King Field completed the manufacturing and assembly of 50,000 pcs of Mercedes-Benz automotive converter PCB in 15 days.

King Field’s accomplishment in manufacturing and assembly sets a new benchmark in the automotive industry. You witness the sheer scale of their achievement as they deliver 50,000 Mercedes-Benz converter PCBs in just 15 days. This feat showcases unmatched efficiency and precision, qualities that are essential in automotive components manufacturing. Meeting Mercedes-Benz’s rigorous standards highlights King Field’s commitment to excellence. Their success not only advances manufacturing processes but also redefines expectations in the automotive industry.

Key Takeaways

- King Field made 50,000 Mercedes-Benz converter PCBs in 15 days. This shows they work fast and carefully in car part making.

- They used strict quality checks, like first inspections, to find mistakes early. This helped them keep their work at a high level.

- Using smart machines and better plans helped King Field work faster. They avoided delays and made more parts in less time.

- Over 80% of their work met IPC3 rules, proving their parts are top quality and follow strict industry rules.

- King Field’s success is now a new goal for car makers. It inspires others to use new ideas and focus on making better products.

Mercedes-Benz Converter PCB Mass Production Red Emergency Call

King Field Challenge PCB Contract Manufacturing within 15 days

You might wonder how King Field managed to meet the tight deadline of 15 days for this large-scale project. The challenge was immense. Manufacturing 50,000 automotive converter PCBs required precise planning and flawless execution. King Field approached this task with a clear strategy. They optimized every step of the component manufacturing process to ensure efficiency. By leveraging advanced technology and streamlined workflows, they minimized delays and maximized output.

Their ability to adapt to the high standards of automotive production played a crucial role. Every PCB had to meet Mercedes-Benz’s stringent requirements. King Field’s expertise in component manufacturing ensured that the project stayed on track without compromising quality. This achievement highlights their commitment to delivering excellence under pressure.

Complete 50,000 pcs converter PCB assembly within 7 days

The assembly phase was even more demanding. Completing 50,000 PCBs in just seven days required exceptional coordination. King Field utilized their state-of-the-art production facilities to achieve this feat. Their team worked tirelessly, ensuring that every part of the assembly process adhered to strict quality standards.

To maintain consistency, they implemented rigorous quality checks at every stage. This approach ensured that each PCB met the specifications required for automotive applications. The speed and precision of their assembly process set a new benchmark in the industry. You can see how their dedication to excellence redefines what’s possible in component manufacturing.

The proportion of IPC3 must exceed 80%

Meeting the IPC3 standard was another critical aspect of this project. IPC3 represents the highest level of quality in PCB manufacturing. King Field ensured that over 80% of the PCBs met this standard. Achieving this required meticulous attention to detail and advanced testing methods.

Their team conducted regular inspections to identify and address any issues early in the process. This proactive approach ensured that the final products met the rigorous demands of automotive component manufacturing. By exceeding the IPC3 requirement, King Field demonstrated their commitment to delivering top-tier parts for Mercedes-Benz.

What challenges did we face to complete mass production within 15 days?

Completing the mass production of 50,000 Mercedes-Benz converter PCBs in just 15 days was no small feat. You might wonder how King Field overcame the hurdles that arose during this ambitious project. Each stage of the process presented unique challenges, requiring meticulous planning and execution to ensure success.

First Article Inspection – Nip mistakes in the bud.

The first article inspection (FAI) played a critical role in preventing errors from escalating during production. By thoroughly examining the initial batch of PCBs, you can identify potential issues early and address them before they affect the entire production line. This step ensured that every PCB adhered to Mercedes-Benz’s stringent quality standards.

During FAI, King Field’s team focused on verifying design specifications, component placement, and soldering quality. They used advanced inspection tools to detect even the smallest deviations. For example, measurement accuracy issues often arise during high-speed production. These inaccuracies can lead to misaligned components or faulty connections. By catching these problems early, King Field minimized the risk of defects in the final product.

Tip: First article inspections are like a safety net. They help you catch mistakes before they snowball into costly production delays.

Etching test – 10 to 100 regular observation of IPC3 pass rate

Maintaining the IPC3 pass rate above 80% required rigorous testing throughout the production process. The etching test was one of the most critical steps. This test ensured that the PCB’s copper traces were etched precisely, meeting the high-quality standards required for automotive applications.

King Field conducted regular observations, testing every 10 to 100 PCBs to monitor the IPC3 compliance rate. This frequent testing helped you identify trends and address issues like ion suppression, which can affect signal intensity. Variability in signal intensity often leads to unreliable data, making it harder to ensure consistent quality. By randomizing the sample order during testing, King Field mitigated day-to-day signal drift and maintained accuracy.

