Latest Trends Shaping PCB Factory Automation and Sustainability

You can see big changes happening fast in PCB Factory operations. Automation is helping PCB Factory environments work better and faster, improving efficiency by up to 30%. Most manufacturers, about 73%, believe now is the best time for PCB Factory automation. Sustainability is also a key focus in PCB Factory settings, with 68% of workers caring about eco-friendly choices.

| Aspect | Statistic/Insight |

|---|---|

| Automation Growth | The PCB Factory industry may grow from $69.4 billion in 2020 to $102.2 billion by 2025. |

| Efficiency Improvement | Automation can make PCB Factory production work up to 30% better. |

| Manufacturer Sentiment | 73% of PCB Factory manufacturers think it is time to use automation for better performance. |

| Sustainability Awareness | 68% of PCB Factory workers think sustainability will affect product development in the next two years. |

| Green Material Impact | Using sustainable materials may cut greenhouse gas emissions by up to 30% during PCB Factory production. |

| Circular Economy Projection | Material recovery rates in PCB Factory operations could go up by 50% by 2025 because of a focus on a circular economy. |

Automation and sustainability in PCB Factory processes help you stay ahead, save money, and meet new market needs.

| Evidence Description | Impact on Competitiveness and Growth |

|---|---|

| Automation makes PCB Factory production more efficient, accurate, and flexible. | It speeds up production and lowers costs, making PCB Factory companies stronger. |

| Sustainability efforts in PCB Factory operations match rules and what people want. | This gives PCB Factory companies an edge by meeting the need for eco-friendly actions. |

| Robotics technology makes PCB Factory manufacturing more exact and steady. | It lowers mistakes and makes products more reliable, helping PCB Factory companies grow. |

| Using eco-friendly materials and cleaner ways to make things in PCB Factory settings. | This lowers harm to the environment and attracts people who care about nature. |

Keep learning and changing with these PCB Factory trends to do well for a long time.

Key Takeaways

- Automation helps PCB factories work faster by up to 30%. This saves time and lowers costs.

- Sustainability is very important. About 68% of workers care about eco-friendly actions. These actions can make your brand look better.

- Advanced materials like bio-based polyimides make products work better. They also help the environment.

- Use smart factory technologies like AI and IoT. These tools make production better and lower mistakes.

- 3D printing helps make new designs quickly. It cuts down on waste and speeds up product development.

Top Trends in PCB Manufacturing

Many changes are happening in PCB factories now. These changes help you make better products. They also help you keep up with new technology. Here are some important trends in pcb manufacturing you should know.

Miniaturization and HDI

Miniaturization means making PCBs smaller but more powerful. High-Density Interconnect (HDI) technology lets you fit more parts in a small space. This is important for things like smartphones, medical tools, and wearables. HDI helps you make products lighter and more reliable.

Miniaturization saves material and lowers costs. Smaller PCBs use less energy and make less waste.

Here is how miniaturization and HDI help your work:

| Impact Area | Description |

|---|---|

| Manufacturing Efficiency | Smaller PCBs use less material, so you spend less money and make products faster. |

| Product Performance | Miniaturization gives you better signal quality and more reliable devices. |

| Weight Reduction | Lighter PCBs help cars and planes use less fuel. |

| Cost Savings | Lower weight means cheaper shipping and handling. |

| Design Flexibility | You can make thinner and more portable devices. |

| Reliability | Tighter parts placement reduces damage and electrical noise. |

You can now use microvia technology to stack layers and add more parts. Embedded components save space and make products even more reliable. HDI is now used a lot in pcb manufacturing for medical, automotive, and consumer electronics.

Flexible and Rigid-Flex PCBs

Flexible and rigid-flex PCBs change how you design electronics. These PCBs can bend and twist. You can use them in small or oddly shaped devices. Rigid-flex pcbs mix the strength of hard boards with the bendiness of soft ones. This trend is growing quickly, especially in Asia-Pacific and China.

- The global rigid flex PCB market could reach USD 77.7 billion by 2034.

- Asia-Pacific leads the market, and China is growing at 12.4% each year.

