How to Assess Cable and Wire Harness Assembly Providers for Quality and Reliability

You need to use a clear plan when you check cable & wire harness assembly services. If you do not check carefully, you might pick the wrong cables. You could also have bad installation and weak testing. These problems can make things break and cause safety dangers. If you pick cable & wire harness assembly services with good certifications and lots of experience, you get better signal quality. You also get steady power and your equipment lasts longer. Good cable & wire harness assembly services help stop breakdowns and save money on repairs. Always look for long-term value and strong teamwork with your cable & wire harness assembly services provider.

Key Takeaways

- Pick providers with good certifications like ISO 9001 and IPC/WHMA-A-620. These help make sure things are safe and high quality.

- Find providers who have lots of experience in your industry. This helps you avoid mistakes that cost money and get products you can trust.

- Choose makers who use strong testing and quality checks. This helps find problems early and keeps things at a high standard.

- Make sure there is clear talking and help after you buy. This builds trust and helps fix problems fast.

- Check customer reviews and if the company has steady money. This helps you find a partner who will help you for a long time.

Certifications and Industry Standards for Cable & Wire Harness Assembly Services

Certifications help make sure cable assembly services are good and safe. If a provider has the right certifications, you know they follow important rules. These certifications prove the company makes cable assemblies and wire harnesses the right way. They also help you avoid suppliers who might not give you good products.

Key Certifications and ISO 9001 Compliance

You should pick providers with well-known certifications. Some examples are ISO 9001, IPC/WHMA-A-620, RoHS, and REACH. Each one checks a different part of the work. The table below tells what each certification means:

| Certification | Description |

|---|---|

| ISO 9001 | Shows the company cares about quality management. |

| IPC/WHMA-A-620 | Lists rules for cable and wire harness assemblies to make them strong. |

| RoHS | Makes sure cable assemblies are safe for the environment. |

| REACH | Checks chemicals used in making cables to keep people safe. |

ISO 9001 helps you get the same good quality every time. It also helps you trust your provider more. If a company follows ISO 9001, you will see fewer mistakes and better cable assemblies. This standard means the provider uses clear steps and keeps good records.

Industry Experience and Application Knowledge

You need a provider who knows your industry well. For example, cars need wire harnesses that can handle heat, shaking, and chemicals. A provider with special knowledge will pick the best materials and designs for you. This helps stop problems and keeps your work safe. When you choose cable assembly services with lots of experience, you get better results and save money over time.

Safety Protocols and Guarantees

Safety steps protect your equipment and your workers. Good providers use machines to get wires ready and test every cable harness before sending it out. They do things like termination, crimping, and soldering to stop problems. They also use strong materials and keep wires neat to prevent damage. Providers who promise safety usually have fewer mistakes and more good products. The table below shows why strong safety steps are important:

| Measurable Outcome | Description |

|---|---|

| Reduced defect rates | Fewer products break or fail. |

| Improved yield | More good products from each group. |

| Compliance assurance | Fewer troubles with checks and rules. |

| Audit-ready documentation | Easy to find records for customers and inspectors. |

If you pick cable assembly services with these safety steps, you get cable assemblies and wire harnesses that work well and last a long time.

Engineering Capabilities and Custom Cable Assembly Solutions

In-House Design and Customization Services

If you pick a provider with strong engineering skills, you get help with design and custom cable assembly. Many companies now offer these services to meet your needs. Customization lets you match products to your industry, like automotive, medical, or aerospace. You get many benefits:

- Products work for many industries

- You save money by using less material

- Projects finish faster

- Quality and reliability are higher

- You can compete better in your market

- You can use new technology easily

Providers with their own design teams can change plans fast. This helps you solve problems and build good partnerships.

Technical Expertise and Problem-Solving

You should check engineering skills when you choose a cable harness assembly provider. Technical expertise is important for hard cable assembly jobs. Skilled engineers know about design, prototyping, and picking materials. They use special software and 3D modeling to handle tough designs and make sure connectors fit. Technical expertise helps you by:

- Handling tough designs with good routing and connector placement

- Making sure parts work together to stop failures

- Finding good materials for strong products

Custom cable assemblies can have problems like cable length, connector choice, and cost. Providers fix these with careful testing and smart design.

