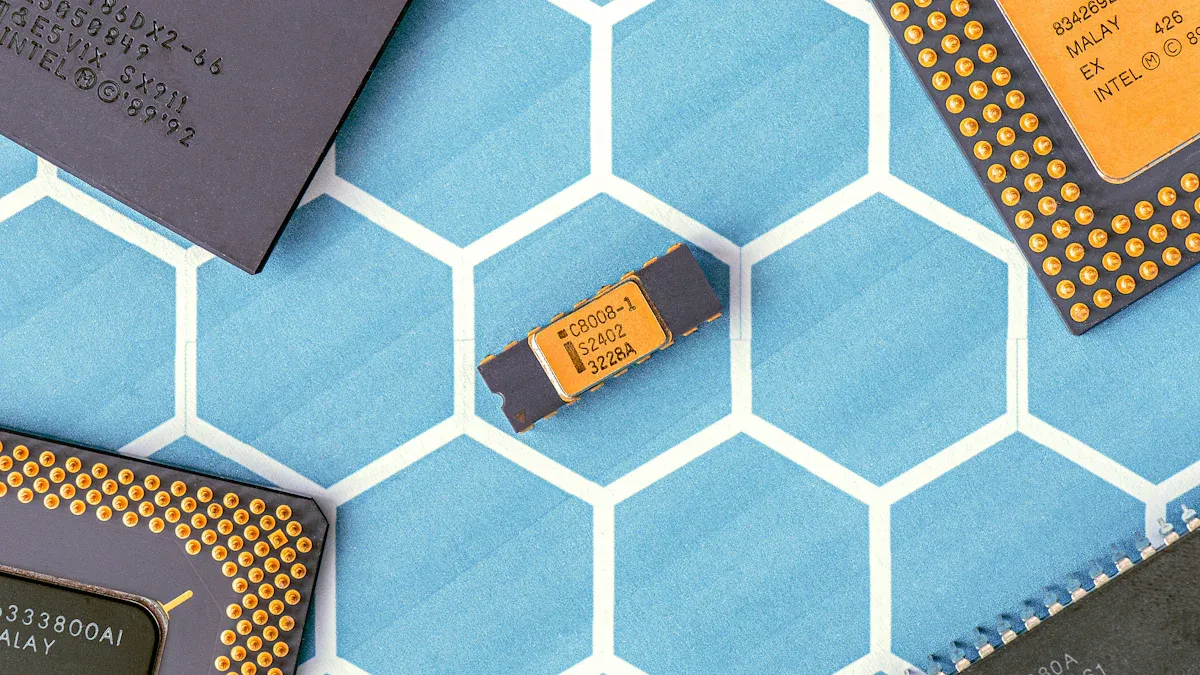

What Are the Different Types of Ceramic PCBs and Their Applications

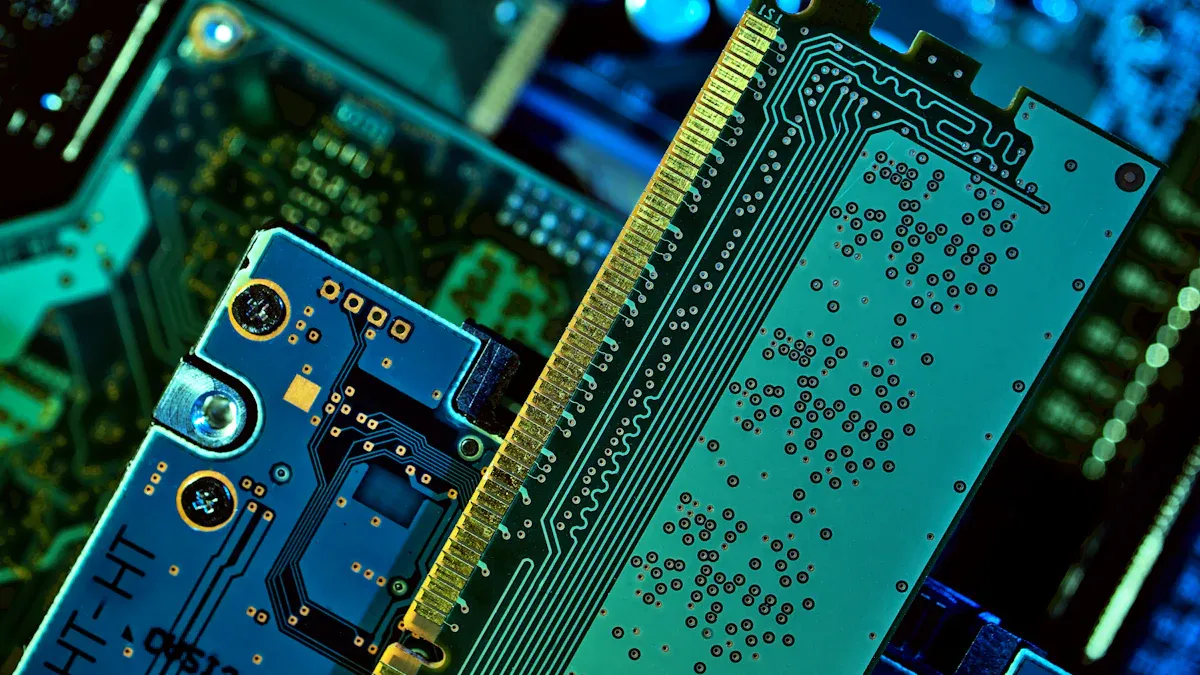

Ceramic PCBs are specialized circuit boards made from ceramic materials, known for their exceptional thermal and electrical properties. These PCBs play a pivotal role in industries requiring high-performance solutions, such as aerospace, automotive, and medical technology.

Their importance becomes evident when we consider market trends. The global electronic PCB market, valued at $70.6 billion in 2024, is projected to grow to $113.2 billion by 2033, driven by the increasing demand for advanced electronics.

The advantages of ceramic PCBs lie in their superior thermal conductivity, low thermal resistance, and mechanical strength. For instance, they can achieve thermal conductivity values up to 230 W/m.K, making them ideal for applications where heat dissipation is critical. However, the disadvantages of ceramic PCBs, such as higher production costs, should also be considered when selecting materials.

By understanding Ceramic PCB Types and their unique properties, industries can leverage these advanced substrates to address complex technological challenges.

Key Takeaways

- Ceramic PCBs move heat well, making them great for high-power uses.

- Materials like alumina and aluminum nitride meet special needs and improve performance.

- Ceramic PCBs work well in tough conditions, helping in aerospace, cars, and medical tools.

- Hybrid ceramic PCBs mix materials to save money while keeping good performance.

- More people want ceramic PCBs because of electric cars, phones, and green energy.