There are many good things about using flexible and rigid-flex PCBs:

| Benefits | Challenges |

|---|---|

| Lower assembly costs | Higher material costs |

| Resistance to vibration and shock | Manufacturing complexity |

| Flexible design options | Thermal management issues |

| Reduced weight and package size | Specialized knowledge required |

| High component density applications | Limited heat spreading capability |

| Minimal interconnections and parts | Economical concerns for high-volume production |

| Enhanced connection reliability | Enhance overall reliability |

You can use these PCBs in wearables, medical implants, and aerospace tools. They help you make products that last longer and work better in tough places. Flexible PCBs also need fewer parts, so assembly is easier and faster.

Advanced Materials

Advanced materials are now a big part of pcb manufacturing trends. You can pick new materials like fluoropolymers, polyimide, and PTFE. These materials give you better performance and help you meet new needs in pcb manufacturing.

- Fluoropolymers do not rust and can handle high heat. You can use them in medical and food devices.

- Polyimide is bendy and strong. It works well in smartphones and wearables.

- PTFE is good for high-frequency uses, like radar and wireless systems.

Advanced materials help make your factory more sustainable. For example, bio-based polyimides can take high heat and are better for the environment. Halogen-free laminates keep signals strong and lower pollution.

Here are more ways advanced materials help:

- Bio-based polyimides work in hot places, like car electronics.

- Halogen-free laminates keep signals clear at high speeds, which is important for industry 4.0 and 5G.

- Eco-design helps you recycle more and waste less.

When you use these new materials, your products get stronger, safer, and greener. This helps you keep up with industry 4.0 and ai-driven manufacturing. You also meet the need for sustainable and high-performance PCBs.

Automation in PCB Factory

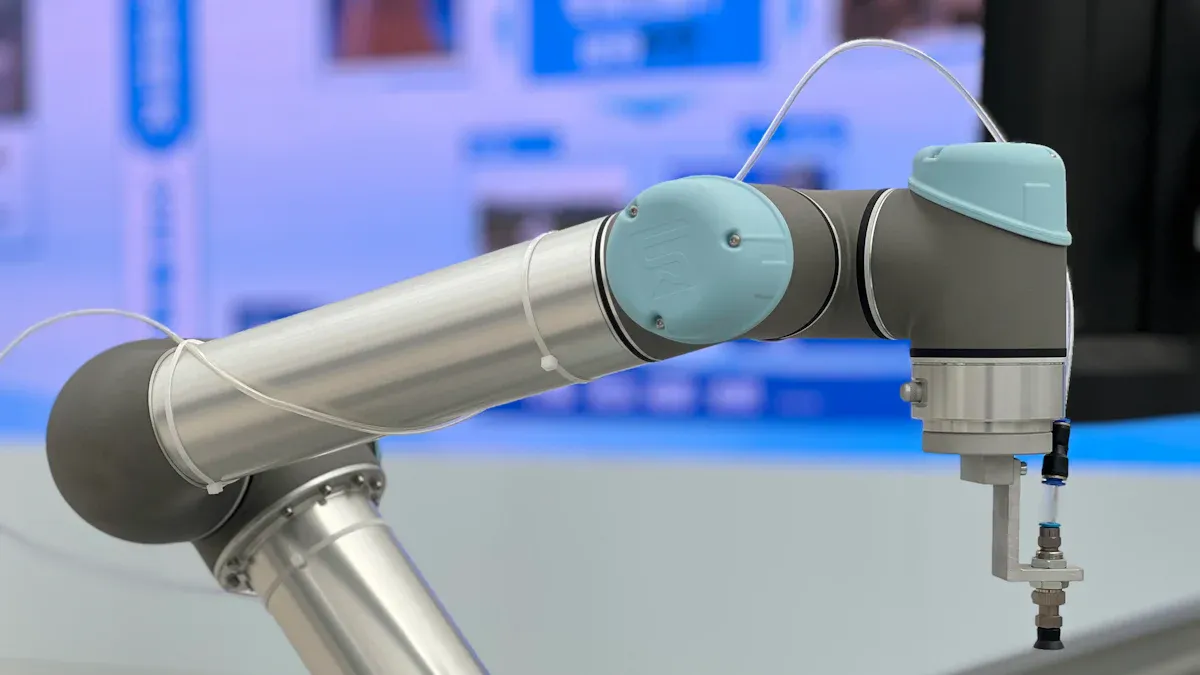

AI and Robotics

Big changes are happening in circuit board manufacturing. Automation and robotics help a lot. Robots can handle small parts very carefully. They pick up and place pieces where they belong. Robots put on solder paste and cut boards with CNC routing. These machines work quickly and never get tired. They make fewer mistakes than people do.

