What is EMS PCB and Why It Matters in Electronics Manufacturing

EMS PCB combines making electronics with Printed Circuit Boards (PCBs). It is key to building modern electronic devices. EMS PCB helps make production faster, easier, and better. New tech like smart machines and AI checks improve quality. For example, Automated Optical Inspection (AOI) finds mistakes like misplaced parts. Statistical Process Control (SPC) spots patterns to keep things running well. The EMS market may grow to $1.4 trillion by 2037. This shows how important it is for new ideas, growth, and reliable products.

Key Takeaways

- EMS PCB mixes making electronics with circuit boards for faster work.

- Advanced tools like Automated Optical Inspection (AOI) find mistakes early.

- PCBs come in many types, from simple to complex, for different uses.

- Picking a good EMS provider is important; check their skills and tools.

- Eco-friendly EMS PCB making helps cut waste and attracts green buyers.

Understanding EMS PCB

What is EMS PCB?

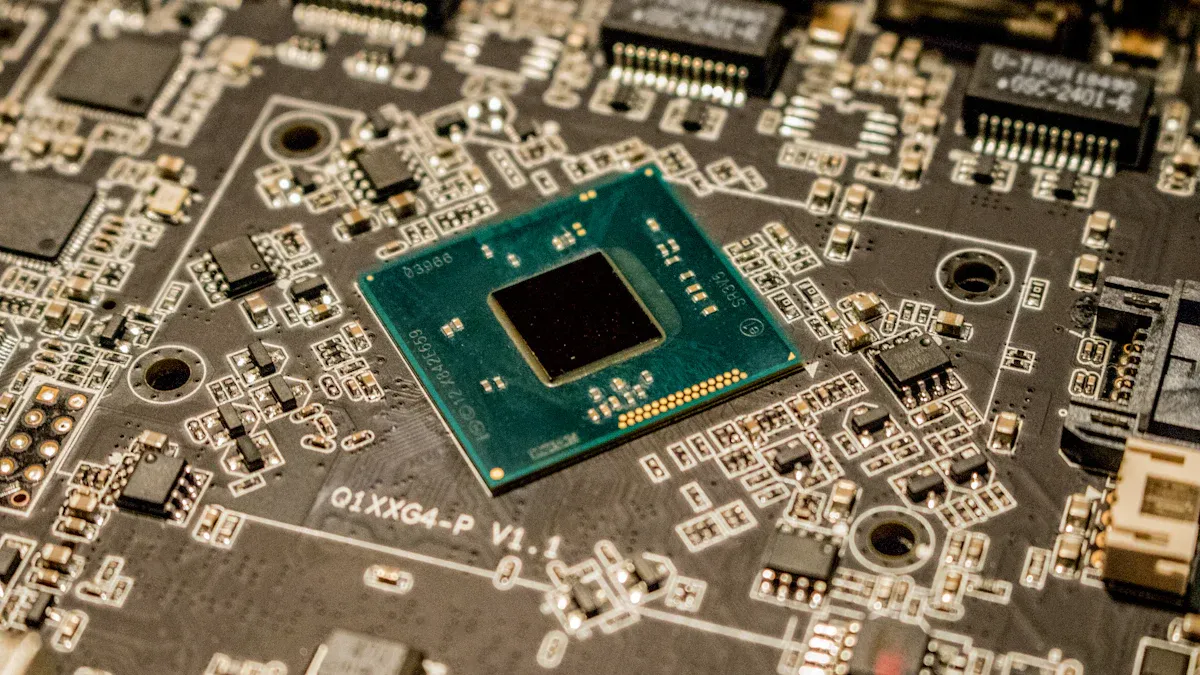

EMS PCB means combining electronics manufacturing services with printed circuit boards. It mixes making PCBs with designing and assembling them. PCBs are the base of modern electronics. Using EMS lets you focus on new ideas while experts handle production. This ensures products are high-quality and meet world standards.