Tip: A provider with experience in hard cable assembly can help you avoid expensive mistakes and keep your project moving.

Prototyping and Application Fit

Prototyping is important to make sure your custom cable assembly fits your needs. When you test a prototype, you check if connectors fit, cables are the right length, and if it works well. This step helps you find problems early and fix them before making lots of products. Prototyping also helps you save money by focusing on what matters most. Providers use real-time testing and special CAD tools to improve designs and make sure they fit your needs. Picking strong materials and making sure things last means your cable harness will work well for a long time.

Manufacturing, Testing, and Quality Control Practices

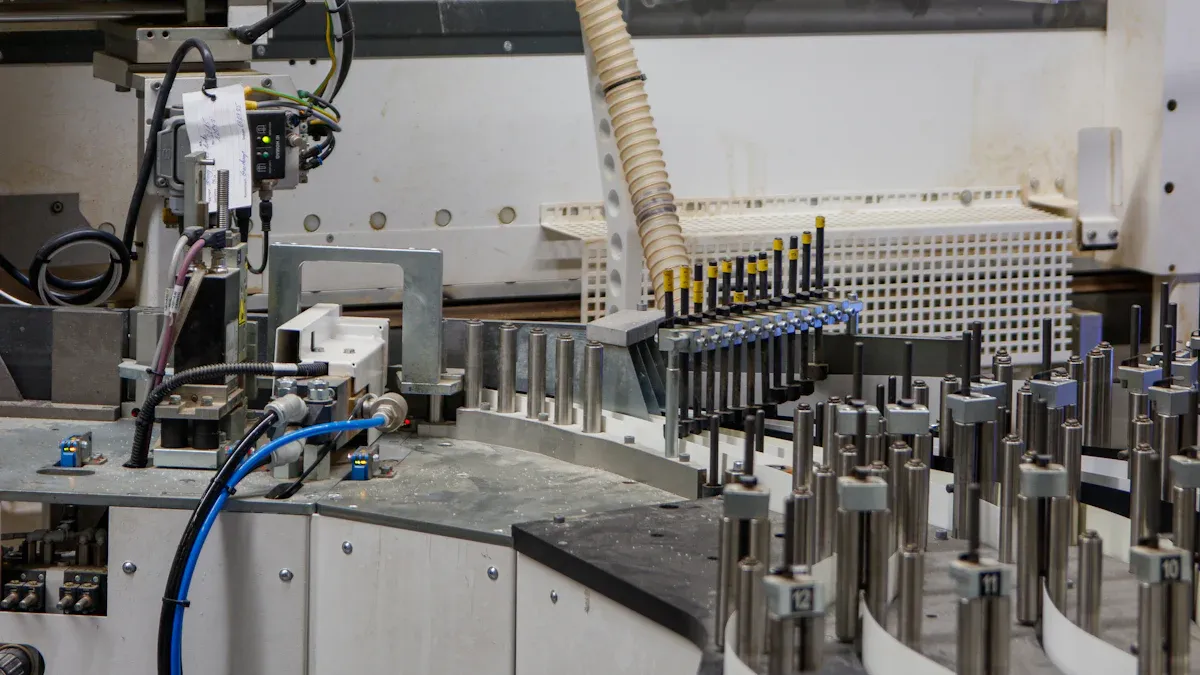

Advanced Equipment and Production Technology

You want your wire harness assembly to be very good. New machines and smart ways of making things help a lot. Today, cable assembly factories use new technology to work faster and better. These tools and methods help save money and time:

- Automation helps make things more exact and quick. Robots and machines do jobs that need careful hands and sharp eyes. This means fewer mistakes and less money spent on workers.

- Digital twin and simulation let you test designs on a computer first. You can find problems early and fix them before building anything.

- Lean manufacturing ideas, like Just-In-Time and Kanban, help stop waste and keep work moving smoothly.

- AI and machine learning look for mistakes fast and find errors people might miss.

- Automated testing equipment checks every wire harness for problems before it leaves the factory.

