First cooperation with Huawei, 50,000 pcs of PCB assembly for automotive display screens, IPC 3 achievement rate 91%

Securing our first cooperation with Huawei marks a pivotal moment for us in the automotive display screen industry. This collaboration involved delivering 50,000 PCB assemblies, a substantial volume that underscores our manufacturing capacity. Achieving an IPC 3 rate of 91% reflects our commitment to stringent quality standards and precision engineering.

The significance of this achievement becomes clearer when viewed against the backdrop of the industry’s growth. The global automotive head-up display market is projected to surge from USD 1.97 billion in 2025 to USD 9.37 billion by 2033, with an impressive CAGR of 21.5%. Furthermore, Chinese companies now command 45.3% of the automotive display market, up from 12.9% in 2016. By partnering with Huawei, a leader in innovation, we position ourselves at the forefront of this expanding industry.

Key Takeaways

- Working with Huawei is a big step for us in making top-quality parts for car display screens.

- Reaching a 91% IPC 3 rate shows we focus on making precise and reliable products for cars.

- We use advanced tools, like 8 SMT and 3 DIP lines, to handle big orders quickly and on time.

- Teaming up with top companies like Huawei helps us create new ideas and improve car electronics.

- More people want better PCBs, which helps make smart cars safer and more user-friendly.

Huawei is looking for an IPC 3 PCBA factory to produce large quantities of PCBs.

Huawei’s commitment to innovation and excellence drives its search for a reliable IPC 3 PCBA factory capable of handling large-scale production. As a global leader in technology, Huawei demands precision, efficiency, and unwavering quality in every component it integrates into its products. Meeting these expectations requires a partner with proven expertise and robust manufacturing capabilities. This is where we step in.

King Field PCB complete IPC3 standard system

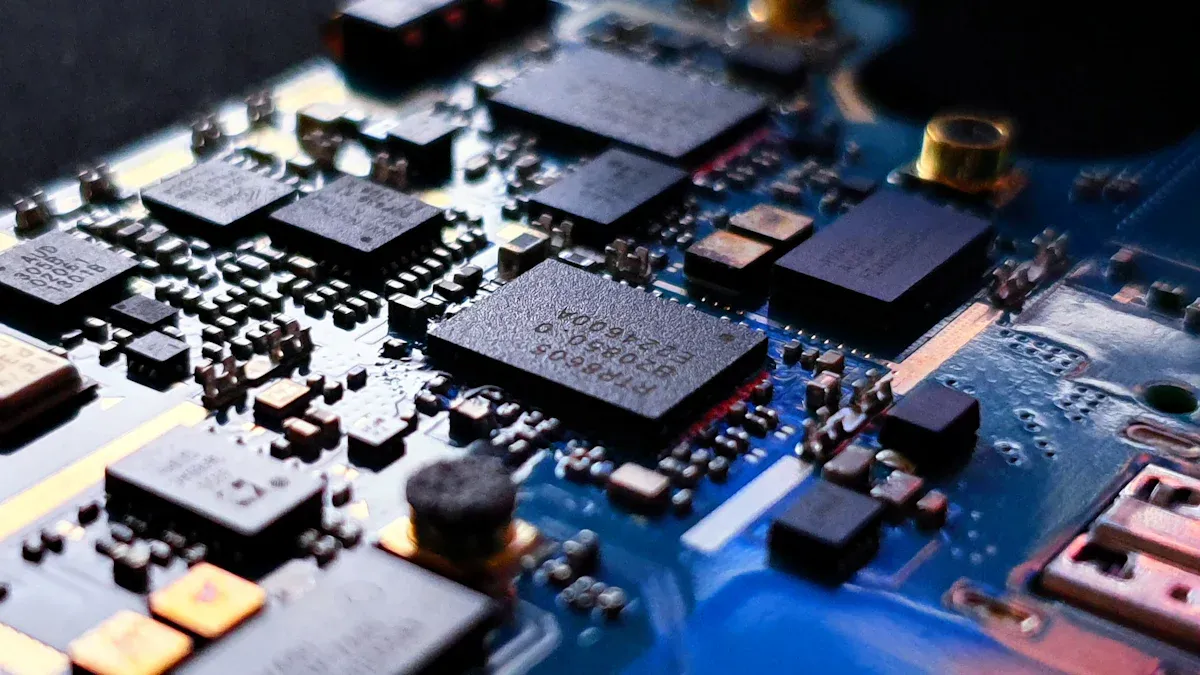

At King Field PCB, we have built a comprehensive IPC 3 standard system that ensures every product meets the highest quality benchmarks. IPC 3, the most stringent classification for PCB assemblies, focuses on performance and reliability in critical applications like automotive electronics. Our system encompasses rigorous quality control measures, advanced testing protocols, and continuous process optimization.

