The role of EMS in PCB manufacturing

Electronics Manufacturing Services (EMS) play a crucial role in producing printed circuit boards (PCBs). By managing design, assembly, and testing, EMS ensures efficient production processes. You benefit from streamlined workflows, which reduce errors and enhance output quality. EMS PCBA solutions also drive innovation by integrating advanced technologies into manufacturing. This approach allows you to meet the growing demand for reliable, high-performance electronics. Whether you’re scaling production or developing prototypes, the role of EMS remains vital in modern electronics manufacturing.

Key Takeaways

- EMS companies help make PCB production easier by handling design, assembly, and testing. This saves time and reduces mistakes.

- Working with EMS lets businesses focus on new ideas. They also get access to better tools and expert skills for making products.

- Hiring EMS can save money and speed up product launches. This is very helpful for companies in tough markets.

- EMS cares a lot about quality. They test PCBs carefully to make sure they work well and last long.

- Teaming up with EMS reduces supply chain problems and improves shipping. This ensures products arrive on time and are high quality.

What is EMS and its role in PCB manufacturing?

Definition of EMS and its scope in the electronics industry

Electronics Manufacturing Services (EMS) encompass a wide range of solutions designed to support the production of electronic devices, including printed circuit boards (PCBs). These services include design, assembly, testing, and supply chain management, making EMS a cornerstone of modern electronics manufacturing. By partnering with an EMS provider, you gain access to specialized expertise and advanced technologies that streamline production processes and enhance product quality.

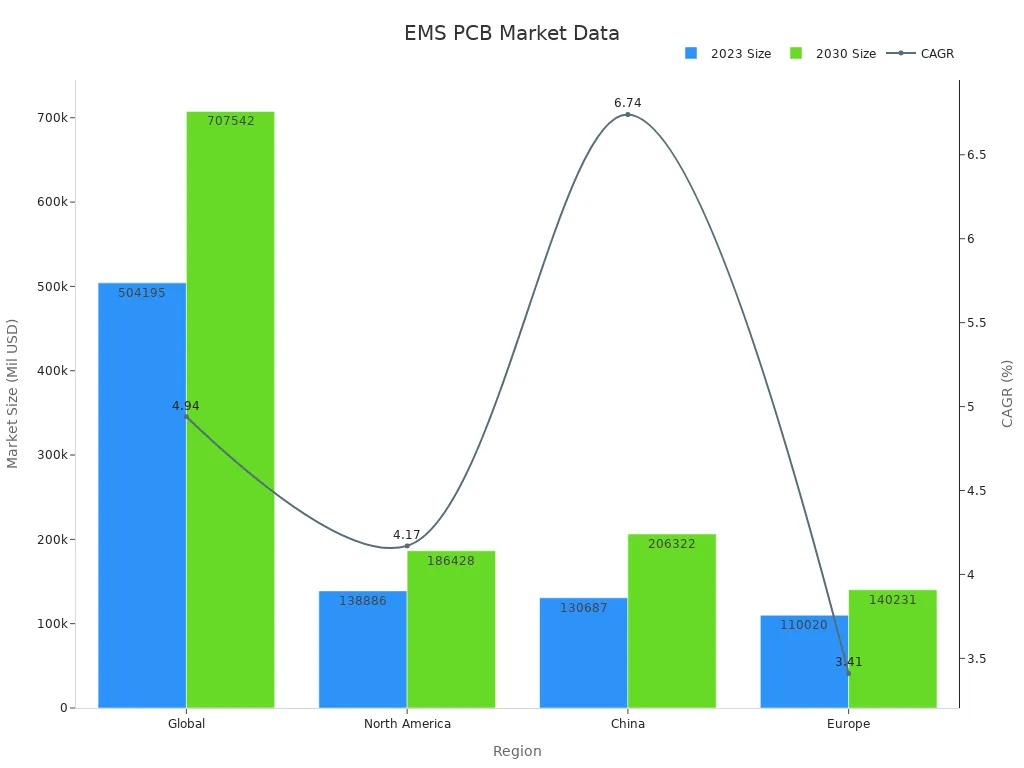

The global EMS market reflects its critical role in the electronics supply chain. In 2023, the market size reached $504,195 million, with projections indicating growth to $707,542 million by 2030 at a compound annual growth rate (CAGR) of 4.94%. The table below highlights the regional breakdown of this growth:

