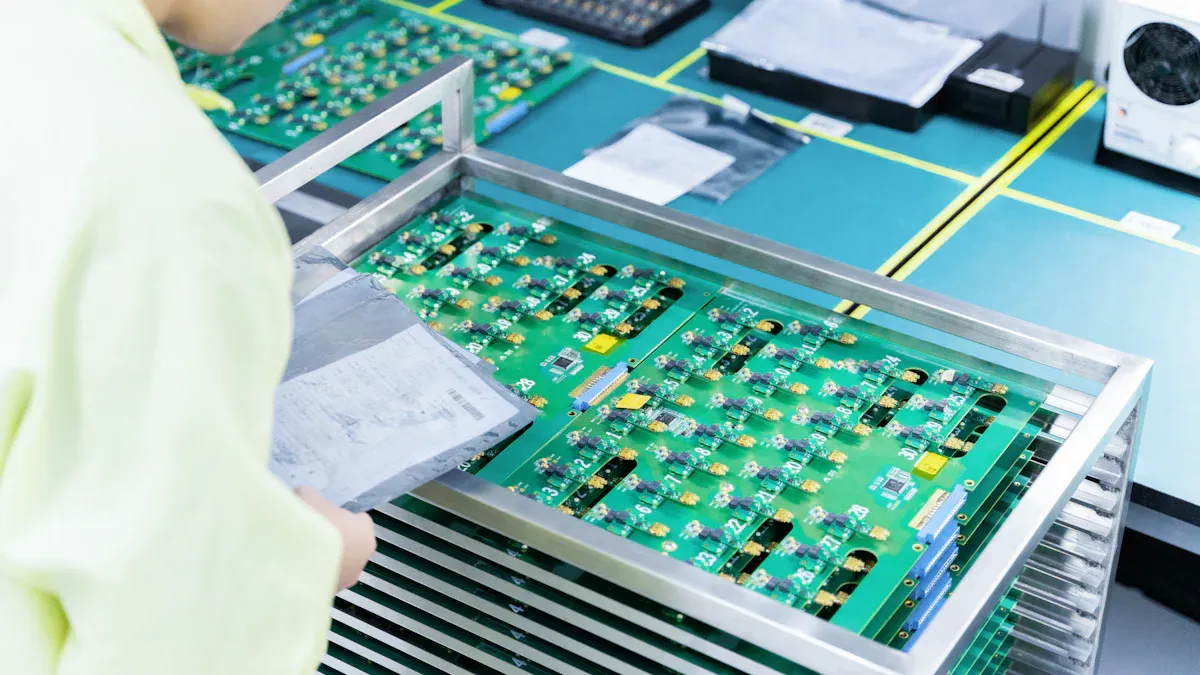

Why RoHS compliance is crucial for sustainable PCB electronics manufacturing

Sustainable PCB electronics manufacturing depends on your commitment to RoHS compliance. By adhering to RoHS regulations, you help reduce the use of hazardous substances like lead and mercury, which are harmful to the environment and human health. This compliance not only ensures safer products but also strengthens your position in global markets by meeting international standards. Moreover, adopting RoHS practices reflects your dedication to innovation and eco-friendly manufacturing, ultimately paving the way for a cleaner, healthier future.

Key Takeaways

- RoHS rules lower harmful materials in electronics, making them safer.

- Following RoHS helps your business sell in eco-friendly markets worldwide.

- Meeting RoHS rules avoids fines, recalls, and builds a good reputation.

- RoHS inspires new ideas by using green materials and better methods.

- Supporting RoHS helps your business grow and keeps Earth cleaner.

Understanding RoHS in PCB Electronics Manufacturing

Definition and scope of RoHS compliance

RoHS, or the Restriction of Hazardous Substances, is a regulatory framework designed to limit the use of specific hazardous substances in electrical and electronic equipment (EEE). Its primary goal is to promote environmental protection and ensure the safety of both consumers and workers. The directive applies to manufacturers, importers, and distributors of EEE, particularly those targeting the European Union (EU) market.

