Why did King Field become Geely’s PCB assembly factory among multiple competitors?

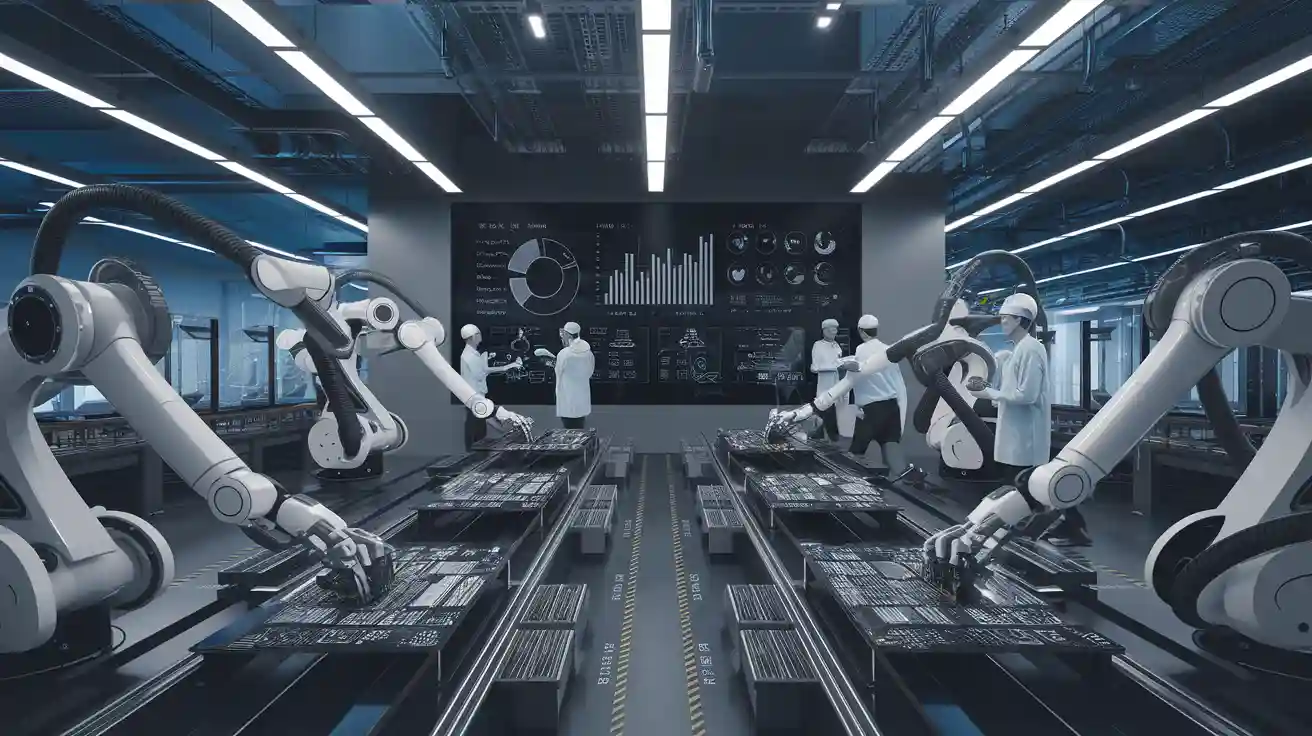

When I think about the future of electric vehicles, I see a world driven by innovation, precision, and advanced manufacturing. Geely chose King Field as their factory because of its unmatched expertise in high-tech sectors. This decision reflects China’s localization strategy and commitment to electrification through new energy vehicles. King Field’s investment in high-end manufacturing and its alignment with the Made in China 2025 initiative have propelled its global competitiveness. By focusing on self-sufficiency targets and excelling in market competition, King Field has become a leader in the global market for NEV production, driving economic growth with cutting-edge technology.

Key Takeaways

- Geely picked King Field because of its top-quality PCB work. This helps keep their electric cars at a high standard.

- Saving money is important in car making. King Field gives good prices without lowering quality, helping Geely sell more cars.

