How Do New Energy Automobile Assembly Technologies Work

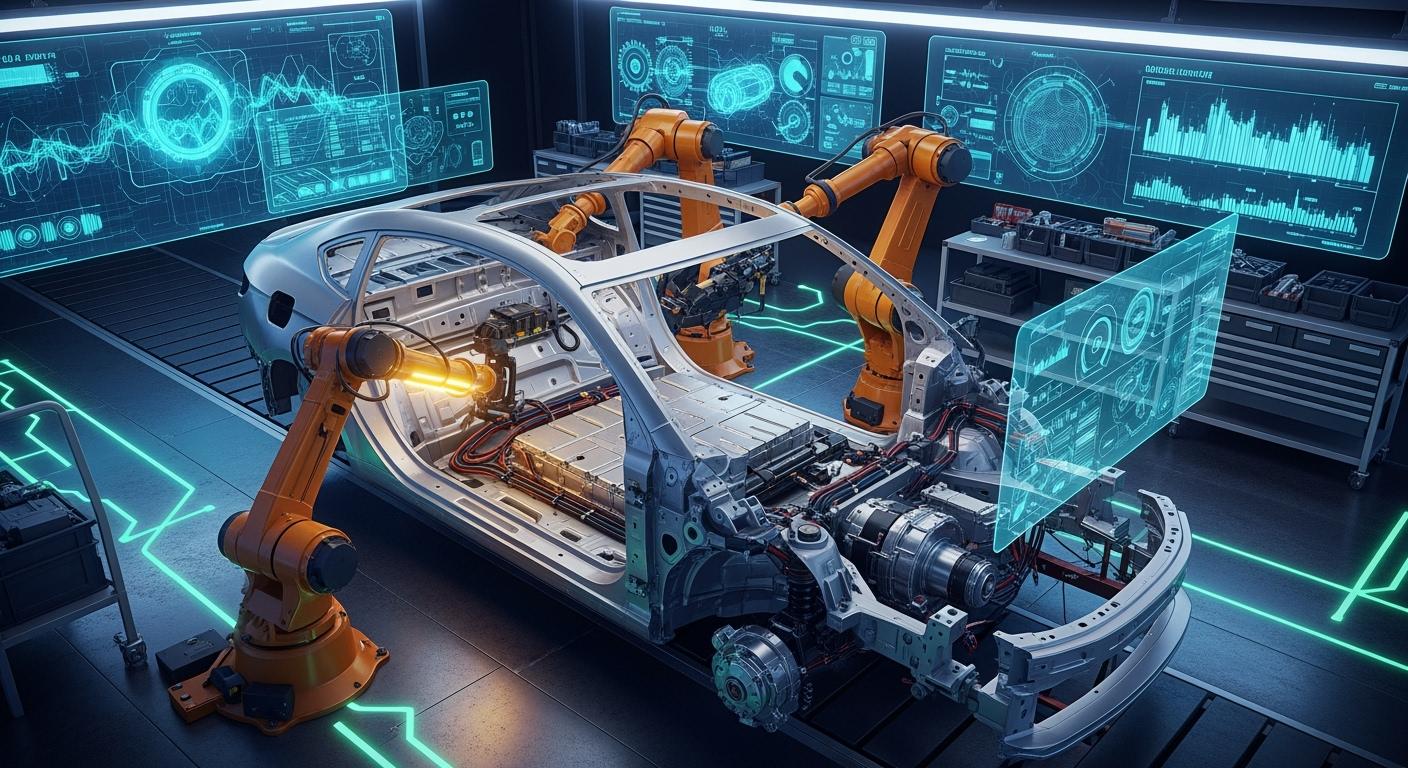

You see New Energy Automobile Assembly transforming how electric and hybrid vehicles are produced. This shift takes you away from traditional car manufacturing methods. Now, New Energy Automobile Assembly relies on advanced automation and smart energy management systems. Every stage in New Energy Automobile Assembly involves precise robotics and digital controls. This evolution means you handle electric batteries, motors, and electronics with greater attention and expertise. As you observe this transition, you notice how factories adapt to support the rise of electric vehicles.