We achieve this through a combination of cutting-edge technology and a skilled workforce. Our engineers meticulously monitor every stage of production, from material selection to final inspection. This attention to detail guarantees that each PCB assembly not only meets but often exceeds IPC 3 standards. By maintaining this level of excellence, we have earned the trust of industry leaders like Huawei.

Experience in cooperating with multiple automobile brands, such as BYD and Geely.

Our experience in the automotive sector further solidifies our position as a trusted partner for Huawei. Over the years, we have successfully collaborated with automakers like BYD and Geely, delivering high-quality PCB assemblies for their advanced display systems. These partnerships have honed our ability to meet the unique demands of the automotive industry, including durability, thermal management, and seamless connectivity.

Working with these automakers has also provided us with valuable insights into the evolving needs of the industry. For instance, the growing emphasis on electric vehicles and autonomous driving has increased the demand for PCBs that support enhanced connectivity and real-time data processing. Our ability to adapt to these trends makes us an ideal collaborator for Huawei as it continues to innovate in the automotive electronics space.

8 SMT production lines + 3 DIP production lines, delivered on time.

Our state-of-the-art manufacturing facility is another key factor that sets us apart. With 8 SMT (Surface Mount Technology) production lines and 3 DIP (Dual In-line Package) production lines, we have the capacity to handle large-scale orders without compromising on quality or delivery timelines. These lines are optimized for efficiency and precision, ensuring that every PCB assembly meets the exact specifications required by Huawei.

To illustrate our operational efficiency, consider the following metrics:

| Metric | Description |

|---|---|

| Overall Equipment Effectiveness (OEE) | Measures how efficiently machines are operating. |

| First Pass Yield (FPY) | Indicates the percentage of products passing quality control on the first attempt. |

| Downtime | Tracks how often production stops due to technical issues. |

| Cycle Time | Measures the time taken to produce a product from start to finish. |

These metrics reflect our commitment to operational excellence. For example, our high OEE ensures that our machines operate at peak efficiency, minimizing waste and maximizing output. Similarly, a strong FPY rate demonstrates our ability to produce defect-free products on the first attempt, reducing the need for rework and ensuring timely delivery. By maintaining low downtime and optimizing cycle times, we can meet Huawei’s demanding production schedules without compromising on quality.

Our ability to deliver on time, even for large orders like the 50,000 PCB assemblies for Huawei, underscores our reliability as a manufacturing partner. This reliability, combined with our focus on connectivity and innovation, positions us as a leader in the PCB assembly industry.

Production Process and Achieving IPC 3 Standards

Overview of the PCB assembly process for automotive display screens

Producing high-quality PCBs for automotive display screens requires a meticulous and well-structured process. At our facility, we follow a ten-step workflow to ensure precision and reliability:

- Stencil Creation for Solder Paste Application

- Solder Paste Application

- Component Placement

- Reflow Soldering

- Optical Inspection

- Statistical Process Control (SPC)

- X-Ray Inspection

- Selective Soldering for THT Components

- Final Inspection and Handling

- Feedback Collection

Each step plays a critical role in maintaining the integrity of the PCB. For instance, SPC allows us to analyze quality data, such as solder joint dimensions and component placement accuracy. This analysis helps us identify trends, optimize processes, and minimize defects. By adhering to this structured approach, we ensure that every assembly meets the rigorous demands of the automotive industry.

What achieving an IPC 3 rate of 91% entails

Achieving an IPC 3 rate of 91% is no small feat. IPC 3, the highest standard for PCB assemblies, is reserved for products requiring exceptional reliability, such as those used in automotive and aerospace applications. This standard demands flawless solder joints, precise component placement, and robust thermal management.