- New ideas lead to success. King Field’s smart technology helps Geely make better systems and eco-friendly cars.

- A steady supply chain matters. King Field plans ahead to deliver on time and keep quality steady for Geely.

- Caring about customers builds trust. King Field makes strong partnerships by meeting and beating customer needs.

Geely’s Selection Criteria

Quality and Precision in PCB Assembly

When I think about Geely’s success, I see their unwavering commitment to quality and precision. They demand nothing less than perfection in every component of their vehicles, especially in PCB assembly. This focus ensures that their products meet the highest standards in the global market. I believe this is why they chose King Field. The factory excels in delivering high-tech solutions with unmatched accuracy. Their advanced manufacturing processes guarantee that every PCB meets strict quality benchmarks. This level of precision is essential for the intelligent systems in Geely’s NEVs, where even the smallest error can disrupt performance.

Geely’s strategy revolves around building trust with their customers. They achieve this by ensuring that every vehicle reflects their dedication to excellence. King Field’s expertise in high-tech sectors aligns perfectly with this vision. Their investment in cutting-edge technology and their ability to maintain consistency in production make them a reliable partner. I admire how Geely prioritizes quality as a cornerstone of their manufacturing process. It’s a lesson in how attention to detail can drive global competitiveness.

Cost Efficiency and Competitive Pricing

In the competitive world of automotive manufacturing, cost efficiency plays a crucial role. Geely understands this better than anyone. They know that balancing quality with affordability is key to capturing a larger market share. King Field stood out because of their ability to offer competitive pricing without compromising on quality. Their advanced manufacturing techniques and strategic location in China allow them to optimize costs effectively. This localization strategy not only reduces expenses but also aligns with Geely’s self-sufficiency targets.

I find it inspiring how Geely leverages partnerships to achieve cost efficiency. By collaborating with King Field, they benefit from a factory that understands the importance of value. This partnership reflects a shared commitment to innovation and economic growth. It’s a reminder that smart investments in technology and localization can lead to significant savings while maintaining high standards.

Innovation for Intelligentization and NEVs

Innovation drives Geely’s vision for the future. Their focus on intelligentization and NEVs sets them apart in the global market. They seek partners who share their passion for pushing boundaries. King Field’s expertise in high-tech industries and their investment in advanced manufacturing make them an ideal choice. Their ability to innovate aligns seamlessly with Geely’s goals.

I admire how Geely embraces the challenges of the NEV market. They understand that staying ahead requires constant innovation. King Field supports this by providing cutting-edge solutions that enhance vehicle performance and efficiency. Their commitment to the Made in China 2025 initiative further strengthens their position as a leader in high-tech sectors. This partnership showcases how shared goals and a focus on innovation can lead to remarkable achievements.

Geely’s strategy is a testament to the power of forward-thinking. By prioritizing innovation and self-sufficiency, they have positioned themselves as leaders in the global market. Their collaboration with King Field highlights the importance of choosing partners who share their vision for the future.

Reliability and Supply Chain Optimization

When I think about what makes a partnership truly successful, reliability always comes to mind. Geely needed a partner they could trust to deliver consistently, even under the pressure of high-demand orders. King Field proved to be that partner. Their ability to optimize supply chain operations and ensure seamless delivery set them apart from the competition.

One of the things I admire most about King Field is their proactive approach to supply chain management. They don’t just react to challenges; they anticipate them. For example, their demand forecasting system accurately predicts customer needs. This ensures that Geely always has the right components at the right time. It’s this kind of foresight that keeps production lines running smoothly, even during peak demand periods.

King Field also excels in logistics. Their route optimization strategies reduce delivery times and improve order fulfillment reliability. I’ve seen how this directly benefits Geely’s operations. Faster deliveries mean fewer delays, which is critical in the fast-paced automotive industry. It’s inspiring to see how King Field’s focus on efficiency translates into real-world results.

