex or emerging requirements. |

Measurable criteria also play a vital role in evaluating manufacturing capabilities. From material requirements to testing methods, these benchmarks ensure your PCB builder delivers a high-quality product.

| Category | Measurable Criteria |

|---|---|

| Materials | Requirements for laminate materials, copper foils, and other fabrication materials. |

| Design | Guidelines for PCB design, including layer stackup, trace width, and spacing. |

| Manufacturing | Requirements for processes like drilling, plating, and etching. |

| Testing | Test methods and acceptance criteria for performance. |

| Quality Assurance | Requirements for quality conformance and reliability assurance. |

| Dimensional | Tolerances for board thickness, hole size, and registration. |

| Electrical | Insulation resistance, dielectric withstanding voltage, and impedance control. |

| Mechanical | Flexural strength, peel strength, and thermal stress resistance. |

| Plating | Specifications for copper plating thickness and quality. |

| Solder Mask | Adhesion, thickness, and coverage specifications. |

| Visual Quality | Guidelines for acceptability based on visual inspection. |

| Imperfections | Acceptable levels of imperfections like scratches and dents. |

By choosing the right PCB manufacturer with robust capabilities, you ensure your project benefits from advanced technology, streamlined processes, and reliable delivery timelines.

Quality assurance and certifications

Quality assurance is the backbone of any successful PCB manufacturing service. Without stringent quality checks, your project risks design failures, operational issues, and invalidated certifications. A reliable PCB builder should adhere to industry standards and possess certifications that guarantee consistent quality.

| Certification/Metric | Description |

|---|---|

| ISO 9001 | A Quality Management System that ensures repeatable and reproducible processes. |

| ISO 13485 | A standard specifically for the medical device industry, ensuring quality in manufacturing. |

| UL 508A | Certification for industrial control panels, ensuring safety and reliability. |

| IPC Corporate Member | Membership indicating adherence to IPC standards in PCB manufacturing. |

| IPC-A-610 Certified IPC Trainer (CIT) | Certification for trainers in IPC-A-610 standards, ensuring quality in assembly processes. |

| Automated Solder Paste Inspection (SPI) | Technique using laser scanning to inspect solder paste quality before assembly. |

| Automated Optical Inspection (AOI) | System that checks component placement and solder joints against a standard reference board. |

| First Article Manual Inspection | A thorough check of the first assembled board against the bill of materials before production. |

Quality assurance also prevents common component issues such as cracked cases, broken leads, and counterfeit parts. These problems can lead to total PCB failure or intermittent operational issues. By choosing a manufacturer with robust quality metrics, you minimize risks and ensure your PCB design aligns with industry standards.

Tip: Always verify certifications and quality metrics before committing to a PCB builder. This step ensures you receive a high-quality product that meets your specifications.

Customer support and communication

Effective customer support is essential for reducing production delays and ensuring smooth collaboration. A PCB builder with strong communication channels helps you address issues promptly and keeps your project on track. Metrics like on-time delivery rates and customer satisfaction scores provide valuable insights into a manufacturer’s reliability.

| Metric | Description | Impact on Production Delays |

|---|---|---|

| On-Time Delivery Rate | Percentage of orders fulfilled by the promised date. | Improves customer satisfaction and operational efficiency. |

| Customer Satisfaction Score | Measures how products/services meet customer expectations. | Higher scores correlate with fewer production delays. |

| Industry Benchmark | Industry leaders maintain an on-time delivery rate of over 95%. | Sets a standard for operational efficiency in PCB manufacturing. |

A manufacturer offering turnkey solutions often excels in customer support. Turnkey services simplify the process by handling everything from design to production, ensuring ease of use and reducing the need for constant oversight. Look for builders who prioritize transparency, responsiveness, and proactive communication. These features enhance collaboration and help you achieve your project goals efficiently.

Note: Strong customer support is not just about resolving issues; it’s about building trust and ensuring your project’s success.

Pricing transparency and lead times

When selecting a PCB manufacturing service, understanding pricing transparency and lead times is crucial. These factors directly impact your project’s budget and schedule. A manufacturer that provides clear and detailed pricing ensures you can plan effectively without unexpected costs. Similarly, reliable lead times help you meet deadlines and avoid disruptions.

Why pricing transparency matters

Transparent pricing allows you to see exactly where your money goes. A trustworthy PCB builder breaks down costs into categories such as materials, tooling, assembly, and testing. This level of detail helps you identify areas where you can optimize expenses. For example, some manufacturers offer cost-saving options like bulk discounts or alternative materials without compromising quality.

Hidden fees can derail your budget. Always ask for a comprehensive quote that includes all potential charges. This includes setup fees, shipping costs, and any additional services like design reviews or expedited production. A manufacturer with clear pricing policies builds trust and reduces the risk of financial surprises.

