What is ODM Electronic PCBA and How is it Different from OEM and EMS

You see odm electronic pcba as a full answer for making electronics. One company will design and build a product for your brand. This market is growing very fast. In 2024, it was worth $592.5 billion. By 2033, it could be $953.7 billion.

| Year | Market Size (USD) | Growth Rate (CAGR) |

|---|---|---|

| 2024 | 592.5 Billion | N/A |

| 2033 | 953.7 Billion | 5.4% |

| 2028 | 1,410.3 Billion | 8.30% (2021-2028) |

When you pick between odm, oem, and EMS, there are big differences. These choices change who owns the design. They also change how much you can change the product. They affect what branding or services you get.

| Role | Design Ownership | Customization | Branding | Service Scope |

|---|---|---|---|---|

| ODM | Owns design and manufacturing | Minimal customization | Customer’s brand | Design and manufacturing services |

| OEM | Customer provides design | Customized per customer | Customer’s brand | Manufacturing based on customer designs |

| EMS | No design ownership | Follows customer specifications | Customer’s brand | Manufacturing, testing, assembly services |

You should know these differences before you choose the best way for your product in electronics.

Key Takeaways

- ODM electronic PCBA lets you sell products fast. You do not need to design them yourself. This helps you save time and money.

- You should pick ODM, OEM, or EMS based on your design needs. ODM gives you less control to change things. OEM lets you own the whole design.

- ODMs do research, development, and testing for you. You can then focus on branding and selling. This helps you get to market faster.

- Think about your budget and how hard your product is to make. ODM works well for simple products and saves money. OEM is better for hard designs.

- Always check if the manufacturer has good quality standards. Make sure they can keep up with changes in the industry. This helps you have a good partnership.

ODM Electronic PCBA

Definition

You might ask what odm electronic pcba is. It means “original design manufacturer” electronic printed circuit board assembly. In this model, one company designs and builds a product for you. You get a product ready to sell. You do not need to make your own design. The odm does research, development, and testing. You can focus on your brand and selling.

ODM electronic pcba helps you launch new electronics faster. You do not need to spend money on research or hire engineers.

Here is how top electronics groups explain odm electronic pcba:

| Term | Definition | Role in Electronics Manufacturing |

|---|---|---|

| ODM | Original Design Manufacturers make products themselves and work with other companies to save on research costs. | ODMs do research, test products, and build them. They often let clients use their designs with new branding. ODMs keep the rights to their ideas and may rent designs to others. |

Features

You get many benefits with odm electronic pcba. The odm makes and builds products just for you. You can ask for changes in how it looks or works. This model is special because it gives you new ideas and lets you change things. The odm keeps the rights to the design. You may not control the design, but you can use your own brand.

- Customization: You can ask for special features or colors.

- Brand targeting: You can sell the product with your brand name.

- Private label solutions: The odm lets you put your brand on their products.

- Integrated services: You get design, pcb assembly, and testing all together.

Odm electronic pcba is used in many fields. Each field needs different things for pcb assembly:

| Industry | Specific Requirements |

|---|---|

| Consumer Electronics | Small size, fast data, saves energy, and advanced PCBA methods. |

| Automotive | Strong against tough places, safe, and works well in important uses. |

| Medical | Very accurate, follows rules, and safe for patients. |

| Aerospace | Very reliable, light, and works in hard conditions. |

New trends in odm electronic pcba are:

- Using AI and machine learning for faster pcb design.

- More electronics made in Asia, Latin America, and Africa.

- More focus on eco-friendly and green ways to make pcb assemblies.