To meet these criteria, we implement advanced quality control measures at every stage of production. Our team conducts multiple inspections, including optical and X-ray evaluations, to detect even the smallest anomalies. Additionally, we utilize automated testing equipment to verify electrical performance and ensure compliance with IPC 3 standards. Achieving a 91% rate reflects not only our technical expertise but also our unwavering commitment to excellence.

Our certifications further validate this achievement. We hold ISO 9001 and IATF 16949 certifications, which underscore our dedication to quality management and automotive industry standards. These credentials reassure our partners, like Huawei, that they can rely on us for critical applications.

Challenges faced during production and how they were overcome

Scaling up production to deliver 50,000 PCB assemblies while maintaining IPC 3 standards presented several challenges. One of the most significant hurdles was ensuring consistent quality across such a large volume. Variations in solder paste application or component alignment could lead to defects, jeopardizing the entire batch.

We addressed this by investing in cutting-edge equipment and refining our processes. For example, we implemented real-time monitoring systems to track key metrics like first-pass yield and cycle time. These systems allowed us to identify and resolve issues before they escalated. As a result, we improved our first-pass yield to 99.7%, significantly reducing rework and delays.

Another challenge involved meeting tight delivery timelines without compromising quality. To overcome this, we optimized our production lines and streamlined workflows. Our 8 SMT and 3 DIP production lines operated at peak efficiency, enabling us to meet Huawei’s deadlines while maintaining the highest standards.

Our experience with other automotive brands, such as BYD and Geely, also proved invaluable. These collaborations taught us how to adapt to the unique demands of the automotive sector, from thermal management to enhanced connectivity. By leveraging this expertise, we successfully navigated the complexities of this project.

Implications for the Automotive Display Screen Industry

Impact of high-quality PCB assemblies on display screen performance

High-quality PCB assemblies play a pivotal role in enhancing the performance of automotive display systems. I have observed that these assemblies ensure seamless integration of electronic components, which directly impacts the user experience. For instance, advanced PCBs improve the responsiveness and clarity of digital screens, making them indispensable for modern vehicles.

- Enhanced electronic systems in luxury cars elevate safety, comfort, and convenience.

- The growing demand for digital screens highlights the importance of reliable PCBs in automotive applications.

In my experience, the precision and reliability of PCB assemblies contribute to the functionality of advanced driving systems. These systems rely on real-time data processing, which high-quality PCBs facilitate. By delivering consistent performance, these assemblies improve the overall user experience and set the foundation for innovation in vehicle electronics.

How this cooperation sets a new benchmark for industry standards

Collaborating with Huawei has allowed us to redefine industry benchmarks. I believe that achieving an IPC 3 rate of 91% demonstrates our ability to meet the highest quality standards. This milestone reflects our commitment to precision engineering and operational excellence.

- Benchmarking against industry standards ensures competitiveness and relevance.

- Tools like Key Performance Indicators (KPIs) and Balanced Scorecards provide objective data for comparison.

Through this partnership, we have aligned our practices with international standards, fostering cross-border collaboration. A study by McKinsey & Company highlights how global benchmarking enhances performance in multinational corporations. I see this as a testament to the value of setting new benchmarks, which not only improve internal processes but also elevate industry-wide expectations.

Ripple effects on innovation and adoption of advanced technologies

The ripple effects of this cooperation extend far beyond PCB assembly. I have noticed that innovations in one area often lead to advancements in others. For example, the application of GPS technology in vehicles has transformed navigation systems, improving user experience across the board.

- Positive spillovers from technology advancements accelerate progress in related sectors.

- Interventions in innovation systems can create both positive and negative externalities.

By partnering with Huawei, we have contributed to the adoption of advanced driving systems and other cutting-edge technologies. This collaboration has sparked innovation, enabling vehicles to become smarter and more connected. I believe these ripple effects will continue to shape the future of automotive electronics, driving progress and enhancing user experience.

Future Prospects for Collaboration with Huawei

Opportunities for scaling production and enhancing quality

I see immense potential to scale production and further enhance quality through our collaboration with Huawei. Their strategic shift from cost-focused to quality-driven operations aligns perfectly with our commitment to excellence. Huawei’s leadership, particularly Ren Zhengfei, has emphasized the importance of prioritizing quality over price wars. This philosophy resonates with our approach to manufacturing, where precision and reliability take precedence.

