HDI Flexible PCB or Rigid-Flex PCB How to Choose for Modern Electronics

The most critical factor you need to consider when choosing between HDI flexible PCB and rigid-flex PCB is how well the design matches your product’s requirements. Your decision depends on the unique demands of your project, such as:

- Circuit complexity—advanced circuits often require multilayer printed circuit boards.

- Space and weight—compact devices benefit from hdi flexible pcb designs, while rigid-flex options suit products that need both durability and flexibility in tight spaces.

- Environmental conditions—high-frequency or high-heat applications need specialized solutions for reliable performance.

- Budget—simpler designs usually cost less, so you must align your choice with financial constraints.

Key Takeaways

- Identify your product’s requirements before choosing between HDI flexible and rigid-flex PCBs. Consider factors like flexibility, space constraints, and environmental conditions.

- HDI flexible PCBs are ideal for compact devices that require high adaptability and miniaturization. They excel in wearables and smartphones where space and weight are critical.

- Rigid-flex PCBs combine the benefits of both rigid and flexible designs. They provide durability and flexibility, making them suitable for complex applications in aerospace and medical devices.

- Cost is a significant factor. HDI flexible PCBs are generally more expensive, but their design can lead to overall savings by reducing the number of connectors and improving reliability.

- Always match your PCB choice to your design needs. Rigid PCBs are cost-effective for stable designs, while flexible PCBs are best for dynamic applications requiring bending.

Comparison Table

Choosing between HDI flexible PCB and rigid-flex PCB requires you to compare their core features side by side. The table below highlights the most important differences you need to consider:

| Feature | HDI Flexible PCB | Rigid-Flex PCB |

|---|---|---|

| Flexibility | High (bend radius ~0.1 mm) | Partial (flexible sections only) |

| Layer Count | 1-8 | 4-12+ |

| Complexity | High (dense, compact circuits) | Very high (integrates rigid & flex) |

| Reliability | High (excellent vibration resistance) | Very high (stable in harsh conditions) |

| Cost | High | Highest |

| Connectors | Fewer needed (direct folding) | Minimal (integrated connections) |

| Weight | Light (~0.2 g/cm²) | Moderate |

| Typical Use Cases | Wearables, smartphones, cameras | Aerospace, medical, automotive |