Overview of Ceramic PCB Materials

What Are Ceramic Materials?

Ceramic materials are inorganic, non-metallic compounds that exhibit exceptional thermal, electrical, and mechanical properties. These materials are formed through high-temperature processing, which gives them their characteristic hardness and durability. In the context of ceramic printed circuit boards, ceramics like aluminum oxide, aluminum nitride, and beryllium oxide serve as the foundation for creating robust and efficient substrates. Their ability to withstand extreme temperatures and provide excellent electrical insulation makes them indispensable in high-performance applications.

Common Ceramic Materials Used in PCBs

Ceramic PCBs rely on a variety of materials, each offering unique advantages. Here’s a quick comparison of some commonly used ceramic materials:

| Material | Thermal Conductivity (W/(m·K)) | Coefficient of Thermal Expansion (CTE) (x10^-6/K) |

|---|---|---|

| Aluminum Oxide (Al₂O₃) | 25.0 | 4.5 to 10.9 |

| Aluminum Nitride (AlN) | 80 to 300 | 4 to 6 |

| Beryllium Oxide (BeO) | 209 to 330 | 7.4 to 8.9 |

Each material serves specific purposes. For instance, aluminum oxide is cost-effective and widely used, while aluminum nitride offers superior thermal conductivity. Beryllium oxide, though less common due to its toxicity, excels in applications requiring extremely high thermal performance.

Additionally, ceramic substrates are often chosen for their ability to handle high power and temperature fluctuations. This makes them ideal for power electronics, hybrid microelectronics, and multi-chip modules.