| Region | 2023 Market Size (Million USD) | 2030 Projected Size (Million USD) | CAGR (%) |

|---|---|---|---|

| Global | 504,195 | 707,542 | 4.94 |

| North America | 138,886 | 186,428 | 4.17 |

| China | 130,687 | 206,322 | 6.74 |

| Europe | 110,020 | 140,231 | 3.41 |

This data underscores the growing reliance on EMS across industries, from consumer electronics to automotive and healthcare. By leveraging EMS, you can focus on innovation while leaving the complexities of manufacturing to experienced providers.

Key services offered by EMS in PCB production

EMS providers offer a comprehensive suite of services to optimize PCB production. These services cover every stage of the manufacturing process, ensuring efficiency and reliability. Here are some of the key offerings:

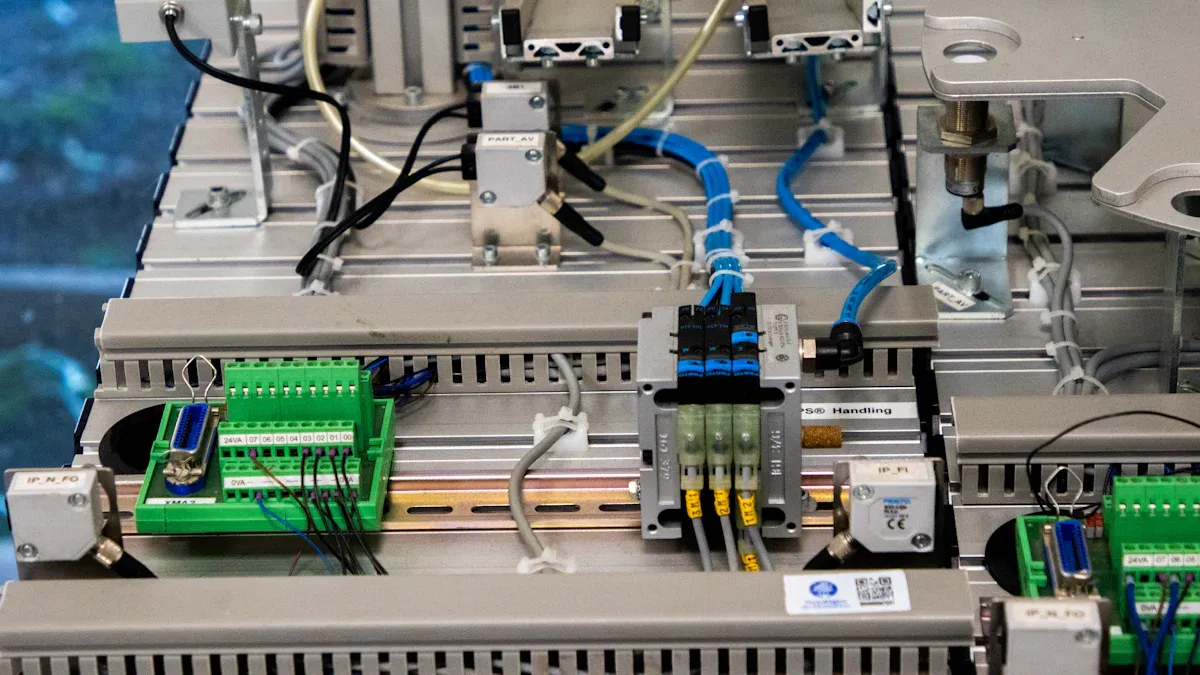

- Production Automation: High-speed, precision placement lines and custom automation systems ensure accurate assembly. Full testing capabilities guarantee that each PCB meets performance standards.

- Quality Assurance: Rigorous testing protocols, including adherence to industry standards like IATF 16949 and ISO 26262, minimize defects and enhance reliability.

