Key Takeaways

- Make sure you know what your project needs. Write down the details, how many you need, and your budget. This will help you pick the best PCB partner.

- See if they have good quality checks. Look for certificates and how they test boards. This helps make sure the boards work well.

- Check what the partner can do. Make sure they can meet your needs and handle special features.

- Learn how they set prices. Ask if there are any extra costs. Do not just pick the cheapest. Look for the best value.

- Good communication is important. Talking clearly with your supplier stops mistakes. It also helps your project go faster.

Define Your Project Needs

You should think about what your project needs before picking a PCB printing partner. This helps you find the right supplier for your project. Every project is different, so you must look at the details.

PCB Specifications

Make a list of all the important things your project needs. These include:

- Physical board specifications

- Manufacturing specifications

- Electrical requirements

- Quality and compliance requirements

- Assembly requirements

Standard PCB specifications include board size, material, layers, copper thickness, trace width, solder mask, and electrical testing. These details help your project work well and stay safe. If your project needs special certifications, check the table below for common ones:

| Certification | Importance |

|---|---|

| ISO 9001 | Shows your project has good quality management. |

| IPC-A-610 | Sets rules for assembly, which is important for boards with many layers. |

| RoHS Compliance | Makes sure your project uses safe materials. |

| IATF 16949 | Needed for projects in cars. |

| AS9100 | Used for aerospace and defense projects. |

Volume and Budget

Figure out how many boards you need and how much money you can spend. The table below shows usual order sizes and costs:

| Order Volume | Per-Unit Cost Range |

|---|---|

| Prototypes (1–10) | $5 to $20 |

| Medium Volume (100–1,000) | $3 to $12 |

| High Volume (10,000+) | $1.5 to $8 |

If you order only a few boards, each one costs more. If you order a lot, each board costs less. Use these numbers to plan your budget.

Special Requirements

Some projects need special features. For example, rigid-flex PCBs have stiff and bendy layers. These are good for aerospace or medical designs. Flexible PCBs use polyimide, which helps your project fit into small spaces like wearable devices. If your project needs advanced features, make sure your partner can do them. This helps you avoid problems later.

Tip: Always match your project’s special needs with what your supplier can do. This helps your project go well from start to finish.