Why Ceramic Is Preferred for Certain Applications

Ceramic substrates outperform traditional materials like FR4 in several critical areas. For example, ceramic PCBs offer thermal conductivity up to 100 times greater than FR4, as shown in the table below:

| Ceramic material | Thermal conductivity |

|---|---|

| Alumina | ~20x FR4 |

| Aluminum nitride and silicon carbide | ~100x FR4 |

| Beryllium oxide and boron nitride | Greater than 100x FR4 |

This exceptional heat dissipation capability makes ceramic circuit boards the go-to choice for high-power and high-frequency applications. Industries like automotive and aerospace increasingly adopt ceramic substrates to meet the demands of electric vehicles and harsh environmental conditions. Furthermore, the miniaturization trend in electronics drives the need for materials that can handle compact designs without compromising performance.

📊 Market Insight: The market for ceramic PCBs is projected to grow significantly, from $6.2 billion in 2023 to $10.5 billion by 2032, driven by advancements in electric vehicles, renewable energy, and telecommunications.

Ceramic PCB Types

Alumina Ceramic PCBs

Alumina PCBs are among the most widely used ceramic PCB types due to their cost-effectiveness and reliable performance. I often recommend alumina PCBs for applications requiring a balance between affordability and functionality. These PCBs are made from aluminum oxide (Al₂O₃), a material known for its excellent electrical insulation and moderate thermal conductivity.

Alumina PCBs excel in demanding environments. Their mechanical strength and durability make them ideal for high-frequency and high-power electronic devices. For instance:

- The ceramic PCB market has grown significantly due to rising demand for high-performance electronics across industries.

- Alumina PCBs provide enhanced stability in extreme conditions, outperforming traditional PCBs in reliability.

- Their thermal conductivity, though lower than some other ceramic PCB types, is sufficient for many applications.

I’ve seen alumina PCBs used extensively in LED lighting systems, power electronics, and consumer devices. Their ability to handle moderate heat dissipation while maintaining electrical insulation makes them a versatile choice.

Aluminum Nitride Ceramic PCBs

Aluminum nitride PCBs, or aluminum nitride ceramic PCBs, are the go-to option for applications requiring superior thermal management. These PCBs are made from aluminum nitride (AlN), a material with exceptional thermal conductivity ranging from 170 to 230 W/m·K.

When comparing aluminum nitride PCBs to other ceramic PCB types, their advantages become clear:

| Property | Aluminum Nitride (AlN) | Alumina (Al₂O₃) | Beryllia (BeO) | Silicon Nitride (Si₃N₄) |

|---|---|---|---|---|

| Thermal Conductivity (W/m·K) | 170–230 | 24–28 | 200–300 | 70–90 |

| Coefficient of Thermal Expansion (ppm/°C) | ~4.6 | ~7.1 | ~6.5 | ~3.2 |

| Electrical Insulation (kV/mm) | ≥15 | ≥10 | ≥10 | ≥12 |

| Dielectric Constant (1 MHz) | ~8.6 | ~9.8 | ~6.6 | ~7.8 |

| Max Working Temperature (°C) | 1000 | 600–800 | 1000 | 850 |

| Toxicity | Non-toxic | Non-toxic | Toxic | Non-toxic |

Aluminum nitride PCBs are non-toxic and offer a low coefficient of thermal expansion, making them suitable for applications requiring precision and stability. I’ve seen these PCBs used in aerospace systems, automotive electronics, and RF devices, where heat dissipation is critical. Their ability to operate at high temperatures without compromising performance sets them apart from other ceramic PCB types.

Beryllium Oxide Ceramic PCBs

Beryllium oxide PCBs, often referred to as BeO ceramic PCBs, are specialized substrates designed for extreme thermal performance. These PCBs boast thermal conductivity values between 200 and 300 W/m·K, making them one of the most efficient ceramic PCB types for heat dissipation.

However, I always caution clients about the toxicity of beryllium oxide. While its thermal properties are unmatched, handling and manufacturing require strict safety protocols. Despite this limitation, BeO ceramic PCBs are indispensable in applications where high thermal conductivity is non-negotiable.

Common applications include high-power microwave circuits, laser systems, and advanced medical devices. Their ability to maintain stability under intense heat makes them ideal for these demanding environments.

