When you pick a pcb manufacturer, you might make mistakes. These mistakes can waste money. They can also cause you to miss deadlines. They may lead to bad product quality. You should write down your technical needs first. Do this before you start choosing. Talk clearly with possible partners. This helps you avoid confusion. Look up information and check details carefully. This keeps your pcb manufacturing project safe from expensive errors.

Key Takeaways

- Write down your technical specifications before picking a PCB manufacturer. This stops mistakes and makes sure everyone understands.

- Always look at the manufacturer’s quality certifications. Certifications like ISO 9001 and IPC A-600 show they care about quality.

- Check the manufacturer’s experience and reputation. Experienced manufacturers make fewer mistakes and can do hard projects.

- Make sure you understand the pricing and get a detailed quote. Knowing all costs early helps you avoid surprise charges.

- Keep good communication with your manufacturer. Regular updates and clear talks stop confusion and keep projects moving.

Common Pitfalls in PCB Manufacturing

Ignoring Quality and Certifications

Sometimes people forget to check quality and certifications. This can cause bad boards and product recalls. Customers may stop trusting your products. If the manufacturer does not have certifications, your project might break rules. You could get fined or banned. Always look for certifications like ISO 9001, IPC A-600, and UL 508A. These show the manufacturer cares about quality and follows rules.

| Certification | Description |

|---|---|

| ISO 9001 | Makes sure the company manages quality well. |

| IPC A-600 | Sets rules for how good PCBs should be. |

| UL 508A | Checks safety for industrial panels. |

Overlooking Manufacturing Capabilities

If you do not check what the manufacturer can do, you may have trouble with hard designs. If their skills are limited, mistakes can happen. You might see problems like signal issues or broken devices. For boards with many layers, make sure they use special methods like micro via technology and sequential lamination. Ask about their machines and how they check their work. This helps you get good pcb manufacturing.

Neglecting Experience and Reputation

If you pick a manufacturer without looking at their experience, you may get more defects. Skilled manufacturers know how to make things right. Ask them about how often they have defects and how they fix problems. Read reviews and case studies to learn about their reputation. Good manufacturers test their products before making a lot.

Underestimating Lead Times

If you do not plan lead times, you might run late. Lead times change based on design and what the manufacturer can do. Delays can mess up your schedule and cost more money. Simple boards may be quick, but hard ones take longer. Talk with your manufacturer to get updates. Use smart design and talk early to avoid slowdowns.

Tip: Share your plans and think about busy seasons to keep your project moving.

Failing to Clarify Pricing

If prices are not clear, you may pay more than you think. Extra fees for fast work, testing, or shipping can surprise you. Always ask for a full quote with every cost listed. This should include making prototypes, assembly, certification, and shipping. Compare prices from different manufacturers so you do not pay too much.

| Hidden Cost Factor | Description | Impact on Cost |

|---|---|---|

| Prototype Fabrication | Checks if the design works, but costs money. | Trying many times can make it expensive. |

| Assembly and Testing | Needed for hard boards. | Uses more time and supplies. |

| Certification | Following rules costs extra. | Makes the total price higher. |

| Logistics | Covers delivery and storage. | Adds to the final cost. |

Poor Communication Practices

Bad communication can make projects fail. About 30% of PCB prototypes do not work because people did not talk enough. Miscommunication can make things take longer. Use clear ways to talk, meet often, and answer questions fast. Write down all changes and share news quickly.

- Use email for sending files and video calls for hard problems.

- Have regular meetings to talk about progress.

- Share design changes with easy-to-read file names.