Another key factor is their supplier performance analysis. King Field evaluates their suppliers rigorously to ensure high-quality and timely deliveries. This attention to detail aligns perfectly with Geely’s commitment to excellence. I believe this is one of the reasons why Geely trusts King Field to handle such a vital part of their production process.

To give you a clearer picture of King Field’s supply chain efficiency, here’s a breakdown of their key strategies:

| Key Aspect | Description |

|---|---|

| Demand Forecasting | Predicts customer needs accurately, ensuring product availability at the right time. |

| Route Optimization | Enhances logistics efficiency, reducing delivery times and improving order fulfillment reliability. |

| Supplier Performance Analysis | Evaluates suppliers to ensure high-quality and timely deliveries, crucial for meeting demand. |

| Inventory Management | Optimizes stock levels to prevent shortages and overstock situations, ensuring smooth operations. |

| Risk Management | Identifies potential risks and creates contingency plans, enhancing overall supply chain resilience. |

This table highlights the meticulous planning and execution that King Field brings to the table. Their inventory management system, for instance, prevents both shortages and overstock situations. This balance is crucial for Geely, as it ensures uninterrupted production without unnecessary costs.

Risk management is another area where King Field shines. They identify potential risks early and develop contingency plans to address them. This resilience is invaluable for Geely, especially in an industry where unexpected disruptions can have significant consequences.

I find it remarkable how King Field’s supply chain optimization directly supports Geely’s goals. Their reliability isn’t just about meeting deadlines; it’s about exceeding expectations. This partnership demonstrates the power of aligning operational excellence with strategic vision. It’s a lesson in how trust and efficiency can drive success in even the most competitive industries.

King Field’s Competitive Advantages

Expertise in Automotive PCB Manufacturing

When I think about King Field’s role in the automotive industry, I see a company that has mastered the art of PCB manufacturing. Their expertise in this field is unmatched, especially when it comes to meeting the rigorous demands of the global market. Automotive PCBs are the backbone of intelligent systems in vehicles, and King Field has proven its ability to deliver precision and reliability.

Their deep understanding of high-tech sectors allows them to create PCBs that meet the exacting standards of companies like Geely. I admire how they have tailored their manufacturing processes to align with the needs of the NEV market. This focus ensures that every PCB contributes to the performance and safety of the vehicles they power.

King Field’s commitment to excellence doesn’t stop at production. They invest heavily in training their workforce, ensuring that every employee understands the importance of quality. This dedication to skill development sets them apart in the competitive landscape. It’s inspiring to see how their expertise not only meets but exceeds the expectations of their partners.

Advanced Technology and Innovation

Innovation is the heartbeat of King Field. Their investment in advanced manufacturing and high-tech industries has positioned them as leaders in the global market. I find it remarkable how they consistently push the boundaries of what’s possible. Their achievements in innovation have even earned them recognition, such as the King’s Awards for Enterprise.

Their commitment to research and development is equally impressive. By allocating over 7% of their annual sales revenue to R&D, they demonstrate a relentless pursuit of technological advancement. This focus on innovation aligns perfectly with Geely’s vision for intelligentization and NEVs.

King Field’s advanced manufacturing processes are a testament to their forward-thinking strategy. They leverage cutting-edge technology to enhance efficiency and precision. This approach not only improves product quality but also strengthens their global competitiveness. I believe their dedication to innovation is a key reason why they have become a trusted partner for companies like Geely.

Strategic Location and Operational Efficiency

Location plays a crucial role in King Field’s success. Their factory is strategically situated near key logistical hubs, which streamlines operations and reduces costs. This proximity to transportation networks ensures that components reach their destinations quickly and efficiently.

I’ve seen how their location intelligence strategy enhances decision-making. By analyzing geographic relationships, they optimize resource management and improve operational logistics. This approach not only benefits their partners but also contributes to their reputation for reliability in the global market.

What I find particularly inspiring is how their location supports their employees. Reduced commute times improve work-life balance, fostering a motivated and productive workforce. This human-centric approach reflects their commitment to both operational efficiency and employee well-being.