- Pick and place robots make assembly faster.

- Automated systems put glue and solder paste in the right spots.

- CNC routing machines cut boards neatly.

- Soldering reflow ovens make strong connections.

AI design automation helps you plan how to build each board. AI checks for mistakes that people might not see. Machine learning finds problems and fixes them right away. This gives you better quality and fewer errors. AI also lowers false alarms during checks by 90%. This saves time and money.

Smart Factories

Smart factories use technology to make work easier. You can watch every step with sensors and smart devices. These tools collect data and help you find problems early. AI gives ideas to fix issues and keeps things running well.

| Technology | Application in PCB Manufacturing |

|---|---|

| IoT Sensors | Watch and collect data during the process |

| AI Systems | Check how well the line works and give advice |

| Predictive AI | Find problems before they slow things down |

| Machine-to-Machine | Help machines talk to each other |

| Machine Learning | Cut down mistakes in assembly |

| Intelligent Devices | Gather data for quality checks |

Smart manufacturing lets you change designs fast. You can meet what customers want. You use less energy and keep workers safe by automating risky jobs.

IoT Integration

AI and IoT together change how you run your factory. IoT sensors watch machine health and energy use all the time. This helps you fix things before they break. Predictive maintenance lowers surprise downtime by 30%. It makes equipment work 25% better.

- IoT vibration sensors keep machines safe.

- Custom PCBs help medical and farm tools work well.

- Tracking devices help shipping go smoothly.

You gather data all the time to make smart choices. Smart factories use this data to keep quality high and costs low. IoT makes circuit board manufacturing quicker, safer, and more dependable.

Sustainability in PCB Manufacturing

Focus on Sustainability

Factories care more about sustainability now. Many use eco-friendly materials and safer ways to make PCBs. You can help by picking biodegradable substrates like cellulose or paper. Lead-free soldering keeps people and nature safe. Recyclable materials such as copper and aluminum save resources. Factories design modular PCBs so you can swap parts instead of tossing the whole board.

- Eco-friendly PCB materials

- Lead-free solder materials

- Recyclable materials

- Modular PCB architecture

- Green manufacturing with less waste

- Cleaner chemical use

- PCB recycling programs

Using these methods helps the environment and cuts down pollution.

Sustainable Circuit Boards

You can find circuit boards that are better for the planet. Some companies use bio-based composites that break down after use. Others use natural fibers like flax to make boards stronger and greener. Agricultural waste can be used in PCB substrates, which helps a circular economy. JIVA’s Soluboard® dissolves in water, so you can recycle valuable parts easily. Polylactic acid comes from organic waste and is another choice for sustainable PCB designs.

- Bio-based flexible PCBs

- Natural fiber integration

- Bio-waste utilization

- Biodegradable conductive inks

- Hybrid designs with minimal non-degradable parts

These new ideas help lower e-waste and move toward carbon-neutral production.

Energy Efficiency

You can save energy and money by using efficient manufacturing. High energy use in lamination and curing costs more and raises your carbon footprint. You can lower both by using energy-efficient equipment and better process controls. Many factories now use solar or wind power for their lines.

| Energy Efficiency Measure | Impact on Costs | Impact on Environment |

|---|---|---|

| Energy-efficient equipment | Lower energy bills | Fewer carbon emissions |

| Advanced process controls | Less energy waste | Reduced energy consumption |

| Renewable energy sources | Less fossil fuel use | Lower carbon emissions |

Choosing energy-smart solutions helps the planet and saves you money.

Fully Automated PCB Factory

Streamlined Assembly

When you walk into a fully automated PCB factory, you notice big changes. Machines do most of the work. This makes production faster and cuts down on mistakes. Circuit boards move from one step to another without stopping. Robots put parts in the right place every time. You need fewer workers on the floor. People can spend more time planning and making things better.

