You use smt assembly to make small and reliable devices. Surface mount technology helps factories work faster. It also lowers the need for workers. With smt, designs can be tiny. Solder joints are strong. You also save money. Many countries use smt assembly in different ways:

| Country | Adoption Rate | Key Factors Influencing Adoption |

|---|---|---|

| China | High | Big manufacturing industry, help from government, more demand |

| Australia | Moderate | Focus on high-tech factories, rewards from government |

| Japan | Moderate | Good technology, focus on new ideas |

| South Korea | Moderate | Strong electronics business, new technology |

| Vietnam | Emerging | Cheap labor, money from other countries, more factories |

You think smt is very important for modern electronics. It helps make things fast, easy to grow, and advanced.

Key Takeaways

- SMT assembly helps make devices smaller and lighter. It uses tiny parts. This is important for modern electronics like smartphones and wearables.

- Automated SMT production makes manufacturing faster. It lowers labor costs. It also reduces mistakes. This helps companies save money.

- Using SMT makes electrical performance better. It lowers noise and boosts signal strength. This is very important for high-speed devices.

- SMT assembly helps with rapid prototyping. It lets people test and change things quickly. This saves time and cuts costs in product development.

- The technology works well with new trends like IoT. It helps create new, energy-saving products. These products meet what the market wants.

SMT Assembly and Miniaturization

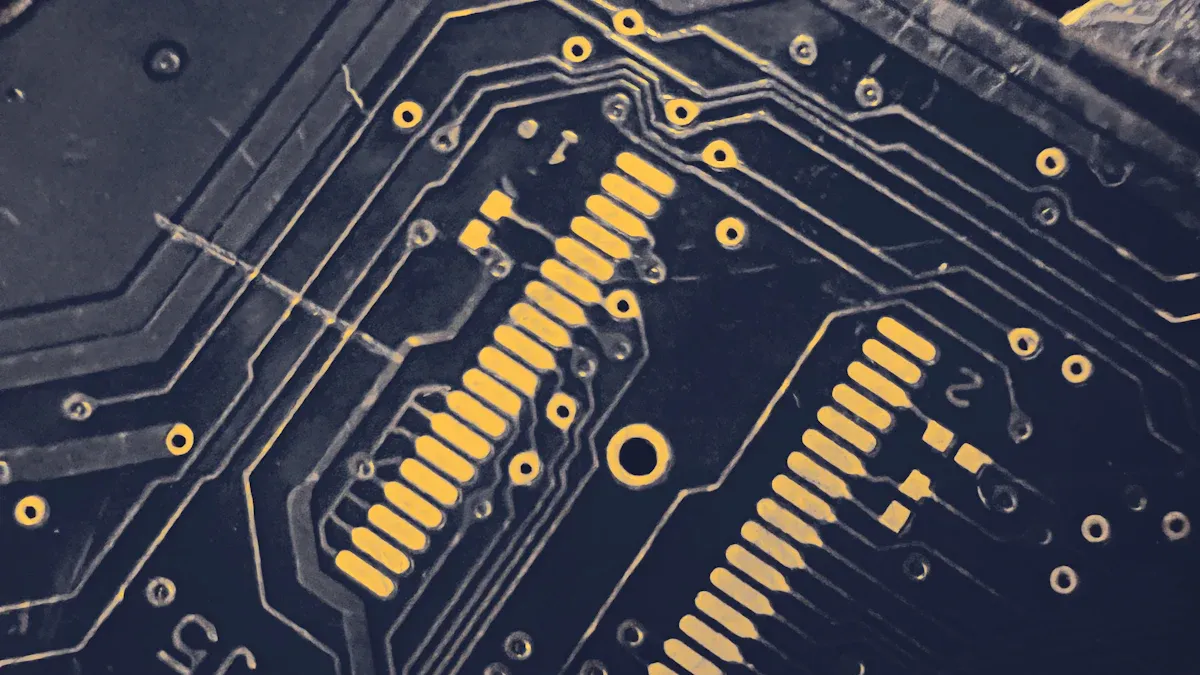

Compact PCB Layouts

smt assembly changes how you make electronic devices. You use much smaller parts than before. These small parts let you add more features in less space. You can put parts on both sides of the board. This gives you more room to work with. It helps you build small things like smartphones and wearables. These devices have many features in a tiny size.