This proactive approach allowed King Field to stay ahead of potential problems. It also ensured that the final products met the reliability and durability standards expected by Mercedes-Benz.

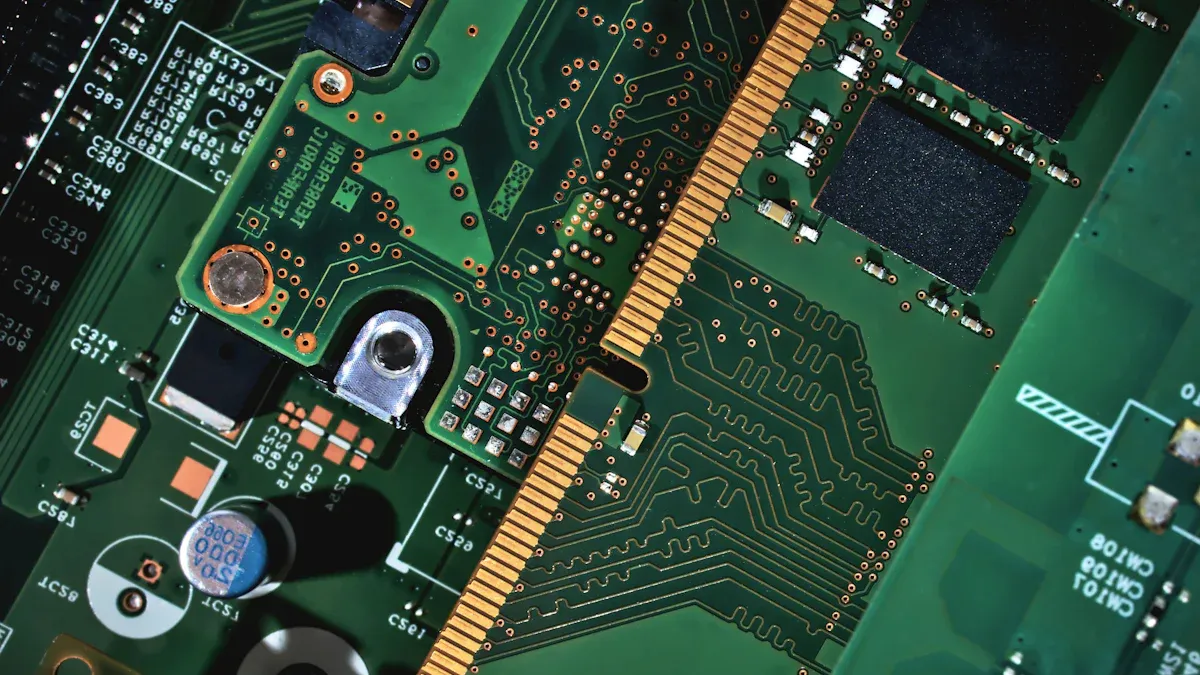

THT & SMT assembly – Batch flying probe inspection in cleanroom

The assembly phase combined Through-Hole Technology (THT) and Surface Mount Technology (SMT) to create high-performance PCBs. This stage required precision and cleanliness, as even minor contamination could compromise the product’s functionality. To ensure quality, King Field performed batch flying probe inspections in a cleanroom environment.

Flying probe testing allowed you to verify the electrical connections and functionality of each PCB without the need for a physical test fixture. This method was ideal for high-mix, low-volume production runs. However, challenges like differing ionization efficiencies and random signal variability made it essential to maintain strict environmental controls. The cleanroom setup minimized contamination risks, ensuring that each PCB met the required specifications.

By combining advanced testing methods with a controlled environment, King Field delivered PCBs that not only met but exceeded industry standards. This commitment to quality reinforced their reputation as a trusted partner in automotive manufacturing.

Note: Cleanroom environments are crucial for high-precision assembly processes. They help you maintain the integrity of sensitive components and ensure consistent quality.

Production lines and personnel support super production capacity

8 SMT production lines + 3 DIP production lines

You might wonder how King Field achieved such remarkable production efficiency. Their facility boasts eight Surface Mount Technology (SMT) production lines and three Dual Inline Package (DIP) production lines. These lines operate with precision and speed, enabling the assembly of thousands of automotive converter PCBs daily.

Each SMT line handles intricate tasks like placing components on the PCB with high accuracy. This technology ensures that even the smallest parts are positioned correctly. DIP production lines complement this by managing larger components that require through-hole soldering. Together, these lines create a seamless workflow that maximizes output without compromising quality.