- Project Management: A dedicated point of contact oversees timelines, key performance indicators (KPIs), and quality audits, ensuring smooth project execution.

- Design for Manufacturing (DfM): Expert consultancy on DfM, Design for Cost (DfC), and Design for Test (DfT) helps optimize designs for production. Bill of Materials (BOM) analysis and custom test tooling further streamline the process.

- Turnkey Supply Chain Management: Comprehensive supply chain solutions include supplier management, logistics support, and counterfeit component checks.

| Service Category | Key Features |

|---|---|

| Production Automation | High-speed, precision placement lines, custom automation lines, full 100% testing capability. |

| Quality Assurance | 100% testing, adherence to industry standards (IATF 16949, ISO 26262, etc.). |

| Project Management | Single point of contact, regular reporting on timelines and KPIs, audits for quality claims. |

| Design for Manufacturing | DfM, DfC, DfT consultancy, BOM life cycle analysis, custom test tooling. |

| Turnkey Supply Chain Management | Supplier management, logistics support, counterfeit component checks. |

These services not only simplify the production of PCBs but also ensure that your products meet the highest quality standards. By outsourcing these tasks to an EMS provider, you can reduce costs and focus on core business activities.

Integration of EMS into the PCB manufacturing lifecycle

EMS integrates seamlessly into every phase of the PCB manufacturing lifecycle, from design to delivery. This integration ensures that your products are manufactured efficiently and meet market demands. Here are some real-world examples of how EMS enhances the manufacturing process:

- Predictive Maintenance: Company A used IoT sensors for predictive maintenance on assembly line machinery. This reduced unplanned downtime by 30% and extended equipment lifespan.

- Enhancing Quality Control: Company B adopted data analytics for real-time monitoring of production. This approach reduced defects by 25% and improved customer satisfaction.

- Supply Chain Optimization: Company C optimized inventory management and supplier collaboration using data analytics. This resulted in a 20% reduction in inventory costs and ensured timely delivery.

| Case Study | Description | Results |

|---|---|---|

| Predictive Maintenance | Company A implemented IoT sensors for predictive maintenance on assembly line machinery. | Reduced unplanned downtime by 30% and extended equipment lifespan. |

| Enhancing Quality Control | Company B integrated data analytics into their quality control process to monitor production in real-time. | Reduced defects by 25% and improved customer satisfaction. |

| Supply Chain Optimization | Company C optimized inventory management and supplier collaboration using data analytics. | Achieved a 20% reduction in inventory costs and ensured timely delivery. |

By integrating EMS into your PCB manufacturing lifecycle, you can achieve greater efficiency, reduce costs, and improve product quality. This holistic approach ensures that your products are ready to meet the challenges of a competitive market.

How EMS supports PCB manufacturing processes

PCB fabrication and prototyping

EMS plays a pivotal role in accelerating PCB fabrication and prototyping. By leveraging advanced technologies and global networks, EMS providers streamline the production process, ensuring efficiency and precision. You benefit from optimized workflows that reduce delays and enhance product quality.

- Global sourcing and supply chain management: EMS companies utilize extensive supplier networks to source components efficiently. This approach speeds up the fabrication process and ensures the availability of high-quality materials.

- Inventory management and control: Effective inventory management ensures components are ready when needed, minimizing downtime during prototyping.

- Design for Manufacturing (DFM) and Design for Assembly (DFA): These methodologies refine product designs for seamless manufacturing and assembly, reducing errors and improving production speed.

- Prototyping and New Product Introduction (NPI): EMS providers facilitate rapid prototyping and pilot production runs, enabling quicker market entry for innovative products.

By integrating these strategies, EMS enhances the efficiency of PCB fabrication and prototyping, allowing you to focus on innovation while meeting tight deadlines.

PCB assembly and component sourcing

The assembly phase is critical in PCB manufacturing, and EMS providers excel in delivering high-quality results. Their expertise in component sourcing and assembly ensures that your products meet industry standards and customer expectations.

- Economies of scale: EMS providers leverage bulk purchasing to reduce costs, making assembly more affordable for businesses of all sizes.