- Huawei plans to reinvest profits into improving product quality, creating a sustainable growth model.

- Their focus on high standards ensures that every project delivers exceptional value to end users.

By leveraging Huawei’s vision and our advanced manufacturing capabilities, we can meet the growing demand for electric powertrains and intelligent cockpit systems. This partnership positions us to deliver cutting-edge solutions that redefine automotive electronics.

Exploring new technologies in automotive electronics

The automotive industry is undergoing a technological revolution, and I believe our partnership with Huawei can accelerate cockpit intelligence and other innovations. Emerging trends like autonomous driving technology, electrification, and connected vehicles are reshaping the market.

| Megatrend | Key Aspects |

|---|---|

| Autonomous Driving | Growth drivers, enabling technologies, and market forecasts |

| Electrification | Opportunities in electric powertrains and sustainable vehicle solutions |

| Connected and Software-Defined Vehicles | Enhanced connectivity and real-time data processing capabilities |

| In-Cabin Monitoring | AI-driven personalization and predictive maintenance |

I see significant opportunities in integrating augmented reality and advanced driver-assistance systems into intelligent cockpit designs. These technologies enhance safety and user experience, making vehicles smarter and more intuitive. Additionally, the shift toward electric powertrains aligns with consumer demand for sustainability, further driving innovation in this space.

Strengthening the partnership for long-term growth in the automotive sector

Long-term growth in the automotive sector requires strong, strategic partnerships. Our collaboration with Huawei mirrors successful alliances like the one between Toyota and Tesla. By combining Tesla’s electric powertrain technology with Toyota’s manufacturing expertise, both companies accelerated the adoption of electric vehicles.

Similarly, our partnership with Huawei can drive innovation and market expansion. For instance:

- Huawei’s focus on intelligent cockpit systems complements our expertise in high-quality PCB assemblies.

- Together, we can develop advanced solutions that meet the evolving needs of the automotive industry.

This collaboration not only strengthens our market position but also contributes to the broader adoption of sustainable and intelligent automotive technologies. I am confident that our shared vision will lead to groundbreaking advancements in the years to come.

This collaboration with Huawei represents a significant milestone. Delivering 50,000 PCB assemblies with an IPC 3 achievement rate of 91% showcases our technical expertise and commitment to quality. These results set a new benchmark for the automotive display screen industry, driving innovation and raising performance standards.

| Study Duration | Performance Improvement | Sustainability of Improvement |

|---|---|---|

| 6 months – 2 years | Reported improvement | Varies by study |

| Longer follow-up | Sustained improvement | Confirmed in multiple studies |

I see this partnership as a foundation for future advancements. Together, we can explore new technologies and redefine the possibilities in automotive electronics.

FAQ

What is IPC 3, and why is it important for automotive PCBs?

IPC 3 is the highest quality standard for PCB assemblies, ensuring exceptional reliability and performance. It is crucial for automotive applications where safety and durability are non-negotiable. Meeting this standard demonstrates our ability to deliver precision-engineered products for critical systems.

How does achieving a 91% IPC 3 rate benefit automotive display screens?

A 91% IPC 3 rate ensures consistent quality and reliability in PCB assemblies. This directly enhances the performance of automotive display screens, improving clarity, responsiveness, and durability. It also reduces the risk of system failures, which is vital for safety-critical applications.

What challenges did you face while producing 50,000 PCB assemblies?

Scaling production while maintaining IPC 3 standards was challenging. Ensuring consistent solder quality and component alignment across such a large volume required advanced monitoring systems and process optimization. Tight delivery timelines added complexity, but our streamlined workflows ensured success.

How does this collaboration with Huawei impact the automotive industry?

This partnership sets a new benchmark for quality and innovation in automotive electronics. By delivering high-quality PCB assemblies, we contribute to the development of smarter, more reliable vehicles. It also accelerates the adoption of advanced technologies like intelligent cockpits and autonomous driving systems.

What are the future prospects for your partnership with Huawei?

I see immense potential for scaling production and exploring new technologies. Together, we can innovate in areas like augmented reality displays and electric powertrains. Strengthening this partnership will drive long-term growth and redefine possibilities in automotive electronics.