💡 Tip: If your application requires extreme thermal management and you can ensure safe handling, beryllium oxide PCBs might be the perfect solution.

Silicon Nitride Ceramic PCBs

Silicon nitride ceramic PCBs stand out for their exceptional mechanical strength and thermal stability. These PCBs are made from silicon nitride (Si₃N₄), a material renowned for its covalent bonding structure, which provides unparalleled robustness. I often recommend silicon nitride PCBs for applications that demand high reliability under extreme conditions.

Several unique properties make silicon nitride an excellent choice:

- It exhibits a low friction coefficient and self-lubricating properties, reducing wear and tear in mechanical systems.

- Its covalent bonds contribute to its high mechanical strength, enabling it to withstand high-pressure environments.

- It performs exceptionally well in high-temperature applications, maintaining stability even under thermal stress.

These characteristics make silicon nitride ceramic PCBs indispensable in industries like automotive and deep-sea exploration. For instance, in electric vehicles, these PCBs handle the intense heat generated by power modules, ensuring consistent performance. Similarly, in underwater robotics, they endure both high pressure and temperature fluctuations, providing reliable operation in harsh environments.

🔍 Did You Know? Silicon nitride ceramic PCBs are also used in aerospace systems, where their ability to resist thermal shock ensures the safety and efficiency of critical components.

Hybrid Ceramic PCBs

Hybrid ceramic PCBs combine ceramic materials with other substrates, such as metal or polymer layers, to create a versatile and cost-effective solution. I find these PCBs particularly useful when balancing performance and affordability is a priority. By integrating ceramic layers with other materials, hybrid PCBs achieve a unique combination of properties that cater to diverse applications.

Key advantages of hybrid ceramic PCBs include:

- Customizable Thermal Performance: The ceramic layer provides excellent heat dissipation, while the additional materials allow for tailored thermal conductivity.

- Enhanced Mechanical Strength: The hybrid structure improves durability, making these PCBs suitable for high-stress environments.

- Cost Efficiency: By using ceramic only where necessary, manufacturers reduce costs without compromising performance.

Hybrid ceramic PCBs are widely used in telecommunications, where they support high-frequency signals with minimal loss. They also play a crucial role in medical devices, offering the reliability needed for life-saving equipment. For example, hybrid PCBs are often found in implantable devices, where their biocompatibility and thermal stability ensure long-term functionality.

💡 Tip: If your project requires a balance between high-temperature performance and cost, hybrid ceramic PCBs might be the ideal solution.

Properties of Ceramic PCBs

Thermal Conductivity

When it comes to thermal performance, ceramic PCBs stand out due to their high thermal conductivity. This property ensures efficient heat dissipation, which is critical for high-power applications. I’ve observed that ceramic PCBs outperform traditional materials like epoxy glass fiber by a significant margin. For instance:

- Ceramic PCBs exhibit thermal conductivity up to 90 times greater than epoxy glass fiber.

- This leads to better conduction cooling and lower junction temperatures for components.

Such excellent thermal conductivity makes ceramic PCBs ideal for applications requiring reliable thermal management, such as LED lighting and power electronics. By efficiently transferring heat away from sensitive components, these PCBs enhance the overall performance and lifespan of electronic systems.

Electrical Insulation

Ceramic PCBs also provide good electrical insulation, which is essential for maintaining the integrity of electronic circuits. Their dielectric properties ensure minimal energy loss and high reliability in demanding environments. Based on technical studies, here’s a breakdown of their electrical insulation properties:

| Property | Description |

|---|---|

| Dielectric Constant | Indicates the material’s ability to store electrical energy. |

| Dielectric Strength | Maximum electric field the material can withstand without breaking down. |

| Loss Tangent | Measures energy dissipation as heat, crucial for minimizing energy losses in electrical systems. |

| Thermal Stability | Evaluates the material’s performance under varying temperature conditions. |

These properties highlight why ceramic PCBs are preferred for high-frequency and high-voltage applications. Their good electrical insulation ensures that circuits remain stable and efficient, even under extreme conditions.

Mechanical Strength

The mechanical strength of ceramic PCBs is another key factor that sets them apart. I’ve seen these PCBs excel in environments where durability is non-negotiable. Their strength is often evaluated using advanced testing methods, such as three- or four-point bending tests. These methods provide accurate insights into their performance under stress.

