Why did Lithuania choose Chinese PCB factory for PCBA?

Lithuania’s tech industry collaborates with Chinese PCB factories for good reasons. They provide fast turn PCBA solutions that save money, time, and ensure quality. Chinese factories utilize advanced tools and streamlined processes to comply with global standards. This enables projects to be completed on time with excellent results. By choosing these factories, Lithuania maintains its competitiveness in the global electronics market and enhances its product manufacturing capabilities.

Key Takeaways

- Lithuania saves money and gets faster production by working with Chinese PCB factories. This makes manufacturing cheaper and quicker.

- Chinese factories follow strict rules and checks to keep quality high. Their products are reliable and well-made.

- Modern machines and automation in Chinese factories help make things faster and more accurate. They deliver prototypes and big orders quickly.

- Working with Chinese PCB factories helps Lithuania grow its tech industry. It brings new ideas and makes the country more competitive.

- Chinese factories offer flexible services for different projects. They work well for both simple and complex PCB designs.

Cost Benefits of Chinese PCB Factories

Lower labor and running costs

Chinese PCB factories save money with lower labor and running costs. Workers earn competitive wages, and operations are made more efficient. These factories cut extra expenses, helping you use money wisely. Choosing Chinese factories means affordable production without losing quality. This helps you grow your business or invest in new ideas.

Big production saves money

Chinese PCB factories save money by making many products at once. Large operations lower costs for prototypes and big orders. They use advanced tools to finish work quickly. Their skills ensure good quality, even for large amounts. Factories can easily switch from small orders to big production runs.

| Advantage | Explanation |

|---|---|

| Money-saving | Lower costs due to making many products at once. |

| Faster work | Quick assembly services speed up delivery times. |

| Reliable quality | Advanced tools keep product quality steady. |

| Flexible sizes | Easy switch from small to big orders. |

This system helps meet deadlines while keeping high standards. It gives your business a strong advantage.

Good prices for big and custom orders

Chinese PCB factories offer low prices for big and special orders. They handle large amounts efficiently, saving you money. Whether you need simple or complex designs, they adjust prices to fit your needs. This helps you stick to your budget while getting great products. Working with these factories lets you save money and improve your profits.

High Standards in PCB Quality

Following global certifications (e.g., ISO, IPC)

Chinese PCB factories follow strict rules to meet global standards. These rules come from well-known certifications that ensure safety and quality. For example:

| Certification/Standard | What It Ensures |

|---|---|

| ISO 9001 | Good quality management |

| ISO 13485 | Safe medical device production |

| UL Recognition | Product safety approval |

| IPC-A-600 | PCB quality and workmanship rules |

| IPC-A-610 | PCB quality and workmanship rules |

| RoHS Compliance | Limits harmful materials in products |

| REACH Compliance | Controls harmful substances in manufacturing |

By following these certifications, factories show they care about quality and the environment. This builds trust and ensures your PCBs meet world standards.

Strong quality checks

Chinese PCB factories use strong systems to keep quality high. These include:

- DFM (Design for Manufacturability): Working early with designers to make production easier.

- Quality Inspection: Checking production steps to stop mistakes early.

- Reliability Testing: Testing products in tough conditions to check durability.

Factories also use a clear quality control plan:

| Quality Control Step | What It Does |

|---|---|

| First Article Inspection (FAI) | Makes a small batch to check for design problems early. |

| In-Process Inspection | Watches production closely to catch mistakes fast. |

| Final Inspection | Tests finished PCBs for quality and performance. |

These steps make sure every PCB works well and lasts long.

Trusted for reliable PCBs

Chinese factories are known for making dependable PCBs. They use modern tools, skilled workers, and strict quality checks. Certifications like ISO 9001 and UL prove their reliability. Many factories also make PCBs for important industries like cars and healthcare, where accuracy is key.

Choosing these factories gives you a trusted supply chain. You can focus on new ideas, knowing your PCBs will work perfectly.

Technological Edge in PCB Manufacturing

Modern tools and equipment

Chinese PCB factories use the latest tools for great results. They work with advanced materials and methods to meet today’s tech needs. For example, they use special materials for high-speed performance. They also manage heat well for powerful AI chips. These upgrades make sure your PCBs work in tough conditions.

