China Electronic Prototype Manufacturing

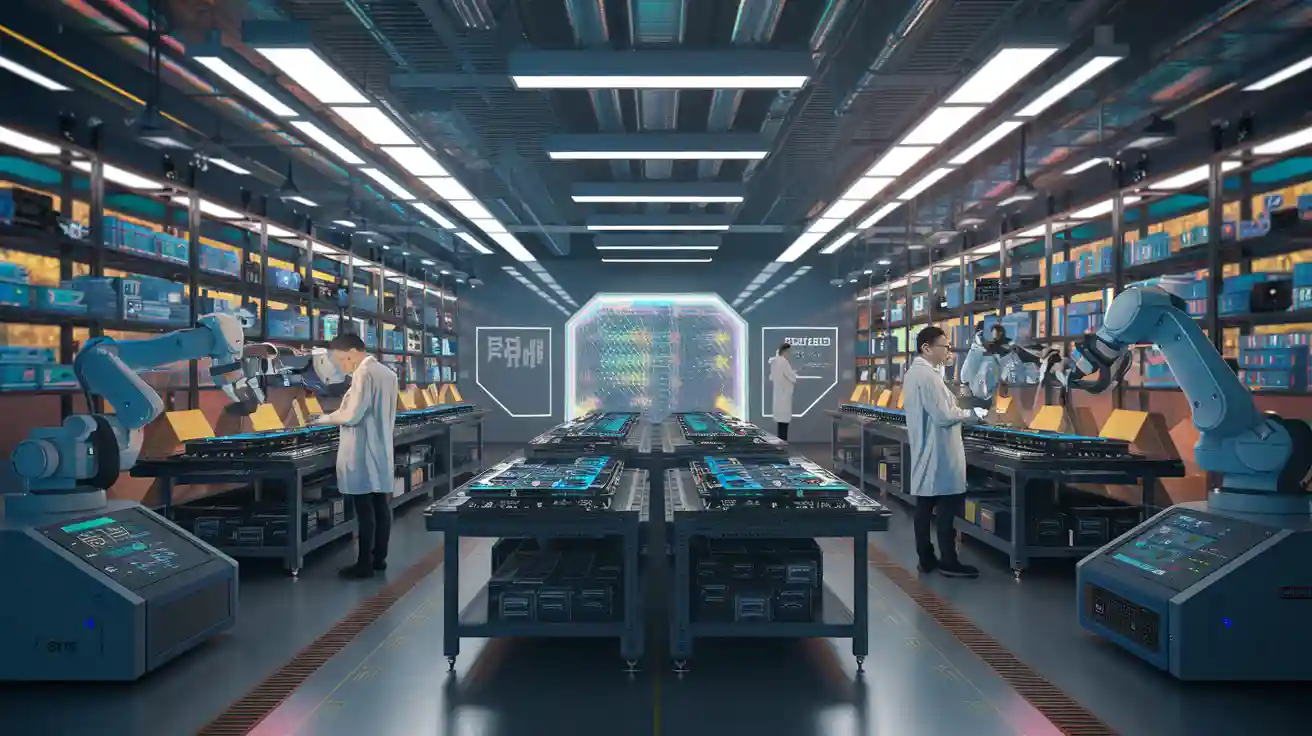

China stands at the forefront of electronic prototype manufacturing, driven by its extensive industrial base and advanced infrastructure. The country’s leadership stems from its ability to combine high-tech innovation with cost-effective production. Companies such as Huawei and DJI showcase China’s prowess in creating cutting-edge technologies, while government-backed initiatives like the ‘Made in China 2025’ program further elevate its global standing.

Several factors attract businesses to China for prototype development. Specialized manufacturing hubs streamline production, reducing turnaround times. Additionally, government-supported industrial zones enhance efficiency and foster innovation. China’s focus on high-tech industries, including robotics and quantum technologies, ensures access to state-of-the-art facilities and skilled labor, making it a preferred destination for electronic prototype creation.