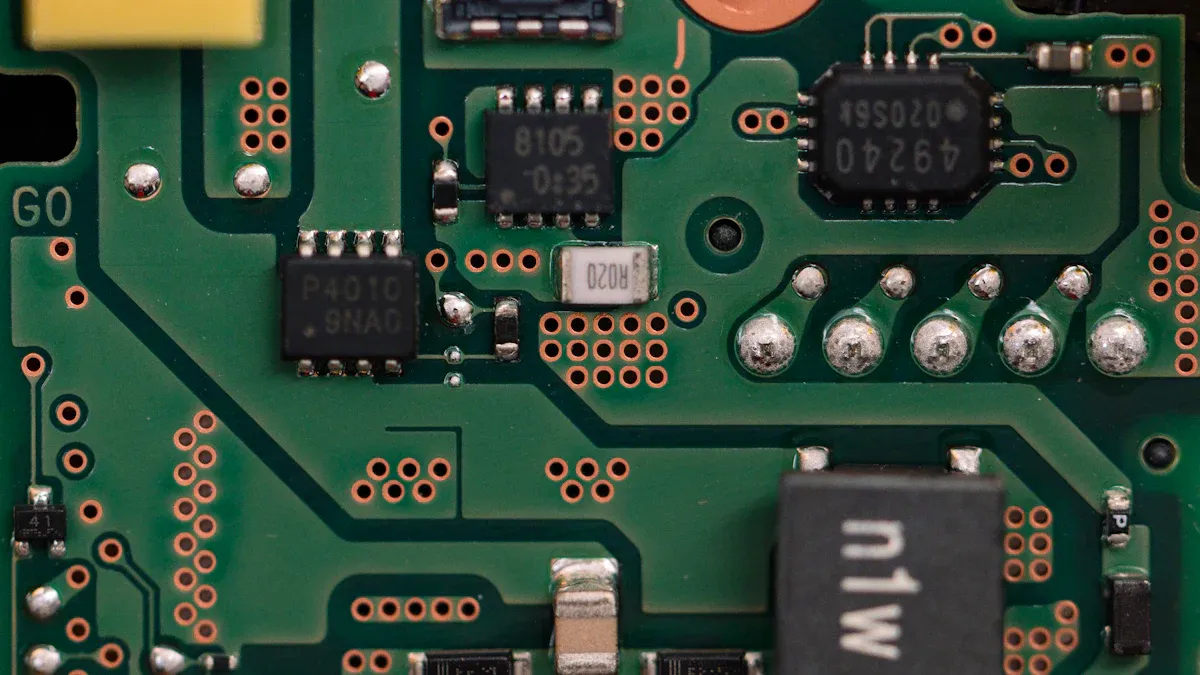

Not Verifying Material Sourcing

If you do not check where materials come from, you might get fake or bad parts. This can break circuits and make products less reliable. Always look at materials and check parts before using them. Use tests like looking, x-ray, and electrical checks to make sure parts are real. Good pcb manufacturing needs good materials and tracking.

- Check papers and packaging.

- Look at device markings for signs of use.

- Do heat and aging tests to make sure parts last.

How to Choose a PCB Manufacturer

Picking the right pcb manufacturer is important. It affects quality, cost, and delivery. You should follow steps to avoid mistakes. This helps you get good results.

Document Technical Specifications

First, write down all your technical details. Good notes help stop errors. They also help the manufacturer know what you want. Here are some documents you should get ready:

- Gerber Files: Show how your PCB looks and its layers.

- Drill Files: Tell the size and spot of each hole.

- Fabrication Drawing: Explain board size, shape, and special needs.

- Bill of Materials (BOM): List every part and where it comes from.

- Material Specifications: Say what materials you want for your board.

- Stack-up Information: Show the order and kind of layers.

- Electrical Properties Requirement: Set rules for how circuits work.

- Surface Finish Specifications: Say how the board should be finished.

- Quality Requirements: List the standards your board must meet.

- Panelization Guidelines: Explain how boards are grouped for making.

- Panel Drawing: Give details about panels and defect limits.

- Packaging: Say how you want boards packed for shipping.

Tip: Clear files help stop mistakes like wrong parts, bad soldering, or holes in the wrong place.

