You can see a big change when you look at an aluminum pcb and a regular printed circuit board. The metal base in an aluminum pcb moves heat away from parts much faster than the fiberglass in normal printed circuit boards. This special design, which often has four layers, helps you use high-power things without getting too hot. Picking the best material makes the board work better and last longer.

The market for aluminum pcbs is growing quickly. Experts think it will grow by 8-10% each year for the next five years. This is because of new technology and more use in electric cars and smart lights.

| Growth Rate | Time Frame | Key Drivers |

|---|---|---|

| 8-10% | Next 5 years | Technological advancements, application diversity |

Key Takeaways

- Aluminum PCBs spread heat better. This helps devices stay cool and last longer.

- Aluminum PCBs have four layers. This helps them handle heat better than fiberglass boards.

- Aluminum PCBs help high-power devices work better. They are great for things like LED lights and car electronics.

- Aluminum PCBs are stronger and handle heat stress well. This means you do not need to replace them as often, so there is less waste.

- Picking the right aluminum PCB for your project is important. It can make your devices work better and be more reliable.

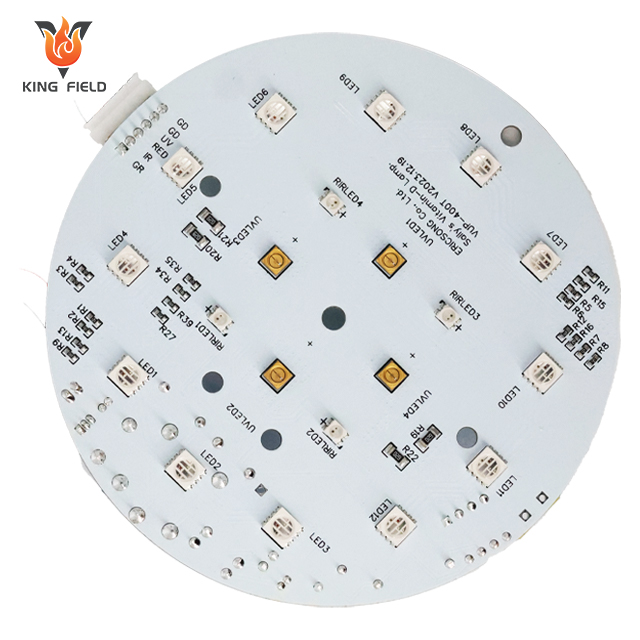

Aluminum PCB Structure

Four-Layer Design

An aluminum pcb has a special four-layer setup. This makes it different from regular printed circuit boards. Each layer helps move heat away from the parts. The table below shows what each layer does for heat control:

| Layer Type | Description | Thermal Conductivity (W/mK) |

|---|---|---|

| Circuit Layer | Copper layer that spreads heat quickly. | 386 |

| Dielectric Layer | Insulates electrically but lets heat pass through. | 0.25 |

| Metal Base Layer | Aluminum core that pulls heat away from the board. | 180 |

This design keeps your devices cool, even with lots of power. Regular printed circuit boards use fiberglass. Fiberglass does not move heat as well. Aluminum pcbs give you much better heat control.

Copper Foil and Dielectric Layer

Aluminum pcbs usually have thicker copper foil than regular boards. Thicker copper lets you carry more current and spread heat better. The dielectric layer sits between the copper and the aluminum base. It stops electricity from jumping between layers. It still lets heat move down to the metal base. This layer is very important for heat control. Picking the right dielectric material helps both heat and electricity flow better in your board.

- The dielectric layer:

- Stops electricity from moving from copper to the metal base.

- Moves heat from hot parts to the aluminum layer.

- Helps the board last longer by handling heat stress.

Aluminum Base and Additional Layer

The aluminum base is the main part of the board. It makes the board strong and acts like a built-in heat sink. This base pulls heat away from the circuit layer faster than fiberglass. Your board stays cooler and works better in places with lots of heat or power. New aluminum alloys and better ways to make boards make them even stronger and more useful. Additive solder mask technology also helps. It makes the process faster and cuts down on waste.

Tip: If you need a printed circuit board for high-power LEDs or power supplies, an aluminum pcb will give you the best thermal results.

Aluminum PCBs vs. Traditional PCBs

Material Comparison

There are big differences between aluminum pcbs and regular boards. Aluminum pcbs have a metal base. Regular boards use fiberglass called FR4. The material changes how the board deals with heat and strength. It also affects how reliable the board is.

| Property | Aluminum PCBs | FR4 PCBs |

|---|---|---|

| Thermal Conductivity | Superior, allows efficient heat dissipation | Lower, not suitable for high heat applications |

| Coefficient of Thermal Expansion | Closer to copper, reduces reliability issues | Higher, prone to thermal expansion issues |

| Mechanical Strength | Greater rigidity and durability | Good strength, but less than aluminum |

Aluminum pcbs control heat better and are stronger. You get fewer cracks and less expansion. Your devices last longer and work better in tough places.

Electrical and Thermal Performance

Aluminum pcbs work well with electricity and heat. You can use them in high-power devices. They move heat away from parts faster than regular boards. The aluminum base helps heat leave the board quickly.

- FR4 has thermal conductivity from 0.1W/mK to 0.5W/mK.

- Aluminum pcbs have much higher thermal conductivity because of the metal base and special dielectric layer.

You can run more current through aluminum pcbs. They do not get too hot. You can make smaller designs or use more power in the same space. Power handling is better, which helps with LED lights and power supplies.