These tools help you make hard cable assembly products with fewer mistakes. They also let you split a big cable harness into smaller parts for faster work. Smart design and Design for Manufacturability make it easier to build good cable assemblies and stop delays.

Tip: Using new materials can help your cable assemblies work better and save energy when making them.

Testing and Quality Control Procedures

You need strong testing and quality checks to make sure your cable assemblies always work. If you skip tests, you might miss 62% of problems in the field. Good testing can stop up to 98% of warranty claims. Fixing a bad wire harness after it ships costs three times more than fixing it during assembly.

Here is a table that shows how different tests help find problems:

| Testing Type | Detection Rate |

|---|---|

| Continuity Testing | 62% of field failures |

| Insulation Resistance | 85% – 99% |

| Hipot Testing | 85% – 99% |

You should pick cable assembly services that use these quality checks:

| Quality Control Procedure | Description |

|---|---|

| Automated Testing | Checks for over-crimping and under-crimping of terminals. |

| Ongoing Quality Checks | Makes sure wires are cut and stripped right, so you have less rework. |

| Final Testing | Uses CableEye to check for opens, shorts, mis-wires, and resistance values. |

| Formal Quality Management System | Follows ISO 9001:2015 and IPC/WHMA-A-620 for strong quality management. |

| Training and Experience | Staff training keeps skills sharp for high-quality manufacturing. |

| Robust Maintenance Program | Preventive maintenance and calibration keep machines working right. |

| Standardized Documentation | Good records help you repeat success and prove quality. |

| Inspection of Incoming Materials | Checks all parts before use to match specs. |

| Setting the Machines | Documented settings stop unauthorized changes and keep quality high. |

| First Crimp and First Article Testing | Pull tests and full checks on the first harness catch problems early. |

| Design for Manufacturability | Custom builds, like braiding for protection, improve quality. |

| Continuous Improvement | Always looking for ways to get better at quality control. |

You should also use lean manufacturing to stop waste, train your team, and set up checkpoints during assembly. These steps help you make hard cable assembly products with fewer mistakes and better reliability.

Note: Top providers keep defect rates below 0.1%. Good testing and quality checks help you reach this goal.

Consistency and Traceability in Wire Harness Production

You want every wire harness to be just as good as the last one. Consistency means you get the same results each time. Traceability lets you track every part and step from start to finish. This is very important for big cable assembly and cable harness jobs.

Traceability systems let you:

- Track where every part comes from and its history.

- Find and fix problems fast if something goes wrong.

- Recall products quickly if you need to.

- Meet all rules and what customers want.

Here is a table that shows how traceability works in wire harness assembly:

| Component | Description |

|---|---|

| Article | Made of many parts. |

| Items | Each is a specific example of an article. |

| Processes | Steps that turn parts into finished cable assemblies. |

| Process Example | Two crimp steps for a wire that needs crimping at both ends. |

| Results | Each outcome gets a unique Process ID for easy tracking. |

You should ask your cable assembly services provider how they use traceability. Good traceability means you can trust your cable assembly to work well. It also helps you follow industry rules and keep your customers happy.

Tip: Traceability is not just for recalls. It also helps you make your process better and show your quality to customers and inspectors.

When you pick a provider with good traceability and quality checks, you get wire harness products you can count on every time.

Supply Chain, Delivery, and Support

Material Sourcing and Inventory Management

You need a cable assembly supplier who handles materials well. Good material sourcing and inventory management help you get reliable products. Many top cable assembly manufacturers use smart ways to manage materials:

- They use fewer suppliers to save money and make things easier.

- They pick the best materials so cable assemblies last longer.

- They use Just-in-Time and Kanban to keep less inventory and move fast.

- They use ERP systems to watch inventory and plan what to make.

These steps help stop shortages and delays. They also make sure your cable harness works for you every time. When your supplier uses these methods, you get better quality and fewer problems.