Here is a table that shows how automated factories and traditional ones are different:

| Feature | Automated PCB Factory | Traditional PCB Factory |

|---|---|---|

| Production Speed | Fast production with machines | Slower, people do the work |

| Precision | Very accurate with machines | Accuracy changes, depends on people |

| Labor Requirements | Fewer people needed | More people needed |

| Quality Control | Machines check for mistakes | People check, can miss mistakes |

| Cost Efficiency | Cheaper for making lots of boards | Costs more when making fewer boards |

Automated lines help you make products the same way every time. Packing is faster and there are fewer packing mistakes. Special systems find problems early, so you fix them before they get worse. Smart assembly systems help you watch and improve the process.

| Automated Process | Impact on Throughput | Impact on Errors |

|---|---|---|

| Automated Packaging | Makes packing faster and better | Fewer packing mistakes |

| Failure Prevention Mechanisms | Keeps quality high | Less fixing and checking needed |

| Intelligent Assembly Improvement | Helps you manage better | Makes the whole process work well |

Tip: Using machines and smart systems helps you work faster and get better results.

Quality Control

Strong quality control is important to make sure every PCB works. Automated factories use computers and AI to look for problems. These systems can see tiny defects, even very small ones. You get feedback right away, so you can fix things fast and keep working.

- Computer vision finds over 95% of defects.

- Real-time checks give you quick feedback.

- AI can handle hard designs and spot many problems.

You do not have to depend on people to find mistakes. Machines help you catch problems early and keep your products good. Safety is better because machines do the dangerous jobs.

Here is a table that shows the good and hard parts of using full automation:

| Benefits of Automation in PCB Manufacturing | Challenges of Automation in PCB Manufacturing |

|---|---|

| More accurate work | Costs a lot to start |

| Faster production | Need skilled people to run machines |

| Lower costs | It can reduce labor costs in the long term |

| Better quality checks | The defect rate has decreased significantly |

| Safer for workers | Replace human labor in high-risk jobs |

Note: Your team needs training to use and take care of these machines. This helps you get the best results from your automated factory.

3D Printing and Additive Manufacturing

Prototyping

3D printing helps you make PCB prototypes much faster. You do not have to wait a long time for production. You can test your ideas right away and change them quickly. This lets you find problems early and fix them before making many boards. 3D printing lets you build shapes that are hard to make with old ways. You can try new layouts and test different materials. This makes your work more creative and flexible. You save money because you only print what you need. Many engineers use 3D printing to make small test batches. This helps you see how your product works in real life.

Tip: When you make prototypes fast, you can show your ideas sooner. You get feedback and can improve your design before making lots of boards.

Material Waste Reduction

3D PCB printing helps you use less material and protect nature. Old PCB manufacturing cuts away extra material and makes waste. 3D printing uses only the amount you need. This makes your process cleaner and more efficient.

Here are some ways 3D printing cuts down on waste:

- You use just the right amount of material, so you throw away less.

- You use fewer bad chemicals and less water than old methods.

- You can make boards when you need them, so you do not make too many. This is great for making prototypes or small orders.

You can see that 3D printing helps your business and the planet. You save money on materials and help the earth at the same time. Cleaner production also means safer work for your team.

You can see that automation and sustainability are changing PCB factories. These changes help you work better and use fewer resources. They also help you follow new rules. To keep up, you can:

- Pick advanced materials to make products better and greener.

- Update your work to follow rules like RoHS and WEEE.

- Spend money on automation and AI to work faster.

- Keep trying new ideas to save money and stay strong.

- Pick eco-friendly PCBs that you can recycle or that break down.

Keep learning about new technology. This helps you stay ahead in a fast-moving industry.

FAQ

What is a pcb factory?

A pcb factory makes printed circuit boards for electronics. These boards go in phones, computers, and cars. People and machines build, test, and pack the boards. You can find pcb factories in lots of countries.

How does automation help in a pcb factory?

Automation helps you finish jobs faster with fewer mistakes. Robots and smart machines do jobs like soldering and checking boards. You save money and make better products. Your pcb factory works more smoothly.

Why is sustainability important in a pcb factory?

Sustainability helps you keep the environment safe. You use eco-friendly materials and recycle waste. Your pcb factory makes less pollution and uses less energy. Customers want green products, so you stay ahead.

Can a pcb factory make boards for wearable tech?

Yes, your pcb factory can make small, flexible boards for wearable tech. You use special materials and designs. These boards fit inside watches, fitness trackers, and smart clothes.

What are the benefits of energy-efficient equipment in a pcb factory?

Energy-efficient equipment helps you pay less for power. You use less electricity and make less carbon pollution. Your pcb factory saves money and helps the earth. You also follow new industry rules.