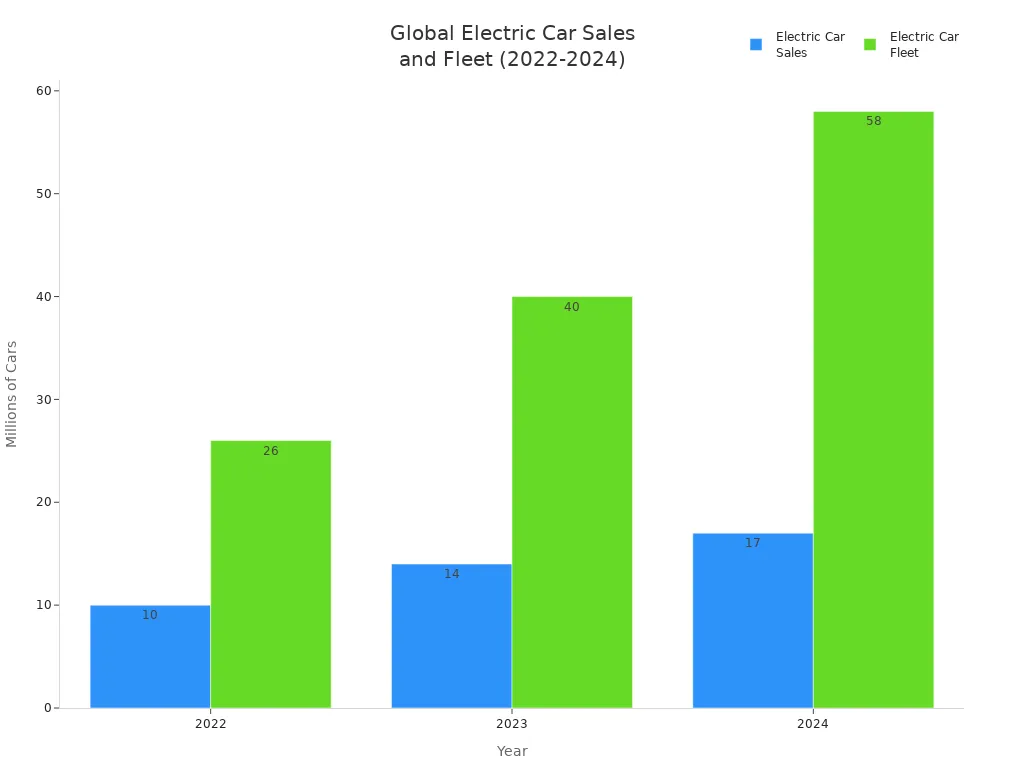

| Year | Global Electric Car Sales (millions) | Global Electric Fleet (millions) | Market Share (%) |

|---|---|---|---|

| 2022 | 10 | 26 | N/A |

| 2023 | 14 | 40 | N/A |

| 2024 | 17 | 58 | 22 |

Over the past five years, New Energy Automobile Assembly has introduced more advanced automation and increased investment in smart testing. The production of electric vehicles has accelerated rapidly. This ongoing change is shaping the future of car manufacturing and driving innovation in new vehicle technologies.

Key Takeaways

- New Energy Automobile Assembly uses smart machines and robots to help make electric cars faster.

- Battery systems are very important. Solid-state technology makes cars safer and helps them go farther on one charge.

- Energy management systems keep car parts at the best temperature. This helps the parts last longer and work better.

- Mixed-model production lines let factories build different cars quickly. Factories can change what they make to match what people want.

- Workers must learn new skills for electric car assembly. Training teaches them technical things and safety to fit what the industry needs.

Key Components in New Energy Automobile Assembly

Battery Systems and Next-Gen Technology

Battery systems are very important for battery electric vehicles and all-electric vehicles. These parts store energy and give power to move the car. Making batteries uses new ways to build big traction battery pack units. These packs have high energy density cells, so cars can go farther with one charge. Solid-state batteries use solid electrolytes, which make them safer and more stable. Making batteries also works on fast charging and making batteries last longer. Battery management systems check each cell to keep the traction battery pack safe and working well. Making batteries for electric vehicles needs strong quality checks to make sure they work right.