Evaluate Quality Control Processes

Check how each manufacturer keeps boards good. The best companies use strong systems. This makes boards reliable. Look for these common steps:

| Quality Control Process | Description |

|---|---|

| ISO 9001 Certification | Makes sure the company follows set rules for quality. |

| Process Control | Plans and checks every step to stop mistakes. |

| Testing Protocols | Uses tests to check if boards work well and last long. |

| Material Selection | Checks all materials to make sure they fit your needs. |

You can ask about staff training and record keeping. Good control means fewer problems and better boards.

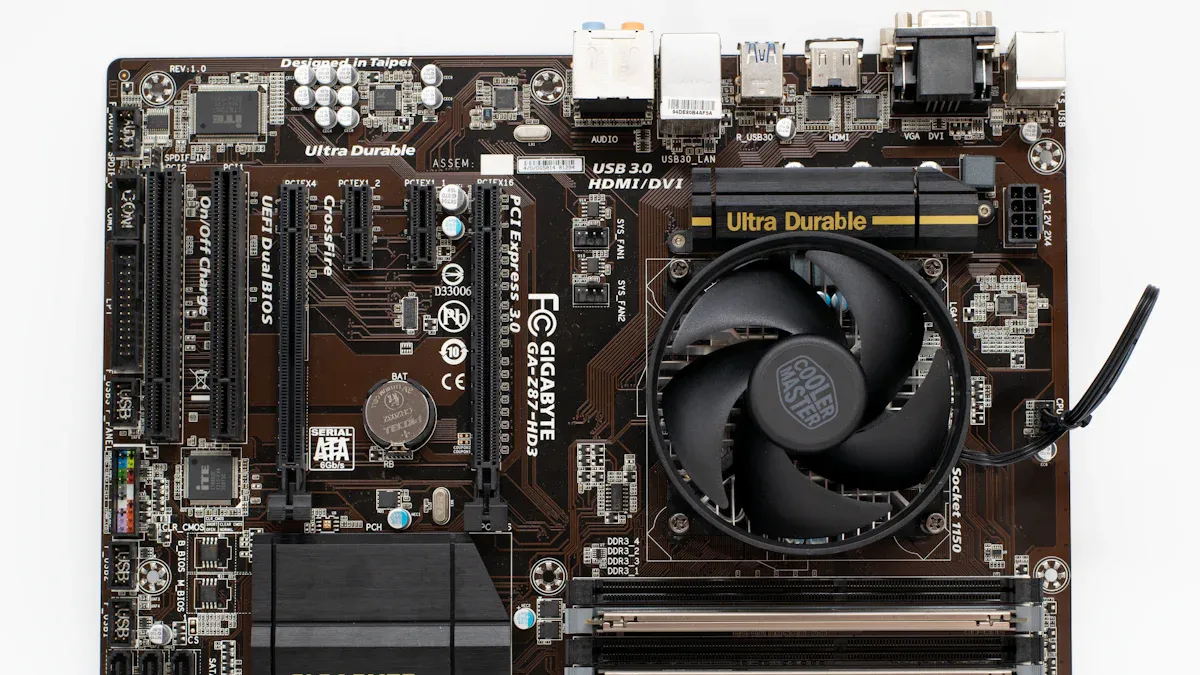

Assess Manufacturing Capabilities

Not every manufacturer can make every board. Match their skills to your project. Ask about their machines and special services. Here are some things to look for:

| Capability Type | Description |

|---|---|

| Certifications | Look for AS9100 or NADCAP for high-reliability needs. |

| Advanced Manufacturing Technologies | Fine line widths, microvias, and high-precision tools. |

| Quality Assurance Systems | Flying probe testers and other advanced test equipment. |

| Multilayer PCB Production | Can they make boards with 20 or more layers? |

| Rigid-Flex PCB Manufacturing | Skills with flexible and rigid boards together. |

| Advanced Surface Mount Technology | Can they handle tiny parts and many pins? |

| Rapid Prototyping Services | Fast turnaround for new designs. |

| Automated Production Workflow | Use of robots and machines to cut down on errors. |

| Thermal Management Solutions | Can they add features to manage heat? |

| Customization Capabilities | Will they work with you to change designs for better results? |

| Environmentally Compliant Production | Do they follow RoHS and other green rules? |

Note: Use a table to compare different manufacturers’ skills side by side.

