Essential Factors to Consider When Selecting a PCB Assembly Manufacturer

Selecting the right pcb assembly manufacturer can seem hard. You want a partner who knows your printed circuit board needs. They should give you good pcba results every time. Experts say you should check if the pcb manufacturer does pcb assembly in-house. They should also have strong production skills.

Here are some important things to remember:

- Look at the pcb manufacturer’s experience and past projects.

- Make sure the company uses strict quality control and testing steps.

- Check if customer support is helpful and answers fast.

- See if they have certifications in Pcb Assembly Manufacturing to show high standards.

If you use these points as your checklist, you can find a pcb manufacturer who fits your project needs.

Key Takeaways

- Look at the manufacturer’s experience and past work. This helps you know if they can make your PCB the way you want.

- Check if they have good quality control and industry certificates. This makes sure their work is safe and meets high standards.

- Make sure the manufacturer has good customer support. They should help you fast if you have any problems. This keeps your project moving.

- Find a partner with strong technical skills and new machines. This helps them work faster and make better products.

- Use a checklist to compare different manufacturers. Focus on quality checks, clear prices, and if they can handle your order size.

Expertise in PCB Assembly Manufacturing

Industry Experience

Picking a pcb assembly manufacturing partner is important. You want a team that has real experience. If a pcb manufacturer has worked for many years, they have seen many projects. This means they know how to fix problems and stop mistakes. You can ask them about their past work with printed circuit board designs like yours. A company with lots of experience can help you through each step. They can help you get the best results for your pcba needs.

You should find a pcb manufacturer that has worked with many industries. This shows they can meet different needs and rules. Some companies only do small projects. Others can handle big orders. If you need both, look for a partner who does prototyping and full production. This helps your project grow when you need it.

Tip: Ask for examples of past projects or customer references. This helps you see if the pcb assembly manufacturing company matches your needs.

Technical Capabilities

You need a pcb assembly manufacturing partner with strong technical skills. Modern projects often need special tools and steps. Here is a table that shows some important technical capabilities you should look for:

| Technical Capability | Description |

|---|---|

| Auto-calibrated SMT lines | For precise component placement. |

| Advanced on-site firmware programming | Essential for complex designs. |

| Component placement | As fine as 7-mil pitch. |

| X-ray laminography and optical inspection | For quality assurance. |

| Ultra-dense component counts | Supports high-layer designs. |

| Laser alignment and vision systems | For optimal SMT placement. |

| 10-zone air convection reflow system | With optional nitrogen atmosphere for superior soldering results. |

| Specialized handling and repair | For BGA, μ-BGA, ultra-fine pitch QFP, QFN, CSP, FCP, and 0201 components. |

You should also check if the pcb assembly manufacturing company offers:

- Prototyping and small-to-large volume production

- Comprehensive material handling and RoHS-compliant processes

- Precision prepping and kitting systems for streamlined assembly

- Automated inspection and testing for defect-free products

When you look at these technical capabilities, you make sure your pcb project will meet high standards. This helps you avoid delays and get reliable products every time.

Certifications and Standards

Industry Certifications

When you pick a pcb manufacturer, check their certifications. These certificates show the company follows important rules. Certifications help you know your pcba will be safe and high quality. You can ask the manufacturer to show their certificates before starting.

Here is a table with some well-known certifications in the pcb industry:

| Certification | Description |

|---|---|

| ITAR | Makes sure defense items and services follow the law. |

| ISO | Sets quality rules for many industries, like ISO 9001:2015. |

| RoHS | Stops dangerous materials in making electronics. |

| UL Listing | Sets safety rules for electronic devices. |

| IPC | Makes quality rules for PCB assemblies, like IPC-A-600 and IPC-6012. |

| MIL | The Department of Defense uses these for strict electronics rules. |

Note: ISO certification is very important. It means the manufacturer uses strong quality systems. IPC standards also help you get good pcb products.

