Top 5 facts about Electronic Components and PCB services

- The quality of components changes how well devices work. PCB design helps devices work well and stay reliable. Manufacturing rules keep things safe and the same every time. Making custom designs and prototypes helps create new ideas. Cost and how long things take can make a project do well or not.

The world PCB market may reach $86.17 billion by 2026. New things like IoT and AI help make things work better and faster. If you know these important facts, you can make better choices in electronics, whether you build for fun or for your business with Electronic Components.

Key Takeaways

- Good electronic components help devices work better and last longer. You should check the quality and how parts are stored before using them.

- A professional PCB design is important for how things work. Placing parts in smart spots and routing traces well can make devices faster. It also helps lower mistakes.

- Certifications like ISO and IPC show safety and good quality in making things. Pick suppliers with these certifications for products you can trust.

- Customization and fast prototyping let you make special designs and test quickly. This makes it easier to try new ideas without spending a lot.

- Knowing what affects prices and how long things take helps you plan money and time. Always ask about delivery choices to keep your project moving.

Electronic Components Quality

Performance Impact

Electronic components help your devices work well and last longer. Good quality parts make your device work better every day. If parts are old or not stored right, they might fail more often. This can cause problems like losing signals or hearing extra noise. Sometimes, one bad part can stop your whole device from working. This is a big problem in important devices.

Tip: Always check how long your electronic components last and how they are stored before using them in your project.

There are many ways quality problems can show up. You might see unstable contact resistance from weak pressure or shaking. Solder joints can break from heat changes or moving atoms. Things like water or rust can hurt PCBs and cause shorts. These problems make your device less reliable and harder to fix.

Here are some common problems you might find:

- Pad cratering under BGA solder joints

- Trace fractures at stress points

- Corrosion on contact surfaces

Assessing Quality

You can check if electronic components are good by looking at industry rules and tests. Groups like the IEC and IEEE make rules for quality. These rules help you know if a part is safe and works well.

| Standard Organization | Type of Component | Application Areas |

|---|---|---|

| IEC | Various | Consumer products, vehicles, medical devices, etc. |

| IEEE | Various | Design, manufacture, testing, and end-of-life procedures. |

Manufacturers also follow rules like ISO 9001 and ISO 14001. These rules make sure products are safe and good for the environment.

Testing is very important before shipping. You might see tests like:

- Insertion testing for connectors

- Abrasion testing for wear resistance

- Temperature testing for thermal stress

- Shock and vibration testing for durability

- Salt spray testing for corrosion resistance

Final product testing checks if everything works and is safe. Good packaging and checking help stop damage during shipping. If you know these steps, you can pick electronic components that help your device work better and last longer.