- Procurement expertise: With established supplier networks, EMS providers source cost-effective components without compromising quality.

- Advanced technologies: Automation, robotics, and AI improve assembly precision and speed, reducing errors and enhancing efficiency.

- Supply chain resilience: EMS providers manage supply chain complexities, mitigating risks like component shortages and production delays.

These capabilities ensure that PCB assembly is both cost-effective and reliable, giving you a competitive edge in the electronics market.

Quality assurance and testing in EMS

Quality assurance is a cornerstone of EMS manufacturing. Rigorous testing protocols and adherence to international standards ensure that every PCB meets stringent performance criteria. You can rely on EMS providers to deliver products that excel in reliability and durability.

| Performance Metric | Description |

|---|---|

| Automated Optical Inspection (AOI) | Cameras inspect PCBs for defects, such as missing components and incorrect placement. |

| In-Circuit Testing (ICT) | Electrical connectivity tests identify shorts and opens. |

| Functional Testing | Verifies product functionality under real-world conditions. |

| Quality Management Systems (ISO 9001) | Demonstrates commitment to quality and continuous improvement through international standards. |

EMS providers also engage in continuous evaluation of risks and opportunities within their quality management systems. By establishing key performance indicators and fostering collaboration, they consistently enhance product quality. These measures ensure that your PCBs perform reliably, even in demanding applications.

Supply chain management and logistics

Efficient supply chain management and logistics are essential for successful PCB manufacturing. EMS providers specialize in optimizing these processes to ensure timely delivery, cost savings, and high-quality production. By partnering with an EMS provider, you gain access to streamlined operations that enhance your manufacturing capabilities.

Key Components of Supply Chain Management in EMS

EMS providers focus on several critical aspects of supply chain management to support PCB production. These include:

- Supplier Selection: EMS providers work with trusted suppliers to source high-quality components. They evaluate suppliers based on reliability, cost, and compliance with industry standards.

- Inventory Optimization: Advanced inventory management systems track component availability and reduce excess stock. This minimizes waste and ensures materials are ready when needed.

- Risk Mitigation: EMS providers anticipate potential disruptions, such as component shortages or transportation delays. They implement contingency plans to maintain production schedules.

- Global Sourcing: Leveraging international networks, EMS providers source components from multiple regions. This approach ensures competitive pricing and access to specialized materials.

Tip: Collaborating with an EMS provider helps you avoid common supply chain pitfalls, such as delays and counterfeit components. Their expertise ensures smooth operations and reliable outcomes.

Logistics Support in PCB Manufacturing

Logistics play a vital role in delivering PCBs to the market. EMS providers handle complex logistics tasks to ensure your products reach their destination efficiently. Here’s how they manage logistics:

| Logistics Task | Description |

|---|---|

| Transportation Management | Coordinating shipments to minimize transit times and reduce costs. |

| Customs Compliance | Ensuring all shipments meet international trade regulations. |

| Warehousing Solutions | Providing secure storage for components and finished products. |

| Real-Time Tracking | Using technology to monitor shipments and provide updates on delivery status. |

These logistics services ensure that your PCBs are delivered on time and in excellent condition. You can focus on innovation while the EMS provider handles the complexities of transportation and storage.

Benefits of EMS Supply Chain and Logistics Expertise

When you rely on an EMS provider for supply chain management and logistics, you unlock several advantages:

- Cost Savings: Bulk purchasing and optimized transportation reduce overall expenses.

- Time Efficiency: Streamlined processes accelerate production and delivery timelines.

- Quality Assurance: Rigorous checks prevent counterfeit components from entering the supply chain.

- Scalability: EMS providers adapt to your production needs, whether you require small batches or large-scale manufacturing.

Note: Choosing an EMS partner with strong supply chain and logistics capabilities can significantly improve your PCB manufacturing outcomes. Their expertise ensures reliability and efficiency at every stage.

By leveraging the supply chain and logistics expertise of EMS providers, you can achieve greater operational efficiency and deliver high-quality products to your customers. This partnership allows you to stay competitive in the fast-paced electronics industry.