The scope of RoHS compliance extends beyond just limiting hazardous substances. It mandates that products, including printed circuit boards (PCBs), meet strict environmental standards and carry the CE mark to demonstrate compliance. This ensures that RoHS-compliant PCBs adhere to global safety and environmental requirements. The table below highlights key definitions and their descriptions:

| Definition | Description |

|---|---|

| RoHS Directive | Restricts hazardous substances in EEE to ensure safety and environmental protection. |

| Compliance Scope | Applies to manufacturers, importers, and distributors of EEE intended for the EU market. |

| Maximum Allowable Concentrations | Sets limits for hazardous substances in EEE to ensure safety and environmental protection. |

| Affected Products | Includes computers, household appliances, lighting equipment, and toys. |

By adhering to RoHS, you align your PCB electronics manufacturing processes with global standards, ensuring your products meet the demands of environmentally conscious markets.

Hazardous substances restricted under RoHS

RoHS restricts the use of ten hazardous substances commonly found in electronics manufacturing. These substances pose significant risks to the environment and human health due to their toxicity and potential for bioaccumulation. The restricted substances include lead, mercury, cadmium, hexavalent chromium, and flame retardants like PBB and PBDEs.

For example, lead, often used in soldering, has been replaced by lead-free solder in RoHS-compliant PCBs. This shift reduces harmful emissions during manufacturing and disposal. Mercury, another restricted substance, is commonly found in lighting components and can contaminate ecosystems if improperly managed. By eliminating these materials, RoHS ensures safer production practices and minimizes environmental harm.

The directive also sets maximum allowable concentrations for these substances, ensuring that even trace amounts do not exceed safe levels. This strict regulation encourages the development of safer alternatives and sustainable materials in PCB production.

Why RoHS matters in PCB production

RoHS compliance is essential for sustainable PCB electronics manufacturing. It ensures that your products meet international standards, reducing the environmental impact of hazardous substances. By producing RoHS-compliant PCBs, you contribute to environmental protection while safeguarding worker and consumer health.

Moreover, RoHS compliance enhances your marketability. Many countries and regions require RoHS certification for electronics, making it a prerequisite for global market access. Non-compliance can result in legal penalties, product recalls, and reputational damage. On the other hand, adhering to RoHS standards positions your business as a leader in sustainable manufacturing, giving you a competitive edge.

RoHS also drives innovation in the industry. By encouraging the use of eco-friendly materials and advanced manufacturing technologies, it supports the transition to a circular economy. This not only reduces waste but also promotes the reuse and recycling of electronic components, further minimizing environmental impact.

Incorporating RoHS into your PCB production processes is not just a regulatory requirement; it is a commitment to sustainability, safety, and long-term success.

Environmental and Health Benefits of RoHS Compliance

Reducing toxic waste and pollution

RoHS compliance plays a pivotal role in reducing toxic waste generated by electronics manufacturing. By restricting hazardous substances like lead, mercury, and cadmium, RoHS ensures that printed circuit boards (PCBs) and other electronic components contribute less to environmental pollution. Lead-free solder, a key innovation driven by RoHS, minimizes harmful emissions during production and disposal. This shift reduces the contamination of soil and water, protecting ecosystems from long-term damage.

Additionally, RoHS-compliant PCBs promote sustainable waste management practices. Electronics manufacturers are encouraged to adopt recycling and reuse strategies, which prevent hazardous substances from entering landfills. These practices align with global environmental protection goals and help create a cleaner, safer environment for future generations.

Tip: Transitioning to RoHS-compliant materials not only reduces pollution but also enhances your brand’s commitment to sustainability, making your products more appealing to eco-conscious consumers.

Protecting ecosystems and biodiversity

The environmental impact of hazardous substances extends beyond pollution; it threatens ecosystems and biodiversity. RoHS compliance mitigates these risks by eliminating substances that can bioaccumulate in wildlife and disrupt natural habitats. For instance, mercury, often found in lighting components, can poison aquatic ecosystems, leading to the decline of fish populations and other marine life.

By adhering to RoHS standards, you contribute to the preservation of ecosystems. RoHS-compliant PCBs reduce the release of toxic chemicals into the environment, ensuring that plants, animals, and microorganisms thrive without exposure to harmful pollutants. This commitment to environmental protection supports global efforts to combat biodiversity loss and maintain ecological balance.

Ensuring worker and consumer safety

RoHS compliance prioritizes the health and safety of workers and consumers. Manufacturing processes that use hazardous substances like lead expose workers to significant health risks, including neurological damage caused by lead dust. By adopting lead-free solder and other RoHS-compliant materials, you create safer working conditions and protect employees from long-term harm.