HDI Flexible PCB

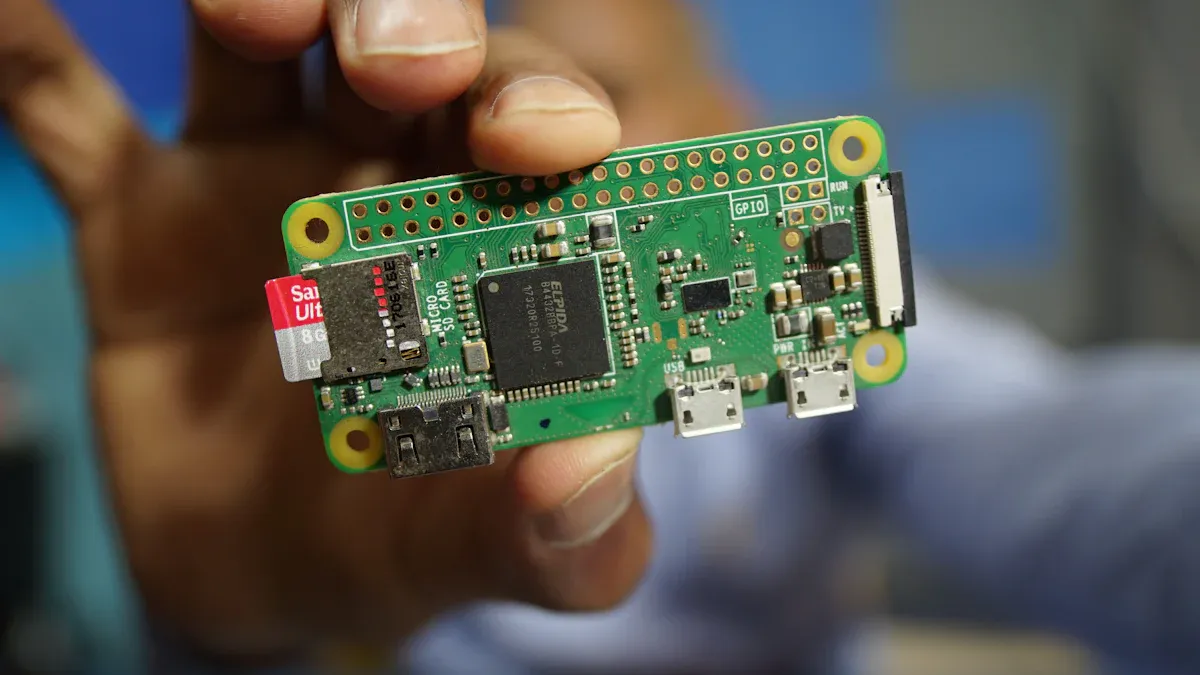

You benefit from HDI flexible PCBs when your design demands maximum adaptability and miniaturization. These boards allow you to fold or twist circuits into tight spaces, which makes them ideal for compact devices. You can reduce the number of connectors, which improves reliability and saves space. HDI flexible PCBs support high-density layouts, so you can fit more functionality into smaller products.

Tip: HDI flexible PCBs work best in wearables, smartphones, and other lightweight electronics where space and weight matter most.

Rigid-Flex PCB

Rigid-flex PCBs combine rigid and flexible layers, giving you the best of both worlds. You can design products that need both sturdy support and flexible movement. These boards handle complex, multilayer circuits and perform well in harsh environments. You often see rigid-flex PCBs in aerospace, medical, and automotive applications, where reliability and durability are critical.

- Over the past five years, prices for both flexible and rigid-flex PCBs have increased by 20-50% because of manufacturing complexity.

- You can manage costs by optimizing your design requirements and procurement strategies.

Note: Rigid-flex PCBs minimize the need for connectors, which reduces failure points and increases reliability in demanding applications.

What is HDI Flexible PCB

Definition and Features

You use an hdi flexible pcb when your design needs to combine advanced technology with adaptability. This type of board uses high-density interconnect technology to pack more connections into a smaller area. You can create high-density circuits that fit into the tightest spaces. The flexibility of these boards lets you fold, twist, or bend them to match your product’s shape.

A hdi flexible pcb supports complex layouts and allows you to add more features to your device without increasing its size. You often see these boards in products that require both lightweight construction and advanced performance. The high-density interconnect approach also helps you reduce the number of connectors, which improves reliability.

Note: Manufacturing an hdi flexible pcb requires careful planning. You must consider signal integrity and thermal management. The process demands high precision, as even small errors can cause defects. Specialized techniques like microvia formation and copper plating are essential. Quality control is critical because minor mistakes can lead to major problems.

Key features of hdi flexible pcb:

- High-density interconnects for complex, compact designs

- Flexible material for innovative shapes and layouts

- Support for advanced, miniaturized devices

- Fewer connectors needed, improving reliability

- Integration of rigid and flexible sections for better performance

Applications

You find hdi flexible pcb technology in many modern electronics. These boards help you build smaller, smarter products that stand out in the market.

Common applications include:

- Smartphones, where space is limited and performance matters

- Wearable devices, such as fitness trackers and smartwatches

- Medical equipment that needs to fit into compact enclosures

- Cameras and imaging devices with advanced features

- Consumer electronics that demand lightweight, flexible solutions

A hdi flexible pcb lets you push the boundaries of design. You can create products that are lighter, thinner, and more reliable, all thanks to high-density interconnect technology.

Flex and Rigid-Flex PCBs

Rigid-Flex PCB Overview

You often choose rigid-flex PCBs when your design needs both mechanical strength and the ability to fit into tight or irregular spaces. Rigid-flex PCBs combine rigid and flexible substrates in a single board. The rigid sections provide solid support for components, while the flexible sections allow the board to bend or fold as needed. This structure lets you create compact, reliable devices that can withstand repeated movement or vibration.