- smt parts are often ten times smaller than old parts.

- You can use both sides of a pcb assembly for parts.

- Miniaturisation and saving space help you make slim, light electronics.

With smt assembly, you do not need to drill holes for every part. This saves time and lets you make tighter layouts. Over 90% of new boards use smt because it helps with high-density designs. smt clips, which are less than 2 mm, help you fit even more parts on a board.

Maximizing Space Efficiency

You want your devices to do more but not get bigger. smt assembly helps you by letting you put more parts in a small area. You can make more complex circuits and add new features. The device does not have to be larger.

Tip: smt helps you use every bit of your board. This is important for handheld devices.

Here is how using smt for space efficiency helps your device:

| Aspect | Impact on Functionality |

|---|---|

| Higher Component Density | Lets you make complex circuits and smaller devices. |

| Improved Performance | Makes signals better and cuts down on interference. |

| Cost Efficiency | Helps make electronic devices more reliable. |

Automated assembly makes building faster and more accurate. smt lets you make tight layouts. You can fit more circuits in the same space. This means better performance and more reliable products.

Using smt assembly supports the trend of miniaturisation and saving space. You can make devices that are smaller, lighter, and stronger than before.

Surface Mount Technology for Performance and Reliability

Enhanced Electrical Performance

You want your devices to be fast and clear. smt assembly helps you do this. smt uses short leads and small parts. These things help stop noise and make signals stronger. You lose less signal and control signals better on your pcb assembly. This matters for devices that must work at high speeds.

Note: Short leads in smt parts mean less noise. Your devices can handle fast signals and do well in high-frequency jobs.

Here is a table that shows how smt assembly helps speed and performance in high-frequency circuits:

| Feature | Impact on Performance |

|---|---|

| Shorter Electrical Paths | Less signal noise, works with higher frequencies |

| Smaller Component Size | Less delay, faster working |

| Reduced Inductance and Capacitance | Less signal change, better for RF circuits |

You see smt in things like smartphones and computers. It is also in communication systems. These need great electrical performance. smt assembly keeps signals clean and fast. You can trust your devices to work well, even when they handle lots of data.

Consistent Quality and Durability

You want every device to work the same way. smt assembly uses machines to put parts in the right place. These machines check their work as they go. Automated Optical Inspection (AOI) systems scan many parts each minute. They find mistakes before they get worse. This means you get fewer problems and more reliable products.

Tip: Automated systems in smt assembly help keep quality high, even when you make many devices at once.

Here is a table that compares reliability in tough places:

| Aspect | Through Hole Assembly | smt Assembly |

|---|---|---|

| Mechanical Stress Resistance | Handles pulling and bending well | Best for devices that do not move much |

| Environmental Durability | Works in very hard conditions | Needs coatings for tough places |

| Long-Term Reliability | Easy to fix and lasts longer | Harder to fix, good for items you throw away |

You get better reliability and strength with smt when you use it for the right things. For most electronics, smt assembly gives you strong solder joints and steady work. Automated checks make sure each device meets your needs. You can count on smt to give you quality every time.

Cost-Effectiveness and Manufacturing Efficiency

Automated Production Benefits

You want to make electronics fast and save money. SMT assembly helps you do this. Machines put parts on your pcb assembly quickly and accurately. These machines do the same job over and over. You need fewer workers. You spend less on labor and make fewer mistakes. SMT lines finish boards much faster than people can. Some machines can place 100,000 parts every hour. This speed lets you make more devices in less time.

Tip: Automated SMT systems help you make more products without hiring extra workers.

SMT assembly helps you use materials better. You waste less because machines put parts in the right spot. Here are ways SMT helps you waste less:

- Good panelization uses 10-20% more material.

- Smart scrap management saves money, especially with costly metals.

- The process helps you do more with less, so you spend less and waste less.

You save a lot when you use SMT assembly instead of old ways. Look at the table below to see the cost difference:

| Production Volume | SMT Cost per Board | Through-Hole Cost per Board | Savings per Unit |

|---|---|---|---|

| 500 units | $1.50 | $2.00 | $0.50 |

| 10,000 units | $0.80 | $1.50 | $0.70 |

You save more money as you make more boards. SMT assembly gives you good value and helps you work better for every project.