Regulatory Compliance

You must make sure your pcb manufacturer follows all needed rules. These rules protect your project and help you follow the law. If you work in medical, military, or consumer electronics, check for special rules.

Here is a table with big regulatory standards for pcb and pcba production:

| Standard | Description |

|---|---|

| ISO 9001 | Focuses on quality systems so makers meet customer and law needs. |

| ISO 13485 | Used for medical pcb production to meet health and safety rules. |

| IPC A-600 | Makes sure PCBs are high quality for many uses. |

| IPC A-610 | Gives rules for what makes electronic assemblies good. |

| IPC A-6012 | Focuses on what makes printed boards good for certain uses. |

| RoHS | Stops dangerous materials in electronics to keep the earth safe. |

| ITAR | Controls sending and getting defense items, including military PCBs. |

| REACH | Looks at how chemicals are made and used and their effects on people and the earth. |

You should always ask about certifications and rules before picking a partner. This helps you avoid trouble and keeps your products safe. Following these rules gives you trust in your pcb and pcba results.

Manufacturing Process

Knowing the manufacturing process helps you pick a good pcb manufacturer. If you learn each step, you can see how the company keeps your project running well. A clear process shows how the manufacturer gives steady results, especially for turnkey solutions.

PCB Assembly Manufacturing Steps

You want your pcba to be high quality. Most turnkey providers use certain steps to make sure every pcb works right. Here is how it usually goes:

- DFA Verification: The team checks your Gerber or ODB++ files and the bill of materials. This step makes sure all parts fit and have enough space.

- SMT Assembly: The manufacturer puts on solder paste, looks at it, and places parts with a pick and place machine.

- Reflow Soldering: The board goes in a special oven. The oven melts the solder and holds the parts in place.

- Inspection and Testing: Machines and people check for mistakes or broken parts.

- Final Assembly and Packaging: Workers add last parts and pack the finished product for shipping.

Using IPC standards in these steps helps your pcb meet industry rules. This makes your pcb more reliable and helps you talk better with your turnkey partner.

- IPC standards are the main rules for PCB assembly.

- They help keep quality and reliability the same in different places.

- Following these standards can lower costs and make the company look better.

