What are the advantages and roles of the post-soldering process in PCBA assembly?

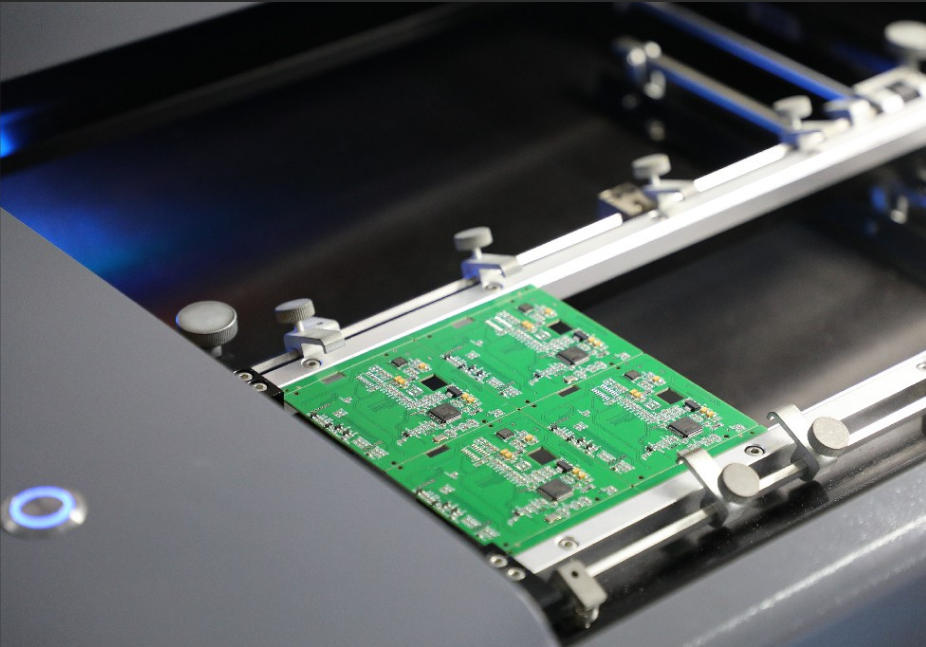

As a one-stop PCBA processing service provider, today we’ll discuss the advantages and functions of subsequent soldering processes in PCBA processing. In-depth analysis of PCBA subsequent soldering processes: Subsequent soldering processes in PCBA (Printed Circuit Board Assembly) processing refer to the secondary soldering operations performed on certain special or easily damaged components after core soldering processes such as surface mount technology (SMT) and through-hole mounting (DIP). This process offers significant advantages in improving product quality, enhancing reliability, and adapting to diverse production needs. Its specific functions are as follows:

Detailed Explanation of the Advantages and Roles of Post-Soldering Process in PCBA Assembly

1. Core Advantages of Post-Soldering Process

-

Reinforcing Solder Joints, Enhancing Operational Stability

The post-soldering process, utilizing a secondary soldering operation, effectively enhances the strength of solder joints for critical components, particularly those designed to handle high currents or perform core functions (e.g., power modules, high-power LEDs). Taking high-power LEDs as an example, their significant current load can lead to solder joint fatigue failure in automated soldering. Post-soldering creates a more robust supporting structure, substantially extending product lifespan. Furthermore, in the automotive electronics sector, by strengthening solder joints, the post-soldering process improves the circuit board’s resistance to vibration, effectively mitigating the risk of solder joint cracking caused by vibration.

-

Protecting Sensitive Components, Avoiding Thermal Damage Risks

Certain heat-sensitive components (e.g., sensors, precision chips) cannot withstand the high temperatures of reflow or wave soldering. The post-soldering process employs low-temperature manual soldering or automated low-temperature soldering methods, maximizing the protection of such components’ integrity. For instance, an automotive manufacturer once discovered that a key resistor within its ECU control unit had become loose due to thermal stress. After reinforcement via the post-soldering process, the long-term stability issue was completely resolved, ensuring the reliable operation of the vehicle control system.

-

Enhancing Production Flexibility, Adapting to Diverse Needs

The post-soldering process allows for flexible adjustment, replacement, or repair of components, making it particularly suitable for small-batch production, prototyping, or trial production phases. For example, during smartphone development, the post-soldering process can quickly accommodate design changes, precisely meeting customers’ personalized needs in functionality or cost control. Additionally, for components located near the circuit board edge, post-soldering avoids issues like poor liquid solder contact or mechanical collisions that can occur during wave soldering.

-

Controlling Production Costs, Improving Resource Utilization

Through localized repairs, the post-soldering process can reduce the scrap rate of entire circuit boards, minimizing material waste. For instance, for defective products resulting from earlier soldering stages, there is no need to disassemble the entire board; simply repairing the problematic area via post-soldering significantly saves production costs. Meanwhile, for large or unusually sized through-hole components, the cost of using post-soldering is often lower than using SMT components, further alleviating financial pressure on enterprises

2. Additional Advantages and Application Value of PCBA Post-Soldering Process

-

Overcoming Soldering Challenges for Special Components

The post-soldering process is especially suitable for components that are physically large, have unique shapes, or possess complex pin structures (e.g., large inductors, high-temperature-sensitive connectors). These components are often difficult to install using automated placement equipment. In the aerospace field, for example, the post-soldering process can tailor low-temperature manual soldering solutions for components with special packaging forms, thereby ensuring their integrity and original performance remain unaffected.

-

Optimizing Electrical Performance, Enhancing Signal Transmission Quality

In application scenarios involving high current or high-frequency signal transmission, the post-soldering process, with its precise manual soldering operations, can effectively improve the electrical contact of critical components like connectors, reduce contact resistance, and thereby enhance signal transmission stability. For instance, within 5G communication equipment, the post-soldering process can ensure the reliability of high-speed signal transmission and reduce the risk of data loss during transmission.

-

Meeting Stringent Standard Requirements in High-End Fields

In high-end sectors such as military, medical, and aerospace, the post-soldering process, with its high-standard soldering quality and reliable process control capabilities, precisely meets the extreme demands for soldering reliability. Taking medical equipment as an example, the precision circuit boards inside rely on the post-soldering process to ensure every solder joint is free from defects, thereby solidifying the foundation for the equipment’s operational stability.

-

Flexibly Handling Unexpected Issues During Production

The post-soldering process enables rapid repair of soldering defects or replacement of faulty components, which not only reduces rework costs but also shortens production cycles. For example, during the production of industrial control equipment, if a cold solder joint is detected on a circuit board, the post-soldering process can quickly locate the fault and complete the repair, preventing the entire production line from stalling due to the issue.

III. Application Scenarios and Related Explanations for PCBA Post-Soldering Process

-

Complex Electronic Product Manufacturing

In the manufacturing of products with high-density circuit boards, such as smartphones and tablets, the post-soldering process is often used to mount special components or perform localized repairs, ensuring the complete realization of all product functions.

-

Industries with High-Reliability Requirements

Industries like automotive electronics and industrial control have extremely high standards for circuit board stability. The post-soldering process enhances the product’s temperature resistance and vibration resistance under harsh operating conditions by reinforcing key solder joints.

-

Customized Production Demand Scenarios

For small-batch, multi-variety production models, the post-soldering process offers the advantage of flexible adjustment of component layout, allowing precise alignment with customers’ personalized needs regarding product performance, functional configuration, or cost control.

The above is a detailed analysis of the advantages and roles of the post-soldering process in PCBA assembly. To learn more related knowledge points, you can follow KINGFIELD PCBA. If you have consulting needs regarding PCBA prototyping, PCBA contract manufacturing, PCBA assembly, or related technical knowledge, feel free to leave a message for more information!