Key features of their modern tools include:

| Feature | Specification |

|---|---|

| Dielectric Constant | 2.20±0.02 at 10GHz |

| Dissipation Factor | 0.0009 at 10GHz |

| Coefficient of Thermal Expansion (CTE) | 31 ppm/°C in X-axis |

| Moisture Absorption | 0.02% |

Factories now make boards with over 16 layers for AI servers. Older servers used only 8-12 layers. They also improved precision, tightening tolerances from ±10% to ±3%.

Skilled in tricky and custom designs

Chinese factories are experts in making complex and custom PCBs. They use tools like Altium Designer to check for errors during assembly. This saves time and fixes problems early. Simulation tools, like Power Analyzer, find power issues before production starts.

They also combine mechanical and electronic designs well. Tools like MCAD CoDesigner prevent design clashes. Wiring tools improve how systems connect. These skills let you create unique designs without losing quality.

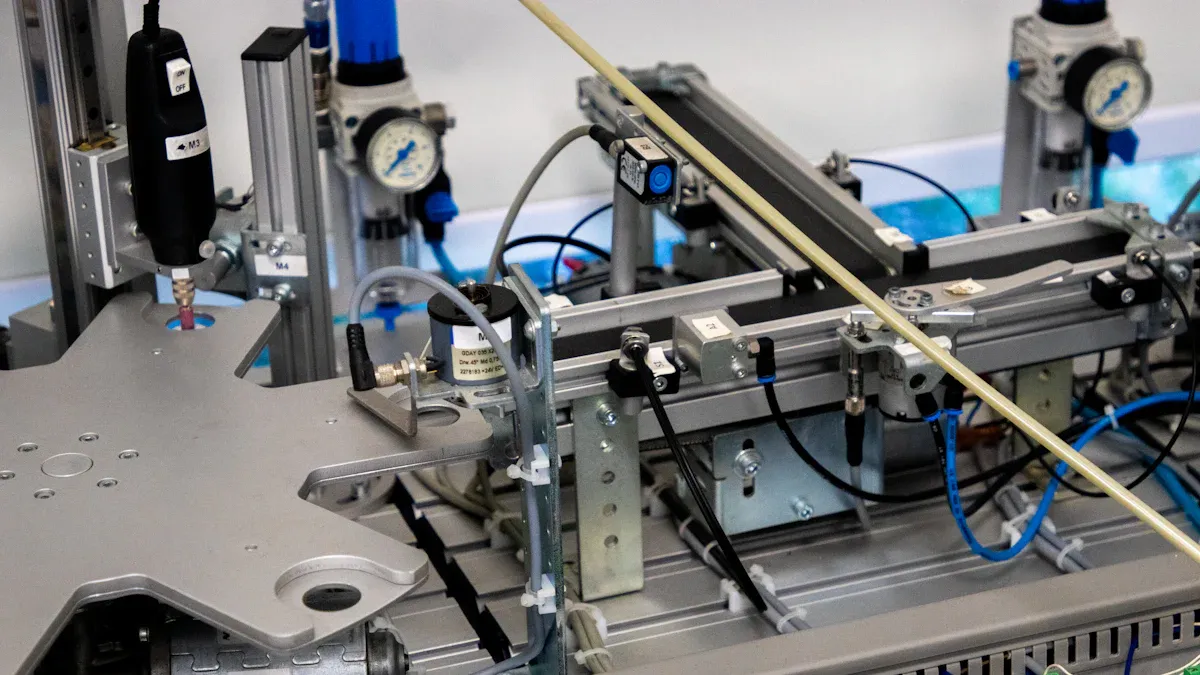

Automation for better speed and accuracy

Automation is key to Chinese PCB factories’ success. AI-powered systems check designs automatically, reducing human errors. This keeps quality steady across all products. Cloud-based tools share data worldwide, improving quality predictions.

They combine SPI and AOI systems for full quality checks. This ensures every part of the PCB meets high standards. With 24/7 automated production, factories handle urgent orders quickly and accurately.

By using modern tools, expert designs, and automation, Chinese PCB factories help you stay ahead in the electronics market.

Speed and Efficiency in Fast Turn PCBA

Quick delivery for prototypes and production

Chinese PCB factories are great at fast PCBA services. They can make prototypes in just 24 hours. This speed helps you test and improve designs quickly. It ensures your products are ready for the market without delays. Whether you need one prototype or a small batch, their advanced tools deliver on time.

Using modern automation tools, they make prototyping faster. For example:

- PCB machines ensure precise results with tiny measurements.

- Special cutting tools last longer, saving time during work.

- Design tools improve teamwork and speed up product creation.