Key Takeaways

- China is a leader in making electronic prototypes. It is affordable and uses advanced tools, making it great for businesses.

- Prototypes are important for creating products. They reduce risks, improve teamwork, and meet industry rules.

- Picking the right maker means checking quality, clear prices, and good communication.

- China’s strong supply chain and skilled workers help make products fast. This lets businesses adjust quickly to market needs.

- Solving problems like quality checks and idea protection is key for good partnerships in China’s factories.

Understanding electronic prototype manufacturing

What is an electronic prototype?

An electronic prototype is a preliminary version of an electronic product created to test its functionality, design, and feasibility. It serves as a tangible representation of the final product, allowing engineers and designers to identify potential flaws and make necessary adjustments before mass production. Prototypes can range from simple breadboard models to fully functional devices, depending on the stage of development. They play a critical role in ensuring that the final product meets technical specifications and user requirements.

Importance of prototypes in product development

Prototypes are indispensable in the process of product development. They act as a safety net, preventing costly errors during production. By providing a physical model, prototypes enhance communication among stakeholders, ensuring everyone involved has a clear understanding of the product’s design and functionality. Additionally, they help verify compliance with industry standards and regulatory requirements, such as safety certifications and electromagnetic compatibility testing. Research shows that projects incorporating feasibility prototypes are 30% more likely to be completed on time and within budget, highlighting their impact on development success rates.

- Key benefits of prototypes in product development:

- Minimize risks of design flaws.

- Facilitate stakeholder collaboration.

- Ensure regulatory compliance.

- Improve project timelines and cost efficiency.

Role of PCB in electronic prototypes

The printed circuit board (PCB) forms the backbone of most electronic prototypes. It provides the physical platform for mounting and connecting electronic components, ensuring the prototype functions as intended. High-quality PCBs are essential for achieving reliable performance and meeting industry benchmarks. Manufacturers adhere to strict standards to ensure the quality of PCBs used in prototypes.

| Key Areas Covered | Description |

|---|---|

| Materials and Equipment Requirements | Specifies types of solders, flux, cleaning agents, and handling tools for reliability. |

| Process Requirements | Establishes criteria for acceptable soldering methods with an emphasis on process control. |

| Soldering Criteria | Covers joint integrity, proper wetting, fillet shape, and solder quality. |

| Workmanship Standards | Provides guidelines for clean, well-aligned, and properly terminated assemblies. |

| Training and Certification | Ensures personnel are trained and certified to maintain production quality. |

| Inspection and Acceptance Testing | Specifies inspection protocols and integrates with IPC-A-610 for visual standards. |

| Classes of Product Quality | Defines quality classes based on the intended end-use application (Class 1, 2, 3). |

| Solder Joint Acceptability | Provides guidelines for acceptable solder joints with visual examples. |

| Component Mounting and Placement | Details correct orientation and positioning of components on PCBs. |

| Board and Component Damage Criteria | Summarizes signs of defects like cracks and solder bridging. |

| Surface Cleanliness and Contamination | Specifies criteria for board cleanliness and foreign materials. |

| Coatings and Markings | Defines criteria for conformal coating application and labeling. |

The PCB’s role extends beyond functionality. It ensures the prototype adheres to quality standards, such as IPC-A-610, which governs solder joint acceptability and component placement. By maintaining these standards, manufacturers can produce prototypes that meet the rigorous demands of industries like healthcare, automotive, and industrial automation.

Why choose China for electronic prototype manufacturing

Cost-efficiency and affordability

China’s electronic prototype manufacturing industry is renowned for its cost-efficiency, making it a preferred destination for businesses worldwide. The country’s well-established electronics industry chain and economies of scale significantly reduce production costs. Manufacturers benefit from local supply chains, which lower the expenses associated with raw materials and labor. For example, PCB production in China is 10-20% cheaper compared to North America or Europe.