Benefits of using EMS in PCB manufacturing

Cost efficiency and scalability

EMS manufacturing offers significant cost efficiency and scalability, making it a valuable solution for businesses in the electronics industry. By leveraging economies of scale, EMS providers reduce production costs, allowing you to allocate resources more effectively. They also integrate regional advantages, such as sourcing components from cost-effective suppliers, to lower the overall expenses of PCB manufacturing.

- EMS services streamline processes, enhancing efficiency in PCB production.

- They enable faster time-to-market, which is crucial in rapidly evolving industries.

- Partnering with EMS allows you to focus on branding and innovation while they handle manufacturing complexities.

- Their expertise supports scalability, especially in fast-paced sectors like IoT and automotive.

This approach ensures that your business remains competitive while meeting the growing demand for high-quality electronic products.

Enhanced quality and reliability

EMS providers prioritize quality and reliability in every stage of PCB assembly. Advanced technologies, such as Automated Optical Inspection (AOI) systems, play a critical role in maintaining high standards. These systems perform real-time inspections, identifying defects and providing data for process control. This reduces the likelihood of rework and enhances the overall efficiency of PCB production.

You can rely on EMS providers to adhere to international quality standards, ensuring that your products meet stringent performance criteria. Their commitment to quality not only improves product reliability but also extends the lifespan of your electronic devices. This focus on excellence makes EMS an indispensable part of modern manufacturing.

Faster time-to-market for electronic products

In today’s competitive market, speed is essential. EMS providers excel in reducing production timelines, helping you bring products to market faster. Their expertise in prototyping and new product introduction (NPI) ensures that your designs are optimized for manufacturing. By managing supply chains and logistics efficiently, they eliminate delays and ensure timely delivery of components.

This faster time-to-market gives you a competitive edge, allowing you to respond quickly to market demands. Whether you’re launching a new product or scaling production, EMS services provide the agility needed to succeed in the fast-paced electronics industry.

Access to advanced technologies and expertise

EMS providers give you access to cutting-edge technologies and specialized expertise that elevate PCB manufacturing. Their advanced tools and systems ensure precision, efficiency, and innovation in every step of the process.

Advanced Technologies in EMS

EMS providers utilize state-of-the-art equipment to enhance PCB production. These technologies include:

- Automated Assembly Lines: High-speed machines place components with unmatched accuracy, reducing errors and increasing efficiency.

- Robotics and AI: Intelligent systems optimize workflows and improve assembly precision.

- Testing Equipment: Tools like Automated Optical Inspection (AOI) and In-Circuit Testing (ICT) identify defects early, ensuring high-quality output.

Tip: Partnering with an EMS provider allows you to leverage these technologies without investing in expensive equipment yourself.

Expertise That Drives Innovation

EMS providers employ skilled professionals who specialize in PCB design, assembly, and testing. Their expertise ensures that your products meet industry standards and customer expectations. Here’s how their knowledge benefits you:

- Design Optimization: Experts refine your PCB designs for manufacturability, reducing production costs and errors.

- Material Selection: Specialists choose the best components for your application, balancing performance and cost.

- Process Improvement: Continuous evaluation of manufacturing processes ensures efficiency and reliability.

By working with EMS providers, you gain access to resources that would otherwise require significant investment. Their technologies and expertise empower you to produce high-quality PCBs while staying competitive in the electronics market.

Challenges and considerations in EMS partnerships

Communication and collaboration challenges

Effective communication is vital when working with an EMS provider. Misunderstandings or delays in sharing information can disrupt manufacturing processes. You must establish clear communication channels to ensure smooth collaboration. Regular updates, detailed project documentation, and defined roles help prevent confusion.

Cultural and language differences may also arise when partnering with global EMS providers. These differences can lead to misinterpretations or delays. To address this, you should work with a trusted EMS partner that prioritizes transparency and uses tools like project management software to streamline communication.

Tip: Schedule regular meetings and use visual aids like flowcharts or diagrams to clarify complex manufacturing processes.