PCB Design Matters

Functionality

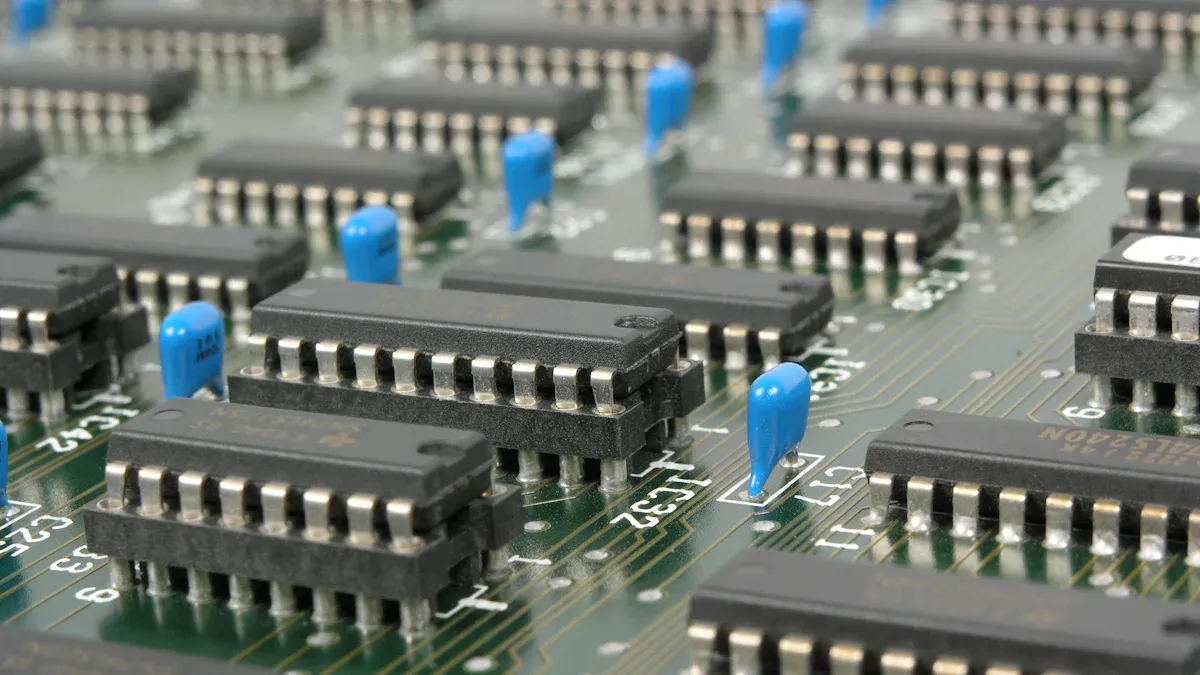

You want your device to work every time you use it. Professional PCB design helps make this happen. Good design means putting parts in smart places. It also means drawing traces carefully. When parts are placed well, building the device is easier. This helps stop mistakes. Short signal paths help your device run faster. They also help stop errors.

Here are some important things that change how your PCB works:

| Design Element | Impact on PCB Functionality |

|---|---|

| Trace routing | Cuts down on crosstalk, noise, and electromagnetic interference (EMI). |

| Component placement | Makes assembly easy and lowers mistakes in making. |

| Thermal management | Stops parts from getting too hot and keeps them working. |

| Via sizes | Makes sure layers connect well with electricity. |

| Solder mask clearances | Helps solder stick to pads and traces the right way. |

| Annular ring sizes | Gives strong electrical links and handles making steps. |

| Grounding and power distribution | Keeps signals clear and lowers EMI with good design. |

| Impedance matching and termination | Keeps signals clear, which is important for fast circuits. |

King Field’s PCB board service lets you pick many design choices. You can choose the layout you want. You can add your logo. You can pick features that fit your project. This helps you make devices that are special and work well.

Reliability

You want your devices to last and work in many places. Professional PCB design helps make this true. Using controlled impedance routing and good spacing keeps signals safe. Good thermal management uses things like thermal vias and heat sinks. These keep your device cool and safe.

A strong PCB design means fewer problems and longer life. Designers use full data sets for testing. They use automated optical inspection to find small mistakes. Working with trusted makers, like King Field, means your boards get checked well before you get them.

Tip: Always pick PCB services that test a lot and let you customize. This helps you get the best results for your Electronic Components and devices.

Manufacturing Standards

Key Certifications

It is important to know which certifications are needed. Certifications prove that a company follows strict rules for safety and quality. The most common ones are ISO, IPC, and UL. Each one checks a different part of making things.

- ISO 9001 is about managing quality and controlling risks.

- IPC gives rules for making and testing PCBs.

- UL checks if products are safe to use.

- RoHS makes sure products do not have harmful materials.

- IATF 16949 is needed for car electronics.

Here is a table with some important IPC standards:

| IPC Standard | Description |

|---|---|

| IPC-A-600 | Shows what good PCBs should look like. |

| IPC-6012 | Checks how well PCBs work and last, including heat and electricity. |

| IPC-A-610 | Gives rules for clean and well-soldered electronic assemblies. |

| IPC-2221 | Shares best ways to design PCBs for good results. |

| IPC-7711/7721 | Tells how to fix or change PCBs safely. |

Certifications like ISO 9001 and IPC help companies keep their work steady. This means you get products that work the same every time. Big companies in aerospace and defense only buy from certified suppliers. They need boards that are safe and always work.

Tip: Always look for certifications before you buy. Certified suppliers care about safety and quality.

Consistency & Safety

You want your devices to work well and be safe. Manufacturing standards help make this happen. Quality control checks that every product meets the same rules. Careful checks find problems early and stop bad products from getting to you.

- Quality control keeps products safe after you start using them.

- Strong testing checks for electrical safety and how products handle the environment.

- International rules like RoHS and WEEE limit bad materials and control how things are thrown away.