EMS PCB is important because it makes production faster and better. New tech like additive manufacturing and surface mount technology (SMT) has changed PCB assembly. SMT puts parts directly on the board, saving time and reducing mistakes. These changes show how EMS PCB improves the electronics industry.

Key Components of EMS PCB

EMS PCB has several parts that make it work well:

- Manufacturing Capabilities: Includes SMT lines, soldering, inspections, and miniaturization. These help build accurate and high-quality PCBs.

- Supply Chain Management: Handles buying parts, managing inventory, and delivery. This avoids fake parts and ensures everything arrives on time.

- Quality Systems: Follows ISO rules, does strict checks, and tracks products for reliability.

- Engineering Support: Offers help like design checks, material reviews, and testing plans to improve production.

- Customer Focus: Good communication, managing changes, and improving processes keep customers happy.

These parts work together to make EMS PCB smooth and reliable, helping you create great products.

Types of PCBs in Electronics Manufacturing Services

PCBs come in different types for various uses:

- Single-Sided PCBs: Parts are on one side, used in simple devices like calculators.

- Double-Sided PCBs: Parts are on both sides, good for complex devices like power supplies.

- Multilayer PCBs: Many layers allow compact designs for phones and laptops.

- Rigid PCBs: Strong boards used in factories and cars.

- Flexible PCBs: Bendable boards perfect for wearable gadgets.

- Rigid-Flex PCBs: Mix of rigid and flexible boards for advanced uses like space systems.

Each PCB type has a special job in EMS, helping you pick the right one for your product.

The Role of EMS PCB in Electronics Manufacturing

Supporting the Manufacturing Process

EMS PCB helps make electronic devices quickly and accurately. It uses smart tools and methods to improve every step. From getting good materials to delivering finished items, EMS PCB covers it all.

Here’s a simple look at the main steps:

| Step | Description |

|---|---|

| Material Procurement | Finds and checks parts to ensure they are good. |

| PCB Assembly | Adds parts to PCBs using machines or by hand. |

| Soldering | Uses heat to attach parts, like reflow or wave soldering. |

| Testing and Inspection | Checks quality with tools like X-rays and functional tests. |

| Packaging and Shipping | Packs items safely and sends them to customers. |

Each step keeps quality high and avoids mistakes. For example, machines help assemble parts correctly, and X-rays find hidden problems. This careful process ensures products meet rules and customer needs.

Applications Across Industries

EMS PCB is used in many industries to create new ideas. It works for everything from gadgets to healthcare tools. Here are some ways EMS PCB helps different fields:

- Electronics Manufacturing Services (EMS): Makes and tests PCBs for many industries.

- Automotive: Strong and bendable PCBs are used in cars and electric vehicles.

- Medical Devices: Reliable PCBs power tools like pacemakers and scanners.

- Microelectronics: Tiny parts like chips are used in phones and wearables.

- Optoelectronics: PCBs help devices like fiber optic tools for fast data sharing.

- Wireless Technologies: PCBs support devices like RFID for easy data transfer.

This flexibility makes EMS PCB important for industries wanting to grow and stay ahead.

Examples of Products Using EMS PCB

Real-life examples show how EMS PCB changes manufacturing. Big companies use EMS to make their best products. Here are some partnerships:

| Company | EMS Provider | Description |

|---|---|---|

| Tesla | Jabil | Helps make parts for electric cars, speeding up production. |

| Philips | Flex | Builds medical tools, making work easier and reaching more people. |

| Apple | Foxconn | Produces iPhones and iPads, letting Apple focus on design. |

These examples show how EMS helps companies grow and improve. Whether it’s a car or a phone, EMS PCB ensures products are top quality and work well.

Benefits of EMS PCB

Saving Money and Scaling Production

EMS manufacturing helps save money and grow production easily. By buying in bulk, EMS providers cut costs and improve processes. For example, they reduce waste and make production more accurate. This keeps costs low while keeping quality high.

| Cost Factor | Description |

|---|---|

| Bulk Buying | Buying in large amounts lowers the cost per item. |

| NRE Costs | One-time engineering costs drop as production grows. |

| Part Costs | Buying many parts at once makes them cheaper. |

EMS also lets you change production levels quickly. You can make more products for a launch or fewer during slow times. This flexibility means you don’t need to spend a lot on new tools or factories.