Intellectual property protection in EMS

Protecting your intellectual property (IP) is a critical consideration in EMS partnerships. Sharing sensitive designs and manufacturing details with an external provider can expose your business to risks. You should implement robust legal agreements, such as non-disclosure agreements (NDAs), to safeguard your IP.

Working with a trusted EMS partner that complies with industry standards, like ISO 13485 for medical electronics, adds an extra layer of security. This certification ensures that the provider follows strict quality management systems, reducing the risk of unauthorized use of your designs. Additionally, you should limit access to sensitive information and share only what is necessary for manufacturing.

Note: Always verify the EMS provider’s track record in handling IP securely before entering a partnership.

Managing lead times and supply chain risks

Lead times and supply chain risks are common challenges in EMS manufacturing. Delays in component sourcing or transportation can disrupt production schedules. You should collaborate with an EMS provider that excels in supply chain management to mitigate these risks.

A trusted EMS partner will use advanced inventory systems to track component availability and anticipate potential disruptions. They will also maintain relationships with multiple suppliers to ensure a steady flow of materials. For industries like medical electronics, where quality and reliability are paramount, continuous evaluation of manufacturing processes is essential. Documentation flaws or inadequate quality control can lead to delays in regulatory approvals, such as those required by the FDA.

To minimize risks, you should work with an EMS provider that prioritizes quality control and adheres to strict standards. This approach ensures timely delivery and reliable outcomes.

Dependence on external EMS providers

Relying on external EMS providers offers many advantages, but it also introduces certain dependencies that you must carefully manage. These dependencies can impact your operations, especially if not addressed proactively.

Key Challenges of EMS Dependency

- Loss of Direct Control: When you outsource PCB manufacturing, you relinquish control over production processes. This can make it harder to monitor quality or enforce changes quickly.

- Vendor Reliability: Your production schedule depends on the EMS provider’s ability to deliver on time. Any delays or disruptions on their end can affect your timelines.

- Limited Flexibility: External providers may prioritize larger clients or have rigid processes, which could limit your ability to make last-minute adjustments.

- Cost Risks: While EMS providers often reduce costs, unexpected price changes in materials or services can increase your expenses.

Tip: Establish clear contracts with your EMS provider to define expectations, timelines, and penalties for delays. This ensures accountability and minimizes risks.

Strategies to Mitigate Dependency Risks

You can take steps to reduce the risks associated with EMS dependency:

- Diversify Suppliers: Avoid relying on a single EMS provider. Working with multiple vendors ensures continuity if one fails to meet expectations.

- Build Strong Relationships: Regular communication and collaboration with your EMS partner foster trust and improve alignment on goals.

- Monitor Performance: Use key performance indicators (KPIs) to track your provider’s reliability, quality, and delivery times.

- Invest in Contingency Plans: Prepare for potential disruptions by maintaining safety stock or identifying alternative suppliers.

Note: A strong partnership with your EMS provider can transform dependency into a strategic advantage. By managing risks effectively, you can focus on innovation and growth.

By understanding and addressing these dependencies, you can maximize the benefits of EMS partnerships while minimizing potential drawbacks.

Industries leveraging EMS for PCB production

OEMs and their reliance on EMS for mass production

Original Equipment Manufacturers (OEMs) depend heavily on EMS for large-scale PCB production. EMS providers handle manufacturing, assembly, and testing, enabling OEMs to focus on core activities like research and development. This partnership enhances operational efficiency and reduces costs. For example, the global electronic manufacturing services market was valued at $499.4 billion in 2022 and is projected to reach $1,252.6 billion by 2030, growing at a compound annual growth rate (CAGR) of 9.7%. This growth reflects the increasing reliance of OEMs on EMS for scaling production.

| Category | Description |

|---|---|

| OEMs | Significant portion of the PCB market, involved in design and production of electronic devices. |

| EMS | Provide manufacturing, assembly, and testing services, crucial for scaling production and reducing costs for OEMs. |

By outsourcing to EMS providers, OEMs can meet the growing demand for high-quality electronics while maintaining competitive pricing. This approach ensures that products are manufactured efficiently and delivered on time.