- Training helps workers handle materials in a safe way.

- Supplier checks make sure every part is safe.

Modern factories use machines and smart tools to find problems fast. They set clear rules and check every batch. This helps your devices work well and cuts down on waste. When you pick a supplier with strong standards, you keep yourself and others safe.

Customization & Prototyping

Custom Solutions

You want your project to be special and work just right. Customization in PCB services lets you make what you need. You can pick special materials for your board. You can add your logo or choose how many layers you want. This control helps you build devices for many things, like smart homes or medical tools.

| Customization Options | Description |

|---|---|

| Materials | Pick from different materials for strength or flexibility. |

| Surface Finishes | Choose finishes that improve performance and durability. |

| Layer Counts | Select the number of layers to match your design needs. |

Custom PCBs let you use parts that are not standard. You can add special sensors or microprocessors. This is important for things like airplanes or defense projects. You can follow strict testing rules and use new ways to make boards, like 3D printing.

King Field makes it simple to customize your boards. You can order one or many boards. This is good for hobbyists and businesses. You can put your logo or pictures on your product. This helps you try new ideas without spending a lot of money.

Tip: Custom PCBs give you strong, exact, and efficient boards for both testing and finished products.

Rapid Prototyping

You want to see your ideas fast. Rapid prototyping lets you test and fix your designs in hours. You do not have to wait weeks. This uses new tools like 3D printers. These tools work with many materials and make hard shapes.

| Advantage | Description |

|---|---|

| Fewer Supply Chain Challenges | Make prototypes without waiting for outside materials. |

| Flexibility in Design | Create complex, multi-functional boards that traditional methods cannot match. |

| Small Batch Runs | Produce just a few boards for testing, saving money and time. |

| Efficiency | Update your design fast after each test, leading to better results. |

| Cost-effectiveness | Save on materials and labor, making development more affordable. |

King Field lets you order just one PCB. This makes rapid prototyping easy for small businesses and hobbyists. You can try many ideas and see how your product works early. You can make smart choices from real tests. This speed helps you bring new products to market faster.

Cost & Lead Time

Pricing Factors

It is important to know what changes the cost of electronic components and PCB services. Many things can make the price higher or lower. Some of the main things that change the price are:

- Delivery Time: If you want your order fast, it costs more. This is because workers need to hurry and shipping is special.

- Circuit Complexity: Harder circuits need more parts and take longer to build.

- PCB Size: Bigger boards use more material and can cost more to send.

- Layer Count: Boards with more layers need extra work and materials.

- Substrate Material: Some materials, like polyimide, are more expensive than FR4.

- Trace Width and Spacing: Tiny traces need special machines, so the price goes up.

- Drill Hole Size and Quantity: More or smaller holes take more time and cost more.

- Surface Treatment: Different finishes, like gold or silver, change the price.

- Copper Thickness: Thicker copper means more material and higher costs.

- Hidden Costs: Things like testing, assembly, and shipping add to the total price.