- Solid-state technology makes battery manufacturing safer.

- Traction battery pack design helps cars drive longer.

- Battery management systems stop batteries from getting too hot.

Electric Motors and Power Electronics

Electric motors change electrical energy into movement. Every electric vehicle has these parts. The electric motor and power electronics work together to control speed and force. New ways of making these use wide-bandgap semiconductors like SiC and GaN. These materials help power electronics work better and waste less energy. The electric motor and power electronics help cars speed up smoothly. Making batteries also helps connect electric motor systems. The electric motor needs careful control from advanced electronics.

| Advancement | Description |

|---|---|

| Wide Bandgap Semiconductors | Make power electronics work better and stay cooler. |

| Modular Power Converters | Help electric vehicles use power better and cost less. |

Energy Management and Thermal Systems

Energy management keeps all parts at the right temperature. Thermal systems use coolants, pumps, and heat exchangers. These parts stop the traction battery pack and electric motor from getting too hot. Making batteries uses thermal interface materials to move heat away from important parts. Advanced control systems save energy and make things safer. Charging equipment and electric vehicle supply equipment also need good cooling. Good energy management helps all parts last longer.

Note: A modern thermal management system can save up to 10% energy compared to older systems.

Lightweight and Safety Structures

New energy vehicles use light materials in their frames. Battery manufacturing now uses strong steel, aluminum alloys, and carbon fiber composites. These parts take in and spread out crash energy to protect the traction battery pack and people inside. Light designs help cars use less energy and go farther. Manufacturing uses smart design and new ways to make cars lighter. The frame also keeps the traction battery pack safe during crashes.

- Aluminum and composites make car parts lighter.

- Strong parts protect the traction battery pack and keep people safe.

- New ways of making cars help them be lighter and stronger.

Electric Vehicle Assembly Process

Chassis and Body Integration

The electric vehicle assembly starts by joining the chassis and body. This step is not the same as how regular cars are made. Composite materials make the car lighter and stronger. Engineers use computer tests to check safety and stability. Aerodynamic wheels help the car use less power. Load paths are changed to keep people and batteries safe in a crash. These updates help electric vehicles use less energy and go farther.

- Composite materials make cars lighter but still safe.

- Aerodynamic wheels help save energy.

- Load paths are changed for better crash safety.

Robotic Battery and Fuel Cell Assembly

Robots put together batteries and fuel cells very carefully. Automation checks quality all the time, so problems are found early. Modular designs help factories make more cars faster. Robots use 3D tools to tighten battery parts and seal covers. Vision systems look at fire protection and check for mistakes. Stacking systems line up fuel cells to make them last longer. Inspection systems help cut waste and track parts. These steps make electric car building safer and better.

| Step | Description |

|---|---|

| 6 | Robots with many tools tighten battery parts using 3D tools. |

| 7 | Battery tools and controllers make sure bolts are tight and in the right place. |

| 8 | Vision systems check fire protection materials. |

| 9 | Tight covers stop water and gas from getting in. |

| 10 | Special fastening closes the battery tray tightly. |

Tip: Automated inspection helps keep battery assembly safe and high quality.

Mixed-Model Production Lines

Mixed-model lines let factories build different cars on one line. These lines can make electric, hybrid, and regular cars together. Honda and BMW use these lines to make many cars each day. Digital twins and AI help make production faster and smarter. IoT platforms let factories change plans quickly. This makes it easy to build more cars when needed.

- Mixed-model lines build many types of cars.

- Digital twins and AI make factories work better.

- Flexible lines help factories change fast.