Key Factors in PCB Printing

Quality Assurance

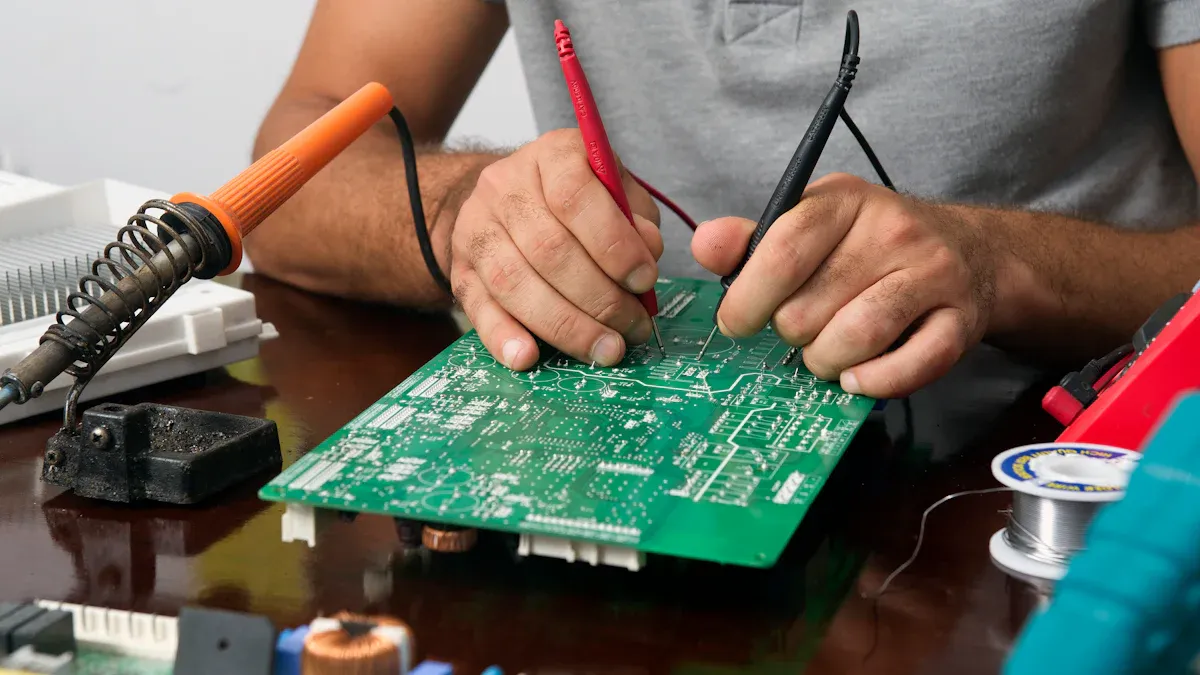

You need strong quality assurance to make sure your boards work well. This helps your project succeed and last longer. Good PCB printing partners check their work in many ways. They look at your design files to find mistakes early. They use high-quality materials and parts for every board. They follow strict rules like IPC-A-600 and IPC-A-610.

Most top companies use special machines to find problems. Automated Optical Inspection uses cameras to spot defects. In-Circuit Testing checks each part and connection. Some partners use X-ray inspection for boards with many layers. They also test boards in tough conditions to see if they hold up.

Here are common quality assurance steps you should look for:

- Design Verification: Checks your files for errors before printing.

- Material Selection: Uses only trusted materials and parts.

- Automated Optical Inspection (AOI): Finds surface defects with cameras.

- In-Circuit Testing (ICT): Makes sure every part works.

- Environmental Stress Testing: Tests boards in heat, cold, and vibration.

- Final Inspection: Checks every board before shipping.

Some companies do even more. They use a Quality Management System with rules for every step. They check random boards and do a full visual check before sending anything out. If your partner has more than one production line, they can deliver on time even when busy. Good partners give feedback on your design to help you avoid mistakes. They talk with you during the process and keep you updated.

Tip: Ask your supplier to explain their quality assurance steps. This helps you know if they can deliver reliable boards.

Certifications and Compliance

Certifications show that a PCB printing partner follows important rules. You should always check which certifications your supplier has. These prove that they care about quality and safety.

Here is a table of common certifications and what they mean:

| Certification | Description |

|---|---|

| ISO 9001 | Ensures quality management and consistent product quality across industries. |

| IPC-6012 | Sets standards for rigid PCBs, focusing on materials and workmanship. |

| IPC-6013 | Defines quality for flexible and rigid-flex PCBs. |

| ITAR | Needed for defense projects, focuses on security and performance. |

| RoHS | Limits harmful materials to protect the environment. |

| MIL | Makes sure military boards meet strict rules. |

| UL Listing | Checks safety for electronic devices and boards. |

You should also look for other rules. For example, IPC-A-600 sets rules for how boards should look. IPC-2221 helps with board design. ISO 13485 is needed for medical devices. IATF 16949 is important for car parts. AS9100 is used in aerospace. RoHS keeps electronics safe for the environment.

Note: Always ask for proof of certifications. You can request copies or check online databases. This helps you avoid problems with quality and legal issues.

Material Options

The materials used in your PCB affect how well it works. They also change the cost and how long it lasts. You should know the main choices and what they mean for your project.

Here is a table of common PCB materials:

| Material | Cost per Square Foot | Performance Characteristics | Applications |

|---|---|---|---|

| FR4 | $1.50 – $3.00 | Good for most electronics, easy to use, low cost | Power supplies, consumer gadgets |

| Rogers | $5.00 – $20.00 | Low signal loss, stable for high-frequency use | RF circuits, microwave, 5G |

| PTFE | > $30.00 | Great thermal and electrical properties, soft and flexible | Aerospace, medical imaging |

The number of layers and thickness change the price. If you need high performance, you may need special materials like Rogers. These cost more and need special skills to make. Boards for high-power use need materials that handle heat well. For example, aluminum-backed PCBs cool better than regular FR4 boards.

Materials also affect signal quality. If you use boards for fast data or radio signals, you need materials with a stable dielectric constant. This keeps signals clear and fast. Cheaper materials may save money at first, but they can cause problems later.

Tip: Talk to your supplier about material choices. Ask how each option affects quality, cost, and reliability.