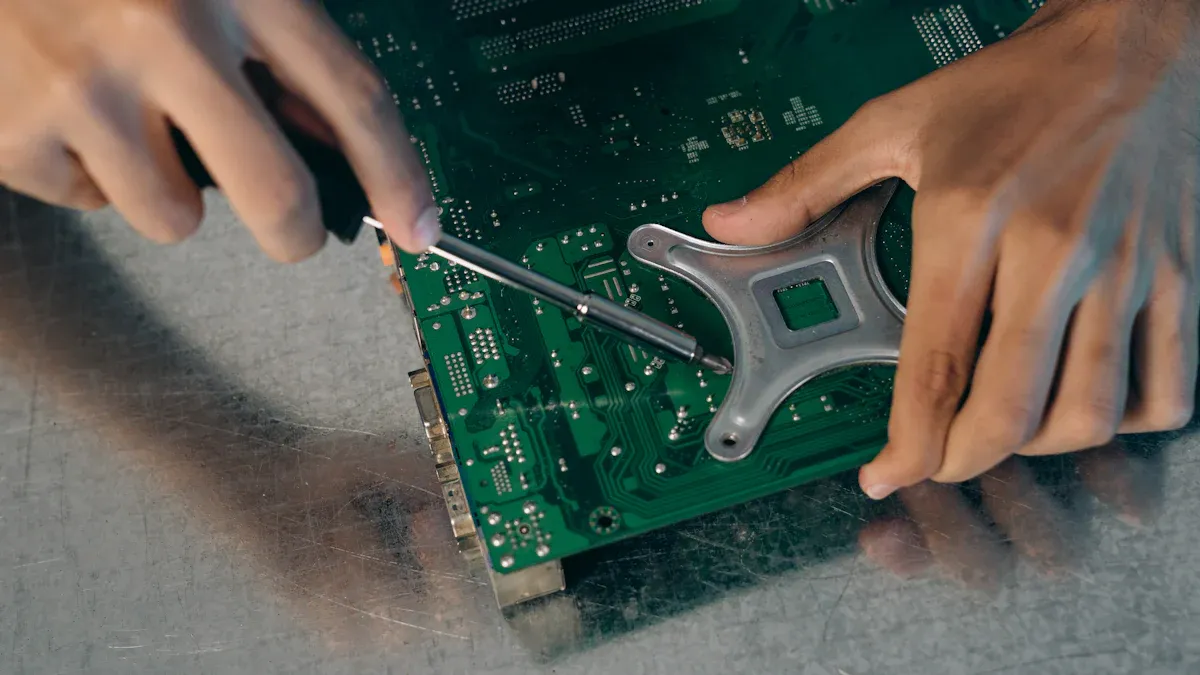

How It Works

You start by asking for a quote. The odm signs an NDA and checks what you need. Then, the odm checks the design and makes a sample. You test the sample and give your thoughts. The odm finishes the design and gets ready for a test run. Next comes quality checks and shipping plans. The odm makes lots of products and helps with support. You get testing, parts, pcb assembly, and packaging.

| Phase | Description |

|---|---|

| Inquiry & Quotation | First step with NDAs, project needs, and price quotes. |

| Design Verification | Detailed design and sample testing to make a strong product. |

| Finalize Design | Careful testing and checking of the best sample, using feedback. |

| Pilot Run | Focus on quality checks and shipping before making many products. |

| Life-cycle Management | Making many products and helping with support. |

| Program and Test | Setting up tests and making sure the product works well. |

| Electronic Components and PCB | Getting parts and handling pcb design and assembly. |

| Mechanical Parts and Assembly | Using new ways to build and put together products. |

| Packaging, Shipment, and | Making packages, testing for safety, and handling shipping and rules. |

You get private label options. The odm connects the supply chain, gives full assembly services, and checks quality closely. You get quick samples and good prices. The odm follows rules like ISO13485 and ISO9001.

| Aspect | Description |

|---|---|

| Supply Chain Integration | Links all parts of making electronics with long partnerships. |

| One-stop Assembly Services | Full services like making pcbs, SMT, and testing. |

| Customization | Special solutions for each client, including parts and assembly. |

| Quality Assurance | Careful checks (IQC, IPQC, OQA) so no bad products are made. |

| Fast Prototyping | Quick samples, saving money (20% less than normal price). |

| Industry Standards | Follows ISO13485, ISO14001, and ISO9001 for health and other areas. |

Odm electronic pcba companies use many tests to check quality. These include looking at products, X-ray checks, automatic checks, and testing how things work. They also follow world rules like IPC-A-610.