Tip: Request a sample invoice or cost breakdown from potential manufacturers. This gives you a better understanding of their pricing structure and helps you compare options effectively.

The importance of lead times

Lead times determine how quickly your PCB manufacturing service can deliver finished products. Delays in production can cascade into missed deadlines for your entire project. Manufacturers with consistent lead times help you maintain a smooth workflow and meet your goals on schedule.

Evaluate a manufacturer’s lead time by considering their production capacity and process efficiency. High-capacity facilities with advanced equipment often handle large orders faster. Additionally, manufacturers offering turnkey solutions streamline the process by managing everything from design to assembly, reducing overall lead times.

Balancing cost and speed

While shorter lead times are desirable, they often come at a higher cost. Expedited services may include additional fees for priority handling or overtime labor. Balancing cost and speed requires careful planning. Determine whether your project can accommodate standard lead times or if faster delivery is worth the extra expense.

Some manufacturers offer flexible options to meet your needs. For instance, they may provide tiered pricing based on delivery speed. This allows you to choose a timeline that aligns with your budget and project requirements.

Questions to ask your manufacturer

To ensure you select the right PCB builder, ask the following questions about pricing and lead times:

- What is included in the quoted price?

- Are there any hidden fees or additional charges?

- What is the standard lead time for projects of my scale?

- Do you offer expedited services, and what are the associated costs?

- How do you handle delays or unforeseen issues during production?

These questions help you evaluate a manufacturer’s transparency and reliability. A builder that provides clear answers demonstrates professionalism and commitment to customer satisfaction.

By prioritizing pricing transparency and reliable lead times, you can avoid common pitfalls in PCB manufacturing. This approach ensures your project stays on budget and on schedule, setting the stage for success.

Researching the Best PCB Manufacturer

Online directories and forums

Online directories and forums provide a wealth of information when researching reputable makers. Platforms like PCB Directory or industry-specific forums allow you to compare manufacturers based on their capabilities, certifications, and customer feedback. These resources often include filters for criteria such as manufacturing volume, technology, and location, helping you narrow down your options efficiently.

Forums also offer valuable insights from industry professionals and peers who share their experiences with different manufacturers. Engaging in discussions can reveal hidden gems or caution you against unreliable providers. When exploring these platforms, focus on manufacturers with consistent positive feedback and active participation in the community.

Tip: Bookmark directories that offer free trials and demos. These features let you test a manufacturer’s services before committing to full production.

Trade shows and industry events

Trade shows and industry events are excellent opportunities for researching reputable makers. These gatherings showcase the latest advancements in PCB manufacturing and connect you with industry leaders. Events like PCB West or Electronica allow you to meet manufacturers face-to-face, evaluate their offerings, and discuss your project requirements directly.

At trade shows, manufacturers often display prototypes, demos, and samples of their work. This hands-on experience helps you assess their quality and compatibility with your needs. Additionally, attending seminars or workshops at these events can deepen your understanding of manufacturing trends and technologies.

Networking is another key benefit. Building relationships with manufacturers and other professionals can lead to exclusive deals, free trials, or valuable recommendations. Keep an eye out for exhibitors specializing in your project’s complexity or scale.

Reviews and testimonials

Reading customer reviews is one of the most reliable ways to evaluate the best PCB manufacturer for your needs. Reviews provide firsthand accounts of customer experiences, offering insights into product quality, delivery timelines, and customer support.

- Review Volume: A higher number of reviews with a solid average rating indicates a consensus among customers, enhancing trustworthiness.

- Recency of Reviews: Recent feedback reflects current product quality and company performance, making it more relevant.

- Verified Purchase Indicator: Reviews marked as from verified purchases ensure that feedback comes from actual customers, increasing credibility.

Testimonials often highlight specific strengths, such as a manufacturer’s ability to meet tight deadlines or deliver high-quality prototypes. Look for patterns in feedback to identify consistent strengths or weaknesses. Combining reviews with other research methods ensures a well-rounded evaluation of potential manufacturers.

Note: Prioritize manufacturers with transparent communication and a history of positive reviews. This approach minimizes risks and increases the likelihood of project success.

Evaluating PCB Manufacturing Service Through Prototypes

Testing samples for quality

Testing prototypes is a critical step in evaluating a pcb manufacturing service. Prototypes allow you to assess the quality of the final product before committing to full-scale production. By examining these samples, you can identify potential flaws, ensure compliance with your requirements, and avoid costly mistakes later.

Start by inspecting the physical attributes of the prototype. Check for issues like uneven solder joints, misaligned components, or visible defects on the board. These problems often indicate poor manufacturing practices. Use tools like magnifiers or automated optical inspection systems to perform a thorough visual check. A high-quality prototype should exhibit clean traces, precise drilling, and consistent solder mask application.