A cost comparison highlights the savings businesses can achieve by choosing China:

| Description | Cost in China | Cost in the U.S. | Savings |

|---|---|---|---|

| 6-layer PCB (200 sq. cm) | $15 per board | $18 per board | $3,000 on 1,000 units |

| High-volume 4-layer PCB (10,000 units, 100 sq. cm) | $4.25 per board | N/A | $7,500 savings |

Additionally, the affordability extends to low volume PCB assembly, where manufacturers can produce prototypes at competitive rates without compromising quality. This cost advantage allows businesses to allocate resources to other critical areas, such as design refinement and functional testing.

Speed and scalability of production

China’s electronic prototype manufacturing industry excels in speed and scalability. The country’s advanced infrastructure and streamlined processes enable manufacturers to deliver prototypes quickly, meeting tight deadlines. Specialized hubs, such as Shenzhen, house numerous PCB assembly facilities, ensuring rapid turnaround times. These hubs also support low volume PCB assembly, allowing businesses to test designs efficiently before scaling up production.

Scalability is another key advantage. Manufacturers in China can handle both small-scale prototype production and large-scale chip production with equal efficiency. This flexibility ensures that businesses can adapt to market demands without delays. For instance, a company requiring 10,000 units of a 4-layer PCB can rely on China’s manufacturing capabilities to meet this demand promptly while maintaining high quality standards.

Access to advanced technology and skilled labor

China’s leadership in electronic prototype manufacturing is bolstered by its access to advanced technology and a highly skilled workforce. The country invests heavily in research and development, particularly in sectors like semiconductors and chips. This focus ensures that manufacturers have access to cutting-edge tools and techniques for PCB assembly and design validation.

Skilled labor plays a crucial role in maintaining quality and precision. Workers in China’s electronics industry undergo rigorous training to meet international standards. Their expertise ensures that prototypes are assembled with meticulous attention to detail, from component placement to functional testing. This combination of technology and talent enables manufacturers to produce prototypes that meet the stringent requirements of industries such as healthcare, automotive, and telecommunications.

Tip: Businesses seeking customization in their prototypes can benefit from China’s advanced capabilities, which allow for tailored designs and specialized assembly processes.

Strong supply chain and material availability.

China’s electronic prototype manufacturing industry thrives on its robust supply chain and abundant material availability. The country’s well-established infrastructure supports seamless sourcing and delivery of essential components, ensuring manufacturers can meet production demands efficiently. This advantage positions China as a global leader in prototype development.

The supply chain in China operates with remarkable efficiency. Manufacturers benefit from proximity to suppliers of raw materials, such as copper for PCB production and silicon for chips. This localized network reduces transportation costs and minimizes delays, enabling faster turnaround times for prototype assembly. Additionally, the availability of specialized suppliers ensures access to high-quality components tailored to specific design requirements.

China’s manufacturing hubs, such as Shenzhen, play a pivotal role in maintaining supply chain strength. These hubs house a dense concentration of suppliers, manufacturers, and logistics providers, creating an ecosystem that supports rapid material sourcing and assembly processes. For instance, low volume PCB assembly becomes more feasible due to the streamlined availability of materials and skilled labor within these hubs.

The country’s focus on semiconductor production further enhances its supply chain capabilities. China semiconductor manufacturing facilities prioritize innovation and scalability, ensuring a steady supply of chips for prototype development. This emphasis on semiconductors allows manufacturers to produce prototypes with advanced functionalities, meeting the demands of industries like telecommunications and healthcare.

Material availability in China extends beyond raw materials. Manufacturers have access to cutting-edge tools and equipment for design validation and functional testing. This ensures prototypes meet stringent quality standards and perform reliably under various conditions. The integration of advanced technology into the supply chain supports customization, allowing businesses to create prototypes that align with unique specifications.

China’s strong supply chain also mitigates risks associated with global disruptions. Manufacturers can rely on local resources to maintain production continuity, reducing dependency on international suppliers. This resilience ensures businesses can proceed with prototype development without compromising timelines or quality.

Note: Businesses seeking cost-effective and scalable solutions for prototype manufacturing can leverage China’s robust supply chain to achieve their goals. The country’s ability to combine material availability with efficient assembly processes makes it an ideal destination for electronic prototype development.