Note: Aluminum pcbs keep parts at safe temperatures. This helps your devices last longer and work better.

Aluminum pcbs also help signals stay strong. They have a dielectric constant of about 3.7 and a low loss tangent of 0.001. Regular boards have higher numbers, so they lose more signal.

Mechanical Properties

Aluminum pcbs make boards stronger. The metal base gives more rigidity and better structure. They are good for big boards or devices that get bumped.

| Property | Aluminum PCB | Traditional FR4 PCB |

|---|---|---|

| Thermal Conductivity | About 600 times higher than FR4 | Low thermal conductivity |

| Structural Integrity | Enhanced, suitable for larger sizes | Limited structural integrity |

| Flexibility | Rigid, less flexible | Greater flexibility |

| Cost | Higher cost | Lower cost |

| Environmental Adaptability | More adaptable to harsh conditions | Performance decreases in high humidity |

Aluminum pcbs are not as bendy as regular boards. If you need a board that bends, FR4 is better. If you want strong and tough boards, aluminum pcbs are best. They also work well in hot or wet places.

Cost and Environmental Impact

Aluminum pcbs can cost more for small orders. If you buy a lot, the price goes down. For big orders, the cost can be less than $1 per square inch. Size, thickness, and extra features change the price.

- Aluminum core pcbs cost less than copper core boards because aluminum is cheaper.

- Making aluminum pcbs costs more than FR4 boards because of extra steps with metal.

- For big production, aluminum pcbs can save money over time.

Aluminum pcbs help the environment. They last longer and handle heat better, so you replace them less. This means less waste. They work well in high-power devices, which helps save energy.

Tip: If you want a board that lasts longer and handles heat well, aluminum pcbs are a smart choice for your budget and the planet.

Types and Applications of Aluminum Backed PCB

Single-Sided and Multilayer Aluminum PCBs

There are different kinds of aluminum pcbs for your project. The most popular types are single-sided and multilayer boards. Each type works best for certain jobs.

| Type | Key Features | Applications |

|---|---|---|

| Single-sided | Metal core on one side, excellent thermal conductivity, high mechanical strength, low cost | LED lighting, power supplies, motor control |

| Multilayer | Multiple layers of metal core and copper, high component density, excellent thermal management | Complex circuits, space-limited, high-power reliability |

Single-sided aluminum backed pcb is good for simple devices. You see these in LED lights and basic power supplies. Multilayer aluminum core pcb is used for advanced systems. These boards are found in medical electronics, aerospace, and car controls. Multilayer boards help with fast signals and stop electromagnetic interference.

Tip: If your device is complex or needs lots of power, multilayer aluminum backed pcb is stronger and works better.

Advantages in High-Power Use

Aluminum core pcb is great for high-power electronics. These boards give you many important benefits:

| Advantage | Description |

|---|---|

| Superior thermal management | Aluminum core spreads and removes heat quickly, so parts do not overheat. |

| Increased mechanical stability | Rigid base resists vibration and temperature swings better than FR-4. |

| Longer lifespan | Less thermal stress means your components last longer. |

Aluminum core pcb can remove heat up to 10 times better than fiberglass boards. This helps your devices stay cool and work well. In cars, aluminum backed pcb keeps transistor and diode temperatures low. This makes them work 5-8% better. The special thermal layer protects sensitive parts and keeps everything safe.

Common Industries and Products

Aluminum backed pcb is used in many industries. These boards help products last longer and work well under tough conditions.

| Industry | Products |

|---|---|

| Automotive | Motor controllers, automotive electronics |

| Power Converters | Power supplies |

| RF Applications | RF circuits |

| General | LEDs, lighting systems |

In renewable energy, like solar inverters and wind turbines, aluminum core pcb helps manage heat and save energy. The high thermal conductivity lets you make smaller and stronger devices. Aluminum pcb manufacturing uses new methods to meet these needs. You also find aluminum pcb manufacturing in LED bulbs and motors, where heat control is very important.

Note: Picking the right aluminum pcb type helps your electronics last longer and work better.

You can easily spot how aluminum PCBs are different from regular printed circuit boards. Aluminum PCBs have a metal base. This helps heat move away from parts faster. Your devices stay cooler and work better. They are stronger and last longer.

- Aluminum PCBs help keep electronics cool in hot projects.

- They are light, tough, and save money. They also handle heat well.

| Advantage | Description |

|---|---|

| Heat Dissipation | Great at controlling heat for hard jobs. |

| Lightweight Solution | Simple to carry and put in place. |

| Durable Choice | Handles heat and bumps without breaking. |

You should pick aluminum PCBs if you want good heat control and strong boards for your next project.

FAQ

What makes aluminum PCBs better for heat management?

You get better heat control with aluminum PCBs. The metal base pulls heat away from parts fast. This keeps your devices cool and helps them last longer.

Can you use aluminum PCBs for flexible circuits?

No, you cannot bend aluminum PCBs easily. The metal base makes them strong but not flexible. If you need a bendy board, choose a flexible PCB made from other materials.

Are aluminum PCBs safe for high-power devices?

Yes, you can use aluminum PCBs in high-power devices. They handle more current and heat than regular boards. This makes them perfect for LED lights and power supplies.

Do aluminum PCBs cost more than regular PCBs?

Aluminum PCBs can cost more for small orders. If you buy in bulk, the price drops. You save money over time because they last longer and need fewer replacements.

How do you pick the right aluminum PCB for your project?

Tip: List your needs first. Think about power, size, and heat. Talk to your PCB maker. They can help you choose the best type for your device.