Software and Electronics Coordination

Software and electronics must work together in electric vehicles. The vehicle control unit (VCU) helps save energy and improve performance. It changes power and braking using data from the battery management system (BMS) and motor control unit (MCU). The MCU controls how fast and strong the motor is. The BMS checks the battery to keep it safe and working longer. All these systems work together to make electric cars more reliable.

| Component | Role in Reliability | Description |

|---|---|---|

| VCU | Saves energy and improves performance | Changes power and braking using data from BMS and MCU. |

| MCU | Controls the motor | Gets commands from VCU to manage speed and strength. |

| BMS | Checks battery health | Keeps battery safe and helps it last longer. |

Final Testing and Quality Control

The last step is testing and checking quality. End-of-Line (EOL) testing checks brakes, lights, and engine. Advanced Product Quality Planning (APQP) means you write down every step. The Production Part Approval Process (PPAP) checks that all parts are good before use. Problems like tolerance drift and warping are fixed with inspection and special tools. Insulated tools and multi-bolt spindles stop electrical accidents. These steps help make sure electric vehicles are safe and work well.

| Quality Control Measure | Description |

|---|---|

| End-of-Line (EOL) Testing | Checks that all systems work right, like brakes and lights. |

| Advanced Product Quality Planning (APQP) | Writes down how cars are made and tested to keep quality high. |

| Production Part Approval Process (PPAP) | Makes sure all parts are good before they go in cars. |

Note: Automated inspection and real-time checks help keep costs low and quality high.

Common Challenges and Solutions

There are some problems when making electric vehicles. Tolerance and concentricity can change, so machines check and fix them. Light materials can bend, so tools and fluids are chosen carefully. Warping is fixed with heat treatment and vacuum tools. Coating errors are solved by planning for extra thickness. Lead-time pressure is handled with modular tools and standard libraries. Cost and yield are balanced by designing for easy building and using inspection early.

| Challenge | Description | Solution |

|---|---|---|

| Unstable tolerance and concentricity | Parts can change shape and not fit right. | Use machines to check and keep parts steady. |

| Machining challenges with lightweight materials | Light parts can bend or get rough edges. | Pick the right tools and fluids. |

| Warping and flatness issues | Some parts can warp from heat. | Use heat treatment and vacuum tools. |

| Surface treatment errors | Coating can change part size. | Plan for coating thickness in design. |

| Lead-time pressure | Fast changes can cost more. | Use modular tools and standard libraries. |

| Balancing cost and yield rate | High quality can cost more, low yield loses money. | Design for easy building and use inspection early. |

Tip: You can make more cars by training workers, using flexible lines, and adding new technology.

Advanced Technologies in New Energy Automobile Assembly

AI Automation and Robotics

AI automation and robotics are changing how electric vehicles are built. Now, advanced robots work with people on the assembly line. These robots do the same jobs over and over. They also do jobs that need to be very exact. Cobots help people put in batteries and do other careful work. AI vision systems look for mistakes that people might not see. This helps make cars better and have fewer errors. Automation lets workers think of new ideas and improve cars. It helps companies stay ahead in a fast-changing world.

- Advanced robots make work faster and easier.

- Cobots help keep workers safe and speed up jobs.

- AI vision systems find mistakes quickly.

Digital Manufacturing and Data Analytics

Digital manufacturing gives new tools to make electric vehicles better. Digital twin technology makes a computer copy of the assembly line. You can test changes and fix problems before they happen. Real-time data helps change battery making and improve quality. Data analytics finds slow spots and helps fix them fast. These tools keep the factory running smoothly and well.

| Aspect | Impact |

|---|---|

| Assembly Lines | Cars are made faster with fewer mistakes. |

| Battery Production | Testing is better and batteries are stronger. |

| Quality Control | AI finds problems and keeps quality high. |

| Predictive Maintenance | Machines get fixed before they break. |

| Supply Chain Logistics | Parts arrive faster and there are fewer delays. |

| Worker Efficiency | Workers get help right away and jobs are easier. |

Digital tools make factories more flexible. You can switch between different cars and batteries with less waiting. This helps meet the need for more electric vehicles.

Green Manufacturing Innovations

You help make factories cleaner and better for the planet. Solar and wind energy power the factory. Biogas is used to lower pollution. Closed-loop systems recycle materials and cut waste. Recycled and plant-based materials are used for car parts. These steps protect the earth and support clean energy.

| Innovation Type | Description |

|---|---|

| Renewable Energy Adoption | Use solar, wind, and biogas to make less pollution. |

| Energy-Efficient Processes | Save energy when making cars. |

| Closed-Loop Systems | Recycle and reuse materials to make less trash. |

| Recycled and Bio-Based Materials | Use recycled or plant-based parts for electric vehicles. |

Rules and standards around the world push factories to use clean energy. High standards and new rules make companies try new ways. Measuring the carbon footprint means checking pollution at every step. Results are reported and ways to improve are found. Green manufacturing helps lower CO2 and makes electric vehicles better for everyone.