Next, evaluate the electrical performance of the prototype. Conduct functional tests to verify that the board operates as intended. For instance, measure signal integrity, impedance, and power distribution to ensure the design meets your specifications. Testing under different conditions, such as varying temperatures or loads, can reveal hidden vulnerabilities.

You should also assess the durability of the prototype. Subject the board to stress tests, such as thermal cycling or vibration testing, to determine its reliability. These tests simulate real-world conditions and help you gauge the board’s lifespan. A reliable pcb manufacturing service will provide prototypes that withstand these challenges without compromising performance.

Tip: Always request multiple prototypes to account for variability in the manufacturing process. Comparing several samples gives you a clearer picture of the manufacturer’s consistency and quality standards.

Compatibility with design specifications

Ensuring compatibility with your design specifications is another essential aspect of evaluating a pcb manufacturing service. A prototype must align with the parameters outlined in your pcb design software. Any deviation can lead to functional issues or production delays.

Begin by cross-referencing the prototype with your design files. Verify that the dimensions, layer stack-up, and trace layouts match your original specifications. Use your pcb design software to generate a Gerber file and compare it against the manufactured prototype. This step helps you identify discrepancies early.

Check the prototype’s adherence to industry standards. For example, ensure the board complies with IPC guidelines for trace width, spacing, and via design. A manufacturer that consistently meets these standards demonstrates a commitment to quality and precision.

You should also test the prototype’s compatibility with your components. Assemble the board using the intended parts and verify that everything fits correctly. Issues like misaligned footprints or incorrect hole sizes can disrupt your production process. A reliable pcb manufacturing service will produce prototypes that integrate seamlessly with your components.

Finally, evaluate the prototype’s scalability for mass production. A design that works well in small batches may encounter challenges when scaled up. Discuss with the manufacturer how they plan to maintain consistency and quality during full-scale production. This conversation ensures that the prototype’s performance translates to the final product.

Note: Collaborating closely with your manufacturer during the prototyping phase can help you address compatibility issues early. Open communication ensures that your design aligns with their manufacturing capabilities.

Making the Final Decision

Comparing shortlisted builders

When narrowing down your options, comparing shortlisted PCB builders requires a structured approach. Start by evaluating key metrics such as cost-effectiveness, quality, reliability, and specializations. The table below provides an example of how you can organize this comparison:

| Manufacturer | Cost-Effectiveness | Quality | Reliability | Specializations |

|---|---|---|---|---|

| AllPCB | Competitive deals on specific board types. | Good for standard FR-4 boards; may vary with complexity. | Reliable with decent turnaround times and strong communication. | Wide range of services, including flex PCBs and assembly. |

| Elecrow | Low prices for small quantities; higher for complex boards. | Acceptable for prototypes; quality checks recommended. | Dependable but occasional delays reported. | Educational market and small batch production. |

| Seeed Studio Fusion | Competitive for small orders; good for rapid prototyping. | Good for standard designs; complex designs need attention. | Dependable with fast turnaround and good support. | Rapid prototypes and assembly services. |

| Aisler | Competitive pricing in Europe. | High precision and adherence to standards. | Highly reliable with consistent output. | Streamlined production for minimal hassle. |

This method allows you to visualize trade-offs and identify the builder that aligns with your project’s priorities.