Rigid-flex PCBs excel in demanding environments. You see them in medical devices, automotive systems, aerospace, industrial robotics, and advanced consumer electronics. These boards reduce the need for connectors, which improves reliability and minimizes failure points. When you design with rigid-flex, you must pay close attention to connector placement. Place connectors away from high-stress bending areas to prevent mechanical failure. You should also consider the pitch and pin count to maintain signal integrity, and use strain relief features to distribute stress evenly.

Tip: Rigid-flex PCBs help you simplify assembly and improve durability in products that require both flexibility and robust support.

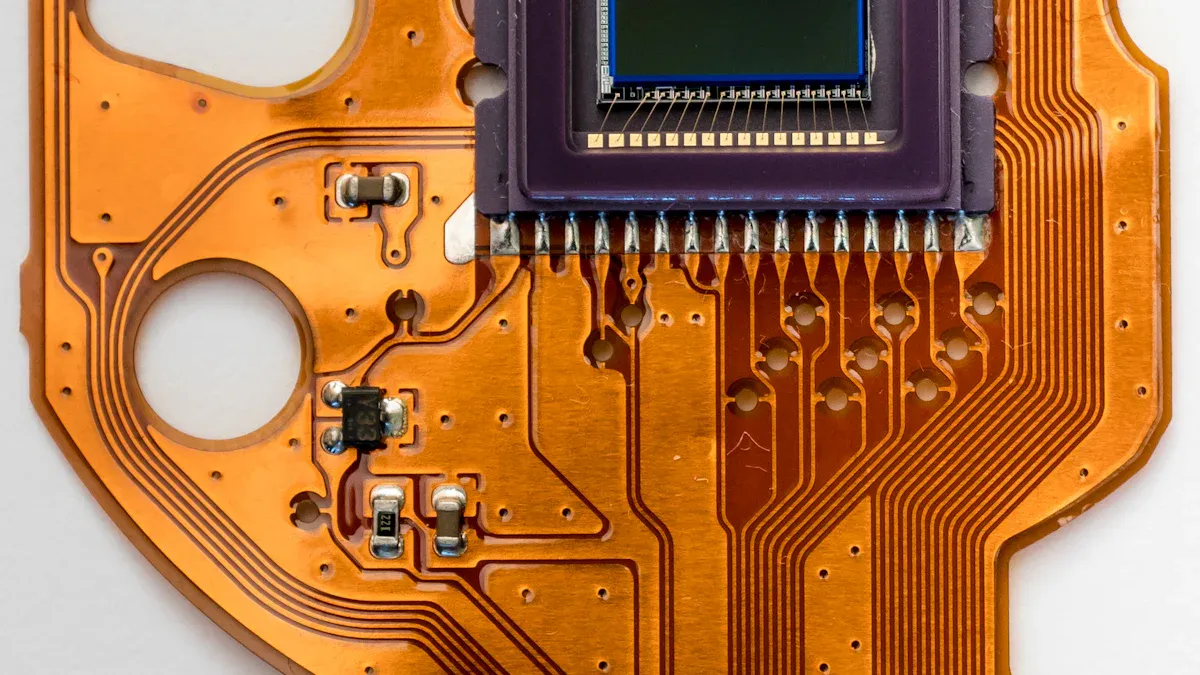

Flex PCB Overview

Flex PCBs use flexible plastic materials, such as polyimide or polyester, which allow you to bend, twist, or fold the circuit to fit your product’s shape. You benefit from flex PCBs in applications where space is limited or the board must move during operation. These boards adapt to unique enclosures and enable innovative product designs.

| Type of PCB | Structure Characteristics | Flexibility |

|---|---|---|

| Rigid PCB | Solid substrate, excellent support, inflexible | Inflexible |

| Flex PCB | Flexible materials, bends and flexes, fits tight spaces | Highly flexible, conforms to shapes |

You find flex PCBs in wearables, foldable phones, cameras, and compact medical devices. When you design with flex PCBs, you must select connectors that match the thin, flexible material. Use low-temperature soldering to avoid damaging the substrate, and always add strain relief to protect against mechanical stress.