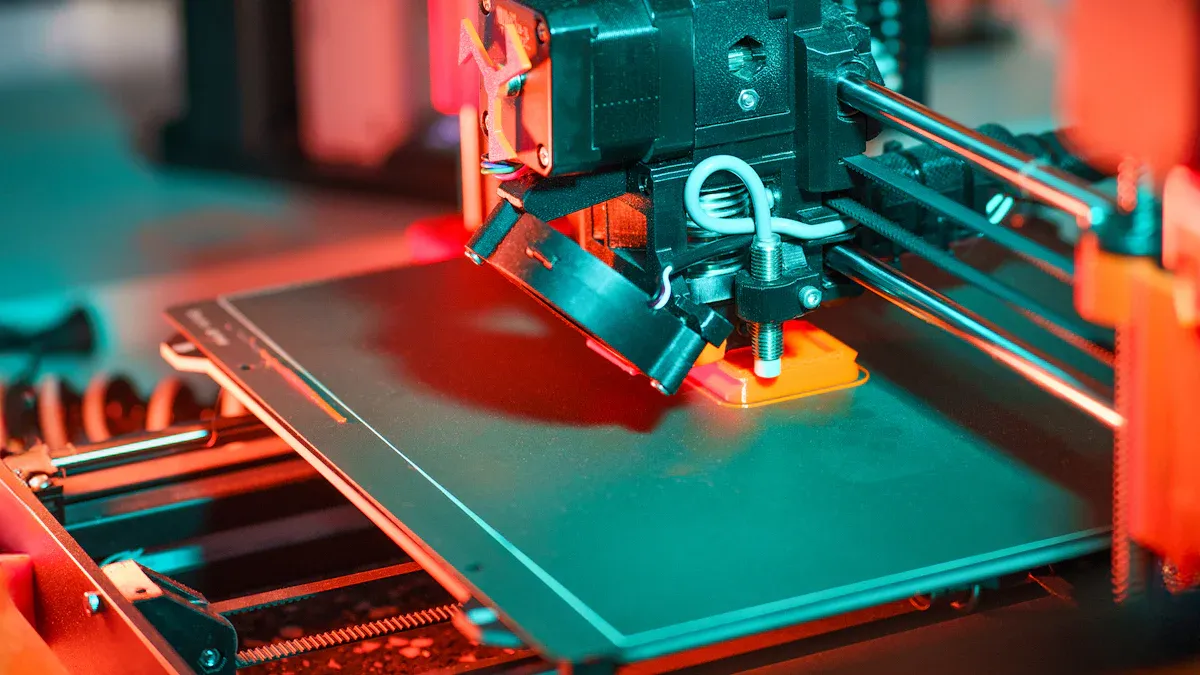

Equipment and Technology

New equipment is important in turnkey pcb assembly. Modern machines and smart systems help your project go faster and have fewer mistakes. Here is how technology helps the process:

| Aspect | Impact on Efficiency and Quality |

|---|---|

| Automated Material Handling | Robots move and sort materials fast, making fewer mistakes and keeping parts ready for assembly. |

| Automated Inventory Management | Real-time tracking helps control parts, saves money, and speeds up work. |

| Automated Quality Assurance | Machines check each pcb for problems, making sure every board is high quality. |

| Machine Learning and AI | Smart systems find problems before they happen, keeping work going smoothly. |

| Collaborative Robots (Cobots) | Cobots do easy jobs, so people can do harder work. |

| Human Oversight | Engineers watch the process, fix problems, and keep things working well. |

If you pick a turnkey provider with new tools, your project gets done faster and better. This helps you trust that your pcba will work for you every time.

Quality Assurance

When you pick a pcb manufacturer, you want good products. Quality assurance is very important for every company. It helps stop mistakes that cost money. It also makes sure your pcba works the way you need. You should check if the company uses quality control at every step. These checks help you get a product that works well and lasts a long time.

Inspection and Testing

You need good inspection and testing to trust your pcb. Quality control starts with a careful look at your design. This step checks if your design follows all rules. During assembly, workers watch for problems all the time. At the end, there is a final check to see if the product works right.

Here is a table that shows common ways to inspect and test pcbs:

| Inspection/Testing Method | Description |

|---|---|

| Visual Inspection | Finds mistakes like wrong parts or bad solder. |

| Automated Optical Inspection (AOI) | Uses cameras to find problems fast and clearly. |

| X-ray Inspection | Looks inside the board to check hidden solder joints. |

| In-Circuit Testing (ICT) | Tests each part and connection to make sure everything works. |

| Functional Testing | Checks if the pcb does its job under real conditions. |

| Environmental Stress Screening | Puts the board under stress to find weak spots. |

| Burn-in Testing | Runs the board for a long time to catch early failures. |

| Final Quality Control | Reviews all test results before shipping. |

In-Circuit Testing (ICT) is a great way to lower mistakes. It finds problems early, so you save money and get better products. If you see these tests, you know the pcb manufacturer cares about quality.

Tip: Ask your supplier how they check for quality. A good company will tell you how they test and inspect every pcb.

Traceability

Traceability is important for keeping quality high for a long time. It lets you follow every part and step in making your pcb. This helps you find and fix problems quickly. If something goes wrong, you can see where it happened and fix it.

- Traceability follows all parts and steps, making sure each one is good.

- It helps you follow rules, which is needed for medical or aerospace work.

- Fast action on problems keeps your products safe and working well.

A strong traceability system helps your quality management. It gives you trust that your pcba will be good now and later.