Challenges in china electronic prototype manufacturing

Quality control concerns

Quality control remains a significant challenge in china’s electronic prototype manufacturing industry. While the country excels in cost efficiency and scalability, maintaining consistent quality across all production stages can be difficult. Variations in the quality of chips, PCBs, and other components often arise due to differences in supplier standards. This inconsistency can lead to functional testing failures, delaying the development process.

Manufacturers address these concerns by implementing stringent quality assurance protocols. Many adopt international standards, such as ISO 9001, to ensure uniformity in production. Advanced inspection tools, including automated optical inspection (AOI) systems, help identify defects in low volume PCB assembly. Despite these measures, businesses must remain vigilant when selecting suppliers to avoid potential quality issues.

Communication barriers and cultural differences

Communication barriers and cultural differences pose another challenge in china’s electronic prototype manufacturing sector. Language differences can lead to misunderstandings, especially when discussing technical specifications or design changes. These issues often result in delays or errors during chip production and assembly.

Cultural differences may also affect business interactions. For instance, indirect communication styles common in china can sometimes create confusion for international clients. To overcome these challenges, many manufacturers employ bilingual project managers who bridge the gap between clients and production teams. Clear documentation and regular updates further enhance communication, ensuring that projects stay on track.

Intellectual property protection

Intellectual property (IP) protection is a critical concern for businesses outsourcing prototype development to china. The country’s rapid growth in semiconductor and chip production has raised questions about safeguarding proprietary designs and technologies. Unauthorized replication of components or designs can undermine a company’s competitive edge.

Leading manufacturers address this issue by adopting robust IP protection measures. Non-disclosure agreements (NDAs) and secure data transfer protocols are standard practices. Additionally, china semiconductor manufacturing facilities increasingly comply with international IP laws to build trust with global clients. Businesses should conduct thorough due diligence to ensure their chosen manufacturer prioritizes IP security.

How top manufacturers address these challenges.

Top manufacturers in China employ a range of strategies to address challenges in electronic prototype development. They prioritize quality by implementing rigorous inspection protocols. Advanced tools like automated optical inspection systems and X-ray machines detect defects in chips and low volume pcb assembly. These measures ensure that components meet international quality standards, reducing the risk of errors during functional testing.

To overcome communication barriers, manufacturers invest in bilingual project managers and detailed documentation. These professionals act as intermediaries, ensuring that technical specifications are accurately conveyed. Regular updates and video conferencing tools further enhance collaboration between clients and production teams. This approach minimizes misunderstandings and keeps projects on schedule.

Intellectual property protection remains a critical focus for leading manufacturers. Many adopt secure data transfer systems and enforce strict non-disclosure agreements. Facilities specializing in semiconductor and chip production often comply with international IP laws to build trust with global clients. By fostering transparency, these manufacturers safeguard proprietary designs and technologies.

China’s top manufacturers also leverage their robust supply chains to maintain consistency in low volume pcb assembly. Proximity to suppliers of chips and other components allows for seamless material sourcing. This efficiency not only ensures high-quality outputs but also keeps costs competitive.

By addressing these challenges proactively, manufacturers in China continue to lead in semiconductor and prototype manufacturing. Their commitment to quality, communication, and IP protection makes them reliable partners for businesses worldwide.

Workflow of electronic prototype manufacturing in China

Initial design and concept development

The workflow begins with the initial design and concept development phase. Engineers and designers collaborate to create a blueprint for the electronic prototype. This stage involves defining the product’s functionality, selecting the appropriate components, and outlining the layout of the PCB. Advanced software tools, such as CAD programs, are often used to create detailed schematics and 3D models. These designs undergo rigorous validation to ensure they meet technical and industry standards. In China, manufacturers leverage their expertise in semiconductor and PCB technologies to refine designs for optimal performance and cost efficiency.