Startups and the role of EMS in prototyping and scaling

EMS plays a vital role in helping startups transition from the prototype stage to full-scale production. Startups often face challenges like limited resources and expertise in PCB manufacturing. EMS providers offer services such as design support, prototype development, and component sourcing, which streamline the production process.

| Service Type | Description |

|---|---|

| Design and Engineering Support | Assists in designing products for manufacturability, optimizing assembly, and minimizing defects. |

| Prototype Development | Helps create prototypes for testing before full-scale production. |

| Sourcing and Procurement | Manages supply chain for electronic components, ensuring availability and quality. |

| PCB Assembly | Involves soldering components onto PCBs, utilizing methods like SMT and through-hole technology. |

These services allow startups to focus on innovation while EMS providers handle the complexities of manufacturing. By leveraging EMS, startups can scale production efficiently and bring their products to market faster.

Research institutions and custom PCB solutions

Research institutions often require custom PCB solutions for experimental and specialized applications. EMS providers cater to these needs by offering tailored manufacturing services. They assist in creating prototypes that meet specific research requirements, ensuring precision and reliability.

For instance, EMS providers use advanced technologies like automated assembly lines and in-circuit testing to produce high-quality PCBs. These capabilities are essential for research projects that demand accuracy and consistency. By partnering with EMS providers, research institutions can access the expertise and resources needed to develop innovative solutions.

Tip: Collaborating with an EMS provider ensures that your custom PCBs meet the highest standards, enabling successful research outcomes.

Emerging applications in IoT, automotive, and healthcare

The integration of Electronics Manufacturing Services (EMS) into emerging industries has transformed how you approach innovation. IoT, automotive, and healthcare sectors are leveraging EMS to create advanced solutions that meet modern demands.

IoT Applications

IoT devices rely on compact and efficient designs. EMS providers help you produce high-quality printed circuit boards (pcb) that power smart devices. These boards enable seamless connectivity and data exchange. For example, EMS supports the production of sensors for smart homes, wearable devices, and industrial automation systems. By using advanced manufacturing techniques, EMS ensures that IoT devices perform reliably in diverse environments.

Tip: Collaborating with an EMS provider allows you to scale IoT production while maintaining quality and reducing costs.

Automotive Innovations

The automotive industry is undergoing a technological revolution. EMS plays a key role in manufacturing PCBs for electric vehicles (EVs), autonomous driving systems, and advanced infotainment solutions. These boards handle critical functions like battery management, navigation, and safety features. EMS providers use specialized testing methods to ensure automotive PCBs meet stringent performance standards. This guarantees reliability in high-stress conditions.

Healthcare Advancements

Healthcare applications demand precision and reliability. EMS providers manufacture PCBs for medical devices like diagnostic equipment, wearable health monitors, and surgical tools. These boards support life-saving technologies by ensuring accurate data processing and device functionality. EMS providers also adhere to strict regulatory standards, ensuring that medical PCBs meet safety and quality requirements.

Note: Partnering with an EMS provider ensures your healthcare devices meet industry standards and deliver consistent performance.

By leveraging EMS expertise, you can drive innovation in IoT, automotive, and healthcare industries. This partnership enables you to create cutting-edge solutions that improve lives and redefine technology.

Emerging trends in EMS for PCB manufacturing

Adoption of smart manufacturing and Industry 4.0

Smart manufacturing is transforming how you approach EMS. By integrating Industry 4.0 technologies like IoT, AI, and robotics, EMS providers enhance efficiency and precision. These advancements allow you to monitor production in real time, identify bottlenecks, and optimize workflows. For example, IoT sensors track equipment performance, reducing downtime through predictive maintenance. AI-driven analytics also help you make data-informed decisions, improving overall manufacturing outcomes.

This shift toward smart manufacturing ensures that EMS providers deliver consistent quality while meeting tight deadlines. You can rely on these innovations to stay competitive in a rapidly evolving market.