Tip: If you pick odm electronic pcba, you pay less for each product because services and design are all together. You also get more value if you want special features and your own brand.

ODM vs OEM

Design Ownership

When you choose between odm and oem, you need to look at who owns the design. In odm, the manufacturer creates and owns the design for the electronics. You get a finished product, but you do not control the design. In oem, you own the design. The manufacturer only builds what you ask for. This gives you more control over the final assembly.

| Model | Design Ownership | Flexibility for Changes | Control for Buyer |

|---|---|---|---|

| ODM | Manufacturer owns the design | Limited | Minimal |

| OEM | Buyer owns the design | High | Full |

Tip: If you want to protect your ideas and have full control, oem is the better choice.

Customization

Customization is another big difference. odm lets you make some changes to the product, like colors or small features. You work with pre-made platforms, so you cannot change everything. oem gives you full design control. You can ask for any feature or shape you want. This is important if your electronics need special parts or must meet strict rules.

| Feature | ODM Customization | OEM Customization |

|---|---|---|

| Customization Level | Moderate, with pre-made platforms | Full, for unique requirements |

| Cost Efficiency | Cost-effective for large orders | More expensive, but fully custom |

| Design Control | Limited | Complete |

| Best Use Cases | IoT, consumer goods, sensors | Medical, aerospace, special devices |

- odm works well if you want to launch a product fast and save money.

- oem fits best when you need a unique design or must follow strict safety rules.

Branding

Branding options also set odm and oem apart. With odm, you can put your brand on a ready-made product. This helps you enter the market quickly and with less risk. Startups often pick odm to test new ideas in electronics. oem lets you control both the design and the brand. You can make sure the product matches your brand’s style and quality.

- odm helps you build a brand fast, even if you do not have much money for research.

- oem gives you more power to shape your brand and build trust with customers.

Note: If you want a quick start and less risk, odm is a smart path. If you want full control and a strong brand, oem is the way to go.

ODM vs Electronic Manufacturing Service

Service Scope

There are big differences between ODM and electronic manufacturing service. ODM companies do both design and manufacturing. They make new electronics and let you use your brand name. EMS providers only focus on making electronics. They do not design products. EMS companies use your designs or ones from an OEM. EMS can build many products, test them, and manage the supply chain. The table below shows the main differences:

| Service Scope | ODM | EMS |

|---|---|---|

| Manufacturing capabilities | Full manufacture capabilities | High-capacity, complex electronics assembly |

| Intellectual Property (IP) | Owns IP unless otherwise agreed | IP remains with OEM |

| Product branding | Under client’s brand | Under OEM’s brand |

| Time-to-Market | Fast, ready-to-market solutions | Fast, efficient for mature products |

| Cost control | Controlled via agreements; depends on project scope | Economies of scale lower costs |

| Scalability | Typically scalable based on client needs | Highly scalable manufacture footprint |

| After-sales services | Contract-dependent; some support full lifecycle | Often includes logistics, repair, warranty |

| Supply chain management | Managed in coordination with client | End-to-end management offered |

Client Involvement

Your role is different with each provider. With ODM, you share your needs and they do the rest. You do not have to design the product. ODMs take care of research, development, and testing. You can focus on your brand and selling. With EMS, you must give them the design. EMS companies follow your plans and build the electronics. You stay involved in the design and may check quality at each step.

EMS providers work with OEMs. The OEM gives the design and goals. The EMS company handles all the manufacturing steps.

Sometimes, you and the provider work together from design to assembly. This is called JDM. Big companies like Foxconn and Flextronics use special ways to help brands at any stage.

Manufacturing Responsibilities

ODMs do more tasks than EMS providers. ODMs design, develop, and make electronics. They handle schematics, PCB design, software, and testing. EMS providers focus on building and putting parts together. They buy parts, make the PCB, and assemble everything. EMS companies do not make new designs but help you make more products.