Consumers also benefit from RoHS standards. Electronics containing hazardous substances can pose risks such as cancer and reproductive system damage. RoHS-compliant PCBs eliminate these dangers, ensuring safer products for end-users. Since the directive’s implementation, lead content in e-waste has decreased by 60%, highlighting its effectiveness in improving safety outcomes.

- Key safety improvements linked to RoHS compliance:

- Reduced lead exposure for workers, minimizing neurological damage risks.

- Safer consumer products, lowering the likelihood of cancer and reproductive health issues.

- Enhanced environmental safety through decreased heavy metal contamination.

By prioritizing RoHS certification, you demonstrate a commitment to safeguarding human health while meeting stringent environmental standards. This approach not only protects individuals but also strengthens your reputation as a responsible manufacturer in the PCB electronics industry.

Regulatory Compliance and Global Market Access

Meeting international environmental standards

RoHS compliance ensures your products meet stringent international environmental standards. These standards are critical for aligning your manufacturing processes with global expectations. By adhering to RoHS, you demonstrate your commitment to environmental protection and sustainable practices. This compliance guarantees that your printed circuit boards and other electronics are free from hazardous substances, making them safer for consumers and the environment.

Countries worldwide have adopted RoHS or similar regulations, creating a unified approach to reducing toxic emissions. Meeting these standards positions your business as a responsible manufacturer in the global market. It also helps you avoid barriers to entry in regions where RoHS certification is mandatory.

Avoiding legal risks and penalties

Non-compliance with RoHS regulations exposes your business to significant legal risks. Authorities impose strict penalties, including fines and product recalls, for failing to meet RoHS standards. These consequences can damage your reputation and disrupt your operations.

By ensuring your products are RoHS compliant, you mitigate these risks. You protect your business from legal challenges and maintain smooth operations. Compliance also demonstrates your dedication to ethical manufacturing practices, which strengthens your credibility with regulators and customers alike.

Note: Legal penalties for non-compliance can be costly. Prioritizing RoHS certification safeguards your business and ensures long-term success.

Unlocking opportunities in global markets

RoHS compliance opens doors to lucrative global markets. Many regions, including the European Union, require RoHS certification for electronics. By meeting these requirements, you gain access to environmentally conscious markets that value sustainable products.

RoHS-compliant PCBs enhance your competitive edge. They appeal to customers who prioritize environmental protection and safety. This advantage helps you build lasting relationships with clients and expand your market share. Additionally, compliance fosters innovation, enabling you to develop eco-friendly products that meet evolving consumer demands.

Tip: Positioning your business as a leader in sustainable PCB electronics manufacturing increases your chances of success in global markets.

Business Value of RoHS Compliance

Enhancing brand reputation and customer trust

RoHS compliance strengthens your brand reputation by showcasing your commitment to environmental protection and sustainable manufacturing. Customers increasingly prefer businesses that prioritize safety and eco-friendly practices. By producing RoHS compliant PCBs, you demonstrate your dedication to creating safer electronics while reducing harmful emissions.

Trust grows when customers know your products meet strict environmental standards. RoHS certification assures them that your printed circuit boards are free from hazardous substances. This transparency builds loyalty and positions your brand as a responsible leader in the industry.

Tip: Highlight your RoHS compliance in marketing materials to attract environmentally conscious consumers and differentiate your brand from competitors.

Gaining a competitive edge in sustainable manufacturing

Adopting RoHS standards gives you a significant advantage in the competitive landscape of PCB electronics manufacturing. Many markets demand RoHS compliant PCBs, making certification essential for global success. By meeting these requirements, you gain access to regions that prioritize environmental protection and sustainable products.

RoHS compliance also drives innovation. You can explore advanced manufacturing techniques and eco-friendly materials to create cutting-edge electronics. These efforts not only reduce emissions but also position your business as a pioneer in sustainable manufacturing.

Callout: Businesses that embrace RoHS standards often outperform competitors by appealing to customers who value environmental responsibility.

Achieving cost efficiency through eco-friendly practices

RoHS compliance encourages cost-efficient practices that benefit your bottom line. Transitioning to lead-free solder and other sustainable materials reduces waste during production. Recycling and reusing components further minimize costs while aligning with environmental goals.