Evaluating Technical Capabilities

Manufacturing Technologies

Check what manufacturing technologies your PCB partner uses. Newer methods help you get better boards. Some make boards smaller and more powerful. Others help with special shapes or fast signals. Here is a table of common technologies you might see:

| Technology Type | Description |

|---|---|

| High-Density Interconnect (HDI) | Makes small, complex boards with fine lines and many connections. Used in phones and AI hardware. |

| Flexible and Rigid-Flex PCBs | Boards that bend or twist. Good for wearables and small devices. |

| Ultra-HDI via Semi-Additive Processes | Reduces layers and boosts speed. Important for AI and edge computing. |

| High-Frequency Systems | Uses special materials for fast signals. Needed in telecom and aerospace. |

| Medical Devices | HDI boards for tiny, reliable circuits in health tech. |

You should also know how your partner prints the boards. Laser Direct Imaging and inkjet printing are very precise. These methods help with quick changes and small orders. Additive processes use less material and make tiny features. Digital methods like LDI and inkjet lower mistakes. They also keep boards the same every time.

Prototyping Services

Prototyping services help you test your design before making many boards. Good partners give fast and accurate prototypes. You can check if your idea works and fix problems early. Here are services top partners provide:

- High-precision PCB fabrication for advanced needs

- Fast turnaround for design checks

- Strict quality control with AOI, flying probe, and ICT testing

- Expert help with PCB design and layout

- Advanced options like HDI, rigid-flex, multilayer, and microvia boards

- Global shipping and logistics support

- Easy move from prototype to full production

Prototyping lets you test and change your design quickly. You can get feedback and improve your board before making many. This helps your project move faster and reach the market sooner.

Scalability

You need a partner who can grow with your project. They should make a few boards for testing and then many for full production. Keeping quality the same for every board is hard. Small changes in soldering or parts can cause problems. Your partner should get good parts at fair prices and deliver on time.

- Make sure your partner can handle your current orders and future growth.

- Ask if they can support new products or bigger orders as your business grows.

Tip: Pick a partner who can make more boards without losing quality. This helps your project do well now and later.

Turnaround Time and Flexibility

Lead Times

You want your project done fast. Turnaround time is important when picking a company. Quick delivery helps you launch products sooner. It also lets you react to changes in the market. PCB printing companies offer different lead times for each order. The table below shows common turnaround times:

| Order Type | Lead Time (Working Days) |

|---|---|

| Standard Lead Time | 20 |

| Quick Turn (varies by complexity) | < 20 |

| Double-sided board | 3-5 |

| 4-6 layers board | 5-8 |

| High-layer or special material | > 10 |

If you need boards quickly, some companies offer rush service. You can ask for this when you send your design file. Or you can talk to your sales rep. Some companies deliver in just 48 hours for urgent jobs. You may pay extra for fast service. Quick turnaround helps you meet tight deadlines.

Order Flexibility

Your project might change while you work on it. Order flexibility lets you change your PCB order if needed. Good companies let you pick size, layers, and special features. You can upload your design file and choose the board size. You can also pick how many layers you want. Many companies let you change panelization to save money. The table below shows common options for order flexibility:

| Order Flexibility Option | Description |

|---|---|

| Upload Design File | Start your order with your own design. |

| Set Size and Layers | Choose the exact size and layers you need. |

| Advanced Options | Adjust special features for your project. |

| Panelization Adjustment | Change panel layout for cost or design. |

| Cost Visibility | See how choices affect price and value. |

You get more value when you see how changes affect price. This helps you control your budget and get the most from your company.

Handling Changes

Sometimes you need to change your design after production starts. A good company has a clear way to handle changes. First, you find the problem and send a change request. All teams check and approve the change before making it. The steps below show how changes are handled:

- Find out what needs to change.

- Send a request to the company.

- All teams review and approve the change.

- Make the change in production.

- Write down everything for clarity.

Good communication and records help stop mistakes and delays. You get more value when your company handles changes well. Fast turnaround and flexible options make your project easier and better.

Tip: Always ask your company about their change process. This helps you get the best value and avoid costly mistakes.