- ODMs: Do R&D, design, PCB layout, software, prototyping, sourcing, and testing.

- EMS: Focus on manufacturing, buying parts, PCB making, and final assembly.

EMS can give you fast, high-quality assembly for your electronics. EMS providers often help with shipping, repairs, and warranties. ODMs give you a product ready to sell with your brand. EMS companies help you build your own designs.

Summary Table

Key Differences

It is important to know how ODM, OEM, and electronic manufacturing service providers are different. The table below helps you see these differences quickly:

| Criteria | ODM | OEM (Original Equipment Manufacturer) | EMS (Electronic Manufacturing Service Providers) |

|---|---|---|---|

| Intellectual Property | Supplier owned | Partially customer owned | Fully customer owned |

| Product Modification | Basic changes (color, packaging) | Customer gives input on specifications | Customer defines specifications |

| Tooling | Belongs to the supplier | Usually only external design owned by buyer | Belongs to the buyer |

| BOM Control | Little to no control for customer | Limited control or input | Fully controlled by the customer |

| Category Specialization | Specialized in certain categories | Specialized in certain categories | Wide range of product categories |

| Speed to Market | Fast, ready-made solutions | Slower due to custom development | Fast for mature products |

| Flexibility | Moderate | High | Very high |

OEMs spend a lot of time on research and design. They own their product ideas. EMS companies use machines that can change quickly. This helps you react fast to new needs.

Choosing the Right Model

You need to think about a few things before picking a model for your pcb assembly services. Here are some easy tips to help you choose:

- Align your business model with your goals. ODM is good if you want your brand fast. OEM is better if you want full design control.

- Check your budget. ODM costs less at the start. OEM needs more money for design and making new things.

- Look at product complexity. ODM is best for simple products or if you want to use designs that already exist. OEM or EMS is better for hard or special products.

- Consider supply chain and lead times. EMS providers are flexible and can react quickly to changes.

- Think about quality and support. Pick a manufacturer that meets industry rules and gives good customer help.

- Always compare prices and check if the company is reliable.

- Ask how they handle problems in the supply chain.

- See if they use new technology, especially if you want cool features.

- Make sure they follow green rules like RoHS and REACH.

Tip: ODM is great if you want your brand and need to sell fast. OEM is best if you want to own your product and control the design. EMS is good for big orders and flexible support.

You have learned that ODM, OEM, and EMS all have special advantages for electronic PCBA. ODM gives you a product that is already made, and you can add your brand. OEM lets you decide how the product looks and works. EMS is good at making lots of products quickly. Before you pick one, think about these things:

| Criteria | Description |

|---|---|

| Depth and scope of management | How well the company runs your project |

| Available technology | What tools and machines they use |

| Manufacturing quality and cleanliness | How clean and good their work is |

| Responsiveness to industry changes | How fast they keep up with new ideas |

| Value as it relates to pricing | If the price is fair for what you get |

- ODM is best if you want a finished product with small changes.

- OEM is better if you want to control the design and own your ideas.

- EMS is great for making many products with good quality checks.

Think about what you want for quality, changes, and service before you decide.

FAQ

What is the main benefit of using an ODM for electronic assemblies?

You do not need to design the product yourself. ODMs do the research, design, and testing for you. You can spend your time on your brand and selling. This helps you get your product to market faster and with less work.

How does a contract electronic manufacturer differ from an ODM?

A contract electronic manufacturer uses your design to build products. You decide how the product looks and works. ODMs make and own the design. You only put your brand on what they make.

Can an electronic contract manufacturer help with product development?

Yes, they can help you develop your product. They give advice, find parts, and build samples. You get help to turn your idea into a real product.

What does full production of printed circuit board assembly mean?

Full production means the manufacturer does every step. They design, find parts, put everything together, test, and pack the product. This makes sure your product is ready to sell.

When should you choose an ODM over an EMS provider?

Pick an ODM if you want to launch fast and do not need a special design. EMS is better if you already have a design and need to make many products.