Better Quality and Dependability

EMS ensures products are high-quality and dependable with strict checks. Providers follow rules like ISO 9001 and use smart tools like AOI and X-rays. These tools find problems early so only perfect products are sold.

| Quality Check Tool | Description |

|---|---|

| AOI | Checks parts on boards for complete accuracy. |

| X-ray Testing | Finds hidden problems in solder joints. |

| Function Testing | Makes sure the board works as it should. |

More tests, like in-circuit and flying probe, make products even more reliable. SPC tracks things like solder heat to keep quality steady. These steps ensure your products meet top standards.

Quicker Product Launches

EMS speeds up making and selling your products. By letting experts handle production, you can focus on creating new ideas. This teamwork helps test prototypes faster and adjust to feedback quickly.

For instance, companies like SEL make PCBs in just days. They go from design to testing very fast. This speed helps you grab market chances, earn money sooner, and stay ahead of others.

EMS providers can also scale production fast to meet deadlines. Whether launching a new product or handling sudden demand, EMS helps you deliver on time without losing quality.

Challenges in EMS PCB Manufacturing

Common Production Challenges

EMS manufacturing often faces problems that affect speed and quality. Two big challenges are:

| Rank | Challenge | Description |

|---|---|---|

| 1 | Data Accuracy | Keeping data correct and consistent is very important. |

| 2 | User Training | Good training helps users manage ERP systems better. |

Mistakes in data can cause errors in PCB design and assembly. These errors make products less reliable. Without proper training, workers may not use systems well. This can slow down production and create problems. Fixing these issues needs strong systems and regular skill updates.

Quality Control and Testing

Quality checks are very important in EMS manufacturing. Automated Optical Inspection (AOI) tools help ensure PCBs are made correctly. These tools find problems during production and give instant feedback to improve processes. AOI tools have many advantages:

- They check PCBs before and after soldering to find defects.

- Special algorithms compare patterns to check quality and save records.

- They reduce fixing mistakes by spotting problems like:

- Scratches, stains, and bumps

- Broken circuits or short connections

- Missing or wrong parts

- Solder bridges and lifted leads

- Misaligned parts or polarity errors

Using AOI tools makes production faster and keeps quality steady.

Regulatory and Environmental Compliance

Following rules is very important in EMS manufacturing. Breaking rules can lead to fines and hurt your reputation. Compliance programs help avoid risks and meet industry standards.

Making PCBs uses harmful chemicals, so safe disposal is needed. Environmental rules push companies to lower their impact on nature. These rules also encourage eco-friendly practices. By following regulations, you stay legal and help protect the planet.

Trends in EMS PCB

Innovations in PCB Design and Materials

Changes in PCB design and materials have improved EMS manufacturing. New technologies help make better and more reliable products. Important advancements include:

- AI-driven design automation: AI makes designing PCBs faster and reduces mistakes.

- Flexible and rigid-flex PCBs: These boards are great for small and bendable devices like wearables and space tools.

- Advanced materials: Strong materials like Rogers and Teflon make PCBs last longer and handle heat better.

These improvements help meet the needs of modern electronics while keeping quality high.

Automation and Smart Manufacturing

Automation and smart tools have changed EMS manufacturing. Industry 4.0 connects systems and uses real-time data to improve production. Here’s how these changes help:

| Aspect | Description |

|---|---|

| Cost Efficiency | Bulk buying and better processes save money. |

| Faster Time-to-Market | Quicker production helps businesses stay ahead of others. |

| Industry 4.0 Impact | Connected systems and live data make work smoother. |

| Advanced Robotics and Automation | Robots and machines do precise work and need less human help. |

| Big Data Analytics and AI | AI and data tools plan better and check quality faster. |

Using these tools lowers costs, speeds up production, and keeps businesses competitive.