Material sourcing and preparation

Material sourcing and preparation form the backbone of the manufacturing process. Manufacturers in China benefit from a robust supply chain that ensures the availability of high-quality components, including chips, resistors, and capacitors. Proximity to suppliers reduces lead times and minimizes costs. Once sourced, materials undergo thorough inspection to verify their quality and compatibility with the design specifications. For PCB production, manufacturers prepare copper-clad laminates and other essential materials. This meticulous preparation ensures that the assembly process proceeds without interruptions or defects.

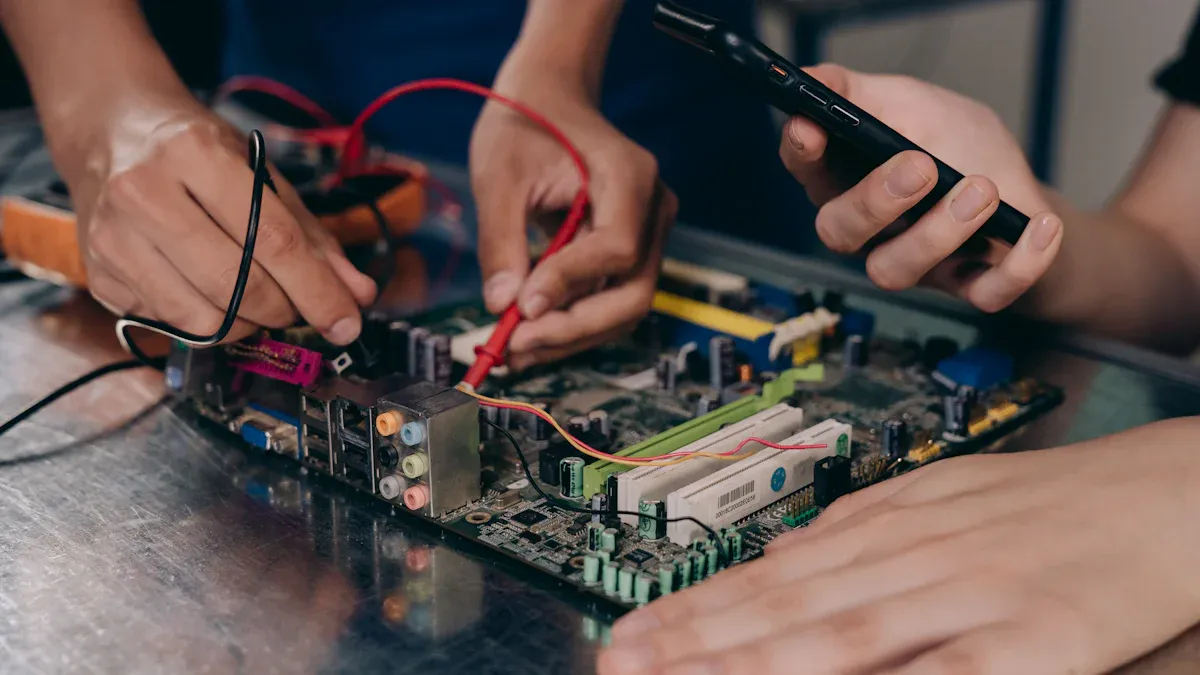

Prototype assembly and testing

The assembly phase involves mounting components onto the PCB and connecting them to create a functional prototype. In China, manufacturers utilize advanced techniques such as surface-mount technology (SMT) and through-hole assembly to achieve precision. Automated systems handle most of the assembly tasks, ensuring consistency and efficiency. After assembly, the prototype undergoes extensive testing to validate its functionality and reliability. Tests include signal integrity checks, thermal analysis, and performance evaluations. Feedback from these tests informs further iterations, ensuring the final prototype meets all design and operational requirements.

Tip: Businesses can expedite the assembly and testing phases by partnering with manufacturers in China who specialize in low-volume PCB assembly and semiconductor integration.

Feedback and iteration process.