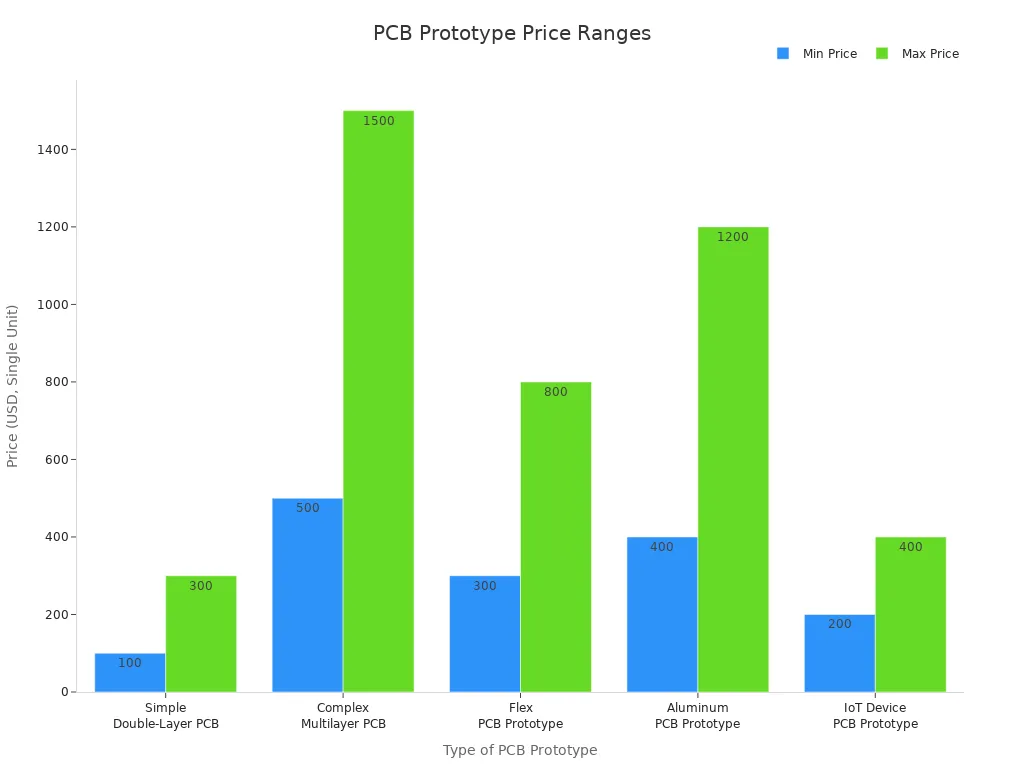

The kind of board you pick also changes the price. Here is a table that shows how much different PCB prototypes can cost:

| Type of PCB Prototype | Price Range (Single Unit) |

|---|---|

| Simple Double-Layer PCB | $100 – $300 |

| Complex Multilayer PCB | $500 – $1,500 |

| Flex PCB Prototype | $300 – $800 |

| Aluminum PCB Prototype | $400 – $1,200 |

| IoT Device PCB Prototype | $200 – $400 |

If you order more boards at once, each board costs less. Small orders cost more for each board because setup and labor are not shared.

Delivery Speed

You want your project to finish on time. How fast you get your boards is called lead time. Most PCB fabrication takes about 4-5 days. But you can get boards in just 24-48 hours if you need them quickly. Assembly usually takes 5-7 days, but some places can do it in 3-5 days. Full turnkey services may take 10-15 days, but you can pay for faster 5-7 day options.

| Service | Standard Lead Time | Expedited Lead Time |

|---|---|---|

| PCB Fabrication | 4-5 days | 24-48 hours |

| PCB Assembly | 5-7 days | 3-5 days |

| Full Turnkey | 10-15 days | 5-7 days |

Getting your boards faster helps you stay on schedule. Quick shipping also means less chance of damage and lower storage costs. If you pick a provider with fast and steady delivery, you can plan better and finish on time.

Tip: Always ask about lead times before you order. Fast delivery can help your project succeed.

You now know five main facts that help you choose electronic components and PCB services. Each fact helps you get better quality, save money, and finish faster. When you pick a provider, look at these important things:

| Criteria | Description |

|---|---|

| Experience | Can the provider do what you need with the right technology? |

| Customer Support | Does the provider answer your questions fast and clearly? |

| Quality Assurance | Do they check parts well and keep problems low? |

| Customization Options | Can you get the designs and features you want? |

- Read reviews and stories from other customers.

- Ask for clear price quotes and see what changes you can make.

- Make sure the provider can deliver on time and grow with your needs.

Providers like King Field give you easy, custom solutions. They help you turn your ideas into real products you can trust.

FAQ

What is a one-stop PCB service?

A one-stop PCB service lets you handle design, manufacturing, and assembly in one place. You save time and avoid mistakes. You can also get help with custom features, testing, and fast delivery.

How can I make sure my PCB is high quality?

You should check for certifications like ISO and IPC. Ask about testing steps. Look for reviews from other customers. Reliable providers, like King Field, share their quality checks and use strong materials.

Can I order just one PCB for my project?

Yes! King Field lets you order as few as one PCB. This helps you test your ideas before making more. You can try different designs without spending a lot of money.

How fast can I get my custom PCB?

You can get your PCB in as little as 24-48 hours with rush service. Standard orders usually take 4-5 days. Always ask your provider about delivery times before you order.

What customization options do I have?

You can choose the board size, shape, and number of layers. You can add your logo or special graphics. You can pick different materials and finishes. King Field offers many options to fit your needs.