Sustainability in Electronics Manufacturing Services

Sustainability is now a big part of EMS manufacturing. Eco-friendly methods help protect the planet and attract green-minded buyers. Key ideas include:

- User-centered designs: Focus on useful designs to avoid waste from redesigns.

- Durable and modular components: Make products last longer and easier to fix, reducing trash.

- Recyclability and biodegradability: Use materials that break down or can be reused.

- Energy-efficient electronics: Create devices that use less power and save energy.

These steps follow environmental rules, improve your brand image, and cut costs over time. By choosing sustainability, you help the planet and meet customer needs.

Choosing the Right EMS Provider

Key Factors to Consider

Picking the right EMS provider is very important. It helps your electronics projects succeed. Here are some things to think about:

- Industry Experience: Pick a provider with success in your field. For example, those making medical devices know the rules and challenges.

- Certifications: Look for ISO 13485 or FDA approval. These show they follow global quality standards.

- Technology and Equipment: Modern tools like automated machines and PCB software make work faster.

- Quality Control: Strong systems ensure every product meets high standards.

- Geographical Location: Being close to your market saves time and improves efficiency.

By checking these points, you can find a provider that fits your needs and goals.

Importance of Expertise and Experience

A provider’s skill and experience affect your product’s quality. Skilled EMS providers bring helpful ideas from their work history. They use proven methods to make better decisions and improve results.

Experienced teams often review their work to get better. For example:

- Certified workers learn from past projects to gain confidence.

- Less experienced teams improve by studying outcomes and learning new skills.

This focus on getting better ensures your products are reliable and reduces mistakes during production.

Evaluating Certifications and Standards

Certifications and rules are key when choosing EMS providers. They prove the provider can make quality products and follow industry rules. The table below shows important metrics to check:

| Metric | Value |

|---|---|

| PCRs Year-to-Date | 13,225 |

| Reporting EMS Agencies | 7 |

| Fastest Time from Record Completion to Database | 22,085,957 mins |

| Compliance Testing Status | Link |

| State Data Maps and Compliance Information | Link |

Certifications like ISO 9001 and ISO 13485 show the provider meets quality and safety rules. These standards improve product reliability and protect your brand in the market.

The use of EMS PCB has changed how electronics are made. It makes production faster, improves quality, and encourages new ideas. EMS PCB helps industries create better products quickly and at lower costs.

| Feature | Example |

|---|---|

| Faster Process | EMS providers speed up production for quicker product launches. |

| Better Quality | Tests like AOI and ICT ensure products work well and last longer. |

| Lower Costs | Working with EMS vendors saves money and allows easy scaling. |

Choosing the right EMS provider is very important. Experts help you focus on creating new ideas while keeping quality high. This smart choice helps your products succeed in a tough market.

FAQ

What is the difference between EMS and PCB?

EMS means Electronics Manufacturing Services. It includes designing and testing electronics. PCB stands for Printed Circuit Board. It connects electronic parts on a physical board. EMS uses PCBs to build complete devices.

How do you choose the right PCB type for your product?

Think about your product’s size, use, and complexity. For example:

- Single-sided PCBs are good for basic gadgets.

- Multilayer PCBs fit small devices like phones.

- Flexible PCBs work for bendable or wearable items.

Why is quality control critical in EMS PCB manufacturing?

Quality checks make sure products work well and meet standards. Tools like AOI and X-rays find mistakes early. This reduces errors and improves product reliability.

Can EMS PCB manufacturing support small-scale production?

Yes, EMS providers can make small batches. They offer flexible options for prototypes or special markets. You don’t need costly equipment for small-scale production.

How does sustainability impact EMS PCB manufacturing?

Sustainability reduces waste and uses eco-friendly materials. Modular designs and recyclable parts help meet green rules. Energy-saving processes also attract eco-friendly buyers.