Several factors influence the mechanical strength of ceramic PCBs:

- Environmental conditions, such as humidity and temperature, can impact their durability.

- Subcritical Crack Growth (SCCG) may occur under prolonged stress, but ceramic PCBs still maintain superior reliability.

- The variability in defect sizes and locations is often modeled using the Weibull distribution, ensuring precise strength predictions.

This robust mechanical performance makes ceramic PCBs suitable for industries like aerospace and automotive, where components must withstand harsh conditions without failure.

Resistance to Environmental Stress

Ceramic PCBs excel in environments where durability is critical. I’ve seen these PCBs withstand extreme conditions that would compromise traditional materials. Their resistance to environmental stress stems from the inherent properties of ceramic materials, which make them ideal for demanding applications.

- Ceramic PCBs endure extreme temperatures, both high and low, without losing functionality. This makes them suitable for aerospace and automotive systems exposed to fluctuating thermal conditions.

- They exhibit zero water absorption, ensuring performance in humid or moisture-rich environments. This property is particularly valuable in marine electronics and outdoor applications.

- Their chemical inertness protects them from damage in chemically aggressive environments, such as industrial processing plants.

- Even under high radiation exposure, ceramic PCBs maintain their properties, making them indispensable in space exploration and nuclear applications.

Before mass production, manufacturers conduct rigorous reliability testing to identify potential design flaws. These tests simulate extreme conditions to ensure the PCBs meet performance standards. I’ve observed that this meticulous approach guarantees the durability and reliability of ceramic PCBs in real-world applications.

💡 Tip: If your project involves harsh environmental conditions, ceramic PCBs offer unmatched resilience and reliability.

Low Signal Loss in High-Frequency Applications

Ceramic PCBs are the preferred choice for high-frequency applications due to their exceptional electromagnetic performance. I’ve worked on projects where maintaining signal integrity was crucial, and ceramic PCBs consistently delivered superior results.

Their low dielectric constant (Dk) minimizes signal delay and distortion, ensuring impedance consistency. This is critical for applications like RF devices and microwave circuits, where precision is paramount. Additionally, their low dissipation factor (Df) reduces energy loss as heat, improving power efficiency and preventing signal attenuation.

| Metric | Description |

|---|---|

| Low Dielectric Constant (Dk) | Helps maintain impedance consistency and reduces signal delay, minimizing distortion and loss. |

| Low Dissipation Factor (Df) | Reduces energy loss as heat, preventing attenuation and improving power efficiency. |

| Rigorous Testing Standards | Ensures electrical performance and thermal dissipation meet industry requirements. |

These properties make ceramic PCBs indispensable in telecommunications, radar systems, and satellite communications. Their ability to handle high frequencies with minimal signal loss ensures reliable performance in critical applications.

📊 Insight: As the demand for high-frequency electronics grows, ceramic PCBs will continue to play a pivotal role in advancing communication technologies.

Applications of Ceramic PCBs

LED Lighting and High-Power Electronics

Ceramic PCBs have revolutionized the LED lighting industry and high-power electronics by addressing critical challenges like heat dissipation and operational reliability. I’ve worked on projects where ceramic PCBs significantly improved LED performance, and the results were remarkable. Their high thermal conductivity ensures efficient heat management, eliminating the need for additional heat sinks. This simplifies designs and reduces overall weight, making them ideal for compact and portable applications.

Here’s a breakdown of performance benchmarks that highlight their impact:

| Metric | Result |

|---|---|

| Light Output Improvement | 40% higher |

| Operational Lifetime | Increased from 50,000 to over 100,000 hours |

| Warranty Claims Reduction | 75% reduction |

| Need for Additional Heat Sinking | Eliminated |

| Overall Weight | Reduced |

These metrics demonstrate why ceramic PCBs are indispensable in high-power LEDs and other electronic systems. For example, I’ve seen them used in automotive headlights, where their ability to handle high temperatures ensures consistent brightness and longevity. Similarly, in industrial lighting, ceramic PCBs enhance energy efficiency while reducing maintenance costs.