Prototyping and Engineering Support

Rapid Prototyping

You need to test new ideas fast. Prototype pcb assembly lets you check if your design works. You do this before making lots of boards. Many pcb manufacturers can finish prototypes quickly. Some make a simple 2-layer pcb in one day. Others finish an 8-layer board in three to five days. Quick-turn pcb options can be ready in one to three days.

| PCB Type | Turnaround Time |

|---|---|

| Simple 2-layer | Same day |

| 8-layer board | 3-5 days |

| Quick-turn PCB | 24-72 hours |

Some companies, like Avanti Circuits Inc., offer same-day and 24-hour services. A-Tech Circuits can finish small or medium orders in one to three days. American Standard Circuits and Sunstone Circuits also work fast. Some companies in other countries might be even quicker.

Customization is very important for prototype pcb assembly. You can ask for special shapes or different materials. You can also ask for extra testing. These choices help you meet your project needs. If your pcb manufacturer lets you customize, you have more control over your prototype pcb assembly.

Design for Manufacturability

Design for manufacturability, or DFM, makes building your project easier. It also helps lower costs. You should always check your design with DFM rules first. This step helps you find problems early. It also helps you avoid waiting.

| Benefit | Description |

|---|---|

| Cost Reduction | DFM saves money by fixing problems early. |

| Streamlined Manufacturing | DFM makes building smoother and cuts down on waste. |

| Decreased Errors | Early checks mean fewer mistakes. |

| Improved Product Quality | DFM gives you a better and stronger pcba. |

Customization is also important for DFM. You can change your design to fit special needs. You can add features if you want. Good customization helps you get the best results from your prototype pcb assembly. If your pcb manufacturer gives strong engineering support and lets you customize, you have a better chance to succeed.

Tip: Always ask about customization before you begin. This helps you get the right pcb for your project.

Scalability and Flexibility

Order Volume Handling

When you choose a pcb manufacturer, you need to know if they can handle your order size. Some projects start small, but others grow fast. Leading companies use smart machines and good systems to manage many orders at once. They can make small batches or very large runs without losing quality.

- Many top manufacturers can handle orders starting from 10,000 units.

- Some can scale up to millions of units for big projects.

- Automation and smooth processes help them work faster and lower the cost for each unit.

If your business grows, you want a partner who can grow with you. This helps you avoid delays and keeps your customers happy. You also save money when you order more because the cost per board goes down.

Adaptability

You need a pcb manufacturer who can change quickly when your needs change. The best companies use flexible production systems. These systems let them switch from one product to another with little downtime. Real-time inventory management helps them see what parts they need and plan for the future. This means they can fill orders fast, even if you want a new design or a different type of pcb.

Adaptable manufacturers support both small and large orders. They can also deliver your pcba quickly, even when the market changes. This flexibility helps you stay ahead of your competition. You get the products you need, when you need them, without long waits.

Tip: Ask your manufacturer how they handle changes in your order or design. A good answer shows they are ready for anything.

Cost and Pricing

Transparent Quotation

When you ask a pcb manufacturer for a quote, you want clear and honest pricing. A transparent quotation helps you understand what you pay for each step in the pcba process. You avoid hidden fees and can plan your budget better.

Here are some key benefits of transparent quotations:

| Benefit | Explanation |

|---|---|

| Clarity in Pricing | You see what drives the cost of your pcb assembly. |

| Avoid Hidden Charges | You spot extra fees before you order. |

| Builds Trust | You feel confident working with the supplier. |

| Better Comparison of Quotes | You compare different offers more easily. |

| Improved Customer Satisfaction | You make better choices and feel happier with the results. |

A transparent pcb supply chain also builds trust. You know where your parts come from and how they are handled. This makes you feel more secure about the final product’s quality.

Value vs. Price

You might think the lowest price is best, but that is not always true for pcb assembly. The real value comes from the balance between cost and quality. Many factors affect the price of your pcb:

- Materials and components

- Board size and complexity

- Quantity and production volume

- Lead time requirements

- Testing and quality control

- Labor and location

For example, a simple FR4 board costs less than a polyimide board. Larger or more complex pcbs need more work and materials, which raises the price. If you order more units, the cost per board usually drops.

Paying more often means you get better equipment and stronger quality checks. This lowers the risk of errors and makes your pcba more reliable. Very low prices can mean poor parts or weak testing, which may cause problems later. You might save money at first, but you could pay more to fix failures or replace bad boards.