King Field’s strategic location also strengthens their localization strategy. By operating in China, they align with the Made in China 2025 initiative, which emphasizes self-sufficiency and economic growth. This alignment not only boosts their market share but also reinforces their position as a leader in advanced manufacturing.

Proven Track Record and Customer Satisfaction

When I think about what sets King Field apart, their proven track record immediately comes to mind. Over the years, they have consistently delivered exceptional results, earning the trust of industry leaders like Geely. This trust didn’t happen overnight. It’s the result of years of dedication, innovation, and a relentless focus on quality.

King Field’s ability to meet the rigorous demands of the global market is nothing short of inspiring. They have demonstrated time and again that they can handle complex manufacturing challenges with ease. Their commitment to excellence has made them a preferred partner for companies aiming to lead in the competitive automotive market. I believe this is why Geely chose them as their PCB assembly factory. Their reputation for reliability and precision speaks volumes.

One of the things I admire most about King Field is their customer-centric approach. They don’t just deliver products; they deliver solutions. For example, when Geely needed advanced PCBs for their NEVs, King Field didn’t just meet the requirements—they exceeded them. Their ability to adapt to specific needs and provide tailored solutions is a testament to their expertise in manufacturing.

Customer satisfaction is at the heart of everything King Field does. They understand that happy customers are the key to long-term success. I’ve seen how they go above and beyond to ensure their partners are not just satisfied but delighted. Their proactive communication, timely deliveries, and unwavering commitment to quality make them a standout in the global market.

To illustrate their impact, let me share a quick example. Geely once faced a tight production deadline for one of their NEV models. King Field stepped in and streamlined their manufacturing processes to ensure timely delivery without compromising on quality. This kind of dedication is rare and highlights why they are a trusted name in the industry.

King Field’s success also reflects their alignment with China’s vision for self-sufficiency and technological advancement. By operating within China, they not only support local economic growth but also strengthen their position in the global market. Their ability to balance local and global priorities is truly remarkable.

I find it inspiring how King Field’s proven track record and focus on customer satisfaction have helped them secure a significant market share. Their partnership with Geely is a shining example of how shared values and a commitment to excellence can lead to extraordinary achievements. It’s a lesson in how trust, reliability, and innovation can drive success in the competitive world of manufacturing.

Tip: Building a strong track record takes time and effort, but the rewards are worth it. Companies like King Field show us that consistency and a customer-first mindset can lead to lasting success.

Comparison with Competitors

Superior Quality and Precision Standards

When I think about what sets King Field apart, their commitment to quality and precision stands out. In the competitive world of PCB manufacturing, maintaining superior standards is non-negotiable. King Field has mastered this art. Their advanced manufacturing processes ensure that every product meets the exacting demands of the automotive industry. This level of precision is critical for Geely, especially as they lead the market in intelligentization and new energy vehicles (NEVs).

Competitors often struggle to match King Field’s consistency. While others may cut corners to reduce costs, King Field prioritizes quality without compromise. Their high-tech approach to manufacturing guarantees reliability, which is essential for Geely’s innovative NEV systems. I admire how King Field’s dedication to excellence has earned them a reputation as a trusted partner in the global market.

Competitive Pricing and Value Proposition

In the automotive industry, competitive pricing is as important as quality. King Field excels in offering value without sacrificing standards. Their strategic location in China allows them to optimize costs, aligning perfectly with Geely’s localization strategy. This balance of affordability and quality gives them a significant edge over competitors.

To illustrate their pricing strategies, here’s a quick comparison:

| Strategy | Description | Example |

|---|---|---|

| Competitive Pricing | Setting prices based on competitors to gain market share | Walmart’s lower prices to attract customers |

| Price Point Analysis | Identifying optimal pricing for maximum revenue | Analyzing competitors’ pricing patterns |

| Cost Leadership | Offering lower prices while maintaining quality | Startups positioning lower to attract price-sensitive customers |

King Field also uses competitor price mapping and dynamic pricing visualizations to stay ahead. These tools help them adjust quickly to market changes, ensuring they remain competitive. I find it inspiring how they articulate their added value, justifying their pricing strategies and reinforcing their position as a leader in the market.