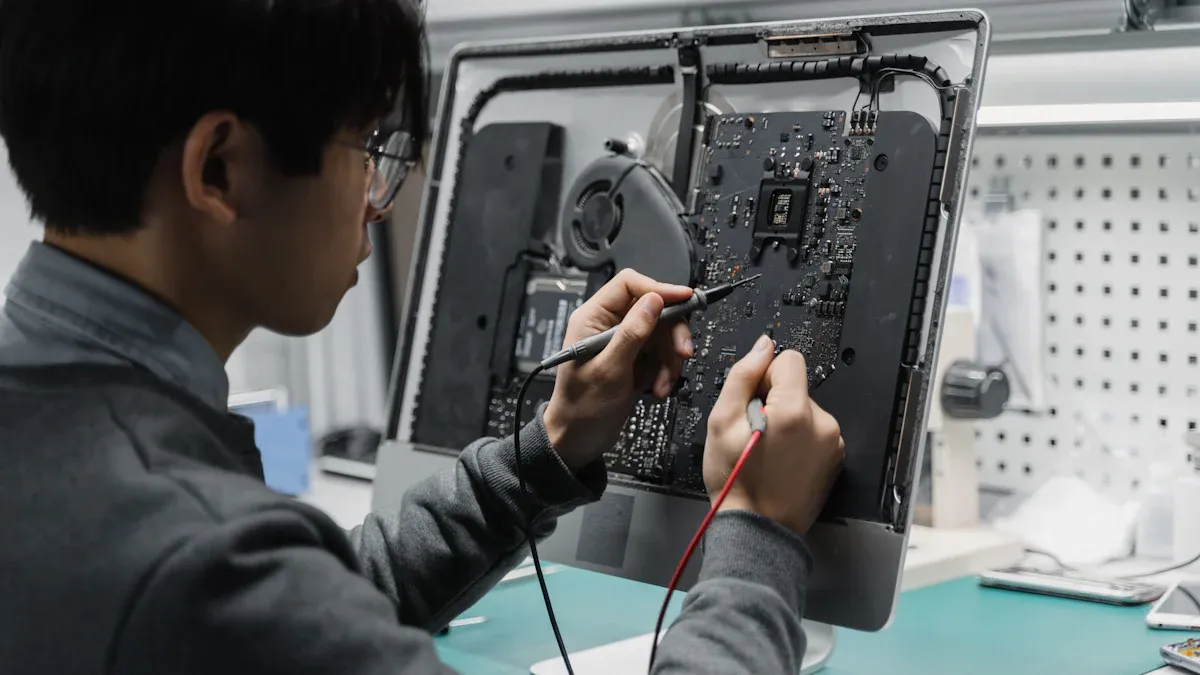

Feedback and iteration are critical components of electronic prototype manufacturing. This phase ensures the prototype aligns with design specifications and meets functional requirements. Manufacturers in China emphasize iterative processes to refine prototypes and address any shortcomings identified during testing.

The feedback process begins with comprehensive evaluations of the prototype’s performance. Engineers analyze test results to identify areas requiring improvement. These evaluations often include input from stakeholders, such as designers and end-users, to ensure the prototype meets both technical and practical expectations. Manufacturers in China leverage advanced diagnostic tools to gather precise data, enabling targeted adjustments.

Iteration involves implementing changes based on feedback and retesting the prototype. Each cycle focuses on enhancing specific aspects, such as signal integrity, thermal performance, or component placement. Manufacturers in China excel in this phase due to their access to skilled labor and cutting-edge technology. For example, automated systems streamline adjustments, reducing the time required for each iteration.

Tip: Businesses can optimize the iteration process by collaborating closely with manufacturers. Clear communication of design goals and testing criteria ensures efficient refinement cycles.

The iterative approach fosters continuous improvement, allowing manufacturers to produce prototypes that meet stringent industry standards. In China, this process benefits from the country’s robust supply chain and material availability. Rapid access to components enables quick modifications, minimizing delays and ensuring timely delivery.

Feedback and iteration not only improve prototype quality but also reduce production risks. By addressing issues early, manufacturers avoid costly errors during mass production. This proactive approach underscores China’s leadership in electronic prototype manufacturing.