Pricing and Transparency

Quotation Structure

You need a clear quote before you start. A good quote shows what you pay for and what you get. Most suppliers want lots of details to give a fair price. You should get these things ready:

- Schematic of your board

- Bill of materials (BOM)

- Placement drawing

- Compliance and special requirements

You might also need to send files like the bare board print, assembly print, and a list of approved vendors. Giving more details helps you get better prices and faster delivery. Your pcb assembly services provider will ask questions before giving a final quote. This helps you avoid mistakes and get the right help for your project.

Hidden Costs

Watch out for hidden costs when you order pcb assembly services. These extra charges can surprise you if you do not plan for them. Common hidden costs are:

- Engineering and setup fees (NRE costs)

- Quick-turn or rush order charges

- Small quantity surcharges

- Upcharges for special surface finishes

- Extra fees for non-standard solder mask colors

- Costs for complex drill requirements

- Impedance control fees for high-speed boards

- Testing and inspection add-ons

- Stencil charges for assembly

- Markups on component procurement

Ask your supplier to explain all possible fees. This helps you keep your budget safe and avoid surprises. You want your pcb assembly services to work well without extra costs.

Value vs. Price

The lowest price is not always the best choice. The value of pcb assembly services is about more than just cost. High-quality boards work better and last longer. Poor quality can cause problems or need fixing. This can make your project cost more in the end.

Complex designs cost more because they need special tools and extra steps. If you pick a simple design to save money, you might lose performance or pay more later. Good pcb assembly services focus on quality, reliability, and performance. You should find a partner who explains how their services help your project.

Tip: Always compare value, not just price. Better performance and reliable services can save you money over time.

Customer Support and Reputation

Support Quality

You need good customer support for your PCB project. Helpful service lets you fix problems fast. If you have questions, quick replies keep things moving. The best pcb supplier has a team ready to help. They answer emails and calls quickly. You want a partner who listens and gives clear answers. This kind of help saves you time and money.

Communication

Clear talking helps your project go well. If you talk often with your supplier, you can stop mistakes. Bad communication makes 29% of projects fail. Sharing your needs early helps your partner know your goals. Good talking can make your project finish 80% faster. It also saves money by finding problems early.

| Evidence Type | Description |

|---|---|

| Project Failure Rate | 29% of projects fail from bad communication. |

| Project Speed | Good talking makes projects finish 80% faster. |

| Cost Savings | Early questions and clear talking stop costly mistakes. |

Try these tips to talk better:

- Say what your project needs at the start.

- Use checklists for all technical questions.

- Pick one person to talk for your team.

- Share design changes quickly to stay on track.

- Give feedback often to make things better.

How to Identify the Best PCB Supplier

You want a partner with a good name and strong results. Start by reading customer reviews to learn about their service. Look for suppliers with good quality checks and certifications like ISO 9001. The best pcb supplier meets standards and keeps customers happy. Make sure they give reliable support and answer fast. A good reputation means you can trust them with your project.

Tip: Always ask for references or case studies before you pick a supplier. This shows how they handle real projects.

You can pick the best PCB printing partner by doing a few things. First, think about what your project needs. This includes cost, how fast you need it, and what skills are needed. Next, look at what different suppliers offer. Check their features and the materials they use. Talk clearly with the company you choose.

Good companies care about quality and have lots of experience. They also give strong support. Make a checklist to help you decide. Your list should include certifications, factory size, and engineering help. Add quality checks and data safety to your list.

Focus on what matters most for your project. Do not give up on important things. Begin your search feeling sure about your choices.

FAQ

What files do you need to order a PCB?

You need to send Gerber files, a Bill of Materials (BOM), and a placement drawing. These files show your design and parts. Your supplier uses them to make your board correctly.

How do you check if a PCB supplier is reliable?

Ask for certifications like ISO 9001. Read customer reviews. Request references or case studies. Reliable suppliers answer questions quickly and share proof of their quality.

Can you get a single prototype before full production?

Yes, you can order just one prototype. This helps you test your design. You can fix problems before making many boards.

What affects the price of PCB printing?

| Factor | Impact on Price |

|---|---|

| Board size | Larger costs more |

| Layers | More layers cost more |

| Material type | Special materials cost more |

| Order volume | Bigger orders cost less |

How fast can you get your PCBs?

Some suppliers offer boards in 48 hours for urgent jobs. Standard orders usually take 5 to 20 days. Ask your supplier about rush options if you need boards quickly.