The coordination between these lines and the skilled personnel operating them ensures consistent results. You can see how this setup allows King Field to meet tight deadlines while maintaining high standards.

Tip: Advanced production lines like SMT and DIP are essential for handling complex automotive components efficiently.

5000 square meters factory + complete equipment

King Field’s factory spans an impressive 5,000 square meters, providing ample space for large-scale production. This facility houses cutting-edge equipment designed to handle high-volume manufacturing. From automated assembly machines to advanced testing tools, every piece of equipment contributes to the factory’s super production capacity.

The spacious layout minimizes bottlenecks and ensures smooth operations. You’ll find that this setup allows workers to focus on precision and efficiency. The factory’s design also supports cleanroom environments, which are crucial for maintaining the integrity of sensitive components during assembly.

King Field’s production capacity has grown significantly over the years. For example, their monthly rack scale production capacity increased from 4,000 to 5,000 racks by FY 2024. This growth reflects their commitment to innovation and continuous improvement.

| Metric | Value |

|---|---|

| Monthly rack scale production capacity | Increased from 4,000 to 5,000 racks by FY 2024 |

| Year over year revenue growth | 110% |

| Compound annual growth rate (last 3 years) | 61% |

| Estimated rack capacity by June 2024 | 5,000 racks/month, 2,000 liquid-cooled racks/month |

This combination of advanced equipment and a spacious factory layout ensures that King Field remains a leader in automotive component production.

Key Metrics and Achievements

Production speed and efficiency metrics

You might wonder how King Field achieved such remarkable efficiency in automotive parts production. Their operations rely on key metrics that validate their speed and reliability. Delivery lead time stands out as a critical measure, ensuring customer requests are fulfilled promptly. Deployment frequency reflects how often production batches are completed, showcasing their ability to maintain a steady workflow.

Operational reliability is another cornerstone of their success. Mean time to restore service highlights how quickly King Field resolves issues, minimizing disruptions. Change fail rate, which tracks the percentage of failed changes during production, underscores their commitment to precision.

| Metric | Description |

|---|---|

| Delivery Lead Time | Time from customer request to satisfaction, focusing on the delivery part for faster feedback. |

| Deployment Frequency | Measures how often deployments occur, serving as a proxy for batch size and efficiency. |

| Mean Time to Restore Service | Indicates how quickly services can be restored after a failure, reflecting operational reliability. |

| Change Fail Rate | Percentage of changes that fail in production, important for assessing the impact of changes. |

These metrics demonstrate King Field’s ability to deliver high-quality automotive parts manufacturing at an unprecedented pace.

Quality assurance measures and adherence to standards

Maintaining quality in automotive parts production requires rigorous measures. King Field employs advanced testing methods to ensure every part meets industry standards. First article inspections catch errors early, preventing defects from spreading across production lines. Regular etching tests verify the precision of copper traces, ensuring signal reliability.

Batch flying probe inspections further enhance quality assurance. These tests check electrical connections without physical fixtures, ensuring functionality and durability. By adhering to IPC3 standards, King Field guarantees that over 80% of their parts meet the highest quality benchmarks.

Their commitment to quality doesn’t stop at testing. Cleanroom environments eliminate contamination risks during assembly, preserving the integrity of sensitive components. You can trust King Field to deliver automotive parts that exceed expectations.

Collaboration with Mercedes-Benz to meet expectations

King Field’s partnership with Mercedes-Benz reflects their ability to meet high expectations in automotive parts manufacturing. Mercedes-Benz’s multimillion-dollar naming rights deal for the Atlanta stadium highlights their focus on visibility and marketing value. This collaboration aligns with their shared commitment to excellence.

King Field’s ability to deliver 50,000 converter PCBs in just 15 days demonstrates their dedication to fulfilling Mercedes-Benz’s rigorous standards. Their seamless coordination and adherence to quality benchmarks ensure that every part contributes to the brand’s reputation for reliability.

By working closely with Mercedes-Benz, King Field sets a new standard for automotive parts production. Their success showcases the power of collaboration in achieving industry-leading results.

The Impact on the Automotive Industry

Implications for automotive manufacturing processes

You can see how King Field’s achievement reshapes automotive manufacturing processes. Their ability to produce 50,000 converter PCBs in just 15 days demonstrates how advanced techniques can transform production workflows. This project highlights several key implications for the industry:

- Process Optimization: By fine-tuning workflows, manufacturers can reduce variability and maintain high-quality standards. Advanced analytics play a crucial role in identifying inefficiencies and improving operations.