Weighing pros and cons

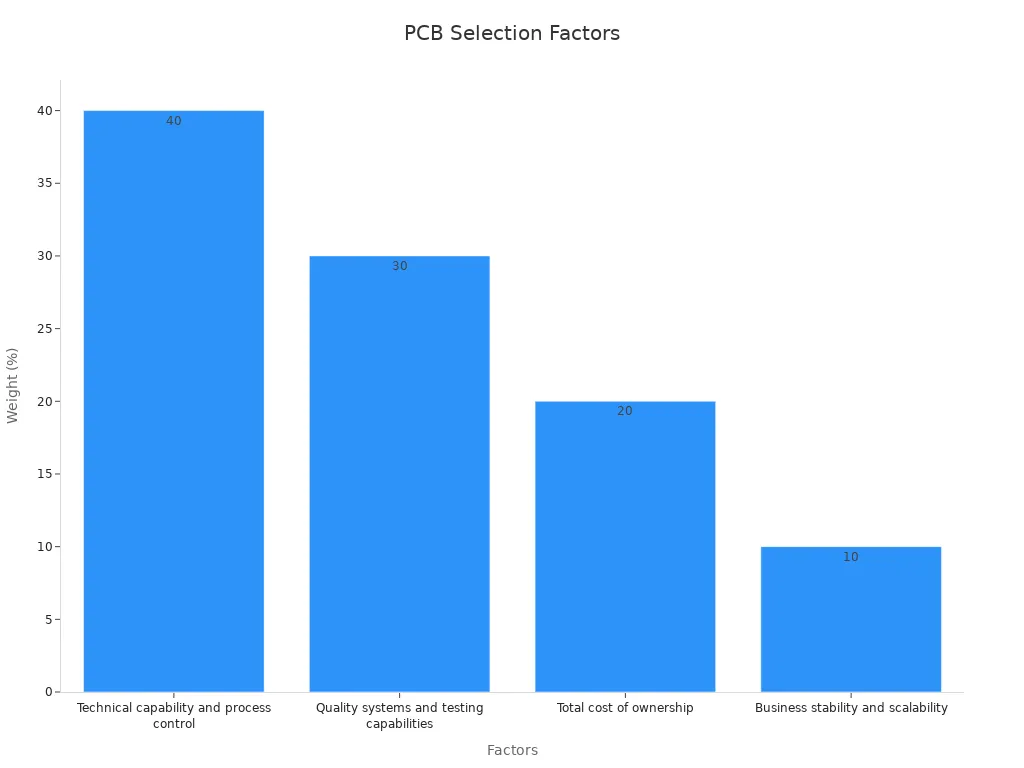

Weighing the pros and cons of each PCB builder ensures you make an informed decision. Consider factors like technical capabilities, quality assurance, and cost structure. For instance:

- Technical Capabilities: Does the builder handle complex designs, such as multi-layer boards or advanced via technologies?

- Quality Assurance: Are certifications like ISO 9001 or IPC standards in place?

- Cost Structure: Are there hidden fees, or is pricing transparent?

Additionally, assess their ability to meet your timeline and scale production. A builder with strong process control and testing capabilities often delivers consistent results. The chart below highlights the weight of various factors in successful PCB manufacturing decisions:

Selecting the builder that fits your needs

Selecting a PCB maker that fits your needs involves aligning their strengths with your project goals. Define your priorities—whether it’s cost, quality, or speed—and choose a builder that excels in those areas. For example, if rapid prototyping is critical, a manufacturer like Seeed Studio Fusion might be ideal.

Ask yourself these questions before finalizing your choice:

- Does the builder’s technology roadmap align with future product needs?

- Can they maintain quality and consistency during mass production?

- How responsive are they to technical queries or design changes?

Working with your maker should feel seamless. A reliable partner will communicate proactively, address concerns promptly, and adapt to your evolving requirements. By following this systematic approach, you can confidently select the best PCB builder for your project.

Selecting the right PCB builder begins with a clear understanding of your project’s requirements. By evaluating factors like complexity, budget, and timeline, you can align your needs with a manufacturer’s capabilities. A systematic approach reduces risks significantly. For example, implementing Failure Mode and Effects Analysis (FMEA) can lower the Lot Reject Rate (LRR) from 5,500 to 900 parts per million, an improvement of over 83%.

| Metric | Before FMEA (PPM) | After FMEA (PPM) | Improvement (%) |

|---|---|---|---|

| Lot Reject Rate (LRR) | 5500 | 900 | 83.64 |

Prototype testing further ensures success by validating designs and identifying flaws early. This step improves production outcomes and minimizes errors. Prototypes also allow for functionality testing, risk mitigation, and process validation, ensuring your final product meets high standards.

| Role of Prototypes | Description |

|---|---|

| Design Validation | Validates design production documentation before large scale production. |

| Risk Mitigation | Tests risky design concepts early in the design flow. |

| Functionality Testing | Confirms the design functions as intended before mass production. |

Finally, rely on reviews to assess a builder’s reliability and quality. Consistent positive feedback highlights manufacturers who prioritize customer satisfaction and deliver exceptional results. By combining thorough research, prototype testing, and systematic evaluation, you can confidently select a PCB builder that aligns with your goals.

FAQ

What certifications should a reliable PCB manufacturer have?

Look for certifications like ISO 9001 for quality management, IPC-A-610 for assembly standards, and UL for safety compliance. These ensure the manufacturer follows industry best practices and delivers high-quality products.

How can I verify a manufacturer’s quality assurance process?

Request details about their testing methods, such as Automated Optical Inspection (AOI) or functional testing. You can also ask for quality metrics, like defect rates, and review customer testimonials for insights into their reliability.

Is it necessary to test prototypes before full production?

Yes, testing prototypes helps identify design flaws and ensures compatibility with your specifications. This step minimizes risks, saves costs, and guarantees the final product meets your expectations.

How do I ensure transparent pricing from a PCB builder?

Ask for a detailed cost breakdown, including materials, tooling, and additional fees. Clarify if there are hidden charges. Comparing quotes from multiple manufacturers can also help you identify fair pricing.

What should I prioritize when selecting a PCB manufacturer?

Focus on their manufacturing capabilities, quality assurance, and lead times. Ensure they align with your project’s complexity, budget, and timeline. Strong customer support and clear communication are also critical for a successful partnership.