From Passion to Profit with Custom PCB Projects

You can turn your love for electronics into real income with custom PCB projects. Every day, more makers and engineers see their ideas come to life through custom printed circuit boards. The industry grows quickly and opens doors for you to join a thriving market.

- The custom PCB market is set to reach over USD 104 billion by 2030, with a steady growth rate of 5.24% each year.

- Experts predict the value could even exceed USD 156.7 billion by 2034, showing a strong future for custom PCBs.

You do not need to wait for the perfect moment. Your next idea could become the next big thing.

Key Takeaways

- The custom PCB market is growing fast. Experts think it will be worth over USD 104 billion by 2030. This gives makers and engineers a big chance. They can turn their ideas into projects that make money.

- You can start with easy projects. This can help you do well. Many hobbyists sell DIY products made from leftover PCBs. This shows you do not need much money to start.

- Open-source projects give helpful resources. Working with others can help you learn new skills. It can also give you new ideas. This makes it easier to create new things with PCBs.

- To begin your custom PCB project, list what you need. Draw your design. Pick software that is easy to use. Check for mistakes before you build. This step-by-step plan helps you do well.

- Good marketing for your PCB business is important. Aim at special markets. Offer extra services. Use social media to find new customers and show your work.

Success Stories

Hobbyist Achievements

You can begin with a few extra printed circuit boards. Many hobbyists use leftover boards to make new DIY products. Some people create custom LED displays or smart home gadgets. They sell these items online. Others make simple tools for classrooms or workshops. These stories show you do not need lots of money to succeed. You just need a good idea and want to share it. When your project helps someone, you feel proud. This makes you want to keep working.

Professional Wins

You can turn your passion into a business. Voltera started with a simple goal. They wanted to make printed circuit board production easier for engineers. Their story shows you can grow from a small team to a big company. Here is a quick look at what they did:

| Business Name | Annual Revenue | Key Milestones | Team Size | Startup Cost |

|---|---|---|---|---|

| Voltera | $3M/year | Made a circuit printer for engineers, sold thousands in 65 countries | 20 | $500K |

Voltera’s story shows you can use your skills to build a strong business. You can start small and reach people everywhere.

Open-Source Inspiration

You do not have to work alone. Open-source projects help people work together and create new things. Many creators share their designs on GitHub. This makes it easy for you to learn and improve. Here are some ways open-source custom PCB projects help you:

- You can share ideas and tools with others.

- You can join a group that helps personal projects and new businesses.

- You can find market gaps and make new products.

Some open-source printed circuit board projects have started many new ideas, like:

- PAA3905 Breakout Board for better navigation in low light.

- Ladybug STM32L432 Development Board for wearables and low power.

- Cheap Walkie-Talkie for easy and clear communication.

These stories show anyone can work with printed circuit boards. Your next project could inspire others and bring more success.

Starting Custom PCB Projects

First Steps

You can begin custom PCB projects by taking a few easy steps. Many people who succeed start this way:

- Figure out what your project needs. Write down all the parts you will use. This helps you pick the right size and shape for your board.

- Make a simple drawing of your idea. Use paper and pencil to sketch it out. This drawing will help you when you design on the computer.

- Pick PCB software that is simple to use. Try to find one with drag-and-drop tools. These tools make designing easier for new users.

- Check your design for mistakes. Fix any problems before you build your board.

Tip: Making a prototype lets you see your idea in real life. You can spot problems early and make your project better.

Finding Opportunities

Electronics has many new chances for you. People want devices that fit their lives better. You can use this need to make something unique. Here are some trends and markets to notice:

- More people want devices that work just for them.

- Experts say the market grows over 27% each year because of AI and satellites.

- Custom devices now solve special problems, not just big market needs.

- Hybrid PCBs are liked for small and packed products.

- Cars, hospitals, and factories need new tech solutions.

- Wearables and smart home gadgets push new ideas.

You can find your spot by looking for things missing in these areas. Your next idea could change how people use tech.

Overcoming Challenges

You might run into problems when you start. Many beginners make mistakes, but you can learn to avoid them. Here is a table to help you:

| Common Mistake | Solution |

|---|---|

| Inadequate Trace Spacing | Leave enough space between traces to stop crosstalk. |

| Improper Trace Widths | Change trace widths to match what each one does. |

| Insufficient Decoupling | Put capacitors close to IC pins and use short, wide traces. |

| Neglecting Signal Integrity | Plan trace paths and keep fast and slow signals apart. |

You can also join groups online and watch how-to videos. These places give you help, answers, and new ideas. You will meet others who love designing and inventing. By working together, you can fix problems and get better at making prototypes.