Lead Times and On-Time Delivery

You want your cable assembly to arrive on time. Lead times can change depending on what you order. Here is a table that shows how long different cable assembly services take:

| Service Type | Average Lead Time |

|---|---|

| Prototype Cable Assembly Services | 7-10 Business Days |

| Shipping Time | 2-5 Days Worldwide |

| Rush Service | 3-5 Days (30-40% premium) |

| Production Delivery Times | 4-7 Weeks |

| Wire Harness Manufacturing | 3-10 Working Days |

| Wire Harness Assembly | 2-4 Weeks |

| Full Turnkey Electronic Assembly | 4-6 Weeks |

Problems in the supply chain can slow things down. Not enough workers, not enough materials, or shipping issues can cause delays. Sometimes, normal lead times can be three times longer. You should ask your cable assembly manufacturer how they handle these problems. A good supplier will tell you what is happening and try to deliver on time.

Communication and After-Sales Support

Clear communication helps stop mistakes. Good cable assembly suppliers talk with you often and give updates. They tell you what to expect after you buy, which builds trust. Regular updates help you know if your project is going well. When you can talk easily, you fix problems faster and get better products.

Tip: Pick a cable assembly manufacturer who listens to you and answers your questions fast. This support helps you feel sure about your choice and keeps your project on track.

Reputation, References, and Cost Evaluation

Customer Reviews and References

When you pick a wire harness assembly partner, you want to know what other people think. Customer reviews and references give you real opinions. They show how a provider solves problems and helps customers. Many people check these things when looking at a provider’s reputation:

- Fast customer service

- Clear paperwork and reports

- Ways to fix issues

- Technical help when needed

- Honest updates about production and problems

You should ask for references from old customers. Good reviews mean you will likely get good products and strong help. A trustworthy manufacturer will share customer stories and answer your questions.

Financial Stability and Longevity

You need a partner who will be there for you later. Financial stability means a provider can handle big orders and hard times. A reliable manufacturer with many years in business has shown they can deliver. You can check how long a company has worked in wire harness. Look for signs that they buy new machines and train workers. This helps you trust your cable harness projects will finish on time.

Balancing Cost, Value, and Reliability

You want the best deal, not just the cheapest price. The right wire harness assembly partner gives you more than low-cost parts. They offer process control, certifications, and engineering help. You should pick providers who test every wire harness and follow strict rules. This helps you avoid expensive mistakes and keeps product quality high.

| Criteria | Description |

|---|---|

| Industry Certifications | Look for providers with certifications like IPC/WHMA-A-620 or ISO 9001 to ensure quality. |

| Advanced Production Capabilities | Providers should handle intricate designs and large-scale production with state-of-the-art equipment. |

| Innovation and R&D | Manufacturers should invest in research to keep pace with advancements and ensure future-ready solutions. |

| Tailored Solutions | Custom solutions for specific industry needs ensure optimal performance. |

| Strategic Location | Proximity to key markets can lower shipping costs and speed up delivery. |

Cables are lifelines. Any technician will tell you most problems happen in the wiring.

A good evaluation process helps you find a partner who balances cost, value, and reliability. You get fewer problems and better results when you choose a provider who cares about quality products and long-term success.

If you follow careful steps, you pick better cable harness assembly providers. You get more reliable products by checking their engineering skills and testing. Good supply chain management also helps your results. When you choose companies with lots of experience, you build better partnerships. Looking for quality is more important than just picking the lowest price. Use the tips in this blog as your checklist. Spending time to check providers helps you avoid problems and helps your company grow.

- Manufacturers who give good engineering feedback help stop reliability problems.

- Using controlled steps and keeping records of tests, like pull-force checks, keeps product quality high for a long time.

- Talking early and looking at samples helps make sure products meet reliability needs.

FAQ

What is a cable harness?

A cable harness is a bunch of wires tied together. It keeps wires neat and safe inside machines or cars. This helps stop damage and makes fixing things easier.

Why do certifications matter when choosing a provider?

Certifications mean the provider follows important rules. They help you know the products are safe and good quality. Checking for certificates can help you avoid problems.

How do I know if a provider offers custom solutions?

You can ask if they do design work for you. Look for companies with their own engineers or who make samples. They should answer your questions and show past custom projects.

What should I do if I find a problem after delivery?

Contact your provider as soon as you notice a problem. Good companies help you after you buy. They will fix the problem or give you a new product if needed.