Tip: Always look at the total value, not just the price. A good pcb manufacturer gives you strong quality, clear quotes, and reliable pcba that lasts.

Lead Time and Delivery

Turnaround Time

You want your project finished on time. Turnaround time tells you how long it takes to get your pcba after you place an order. The time can change based on your order size and the type of assembly you need. A good pcb manufacturer will tell you how long each step takes. You can use this table to see the average lead times in the industry:

| Type of Assembly | Typical Lead Time |

|---|---|

| Prototype Assembly | 3 – 5 days to 2 – 3 weeks |

| Small Batch Production | 2 – 4 weeks |

| Large Scale Production | 4 – 8 weeks or more |

Many things can affect how fast you get your pcb. If you need a prototype, you may get it in just a few days. Large orders take longer. The time also depends on how easy it is to get the parts you need. If your design is simple, you will get your boards faster. If you want special testing or high quality, the process may take more time.

Tip: Always ask your pcb manufacturer for a clear timeline before you start. This helps you plan your project and avoid surprises.

On-Time Delivery

You need your pcba delivered when promised. On-time delivery keeps your project on track and helps you meet your goals. Top manufacturers use many strategies to make sure you get your boards when you need them.

| Strategy | Description |

|---|---|

| Design for manufacturability checks | Teams check your design early to spot problems. |

| Component availability | They keep parts in stock to avoid waiting. |

| Automated processes | Machines help speed up work and lower mistakes. |

| Effective communication | Teams talk often to fix issues fast. |

Manufacturers also use steps like DFM, prototyping, pre-production, and full production to keep things moving. They follow IPC standards and use inspections like AOI and flying probe testing to keep quality high. These steps help you get reliable pcb products on time.

Note: When you choose a partner who values quality and clear delivery, you lower your risk of delays and get better results.

Customer Support

Responsiveness

You want a pcb assembly manufacturer who replies fast. Quick answers help you fix problems early. Good customer support lets you talk by phone, email, or chat. This keeps your project on track and stops delays. If the company talks with you often, you feel sure about your order.

Surveys show customers care about design checks, picking materials, and solving problems. You also want help with shipping and clear updates. The table below shows what matters most to customers:

| Aspect | Description |

|---|---|

| Design Validation | Checks design files to find mistakes before making boards. This stops expensive fixes later. |

| Material Guidance | Helps you pick the right materials for your needs. This makes your board work better and last longer. |

| Streamlined Communication | Gives you many ways to talk so you do not wait or get confused. |

| Troubleshooting | Helps you fix problems during or after making boards. This keeps your product working well. |

| Logistics Expertise | Manages shipping so your boards arrive on time and your project finishes as planned. |

Find a pcb partner who gives great service and keeps you informed. Good customer support helps you avoid errors and finish your pcba project on time.

Technical Assistance

You need more than quick replies. You also need strong technical help. The best pcb manufacturers help from start to finish. They help with design, making samples, and testing. You can ask for advice about materials or get help with quality checks. This support makes your project better and stronger.

Customers like these kinds of technical help:

- Great customer service

- Solving technical problems

- Help through all steps of making boards

- Working together on design

- Making samples

- Testing

- Quality checks

You also get help with making samples, starting new products, and big production runs. Many companies offer design for manufacturability and design for testability. These services help you get the best results for your pcb project.

Tip: Pick a manufacturer who gives fast replies and expert technical help. This helps you feel calm and reach your goals.

Reputation of PCB Manufacturer

Reviews and References

You want to know if you can trust a pcb manufacturer. Reading reviews helps you learn from other customers. Reviews tell you how the company treats people like you. You can see if they deliver on time. You can check if their pcba products are good.

- Reviews share real stories about the company’s work.

- You can find patterns in what people say. Many good reviews mean the company is reliable.

- Testimonials often show strong customer service and quality.

- References from past clients help you check the company’s history.