This mix of speed and accuracy ensures your prototypes are ready for testing. Quality is never sacrificed during the process.

Better logistics and supply chain

Good logistics and supply chains are key to fast PCBA. Chinese factories use a strong supply chain to get quality parts quickly. This system shortens wait times and ensures reliable materials for your products.

Main benefits include:

- Access to global suppliers for authentic and compatible parts.

- Lower labor costs make assembly cheaper and more efficient.

- Steps in the supply chain are optimized to avoid delays.

These advantages help you get finished products faster. This keeps you ahead in competitive markets.

Non-stop production for urgent needs

Chinese PCB factories work 24/7 to meet tight deadlines. They handle big orders quickly without losing quality. Some factories can produce 25,000m² and respond to urgent needs in two hours.

Their facilities follow strict quality rules like IPC Class 2/3. Even rush orders meet high standards. This flexibility lets you scale production fast, whether for prototypes or large orders.

With advanced tools, strong supply chains, and nonstop work, Chinese factories offer unmatched speed. They ensure your projects are always finished on time.

Strategic Partnerships and Global Supply Chain Benefits

Strong trade ties between Lithuania and China

Lithuania and China work together in trade to help both countries. This teamwork lets Lithuania use China’s advanced factories and grow its economy. Chinese PCB factories provide steady delivery of top-quality parts. These strong connections also help Lithuania learn new ways to make electronics better. By working with China, you can improve how fast and well your products are made.

Comprehensive PCBA services (design, assembly, testing)

Chinese PCB factories handle all PCBA steps, like design, assembly, and testing. They make sure every part of the process is done well. For example:

| Service Type | What It Includes |

|---|---|

| Embedded Development | Full design help, like making circuits and software. |

| Quality Assurance | Careful checks like Design for Manufacturability (DFM) and Design for Testability (DFT). |

| Electronic Components Sourcing | Options to get parts from trusted suppliers. |

These services include:

- Factories checking their own work and each other’s.

- Experts reviewing designs to meet high standards.

- Careful checks at every step of the process.

You can pick how to get parts:

- Get all parts from trusted suppliers.

- Bring your own parts for the factory to use.

- Mix: You bring some parts, and the factory provides others.

This setup makes sure your project gets what it needs without losing quality.

Flexibility to meet diverse project requirements

Chinese PCB factories are great at handling different project needs. Whether you need a simple board or a complex one, they can help. They can quickly make more products if needed to meet deadlines. Their global supplier partnerships ensure they use the best materials. This flexibility makes them a good choice for any project, big or small.

Impact on Lithuania’s Tech Industry

Using saved money for new ideas

Choosing Chinese PCB factories helps save a lot of money. Lithuania can use these savings to work on new ideas. More money means better research and improved products. For example, saved funds can help test new materials or designs. This makes Lithuania stronger in technology and helps it grow in the electronics field.

Competing better in the world market

Chinese PCB factories help Lithuania make great products for less money. This lets Lithuania sell affordable and reliable electronics. Lower prices attract more customers from around the world. Fast production also helps meet tight deadlines. These benefits let Lithuania compete with bigger companies and grow in the global market.

Teaming up with top Chinese tech companies

Working with Chinese PCB factories creates chances to partner with big tech firms. These partnerships bring new tools and skills to Lithuania. Lithuania can learn how to handle tricky designs and large orders. Sometimes, these partnerships lead to creating new products together. This teamwork improves Lithuania’s skills and connects it to the global tech world.

Lithuania works with Chinese PCB factories for key reasons. They offer fast and reliable services to meet deadlines. Their skills in PCBA make them great for improving production. This shows how global teamwork helps tech grow and compete. By partnering with them, you can succeed in a fast-changing market.

FAQ

Why choose a Chinese PCB manufacturer?

Chinese PCB makers are affordable, fast, and use advanced tools. They handle big orders well and keep prices low. This makes them great for both small and large projects.

How do they make PCBs quickly?

Chinese factories use automation and smart tools to save time. They also have good logistics to finish orders fast without losing quality.

Can I buy a small number of PCBs?

Yes, you can order small amounts from Chinese factories. They offer flexible options, like prototypes, to test your designs before making more.

What certifications do they follow?

Chinese PCB factories follow global rules like ISO 9001 and RoHS. These certifications ensure safety, quality, and eco-friendly production.

How do I order from them?

You can contact them directly or use their websites. Share your design files, details, and how many you need. Many factories also help improve your designs with prototype services.