Flex PCBs let you create lighter, thinner, and more adaptable electronics that stand out in today’s competitive market.

Key Differences Between Rigid PCB and Flex PCB

Flexibility

You will notice the most obvious difference when you compare the flexibility of rigid pcbs and flex PCBs. Rigid pcbs use a non-conductive substrate, usually fiberglass, which gives them strength but makes them inflexible. Flex PCBs use materials like polyimide, allowing you to bend, twist, or fold the board into almost any shape. This flexibility lets you design products that fit into tight or irregular spaces.

| Feature | Rigid PCBs | Flexible PCBs |

|---|---|---|

| Base Material | Non-conductive substrate, usually fiberglass | Flexible materials like polyimide |

| Flexibility | Strong and rigid | Can bend and fold into various shapes |

| Conductors | Electro-deposited copper | Rolled annealed copper for flexibility |

| Durability | Higher strength | Absorbs vibrations, endures many bending cycles |

If your application requires frequent movement or vibration absorption, flex PCBs offer a clear advantage.

Complexity

When you evaluate complexity, you must look at both the manufacturing process and the circuit design. Rigid pcbs can support more layers, which helps you build advanced, multilayer circuits. Flex PCBs, on the other hand, usually have fewer layers to maintain their flexibility. However, flex PCBs can achieve higher interconnect density, which is essential for compact and high-performance devices.

| Comparison Factor | Rigid PCB | Flexible PCB |

|---|---|---|

| Layers | Can have more layers | Fewer layers for flexibility |

| Interconnect Density | Lower | Higher |

You should choose flex PCBs if your design needs dense interconnections in a small space. For complex, multilayer circuits that do not require bending, rigid pcbs remain the standard.

Reliability

Reliability plays a critical role in your decision. Flex PCBs minimize the number of connectors and solder joints, which reduces failure points. They also absorb vibrations and can withstand repeated bending cycles. Rigid-flex pcbs combine the strengths of both types, offering enhanced signal integrity and mechanical stability in demanding environments.

| Performance Metric | Description |

|---|---|

| Enhanced Signal Integrity | Minimizes interconnects, reducing noise and EMI. |

| High Reliability | Reduces risk of failure due to fewer solder joints; can bend and flex safely. |

| Improved Mechanical Stability | Withstands higher mechanical stress, enhancing overall stability. |

Tip: You can increase the fatigue life of rigid-flex pcbs by selecting thicker copper plating and optimizing hole diameters.

Cost

Cost differences between rigid and flex PCBs can impact your project budget. Flexible PCBs are typically 20–50% more expensive than rigid pcbs for similar design requirements. Rigid pcbs have a lower baseline cost, usually ranging from $0.10 to $5.00 per square inch. Flexible PCBs often cost $0.50 to $15.00 per square inch, making them two to five times more expensive.

- Flexible PCBs are 20–50% more expensive than rigid PCBs.

- Rigid PCBs typically cost between $0.10 to $5.00 per square inch.

- Flexible PCBs generally range from $0.50 to $15.00 per square inch.

You should weigh the benefits of flexibility and space savings against the higher upfront cost.

Design Constraints

You will encounter several design constraints when choosing between rigid and flex PCBs. Consider the following:

- The operating environment, including temperature limits and signal speed requirements.

- Budget constraints, which may limit your choice.

- Space optimization, especially for compact or portable devices.

- Weight reduction, which is crucial for wearables and handheld electronics.

- Environmental conditions, such as temperature and humidity, which affect material selection.

- Manufacturing costs, since flexible PCBs are more expensive but can offer system-level savings.

- Rigid pcbs are more affordable and durable, making them ideal for stable designs.

- Flexible PCBs are better for dynamic applications that require bending and lightweight construction.

- Rigid-flex pcbs combine the benefits of both, making them suitable for complex and high-reliability systems.

Note: Always match your design requirements to the strengths of each PCB type. The key differences between rigid pcb and flex pcb will guide you to the best solution for your application.