Look for testimonials on the company’s website. You can also find reviews on other websites. These places help you see if the pcb manufacturer keeps promises. If you see lots of good testimonials, you know the company cares about its customers.

Tip: Ask the manufacturer for references. Talking to past clients gives you a clear idea of what to expect.

Industry Recognition

Industry recognition means a pcb manufacturer stands out. Awards and certifications show the company meets high standards. You can trust a company that wins awards for quality or service.

| Recognition Type | What It Means for You |

|---|---|

| Industry Awards | The company has shown excellence. |

| Certifications | The company follows strict rules. |

| Published Projects | The company has a strong portfolio. |

Check if the manufacturer lists awards or special honors. These signs show the company works hard to be the best. A strong reputation in the industry means you get better pcba results. When you see both good reviews and industry recognition, you know you have found a reliable pcb partner.

Choosing a Reliable PCBA Supplier

Evaluation Checklist

You need to pick a reliable pcba supplier for your project. A checklist helps you compare companies and choose the best one. Here are some things you should check:

- Quality control processes: See if the supplier uses strong quality rules, like ISO 9001 certification.

- Equipment and technology: Look at their machines and tools. New equipment often gives better results.

- Supply chain management: Check how they get parts and keep inventory. Good planning helps avoid delays.

- Product testing and inspection: Ask about their testing steps. Careful inspection finds problems early.

- Experience and expertise: Find out how long they have done pcb assembly. A good history means they know how to fix issues.

- Shipping deadlines: Make sure they deliver boards on time.

- Parts procurement: See how they buy parts and if they work well with suppliers.

- Price effective pricing: Compare their prices with others. Good suppliers offer fair prices for quality work.

Tip: Use this checklist when you talk to new suppliers. It helps you find the most reliable pcba supplier for your needs.

Red Flags

Some signs show a company may not be a good pcba supplier. Watch out for these problems when you check a pcb assembly manufacturer:

- Bad soldering: Cold or weak joints can make your pcb fail.

- Missing solder mask: This can expose copper and cause shorts or rust.

- Opens and solder bridges: Open connections or bridges can hurt your circuit.

- Component shift or placement errors: Parts in the wrong spot can stop your pcba from working.

- Solder paste application problems: Bad paste can cause weak joints and short circuits.

- Design rule violations: If the supplier ignores your design limits, you may need expensive changes.

- Copper balancing issues: Uneven copper can bend or stress your pcb.

- Pad cratering: Poor drilling can lift pads and cause failures.

If you see any of these red flags, keep looking for a better pcba supplier. Your project needs quality and trust.

You should look at every factor before picking a pcb assembly manufacturer. Using a checklist helps you compare choices and find problems early. This way, you get better quality and fewer issues with your pcb or pcba. The table below shows the main benefits:

| Benefit/Risk | Description |

|---|---|

| Comprehensive Evaluation | Checks important things like quality assurance and factory skills. |

| Risk Identification | Helps you spot risks and see if suppliers are good enough. |

| Quality Assurance | Makes sure manufacturers meet technical needs and quality goals. |

| Process Improvement | Lets suppliers make their work better, so products improve. |

| Long-term Confidence | Builds trust and keeps the supply chain strong, so you avoid delays and failures. |

Spend time learning about different manufacturers and comparing them. Careful research helps your project succeed.

FAQ

What is the most important factor when choosing a PCB assembly manufacturer?

You should pick a company with good quality control. This helps your boards work well and last longer. Testing and inspection steps help you avoid mistakes that cost money.

How do I know if a manufacturer can handle my project size?

Ask the company about how many boards they can make. Some companies make small batches. Others can make thousands of boards. You need a partner who fits your order size.

Why do certifications matter in PCB assembly?

Certifications show the company follows important industry rules. They help you trust your pcb will be safe and high quality. Always look for ISO or IPC certificates.

Can I get help with design changes during production?

Many manufacturers give engineering support. You can ask for help with design changes or updates. This support helps you get the best results for your pcb project.