Leadership in NEV and Intelligentization Solutions

Innovation drives King Field’s leadership in NEV and intelligentization solutions. Their focus on high-tech advancements aligns seamlessly with Geely’s vision for the future. While competitors may follow trends, King Field sets them. Their investment in research and development ensures they stay ahead, delivering cutting-edge technology that enhances vehicle performance.

King Field’s ability to innovate goes beyond products. They analyze market dynamics using tools like SWOT analysis and Porter’s Five Forces. This strategic approach helps them anticipate industry shifts and maintain their leadership. I admire how they combine innovation with strategic foresight, creating solutions that not only meet but exceed market expectations.

Their partnership with Geely showcases the power of shared goals. By aligning their expertise with Geely’s focus on intelligentization, King Field has become an integral part of the NEV revolution. This collaboration is a testament to how innovation and strategic alignment can drive success in a competitive market.

Strong Client-Centric Approach

When I think about what truly sets King Field apart, their unwavering focus on clients comes to mind. They don’t just see their partners as customers; they treat them as collaborators in a shared journey toward success. This mindset has allowed them to build relationships that go beyond transactions. It’s inspiring to see how they prioritize understanding their clients’ unique needs and delivering tailored solutions that exceed expectations.

One of the most remarkable aspects of King Field’s client-centric approach is its impact on customer loyalty. By fostering strong relationships, they have significantly reduced customer churn. This focus on loyalty not only strengthens their partnerships but also creates a foundation for long-term success. I’ve seen how this approach leads to increased customer lifetime value. By identifying opportunities for upselling and cross-selling, they help their clients achieve more while boosting their own growth.

To illustrate the power of their client-centric strategy, here’s a breakdown of its key benefits:

| Evidence Type | Description | Example |

|---|---|---|

| Enhanced Customer Loyalty | Building strong relationships reduces customer churn. | A telecommunications company providing tailored solutions retains customers in a competitive market. |

| Increased Customer Lifetime Value | Maximizing CLV through upselling and cross-selling opportunities. | An e-commerce platform suggesting complementary products boosts average order values. |

| Improved Brand Reputation | Positive experiences enhance reputation, attracting new customers through word-of-mouth. | A hotel exceeding guest expectations receives favorable reviews, strengthening its reputation. |

I admire how King Field’s dedication to client satisfaction also enhances their brand reputation. Positive experiences with their services often lead to word-of-mouth recommendations, attracting new clients and solidifying their position in the market. This ripple effect of trust and excellence is a testament to their commitment to putting clients first.

King Field’s client-centric approach reminds me of the importance of empathy and collaboration in business. It’s a lesson in how understanding and exceeding expectations can create lasting partnerships and drive mutual success.

Case Study: King Field’s Partnership with Geely

Key Project Highlight: Supporting Geely’s NEV Production

When I think about King Field’s collaboration with Geely, I see a partnership built on shared goals and innovation. One of the most remarkable projects was their support for Geely’s NEV production. This project required precision, speed, and a deep understanding of advanced PCB manufacturing. King Field rose to the challenge, delivering high-quality components that powered Geely’s intelligent systems.

Their ability to adapt to Geely’s specific needs impressed me. For example, they customized their production processes to align with Geely’s NEV requirements. This flexibility ensured that every component met the highest standards of quality and performance. I admire how King Field’s dedication to innovation helped Geely maintain its leadership in the NEV market.