- Supply Chain Transparency: Real-time monitoring of materials ensures smooth operations and builds trust among stakeholders. This transparency minimizes delays and enhances collaboration across the supply chain.

- Quality Control: Automated systems detect deviations from standards, ensuring consistent quality. These systems reduce human error and improve the reliability of automotive parts.

- Risk Assessment Models: Manufacturers can now quantify risks related to production and supply chain disruptions. This proactive approach allows them to make informed decisions and avoid costly delays.

- Cost Reduction: Tracking expenses across production stages helps identify non-value-added processes. By eliminating these inefficiencies, manufacturers can reduce costs without compromising quality.

These advancements set a new standard for automotive production. They show how innovation can drive efficiency and reliability in the manufacturing process.

Benefits for Mercedes-Benz and its customers

This project delivers significant benefits for Mercedes-Benz and its customers. The collaboration with King Field ensures that the automotive giant receives high-quality parts that meet their rigorous standards. The following table highlights some of the measurable improvements achieved during this production process:

| Metric | Baseline Model | Final Model | Improvement |

|---|---|---|---|

| Coefficient of Determination | 5th Percentile | 75th Percentile | 4.86% (Training), 3.95% (Testing) |

| Testing Process Optimization | Not Optimized | Optimized | Significant Reduction in Time and Emissions |

These improvements translate into tangible benefits for Mercedes-Benz customers. Faster production times mean vehicles can reach the market more quickly. Optimized testing processes reduce emissions, aligning with the growing demand for environmentally friendly practices. Additionally, the enhanced reliability of parts ensures a better driving experience for customers.

By partnering with King Field, Mercedes-Benz strengthens its reputation for delivering high-performance vehicles. This collaboration showcases how efficient production processes can benefit both manufacturers and end-users.

Setting a benchmark for future automotive parts manufacturing projects

King Field’s success sets a new benchmark for the automotive industry. Their ability to deliver high-quality parts under tight deadlines proves that innovation and efficiency can coexist. Future manufacturing projects can draw inspiration from this achievement in several ways:

- Adopting Advanced Technologies: Manufacturers can integrate automated systems and real-time monitoring tools to enhance production efficiency.

- Prioritizing Quality Standards: Meeting high standards like IPC3 ensures that parts are reliable and durable. This focus on quality builds trust with customers and partners.

- Streamlining Supply Chains: Transparent and efficient supply chains reduce delays and improve collaboration. This approach ensures that materials and parts flow seamlessly through the production process.

- Emphasizing Sustainability: Optimized processes that reduce emissions and waste align with global sustainability goals. These practices benefit both the environment and the bottom line.

This project demonstrates what’s possible when manufacturers embrace innovation and collaboration. It sets a precedent for future projects, encouraging the industry to aim higher and achieve more.

King Field’s achievement in delivering 50,000 Mercedes-Benz converter PCBs in just 15 days showcases what’s possible when precision meets innovation. You’ve seen how their commitment to efficiency and quality sets a new standard in automotive manufacturing.

Key Takeaway: Efficiency and innovation aren’t just goals—they’re essential for staying competitive in today’s fast-paced industry.

By embracing advanced technologies and rigorous quality control, King Field has solidified its position as a leader in the automotive sector. Their success inspires you to think about how innovation can drive progress in your own field.

FAQ

What makes King Field stand out among automotive parts manufacturers?

King Field excels in delivering high-quality components under tight deadlines. Their advanced production lines, rigorous quality checks, and commitment to innovation set them apart. You can trust their expertise to meet the demands of car parts production.

How does King Field ensure quality in car parts production?

King Field uses advanced testing methods like first article inspections and flying probe tests. These processes catch defects early and ensure every part meets industry standards. Their cleanroom environments also prevent contamination during assembly.

Why is IPC3 compliance important in automotive component manufacturing?

IPC3 compliance ensures that PCBs meet the highest quality standards. This guarantees reliability and durability in vehicles. King Field’s ability to exceed the 80% IPC3 requirement demonstrates their dedication to producing top-tier spare parts.

How does King Field’s achievement impact vehicle production?

King Field’s efficiency in producing 50,000 PCBs in 15 days accelerates vehicle production timelines. This allows manufacturers to bring vehicles to market faster while maintaining high-quality standards.

What benefits do manufacturers gain from collaborating with King Field?

Manufacturers benefit from King Field’s advanced technology, streamlined workflows, and commitment to quality. Their ability to deliver reliable automotive components on time strengthens supply chains and enhances production efficiency.