HDI in Modern PCB Design

HDI Technology

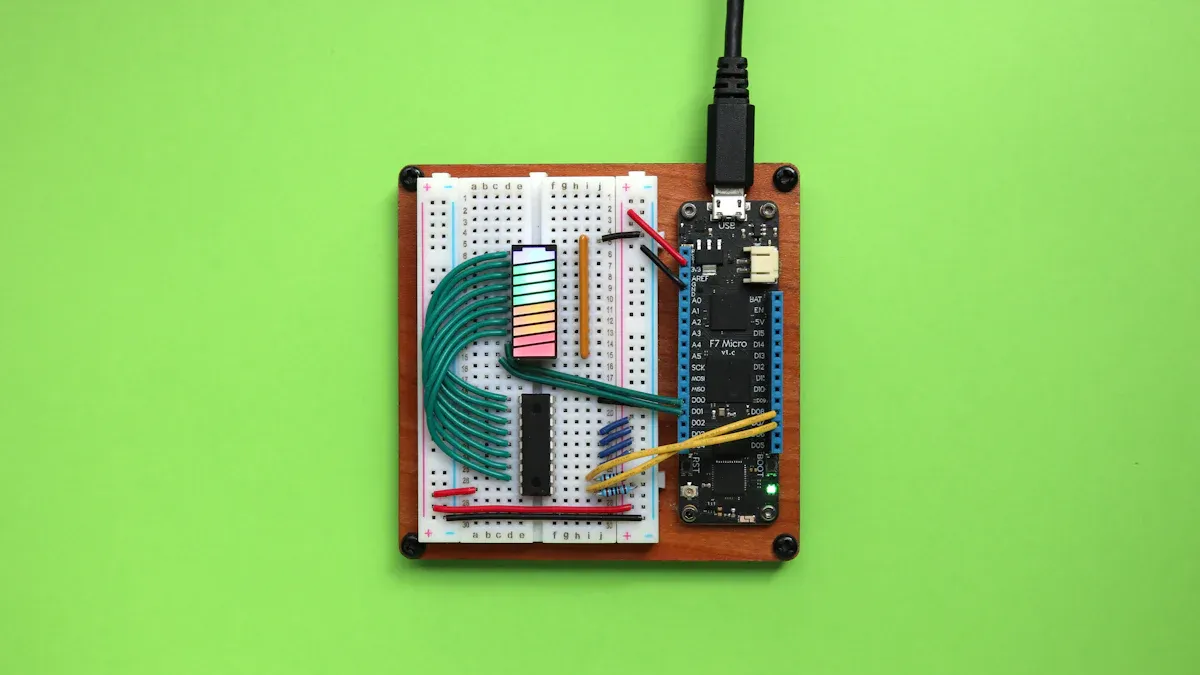

You rely on hdi technology to push the boundaries of modern electronics. This approach lets you design smaller, more powerful devices without sacrificing performance. Hdi uses microvias, advanced materials, and embedded components to achieve high-density layouts. You can route more signals in less space, which is essential for compact products.

- Microvias allow higher routing density, so you fit more connections into tight areas.

- Embedding components within layers reduces the overall size and boosts performance.

- Advanced materials improve signal integrity and thermal management.

- Enhanced soldering methods ensure strong connections and reliable operation.

Hdi technology helps you create devices that are lighter, thinner, and more efficient. You see these benefits in smartphones, wearables, and other portable electronics.

When you use hdi, you also improve electrical performance. Shorter paths between components reduce signal loss and increase power efficiency. Optimized layouts help you minimize electromagnetic interference, which is critical for high-speed circuits.

- Size reduction: Microvias and dense routing make your designs more compact.

- Better performance: Shorter electrical paths mean less signal loss.

- Enhanced signal integrity: Careful layouts reduce interference.

Hdi technology supports the miniaturization trend in electronics. You can build complex circuits in smaller spaces while maintaining high reliability.

HDI in Rigid-Flex and Flex PCBs

You face important choices when you apply hdi to rigid-flex and flex PCBs. Hdi in rigid-flex PCBs combines the strengths of rigid and flexible designs. You get durability, space savings, and the ability to handle complex circuits. Hdi in flex PCBs lets you create ultra-compact, lightweight products that can bend or fold.