Tools and Resources

Essential Tools

You need the right tools to make your ideas real. Many engineers start with basic equipment. They add more tools as they learn. Here is a table that lists some important tools and their usual prices:

| Tool | Description | Typical Cost Range |

|---|---|---|

| CAD Software | Needed for making PCB designs, layouts, and running tests. | $100 – $500+ |

| Online Cost Calculators | Help you guess costs by looking at size and layers. | Free |

You can also improve your project by:

- Making the circuit design easier

- Using fewer layers

- Picking standard parts

- Changing the PCB’s size and shape

- Using design for manufacturability (DFM) rules

These steps help you save both money and time. They also show why pcbs matter in every project.

Learning Platforms

You can learn new things from many online classes. These websites give you lessons and real projects to try. Here is a table with some good choices:

| Platform | Course Title | Description |

|---|---|---|

| Altium Education | Learn Printed Circuit Board Design | Gives free STEM classes, hands-on projects, and certificates in PCB basics. |

| UC San Diego | PCB Fabrication Technology | An online class that teaches how to make PCBs from start to finish. |

You can begin with these classes and build your skills. Many engineers use these sites to keep learning about electronics.

Community Support

You do not have to work by yourself. Many groups are ready to help you learn and grow. These groups help you fix problems, share ideas, and meet new people. Here are some of the most active groups:

| Community Name | Description | Features |

|---|---|---|

| Product Hunt | A place to launch new products and get feedback from users. | Maker profiles, forums, and special collections for focused talks. |

| Founders Network | A group for tech founders and startup leaders. | Monthly online meetings, a Slack group, and a mentorship program called FN Labs. |

| StartupNation | A website for new business owners and entrepreneurs. | Forums for questions, expert articles, and case studies with tips. |

| Women 2.0 | A group that helps women entrepreneurs with special resources. | Webinars, mentor circles, guides for raising money, and events for meeting others. |

| Young Entrepreneur Council (YEC) | A private group for experienced business owners. | A private place to share ideas, get advice, and work together. |

You can join these groups to ask questions and get help. Many people in these groups love electronics and want you to do well.

Business Success Stories

Monetizing Projects

You can make money from your custom PCB projects. Many people start with one idea and turn it into a business. There are different ways to earn from your printed circuit board designs.

- You can offer custom PCB design and manufacturing services. This is how most businesses make the most money. In 2022, about 40% of big companies’ money came from these services.

- You can help engineers by making small batches for testing. This is called prototyping. It lets them check their ideas before making lots of boards.

- You can sell support and maintenance. If you help customers keep their boards working, they will trust you and come back.

- You can sell extra things like coatings, assembly parts, or design software. These extras help you make more money.

Most small businesses in this area make between 10% and 20% profit. Some do even better and reach 30% by making production better and finding the right customers. Your project can be more than just a hobby. If you take the right steps, you can become a business success story in printed circuit board production.

Tip: Start with one service first. Add more as you learn what your customers want.

Marketing Strategies

You need good marketing to get noticed in custom PCB projects. Many businesses do well by focusing on special markets. For example, you can work with medical devices, aerospace, or car electronics. These groups pay more for quality and custom work.

Here are some ways to market your printed circuit board business:

- Pick a special market and become an expert. This helps you build a good name and earn more money.

- Offer extra services like full assembly, electronic design, or fast prototyping. These bring in more customers and steady income.

- Use digital marketing. Make a website and use online platforms to reach people everywhere.

- Show you care about the environment. Use eco-friendly materials and processes. Many customers want green products.

Social media can help you reach more people. Instagram, Facebook, and TikTok let you share photos and videos of your work. You can talk to customers in real time with comments and live videos. Many businesses use shoppable posts and in-app checkout to make buying easy, especially for young people.

Note: Share your printed circuit board production story online. People like to see behind-the-scenes and real results.

Scaling Up

You can grow your custom PCB projects from small to big. The need for printed circuit boards keeps going up. In 2022, the world market was about $60 billion. Experts think it will grow by 4% each year until 2026. This gives you a big chance to make your business bigger.

To go from small batches to big orders, follow these steps:

- Use lean manufacturing to save time and cut waste.

- Build good relationships with suppliers. This helps you get better prices and parts you can trust.

- Find your own special market. These markets often pay more.

Here is a table that shows how businesses grow by volume:

| Volume Tier | Annual Spend | Typical Unit Range |

|---|---|---|

| Just-In-Time | Under $20K | Small batches as needed |

| Small-Scale | $50K–$500K | 100s–10,000 boards/year |

| Mid-Sized | $500K–$1M+ | 10,000–100,000+ boards/year |

| High Volume | $1M+ or 1M+ units/year | Large-scale global production |

You will face problems as you grow. Keeping quality high for thousands of boards is hard. You must balance cost and quality, especially when picking materials. Handling complex designs and a busy supply chain can also be tough.

Many business success stories show how to fix these problems:

- Design your boards so they are easy to make. This helps you avoid mistakes.

- Work with good suppliers and keep extra parts in stock.

- Use machines and smart tech to check quality.

- Use more than one supplier to avoid delays.

- Use eco-friendly materials and keep your process fast.