Choosing the right manufacturer for electronic prototypes in China

Evaluating quality standards and certifications

Selecting a reliable manufacturer begins with evaluating their quality standards and certifications. Certifications such as ISO 9001 and IPC-A-610 demonstrate a commitment to maintaining high production standards. These certifications ensure that manufacturers adhere to rigorous quality control processes, which are essential for producing reliable electronic prototypes. Additionally, manufacturers undergo audits to verify compliance with industry regulations and assess their production capabilities.

A structured vetting process can help businesses identify trustworthy manufacturers. This process typically includes reviewing certifications, analyzing production histories, and assessing financial stability. For example, a multi-tiered assessment evaluates a manufacturer’s ability to meet deadlines, maintain consistent quality, and comply with international standards. The table below summarizes key aspects of this evaluation:

| Aspect | Description |

|---|---|

| Quality Assurance | Manufacturers are assessed based on their certifications, audits, and production histories. |

| Rigorous Vetting | A multi-tiered assessment process reviews capabilities, financial health, and compliance histories. |

| Certification Review | Verification of certifications and permits is conducted to ensure compliance with standards. |

By prioritizing manufacturers with strong certifications and a proven track record, businesses can minimize risks and ensure their prototypes meet industry benchmarks.

Tip: Always request documentation of certifications and audit reports to verify a manufacturer’s credibility.

Comparing pricing and cost transparency

Cost transparency plays a crucial role in selecting the right manufacturer. While China is known for its cost-efficient production, businesses must carefully analyze pricing structures to avoid hidden fees. Transparent manufacturers provide detailed quotes that outline costs for materials, labor, and additional services such as testing or shipping. This clarity helps businesses budget effectively and avoid unexpected expenses.

A comparative pricing analysis can reveal significant cost differences between manufacturers. For instance, some manufacturers may offer lower initial quotes but charge extra for design modifications or expedited production. Businesses should also consider the long-term value of working with a manufacturer. A slightly higher upfront cost may be justified if the manufacturer delivers superior quality and faster turnaround times.

Note: When comparing pricing, ensure that quotes include all relevant costs, such as tooling fees and quality inspections. This approach prevents surprises during the production process.

Assessing technical support and communication

Effective technical support and clear communication are vital for successful prototype development. Manufacturers in China vary in their ability to provide consistent support and maintain open lines of communication. Businesses should evaluate a manufacturer’s responsiveness, technical expertise, and ability to address concerns promptly.

Customer reviews and performance evaluations offer valuable insights into a manufacturer’s service quality. For example, AllPCB, a prominent manufacturer, has received mixed reviews on PCBShopper. While some customers praise their representatives for being helpful, others report issues with inconsistent support and quality control. The table below highlights key aspects of technical support and communication:

| Aspect | Evidence |

|---|---|

| Average Rating | AllPCB has a 3.3/5 average rating on PCBShopper, indicating mixed reviews. |

| Quality Control Issues | Reports of defects such as misaligned diodes suggest inconsistent oversight. |

| Customer Support Variability | Praise for some representatives contrasted with complaints about others. |

To mitigate potential challenges, businesses should prioritize manufacturers that assign dedicated project managers. These managers act as liaisons, ensuring that technical specifications are accurately communicated and that any issues are resolved efficiently. Regular updates and clear documentation further enhance collaboration, reducing the likelihood of misunderstandings.

Tip: Schedule an initial consultation with the manufacturer to assess their communication style and technical expertise before committing to a partnership.

Checking reviews and client testimonials.

Evaluating reviews and client testimonials is a crucial step in selecting the right manufacturer for electronic prototypes. These insights provide a window into the experiences of previous clients, offering valuable information about the manufacturer’s reliability, quality, and customer service. Businesses can use this data to make informed decisions and minimize risks.

Online platforms and forums dedicated to electronics manufacturing often host reviews from global clients. Websites like PCBShopper and Trustpilot allow users to share their experiences with manufacturers in china. These reviews typically highlight key aspects such as production quality, delivery timelines, and communication efficiency. By analyzing these reviews, businesses can identify patterns that indicate consistent performance or recurring issues.