Focus on sustainability and eco-friendly practices

Sustainability has become a priority in EMS manufacturing. Providers now adopt eco-friendly practices to reduce waste and energy consumption. For instance, many EMS companies use lead-free soldering and recyclable materials in PCB production. These steps minimize environmental impact while maintaining high-quality standards.

You can also benefit from green manufacturing initiatives like energy-efficient production lines and waste management systems. These practices not only align with global sustainability goals but also appeal to environmentally conscious consumers. By partnering with an EMS provider committed to sustainability, you contribute to a greener future.

Increasing demand for miniaturization and high-density PCBs

The demand for smaller, more powerful devices drives the need for miniaturized and high-density PCBs. EMS providers meet this challenge by using advanced manufacturing techniques like microvia drilling and high-density interconnect (HDI) technology. These methods allow you to create compact PCBs without compromising performance.

Miniaturization is especially critical in industries like IoT and healthcare, where space-saving designs are essential. By leveraging EMS expertise, you can produce cutting-edge products that meet market demands for smaller, more efficient electronics.

The rise of regional EMS providers for localized production

Regional EMS providers are gaining prominence as businesses seek localized production solutions. These providers offer several advantages, especially in a world where supply chain disruptions and geopolitical challenges are becoming more common. By working with a regional EMS provider, you can achieve faster turnaround times and reduce logistical complexities.

Why Regional EMS Providers Matter

Localized EMS providers bring production closer to your target market. This proximity reduces shipping times and costs, ensuring that your products reach customers quickly. Additionally, regional providers often have a better understanding of local regulations and market demands. This knowledge helps you navigate compliance requirements more efficiently.

Tip: Partnering with a regional EMS provider can also enhance your ability to respond to sudden changes in demand. Their proximity allows for quicker adjustments to production schedules.

Benefits of Localized EMS Manufacturing

- Reduced Lead Times: Shorter distances between production facilities and end-users minimize delays.

- Lower Transportation Costs: Local sourcing and manufacturing reduce shipping expenses.

- Improved Communication: Operating in the same time zone simplifies collaboration and decision-making.

- Support for Regional Economies: Choosing a local EMS provider contributes to economic growth in your area.

A Growing Trend

The rise of regional EMS providers reflects a shift toward decentralized manufacturing. This trend aligns with the increasing demand for flexibility and resilience in EMS manufacturing. By choosing a regional partner, you can build a more agile and sustainable supply chain.

Note: Regional EMS providers are particularly valuable for industries like automotive and healthcare, where speed and reliability are critical.

The role of EMS in PCB manufacturing transforms production processes, enabling you to achieve operational efficiency and innovation. EMS providers streamline workflows, reduce costs, and enhance inventory management. Their average gross profit rates often exceed 10%, with some reaching 21.4%, showcasing their ability to deliver strong ROI. By outsourcing to EMS, you gain faster time-to-market and improved resource allocation. Careful selection of EMS partners ensures your products meet quality standards while maximizing business success.

FAQ

1. What is the difference between EMS and OEM in PCB manufacturing?

EMS focuses on manufacturing, assembly, and testing of PCBs. OEM designs and markets electronic products but relies on EMS providers for production. EMS handles the technical aspects, while OEM drives innovation and branding.

2. How does EMS ensure PCB quality?

EMS uses advanced testing methods like Automated Optical Inspection (AOI) and In-Circuit Testing (ICT). These tests detect defects and verify functionality. EMS providers also follow international standards like ISO 9001 to maintain consistent quality.

3. Can EMS help startups with PCB prototyping?

Yes, EMS supports startups by offering design assistance, rapid prototyping, and component sourcing. These services simplify production and reduce costs. You can focus on innovation while EMS handles manufacturing complexities.

4. Why is supply chain management important in EMS?

Efficient supply chain management ensures timely delivery of components and minimizes production delays. EMS providers optimize inventory, mitigate risks, and source materials globally. This approach enhances reliability and reduces costs.

5. What industries benefit most from EMS in PCB manufacturing?

Industries like IoT, automotive, and healthcare rely heavily on EMS. IoT devices need compact designs, automotive systems demand reliability, and healthcare applications require precision. EMS providers meet these unique needs with tailored solutions.