Cost and design implications matter. You must understand the variables that drive cost, such as the use of microvias, blind and buried vias, and thin core dielectrics. Hdi can sometimes reduce the number of external layers, but the costs of advanced features may offset these savings. You should evaluate trade-offs carefully before you commit to hdi in your design.

- High-density interconnects and advanced via structures increase the price.

- Manufacturing complexity rises with hdi, especially in rigid-flex PCBs.

- You can optimize your budget by balancing performance needs with design complexity.

Note: Always consider both the technical and financial impact of hdi. Smart planning helps you get the most value from your investment.

Hdi gives you the flexibility to innovate. You can design products that meet strict space, weight, and performance requirements. Whether you choose rigid-flex or flex PCBs, hdi technology lets you deliver advanced solutions for modern electronics.

How to Choose Between Rigid PCB and Flex PCB

Application Needs

When you start your design process, you must first identify your application’s core requirements. The right choice between flex and rigid-flex pcbs depends on how your product will function and the environment it will face. Consider these factors:

- Flexibility: Does your device need to bend, twist, or fold during use?

- Space constraints: Will your circuit fit into a tight or irregular enclosure?

- Mechanical stresses: Will the board experience frequent movement or vibration?

- Environmental conditions: Will your product operate in extreme temperatures or high-humidity areas?

- Need for durability: Does your application demand long-term reliability and resistance to wear?

If your device must move or fit into a compact space, flexible pcb solutions offer clear advantages. For products that require both flexibility and structural support, flex and rigid-flex pcbs provide the best balance. You should always match your PCB type to the specific needs of your application.

Tip: Ignoring the bend radius requirements or miscalculating the minimum bend radius can lead to early failure. Always check these specifications during your design phase.

Design Complexity

Design complexity plays a major role in your decision. Flex and rigid-flex pcbs allow you to create intricate layouts that fit into unique shapes. You can route circuits around corners, through hinges, or into small compartments. Flexible pcbs work well for compact and lightweight devices, especially when you need to save space and reduce weight.

Rigid-flex pcbs combine flexible and rigid sections, giving you both adaptability and strength. This combination is essential for complex designs in demanding environments, such as aerospace or medical devices. You can integrate multiple functions into a single board, reducing the need for connectors and improving reliability.

Note: Common mistakes include choosing the wrong dielectric materials, misplacing through-holes, or failing to optimize the stack-up. These errors can cause signal integrity problems or manufacturing challenges.

| Mistake | Description |

|---|---|

| Wrong choice of dielectric materials | Selecting inappropriate materials can lead to performance issues in rigid-flex designs. |

| Misplacing the through-holes | Incorrect placement can affect the functionality and reliability of the PCB. |

| Insufficient bend radius | Not adhering to bend radius requirements can cause damage to the flexible sections. |

| Unoptimized stack-up | A poorly designed stack-up can lead to signal integrity issues and manufacturing challenges. |

| Inadequate spacing between conductors | Insufficient spacing can result in short circuits and other electrical failures. |

You should always review your design for these issues before moving to production. This step ensures your flex and rigid-flex pcbs will perform as expected in real-world conditions.

Space and Budget

Space and budget constraints often determine your final choice. Flex and rigid-flex pcbs excel in compact designs, especially when you need to fit circuits into tight spaces or around moving parts. Flexible pcbs can bend and adapt, making them ideal for wearables, foldable phones, and 5g devices where every millimeter counts.

Consider these points:

- Flex and rigid-flex pcbs are perfect for applications that require bending or folding, such as 5g antennas or medical sensors.

- Rigid pcbs offer a cost-effective solution for low to medium volume production, providing stability and durability.

- Flexible pcbs may have higher upfront costs, but their space-saving design can reduce the overall cost of your final product.

- Flex and rigid-flex pcbs help you minimize connectors, which lowers assembly costs and increases reliability.

⚠️ Watch out for miscalculating the minimum bend radius or ignoring bend radius requirements. These mistakes can cause material fatigue and circuit failure, especially in 5g and high-frequency applications.