Tip: Every step toward clean energy and smart factories helps make a better future for electric vehicles.

Workforce Impact and Skills

Changing Roles and Job Quality

Big changes are happening in car factories. Electric vehicles are becoming more common. Many jobs now use automated machines and robots. Workers need new skills to keep up. Union deals help make jobs better. They raise pay and improve working conditions. Some battery factories work together in joint ventures. Workers must team up to protect their rights. Jobs in electric vehicle plants need more technical knowledge. Companies want more skilled workers as they build more cars. These jobs often pay better and are safer for workers.

- Many jobs now use robots and computers.

- Union deals make jobs safer and pay higher.

- Battery factories bring new jobs and new challenges.

New Skills and Training Needs

Workers need new skills for electric vehicle assembly. Training teaches about batteries, motors, and energy storage. You can join academies or earn certificates in electric vehicle technology. Some programs have short courses so you can learn fast. Jobs in this field need both technical and digital skills. You can choose advanced manufacturing or energy storage as a career path. These programs help you get ready for clean energy and electric vehicle jobs.

| Training Program | Focus Areas | Description |

|---|---|---|

| Electrification Training | Electric Vehicle Assembly, Battery Production | Learn safety, production, and maintenance for electric vehicles. |

| EVES Manufacturing Training Academy | EV and Energy Storage Technology | Get certificates in advanced manufacturing and maintenance. |

| DOE ITAC Program | Clean Energy and Manufacturing | Train for clean energy jobs and improve productivity. |

| IBEW Training Trust | Clean Transportation and Manufacturing | Learn about electrical systems and advanced manufacturing. |

Tip: You can earn certificates in electric vehicle basics, battery assembly, and energy storage. This helps you get more job options.

Safety and Labor Trends

Safety is very important in new energy automobile assembly. Robots work with people to make jobs safer and faster. Companies follow strict rules like ISO and OSHA to protect workers. You must join training to learn how to use new machines safely. Jobs in these factories use advanced technology. Labor trends now focus on skill building and teamwork with robots. More jobs need you to know machines and safety rules.

- Robots and people work together for safety.

- Training teaches you to use new machines.

- Labor trends show more jobs need technical and digital skills.

Note: You can get ready for future jobs by learning new skills and following safety rules in electric vehicle assembly.

You notice that new energy automobile assembly is changing cars and factories a lot.

- Using lighter materials and smart designs helps cars use less energy. This also means cars make less pollution.

- Electric motors and smart controls help cars go faster and work better.

Flexible assembly lines make work faster by up to 10%. They also let you keep working if one part breaks.

You see more jobs for people with special skills, like battery technicians and assemblers.Role Growth Rate (2021-2031) Electrical assemblers 21.0% Miscellaneous assemblers 2.8% By 2028, there will be more electric and hybrid cars. People will need new skills for these jobs.

FAQ

What makes new energy automobile assembly different from traditional car assembly?

You use electric batteries, motors, and advanced electronics. Robots and digital tools help you build cars quickly and safely. Lighter materials are used to save energy. This way, you make cars that are cleaner and smarter.

How do robots help in electric vehicle assembly?

Robots lift heavy battery packs and put in parts very carefully. They use cameras and sensors to find mistakes. You can finish jobs faster and make fewer errors. Robots also keep you safe by doing dangerous work.

Why is battery safety important in assembly?

Batteries must be safe to stop fires and accidents. Battery management systems check each cell all the time. Special covers and cooling systems are used. These steps keep you safe and help the car last longer.

What skills do you need for working in new energy automobile factories?

You need to know about batteries, electric motors, and digital tools. Training programs show you how to use robots and follow safety rules. You also need to solve problems and use computers.

How do factories make electric vehicle assembly more eco-friendly?

Factories use solar and wind power to make energy. They recycle materials and use less water. You help lower pollution by following green rules. These steps protect the planet and make your work better for the earth.