💡 Tip: If your project involves high-power LEDs or electronics, ceramic PCBs offer unmatched thermal management and reliability.

Aerospace and Defense Systems

The aerospace and defense sectors demand electronic systems that can withstand extreme conditions, and ceramic PCBs excel in meeting these requirements. I’ve observed their adoption in applications where reliability and safety are paramount. Their high-temperature stability and excellent thermal conductivity ensure consistent performance in high-stress environments.

Here’s a summary of their reliability and safety characteristics:

| Characteristic | Description |

|---|---|

| High-Temperature Stability | Essential for defense applications where extreme temperatures are common. |

| Thermal Conductivity | Ensures efficient heat dissipation in high-performance systems. |

| Insulation Properties | Provides excellent electrical insulation, enhancing safety in electronic systems. |

Additionally, the military and defense sector relies on ceramic PCBs for their durability and ability to handle complex electronic systems. These systems often operate in harsh environments, such as high altitudes or combat zones, where traditional PCBs would fail. I’ve seen ceramic PCBs used in radar systems, missile guidance electronics, and satellite communication devices. Their ability to maintain functionality under extreme conditions makes them a critical component in defense technology.

📊 Insight: The complexity of military electronics drives the need for specialized PCBs that meet stringent requirements. Ceramic PCBs consistently deliver the reliability and performance needed for these demanding applications.

Medical Devices and Equipment

Ceramic PCBs play a vital role in medical device manufacturing, where precision and reliability are non-negotiable. I’ve worked with clients in the healthcare industry who rely on ceramic PCBs for their biocompatibility and thermal stability. These properties ensure the safety and effectiveness of life-saving equipment.

Regulatory standards further emphasize their importance:

| Regulatory Body | Region |

|---|---|

| FDA | United States |

| EMA | European Union |

Medical devices must comply with stringent regulations, such as FDA’s Quality System Regulation (21 CFR Part 820) and EU MDR/IVDR. Ceramic PCBs meet these requirements by offering exceptional performance and reliability. For instance, their high thermal conductivity ensures stable operation in devices like pacemakers and defibrillators, where consistent performance is critical.

Key standards supporting their use include:

| Standard | Description |

|---|---|

| ISO 10993 | Certification for biocompatibility of medical devices, essential for compliance with FDA and EU regulations. |

| ISO 13485 | Provides a framework for quality management systems in medical device manufacturing. |

| ISO 14971 | Focuses on risk management specific to medical devices, ensuring safety and compliance. |

I’ve seen ceramic PCBs used in imaging equipment, such as MRI and CT scanners, where their ability to handle high frequencies and thermal loads ensures accurate diagnostics. Their reliability also makes them ideal for implantable devices, where long-term functionality is crucial.

💡 Tip: If your medical device project requires compliance with strict regulatory standards, ceramic PCBs provide the reliability and performance needed to meet these demands.

Automotive Electronics

Ceramic PCBs have become indispensable in automotive electronics, where reliability and performance are critical. I’ve worked on projects where these PCBs addressed challenges like heat dissipation, vibration resistance, and compact design requirements. Their ability to withstand extreme conditions makes them ideal for modern vehicles, especially electric and hybrid models.

One of the key reasons ceramic PCBs excel in automotive applications is their compliance with stringent quality standards. For instance:

- ISO 9001 ensures a structured approach to quality management, tracking every step from raw ceramic substrates to the final product.

- IATF 16949 focuses on the automotive industry, covering the entire production chain, including substrate punching and surface finishing.

- UL Certification guarantees flame resistance and dielectric strength, essential for thermal and electrical stability.

To verify durability, manufacturers subject ceramic PCBs to rigorous testing. These include thermal cycling tests, which expose boards to temperature swings from -55°C to +150°C, and thermal shock testing, which rapidly transitions between hot and cold environments. I’ve seen these tests identify potential expansion mismatches between metal layers and ceramic substrates, ensuring long-term reliability.

In automotive electronics, ceramic PCBs are commonly used in:

- Power Modules: They handle high currents and voltages in electric vehicles, ensuring efficient energy transfer.

- LED Headlights: Their excellent thermal conductivity eliminates the need for bulky heat sinks, enabling sleek designs.