Check Experience and Track Record

Pick a manufacturer with lots of experience. This means they have solved problems before. They know how to avoid mistakes. Look for these signs:

| Indicator | Description |

|---|---|

| Line Efficiency | Shows how well they use their machines and workers. |

| Overall Equipment Effectiveness (OEE) | Measures how well their equipment works. |

| Overall Resource Effectiveness (ORE) | Checks how well they use all resources. |

Check for certifications like ISO 9001, IPC-A-610, RoHS, IATF 16949, and AS9100. These show they meet industry rules. Ask for testing reports, equipment lists, and client feedback. Reviews and case studies help you see if they deliver on time and fix problems.

Compare Lead Times and Flexibility

Lead time means how long boards take to make and ship. You need to know if they can meet your schedule. Here are steps to compare lead times and flexibility:

- Check if they have ISO 9001 and UL certifications.

- Ask what boards they make and if they can customize.

- Review their experience and customer feedback.

- Test their service by asking questions.

- Look at prices and how fast they deliver.

Planning ahead saves money. Rush orders cost more, sometimes 20-40% higher. Quick-turn services work best for small runs. Standard lead times save money for big projects.

Clarify Pricing and Hidden Costs

Always ask for a full quote before you agree. Some costs hide in the fine print. Here are questions to ask:

- Is the quote all-inclusive, with no extra fees?

- Can you plan ahead to avoid rush charges?

- Can you combine orders to save on setup costs?

- Are you using standard materials to keep costs low?

- Is your design easy to make, or does it need special steps?

- Can you get a better deal with a long-term partnership?

- What are the shipping and logistics costs?

Tip: Clear pricing helps you avoid surprises and keeps your project on budget.

Test Communication and Support

Good communication helps your project run smoothly. Pick a manufacturer who answers quickly and helps solve problems. Here is what to look for:

- Do they offer support by phone, email, and chat?

- Can you talk to engineers if you have design questions?

- Do they have 24/7 support or a dedicated account manager?

- Are they open to answering many questions?

- Do they explain their processes clearly?

Strong support helps you fix issues fast. It keeps your project on track. Good communication builds trust and helps future projects.

Remember: The best manufacturers value your questions and work with you to find solutions.

You can stop common mistakes if you learn about each manufacturer. Write down what you need for your project. Talking clearly helps you avoid problems and being late. Use a checklist to help you choose:

- Look at their skills and how long they have worked.

- See what machines and workers they have.

- Ask if they make prototypes.

- Make sure they check quality and have certifications.

- Check what technology and buildings they use.

- See if they can change things for you.

- Make sure they can grow with your needs.

- Compare their prices and what they offer.

- Check how fast they work and deliver.

Follow these steps to get better results for your next PCB project.

FAQ

What should you ask a PCB manufacturer before starting a project?

Ask about their experience and how long they have worked. Find out how fast they can finish your project. Ask what steps they use to check quality. Good communication helps you know what will happen. Ask how they deal with changes. Clear answers mean they care about your project.

Why does communication matter in PCB manufacturing?

Talking helps you stop mistakes before they happen. You can tell them what you need and get updates. If you have questions, quick replies help you stay on track. Good communication builds trust and helps you fix problems early.

How do you handle design changes during production?

Tell your manufacturer about changes as soon as you can. Use simple words to explain what you want. Ask for written updates about the changes. This stops confusion and keeps your project moving.

What if you find a problem after delivery?

Contact your manufacturer right away if you see a problem. Explain the issue clearly so they understand. Ask for help or a replacement. Good manufacturers answer fast and help you fix things.

How can you improve communication with your PCB manufacturer?

Set up regular meetings to talk about your project. Use email to send updates and files. Name your files so they are easy to find. Ask questions if you do not understand something. Good communication helps you avoid delays and keeps your project going well.