Eco-friendly manufacturing also lowers long-term expenses. By reducing hazardous emissions, you avoid penalties and legal risks associated with non-compliance. These savings allow you to reinvest in innovative technologies and improve your production processes.

Note: Cost efficiency achieved through RoHS compliance not only enhances profitability but also supports your commitment to sustainable PCB electronics manufacturing.

RoHS as a Catalyst for Innovation in PCB Electronics Manufacturing

Development of sustainable materials

RoHS drives the development of sustainable materials in pcb electronics manufacturing. By restricting hazardous substances, it encourages you to explore safer alternatives that align with environmental protection goals. For instance, lead-free solder has become a standard in rohs compliant pcbs, reducing harmful emissions during production and disposal. Manufacturers now invest in materials like biodegradable polymers and halogen-free laminates, which minimize environmental impact without compromising performance.

This shift not only benefits the environment but also enhances product quality. Sustainable materials often exhibit improved durability and thermal stability, making them ideal for advanced electronics. By adopting these innovations, you position your business as a leader in eco-friendly manufacturing while meeting the growing demand for sustainable printed circuit boards.

Advancements in manufacturing technologies

RoHS compliance fosters advancements in manufacturing technologies. To meet stringent standards, you must adopt cutting-edge processes that reduce emissions and improve efficiency. Techniques like selective soldering and vapor phase reflow have emerged as effective solutions for producing rohs compliant pcbs. These methods optimize material usage and minimize waste, ensuring a more sustainable production cycle.

Automation also plays a crucial role. Smart manufacturing systems enable precise control over hazardous substance levels, ensuring compliance with rohs regulations. By integrating these technologies, you streamline operations, reduce costs, and enhance product consistency. This approach not only supports environmental goals but also strengthens your competitive edge in the electronics industry.

Supporting a circular economy in electronics

RoHS compliance aligns with the principles of a circular economy by promoting the reuse and recycling of electronic components. By eliminating hazardous substances, it simplifies the recovery of valuable materials from discarded pcbs. This reduces the need for raw material extraction, conserving natural resources and lowering environmental emissions.

You can further support this model by designing products with end-of-life considerations in mind. Modular pcbs, for example, allow for easy disassembly and component replacement, extending the lifespan of electronics. These practices not only reduce waste but also create new revenue streams through refurbished products and recycled materials. By embracing a circular economy, you contribute to a sustainable future while meeting consumer expectations for environmentally responsible solutions.

RoHS compliance drives sustainable PCB electronics manufacturing by addressing critical environmental and health concerns. It ensures your products meet global standards, reducing toxic waste and protecting ecosystems. By adopting RoHS practices, you unlock access to international markets, avoid legal risks, and enhance your brand’s reputation. Additionally, it fosters innovation by encouraging the use of eco-friendly materials and advanced technologies.

Key takeaway: Embracing RoHS compliance positions your business for long-term success while contributing to a cleaner, healthier planet. Your commitment to sustainability today shapes a better future for generations to come.

FAQ

What is the primary goal of RoHS compliance?

RoHS compliance aims to restrict hazardous substances in electronics manufacturing. It ensures safer products, reduces environmental harm, and protects human health. By adhering to these standards, you contribute to sustainability and align with global environmental regulations.

How does RoHS compliance impact PCB manufacturing costs?

RoHS compliance can initially increase costs due to material changes and process upgrades. However, it reduces long-term expenses by minimizing waste, avoiding legal penalties, and improving production efficiency. These savings enhance your profitability over time.

Are all electronic products required to be RoHS compliant?

Not all electronic products fall under RoHS regulations. However, most devices sold in regions like the EU must comply. Check the specific requirements for your product category to ensure compliance with applicable laws.

What are the penalties for non-compliance with RoHS?

Non-compliance can lead to severe penalties, including fines, product recalls, and restricted market access. These consequences harm your reputation and disrupt operations. Ensuring compliance protects your business from these risks.

How does RoHS compliance support innovation?

RoHS compliance drives innovation by encouraging the development of eco-friendly materials and advanced manufacturing technologies. It fosters sustainable practices, enabling you to create cutting-edge products that meet environmental standards and consumer demands.

Tip: Embrace RoHS compliance as an opportunity to innovate and lead in sustainable electronics manufacturing.