- Advanced Driver Assistance Systems (ADAS): These systems rely on ceramic PCBs for their high-frequency performance and durability.

🔍 Note: Automated optical inspection (AOI) and X-ray inspection play a crucial role in detecting defects like voids in vias or solder joints, ensuring the reliability of ceramic PCBs in safety-critical automotive systems.

The automotive industry’s shift toward electrification and autonomous driving continues to drive demand for ceramic PCBs. Their ability to meet the rigorous demands of these applications makes them a cornerstone of modern vehicle electronics.

RF Devices and Microwave Circuits

Ceramic PCBs are the backbone of RF devices and microwave circuits, where high-frequency performance and thermal management are paramount. I’ve seen their adoption in industries like telecommunications, aerospace, and medical electronics, where precision and reliability are non-negotiable.

The unique properties of ceramic materials make them ideal for these applications:

- Thermal Management: Ceramic PCBs offer exceptional thermal conductivity, dissipating heat efficiently in high-power RF systems.

- Signal Integrity: Their low dielectric loss ensures minimal signal distortion, maintaining quality in high-frequency circuits.

- Material Versatility: Options like aluminum nitride and beryllium oxide provide tailored thermal and electrical properties, enhancing performance.

In my experience, ceramic PCBs excel in applications such as:

- Telecommunications: They support high-frequency signals in 5G infrastructure, ensuring low signal loss and high reliability.

- Radar Systems: Their ability to handle high power and temperature fluctuations makes them indispensable in defense and aerospace.

- Medical Imaging: Devices like MRI and CT scanners rely on ceramic PCBs for their stability and precision in high-frequency operations.

Testing and validation are critical for these applications. For example, thermal cycling and highly accelerated stress testing (HAST) evaluate resistance to delamination and microcracks. These tests ensure that ceramic PCBs can withstand the demanding conditions of RF and microwave environments.

💡 Tip: When designing RF circuits, consider the dielectric constant and dissipation factor of the ceramic material. These parameters directly impact signal quality and overall system performance.

As the demand for high-frequency and high-power applications grows, ceramic PCBs will remain a key enabler of innovation in RF and microwave technologies.

Ceramic PCBs offer unmatched advantages, including exceptional thermal conductivity, low dielectric loss, and high mechanical strength. Each type—alumina, aluminum nitride, beryllium oxide, silicon nitride, and hybrid ceramics—caters to specific needs, from high-power LEDs to aerospace systems. Their versatility drives growth across industries like telecommunications, automotive, and defense.

| Statistic/Trend | Value/Description |

|---|---|

| Market Growth Rate | CAGR of 6.5% from 2025 to 2033 |

| Expected Market Size | $82.5 billion by 2026 |

| Key Industries Driving Growth | Telecommunications, Automotive, Aerospace |

🌟 Tip: Explore ceramic PCBs to unlock innovative solutions for your high-performance applications. Their reliability and efficiency make them a game-changer in modern technology.

FAQ

What is a high-temperature co-fired ceramic PCB?

A high-temperature co-fired ceramic PCB uses ceramic layers bonded at high temperatures to create a durable substrate. I recommend it for applications requiring excellent thermal conductivity and mechanical strength, such as aerospace systems and industrial electronics.

How does a silicon carbide PCB differ from other ceramic PCBs?

Silicon carbide PCBs offer superior thermal conductivity and mechanical strength compared to alumina or aluminum nitride PCBs. I’ve seen them excel in high-temperature applications, especially in power electronics and automotive systems.

Are ceramic PCBs suitable for high-frequency circuits?

Yes, ceramic PCBs minimize signal loss due to their low dielectric constant and dissipation factor. I often use them in RF devices and microwave circuits where precision and reliability are critical.

What industries benefit most from ceramic PCBs?

Ceramic PCBs are widely used in industries like automotive, aerospace, telecommunications, and medical devices. Their ability to handle extreme conditions and high-power applications makes them indispensable in these fields.

Can ceramic PCBs handle high-temperature applications?

Absolutely. Ceramic PCBs, especially those made from materials like aluminum nitride and silicon carbide, excel in high-temperature applications. I’ve seen them perform reliably in environments exceeding 1000°C.