Scalable for Prototypes and Mass Production

You need to test ideas and then make thousands of devices. SMT makes this easy. You can build prototypes in just a few days. Fast prototyping helps you find problems early and fix them before you make lots of devices. This saves time and money. When you start making many products, SMT lines keep up with your needs. Machines put parts quickly and correctly, so your products work well every time.

Here is a table showing how SMT helps you go from testing to making many products:

| Evidence Description | Key Benefit |

|---|---|

| Rapid prototype SMT assembly helps teams test and improve ideas in days, not weeks. | Makes products ready faster. |

| Rapid prototype SMT assembly gives working PCBs in just 24 hours, so you can test designs early. | Lets you check designs sooner. |

| Early prototyping finds problems in design or parts before you make lots of products—saving up to 40% in fixing costs. | Cuts risks and costs for fixing mistakes. |

| Automated pick-and-place machines can put 100,000 parts every hour, so you make products quickly. | Makes mass production faster. |

You can go from one test product to thousands of finished items without changing your process. SMT assembly works for small and big projects. You get speed, good quality, and save money at every step.

Design Flexibility and Future Innovation

Supporting Advanced Electronic Designs

You want to make new products that are small and strong. smt lets you design devices that fit these needs. You can put more parts in a tiny space. This helps you add features without making things bigger. You can use this for many types of products, like smartwatches or medical tools.

Here is a table that shows how smt assembly helps you design better products:

| Advantage | Explanation |

|---|---|

| Higher Component Density | Lets you make smaller and lighter products with more features. |

| Smaller and Lighter Assemblies | Helps you build compact devices, which is good for things you carry. |

| Improved Automation Potential | Means less hand work, faster building, and fewer mistakes. |

| Higher Reliability and Longevity | Makes strong connections, so your products last longer and work better. |

You see smt in lots of places. It is in smartphones, laptops, and game consoles. It is also used in cars, hospital tools, and factory robots. The table below shows some examples:

| Industry | Example Applications |

|---|---|

| Consumer Electronics | Smartphones, laptops, gaming consoles, smartwatches |

| Automotive | Engine control, infotainment, safety systems, autonomous driving features |

| Medical Devices | Pacemakers, hearing aids, imaging systems, diagnostic tools |

| Industrial Equipment | Robotics, manufacturing equipment, high-speed processing, real-time data handling |

Adapting to Emerging Technologies

You need to keep up with new things like IoT and wearables. smt helps you make small, energy-saving products. You can go from an idea to a finished product quickly. This is important if you want to be first to sell new things.

- You can mix electrical and mechanical design early, so you finish faster.

- Small, powerful assemblies help you get your product ready and make it last.

- More connected devices are being made every year. smt helps by making tiny, smart products for IoT and wearables.

- smt lets you build small, low-power things like smart sensors and monitors.

New smt machines, like fast pick-and-place and AI inspection, make your job easier. These tools help you keep up with new ideas in electronics. You can make good products faster and waste less. This lets you focus on inventing the next cool thing.

You can see how smt assembly changes electronics. It helps you make devices smaller and faster. Your products also become more reliable. You use tiny parts to add more features to each device.

- You fit more parts on the board for better results.

- You finish your work faster and spend less money.

| Benefit | Impact |

|---|---|

| Faster Production | Make more devices quickly |

| Lower Costs | Spend less on parts and workers |

| Room for Innovation | Create smart, new products |

smt assembly helps you build the next big thing in electronics.

FAQ

What does SMT stand for in electronics?

SMT stands for Surface Mount Technology. You use this method to place electronic parts directly onto the surface of a printed circuit board (PCB).

Why should you choose SMT over through-hole assembly?

You should choose SMT because it lets you make smaller, lighter, and more reliable devices. SMT also helps you build products faster and save money.

Can you repair SMT boards if something breaks?

Yes, you can repair SMT boards. You use special tools like hot air guns or tweezers to remove and replace small parts. Many repair shops offer this service.

Is SMT assembly good for making prototypes?

Yes, SMT assembly works well for prototypes. You can test your ideas quickly. Automated machines help you build and change designs fast.