Client testimonials, often featured on a manufacturer’s website, serve as another valuable resource. These testimonials usually emphasize positive experiences and successful projects. While they provide useful insights, businesses should approach them with caution, as they may not always reflect the full spectrum of client feedback. Cross-referencing testimonials with independent reviews ensures a balanced perspective.

To effectively assess reviews and testimonials, businesses should focus on specific criteria:

- Consistency in Quality: Look for mentions of product reliability and adherence to specifications. Consistent quality is a hallmark of reputable manufacturers in china.

- Timeliness: Evaluate feedback on delivery times. Delays can disrupt project timelines, making punctuality a critical factor.

- Communication: Pay attention to comments about responsiveness and clarity. Effective communication minimizes misunderstandings during the prototype development process.

- Problem Resolution: Consider how manufacturers handle issues. Positive reviews often highlight proactive problem-solving and customer support.

Tip: Use a scoring system to compare manufacturers based on these criteria. Assigning numerical values to factors like quality, timeliness, and communication can simplify the decision-making process.

In addition to online reviews, direct references from past clients can provide deeper insights. Reputable manufacturers in china often share contact details of previous clients willing to discuss their experiences. Speaking directly with these references allows businesses to ask specific questions about the manufacturer’s capabilities and reliability.

Lastly, businesses should remain vigilant for red flags in reviews. Frequent complaints about quality control, hidden costs, or poor communication may indicate underlying issues. Manufacturers with overwhelmingly negative feedback should be avoided, regardless of their pricing or production capacity.

By thoroughly analyzing reviews and testimonials, businesses can identify manufacturers in china that align with their needs. This step not only reduces risks but also ensures a smoother prototype development process.

China’s electronic prototype manufacturing offers unmatched benefits, including cost efficiency, rapid production, and access to advanced technology. Its robust supply chain and skilled workforce further solidify its global leadership. However, challenges like quality control and intellectual property protection require careful navigation.

Selecting a reliable manufacturer is crucial for ensuring high-quality prototypes and smooth project execution. Businesses should prioritize certifications, transparent pricing, and strong communication.

Call to Action: Explore China’s manufacturing capabilities to unlock innovation and efficiency. Partnering with the right manufacturer can transform your ideas into market-ready products. 🌟

FAQ

What industries benefit the most from electronic prototype manufacturing in China?

Industries such as healthcare, automotive, telecommunications, and consumer electronics gain the most from China’s electronic prototype manufacturing. These sectors rely on rapid prototyping, cost efficiency, and access to advanced technologies to develop innovative products and maintain competitive advantages.

How long does it take to produce an electronic prototype in China?

The production timeline depends on the complexity of the design and the manufacturer’s capacity. On average, simple prototypes take 1-2 weeks, while more intricate designs may require up to 4 weeks. Manufacturers in China often expedite timelines due to their streamlined processes.

Are manufacturers in China equipped to handle low-volume prototype production?

Yes, many manufacturers specialize in low-volume production. They offer flexible services tailored to startups and small businesses. This capability allows companies to test designs and refine products before committing to large-scale manufacturing.

Tip: Businesses should confirm a manufacturer’s low-volume production capabilities during the selection process to avoid delays.

How do manufacturers in China ensure quality control during prototype production?

Manufacturers implement strict quality assurance protocols, including automated optical inspections and functional testing. Many adhere to international standards like ISO 9001 and IPC-A-610. These measures ensure prototypes meet technical specifications and industry benchmarks.

What steps can businesses take to protect intellectual property when working with Chinese manufacturers?

Businesses should sign non-disclosure agreements (NDAs) and choose manufacturers with a proven track record of IP protection. Verifying compliance with international IP laws and using secure data transfer methods further safeguards proprietary designs and technologies.

Note: Conducting due diligence on a manufacturer’s reputation and IP policies is essential for risk mitigation.