You can also use Total Quality Management and Lean Manufacturing to keep getting better. Upgrade your tools as you grow. Follow environmental rules to keep your business safe and strong.

Remember: Every big business started small. Your printed circuit board project can grow with a good plan and a strong community.

You have learned that testing ideas quickly helps you make better PCBs. Listening to what customers say can help you fix problems. When you test your boards, you find ways to make them better. Saving money is important so your project lasts a long time.

- Try making quick prototypes to check your ideas fast.

- Use what customers tell you to make your designs better.

- Keep testing your boards and make changes each time.

- Work on saving money so your project can last.

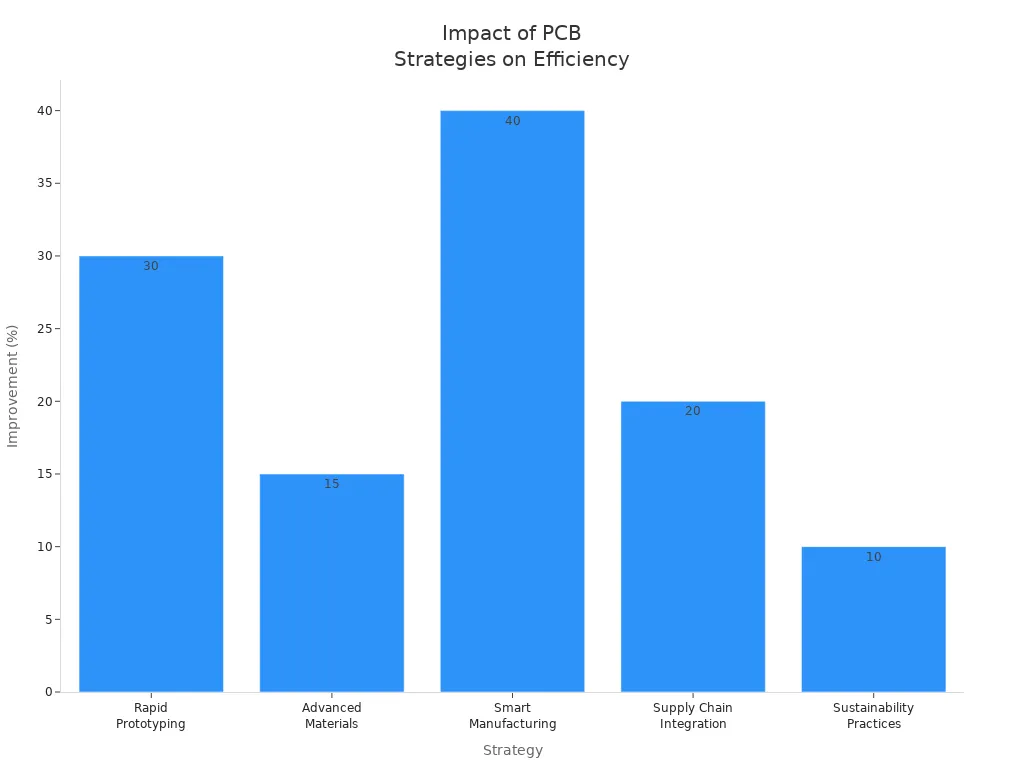

| Strategy | Benefits | Impact on Costs and Efficiency |

|---|---|---|

| Rapid Prototyping | You can launch products faster | Time-to-market goes up by 30% |

| Advanced Materials | Boards work better and last longer | Costs go down by 15% |

| Smart Manufacturing | Makes things faster and wastes less | Production speed goes up by 40% |

| Supply Chain Integration | Helps you work better with suppliers | Lead times go down by 20% |

| Sustainability Practices | Good for the planet and saves money | Costs go down by 10% |

You can begin your own project right now. Forums like KiCad and step-by-step guides on Instructables can help you. Your love for PCBs can help you earn money, one project at a time. 🚀

FAQ

How do you start your first custom PCB project?

You can begin with a simple idea. Sketch your design on paper. Use free PCB software to create your layout. Order a prototype from a trusted manufacturer. Test your board and learn from each step. Every project helps you grow.

What tools do you need for basic PCB design?

You need a computer, PCB design software, and a multimeter. Soldering tools help you build and test your boards. Many beginners use free software like KiCad or EasyEDA. Start small and add more tools as you gain experience.

Can you sell your custom PCB designs online?

Yes! You can sell your designs on platforms like Tindie, Etsy, or your own website. Many makers find success by sharing their story and showing real results. Customers love unique solutions and creative ideas.

What if you make a mistake in your PCB design?

Mistakes help you learn. Check your design with software tools before you order. Ask for feedback from online communities. Fix errors and try again. Every mistake brings you closer to success.

How do you find support when you get stuck?

You can join online forums, Discord groups, or local maker spaces. Many people love to help and share advice. Ask questions and share your progress. The community will inspire you to keep going.