When you decide how to choose between rigid pcb and flex pcb, always balance your technical needs with your budget. Flex and rigid-flex pcbs give you the flexibility to innovate, especially in advanced 5g electronics and next-generation consumer products.

Real-World Scenarios

When to Use HDI Flexible PCB

You often select HDI flexible PCBs when your design demands miniaturization, lightweight construction, and high reliability. These boards excel in products that require tight bends, compact layouts, and advanced signal integrity. The table below highlights common industries and examples where HDI flexible PCBs deliver the most value:

| Industry | Examples | Why Choose HDI Flexible PCB |

|---|---|---|

| Wearable Electronics | Smartwatches, fitness trackers, smart glasses | Curves around the body, reduces weight, enables compact sensor layouts |

| Medical Devices | Hearing aids, portable ECG monitors | Small size for discreet use, lightweight for comfort, high reliability |

| Automotive Electronics | Airbag modules, infotainment systems | Fits irregular spaces, withstands harsh conditions, fewer connectors |

| Aerospace & Defense | Avionics displays, satellite electronics | Low weight, survives high G-forces and temperature changes |

| Consumer Electronics | Foldable phones, digital cameras | Enables foldable designs, reduces part count, saves space |

HDI flexible PCBs support wearable technology by allowing you to create devices that fit the human body, stay lightweight, and maintain strong performance. You benefit from improved signal integrity and efficient power distribution, which are essential for high-speed and portable applications.

Tip: Choose HDI flexible PCBs when your product must be small, light, and reliable, especially in environments where space and weight matter most.

When to Use Rigid-Flex PCB

You turn to rigid-flex PCBs for applications that demand both flexibility and structural support. These boards shine in products that require repeated bending, complex shapes, or integration of rigid and flexible sections. Here are some real-world scenarios where rigid-flex PCBs are the optimal choice:

- Surgical tools that need to withstand sterilization and repeated use

- Pacemakers and implantable heart monitors, where compact size and reliability are critical

- Endoscopic equipment that must navigate tight spaces inside the body

- Blood glucose monitors and hearing aids, which require both comfort and durability

- Automotive sensors that operate in harsh environments and need stable connections

- Aerospace and defense systems, where vibration resistance and reliability are essential

- Portable medical monitoring devices and advanced consumer electronics like smartphones

Note: Rigid-flex PCBs handle repeated sterilization processes, making them ideal for medical devices that require frequent cleaning and long-term reliability.

You gain the advantage of fewer connectors, enhanced mechanical stability, and the ability to design products that combine rigid and flexible features. Rigid-flex PCBs help you meet strict requirements for reliability and performance in demanding applications.

When you choose between HDI flexible and rigid-flex PCBs, focus on your device’s needs.

- Use rigid PCBs for cost savings and stable designs.

- Choose flexible PCBs for tight spaces or moving parts.

- Select rigid-flex PCBs for high reliability, space efficiency, and fewer connectors.

Flex-rigid PCBs can save up to 50% in space and 30% in weight, making them ideal for dynamic, compact electronics. Always match your application, complexity, space, and budget to the right PCB type for the best results.

FAQ

What is the main advantage of HDI flexible PCBs?

You gain maximum miniaturization and adaptability. HDI flexible PCBs let you fit advanced circuits into tight spaces. You can reduce connectors, which improves reliability and saves space in compact devices.

Tip: Use HDI flexible PCBs for wearables and portable electronics.

When should you choose a rigid-flex PCB over a flexible PCB?

You should select a rigid-flex PCB when your design needs both sturdy support and flexible movement. Rigid-flex PCBs work best in products that require repeated bending, high reliability, and complex layouts.

How do HDI features impact PCB cost?

HDI features increase manufacturing complexity. You pay more for microvias, fine lines, and advanced materials. However, you can save space and reduce the number of layers, which may lower system-level costs.

Can you use HDI technology in both flex and rigid-flex PCBs?

Yes, you can apply HDI technology to both types. You achieve higher circuit density and better performance. You must consider the increased cost and manufacturing challenges before choosing this option.