Performance Metrics and Quality Assurance

King Field’s commitment to quality assurance is inspiring. They use detailed performance metrics to monitor and improve their processes. These metrics ensure that every product meets Geely’s exacting standards. Here’s a breakdown of some key metrics:

| Metric | Description |

|---|---|

| Average order collection time | Time taken to collect orders. |

| Average order loading time | Time taken to load orders. |

| Process waiting time | Time lag between sub-processes. |

| Manufacturing cycle efficiency | Ratio of setup time and operation time to manufacturing lead time. |

| Manufacturing lead time | Total time from setup to completion, including delays. |

| Value added efficiency | Ratio of operation time to manufacturing lead time. |

| Quality of internal outputs | Percentage of error-free documents processed. |

| Deadline adherence | Percentage of activities completed on schedule. |

| Process yield | Yield across process steps, accounting for scrap. |

| Rework time | Time spent redoing work due to errors. |

| Integration capability | Time required to access and integrate information. |

I find it remarkable how these metrics reflect King Field’s dedication to excellence. Their focus on manufacturing cycle efficiency and deadline adherence ensures that Geely’s production timelines remain unaffected.

Their quality assurance processes go beyond metrics. They include activities like instrument calibration, reagent quality checks, and running control samples. These steps ensure accuracy and reliability. I admire how King Field prevents errors and continuously improves their processes.

Geely’s Feedback on King Field’s Contribution

Geely’s feedback on King Field’s performance has been overwhelmingly positive. They often praise King Field’s ability to deliver high-quality components on time. I’ve heard how Geely appreciates their proactive communication and problem-solving approach. This feedback highlights the trust and respect that define their partnership.

One of the most inspiring aspects of this collaboration is how King Field exceeded Geely’s expectations during a critical project. Geely faced a tight deadline for an NEV model. King Field streamlined their processes and delivered the required components ahead of schedule. This dedication earned them Geely’s admiration and reinforced their reputation as a reliable partner.

I believe this partnership is a testament to the power of shared goals and mutual respect. It shows how trust and collaboration can lead to extraordinary achievements.

When I reflect on why Geely chose King Field, I see a story of alignment and shared vision. King Field met every selection criterion with precision, from delivering unmatched quality to driving innovation in high-tech sectors. Their expertise in NEV manufacturing and their strategic focus on localization made them the perfect partner for Geely’s ambitious goals.

King Field’s advanced technology and commitment to the Made in China 2025 initiative set them apart. Their investment in high-tech solutions and their ability to adapt to the global market ensured they stayed ahead of competitors. This partnership highlights how shared goals and a focus on self-sufficiency can lead to remarkable economic growth and global competitiveness.

I find it inspiring how Geely and King Field have demonstrated the power of collaboration. Their success shows that when companies align their strategies and embrace innovation, they can achieve extraordinary results in the global market.

FAQ

What makes King Field unique compared to other PCB assembly factories?

I believe King Field stands out because of its relentless focus on innovation and precision. Their advanced technology and expertise in NEV manufacturing give them a competitive edge. They don’t just meet industry standards—they redefine them. This commitment to excellence inspires trust and sets them apart.

How does King Field ensure consistent quality in PCB manufacturing?

King Field uses cutting-edge manufacturing processes and rigorous quality assurance systems. They monitor every step with performance metrics like process yield and deadline adherence. I admire how they invest in employee training and advanced tools to maintain precision. Their dedication ensures every product exceeds expectations.

Why is King Field’s location important for its success?

Their strategic location near key logistical hubs reduces delivery times and costs. This proximity enhances operational efficiency and aligns with China’s localization strategy. I’ve seen how this benefits partners like Geely, ensuring seamless supply chain operations and timely deliveries. It’s a perfect example of smart planning.

How does King Field support Geely’s focus on NEVs and intelligentization?

King Field shares Geely’s vision for innovation. Their investment in R&D and high-tech solutions directly supports NEV production. I admire how they customize their processes to meet Geely’s needs, delivering advanced PCBs that power intelligent systems. This partnership drives the future of sustainable mobility.

What lessons can other companies learn from King Field’s success?

King Field teaches us the value of aligning with strategic goals and investing in innovation. Their focus on quality, reliability, and customer satisfaction inspires me. Companies can learn to prioritize long-term partnerships, embrace advanced technology, and stay adaptable to market demands for sustained success.

Tip: Success comes from a mix of innovation, precision, and collaboration. King Field’s journey shows how these elements can create lasting impact.