High-tech & High-quality Complex PCB one-stop Manufacturer

- Home

- PCB Fabrication

Fabrication Capability-King Field PCB

| PCB Types | Rigid PCB | FR-4 PCB | Aluminum PCB | Copper PCB | Ceramic PCB | Flex PCB | Rigid Flex PCB |

| PCB Samples | 3 Days | 3 Days | 3 Days | 3 Days | 8-10 Days | 4-6 Days | 4-6 Days |

| Expedited Samples | 48 Hours | 24 Hours | 48 Hours | 48 Hours | 5 Days | 3 Days | 3 Days |

| Double-sided PCB | 3-5 Days | 3-5 Days | 7-9 Days | 7-9 Days | None | 10-12 Days | 10-12 Days |

| Multi-layer PCB | 5-10 Days | 10-12 Days | 10-12 Days | 10-12 Days | None | 7-9 Days | 9-13 Days |

| Volume Production | 8-10 Days | 8-10 Days | 2 Weeks | 2 Weeks | 2 Weeks | 2 Weeks | 2 Weeks |

| Item | Capabilities | PCB Materials | Attribute |

| Layer Count | 1 – 10 Layers | Brand | Bergquist / Bode / Boyu / Larid / Metal board / Ventec |

| Max Board Dimension | 24*64″(610*1625mm) | Base Material | Aluminum / Copper / Stainless steel |

| Min Board Thickness | 0.6mm | Base Material Thickness (exclude CU) | 0.30mm / 0.40mm / 0.50mm / 0.60mm/ 0.80mm /1.0 mm/ 1.2 mm / 1.6mm / 2.0 mm / 2.4mm / 3.0mm |

| Max Board Thickness | 4.0mm | Thermal Conductivity | 1W / 1.5W / 2.0W / 3.0W |

| Conductor Thickness | 0.5oz – 10oz | Soldermask Type | Soldermask oil (white , black , green , blue , yellow , red ) |

| Min Line Width/Line Space | 4/4mil (0.10/0.10mm) | Tg Value | 130 / 150 |

| Min Hole Diameter | 10mil (0.25mm) | Halogen Free | Yes(optional) |

| Min Punch Hole Dia | 0.12″ (3.0mm) | ROHS | Yes |

| Min Hole Spacing | 16mil (0.4mm) | Flammability | 94V-0 |

| Min PAD Ring(Single) | 3mil (0.075mm) | Thermal Conductivity (W/m.K, or W/m.C) | Normal: 0.8~1.0, 1.5; High: 2.0, 3.0 |

| PTH Wall Thickness | Normal: 0.59mil (15um); HDI: 0.48mil (12um) | Dielectric Strength | >1.5 Kv (L/S >1.5mm); >3.0 Kv (L/S >3.0mm) |

| Min Solder PAD Dia | 14mil (0.35mm) | Wrap & Twist | ≤ 0.75% |

| Min Soldermask Bridge | 8mil (0.20mm) | Thermal Stress | 3 x 10 Sec @ 280 ℃ |

| Min BAG PAD Margin | 5mil (0.125mm) | ||

| PTH/NPTH Dia Tolerance | PTH: ±3 mil (0.075mm); NPTH: ±2mil (0.05mm) | ||

| Hole Position Deviation | ±3mil (0.075mm) | ||

| Outline Tolerance | CNC: ±6 mil (0.15mm); Die Punch: ±6 mil (0.1mm) | ||

| Max Aspect Ratio | 10:01 | ||

| Surface Treatment | ENIG, Flash Gold, Hard Gold Finger, Gold Plating(50mil), Gold finger, Selected Gold Plating, ENEPIG, ENIPIG, HAL, HASL(LF), OSP, Silver Imm, Tin Imm |

| Item | Flex PCB | Rigid PCB | Rigid Flex PCB |

| Materials | PI/PAA/PA/PEN/FEP | XPC/FR-1/FR-2/FR-3/FR-4/CEM | PI/PET |

| Pros | Soft & Bendable & Reduce Space | High Heat Resistance & Low Loss | Perfect Combination |

| Layer | 1-6 Layers | 1-40 Layers | 1-40 Layers |

| Maximum Cutting Board size | 500*400mm | Minimum 3*3mm/Max Legth 1200mm | 500*420mm |

| Finished Plate Thickness | Double-side 0.07-0.2mm | 0.18-5.0mm | 0.20-6.0mm |

| Minimum Finished Product Aperture | 0.075mm | 0.075mm | 0.075mm |

| Aspect Ratio | / | 14:1 | 14:1 |

| Inner layer line width/line spacing | 0.03mm | 0.05mm | 0.05mm |

| Inner layer copper foil thickness | 1/6oz-1oz | 1/2oz~3.0oz | 1/6oz-1oz |

| Minimum dielectric layer thickness | 20um | 50um | 20um |

| Outer layer copper foil thickness | 1/3oz-1oz | Hoz-14oz | 1/3oz-1oz |

| Outer layer line width/line spacing | 0.035mm | 0.05mm | 0.035mm |

| Minimum SMD width | 0.05mm | 0.05mm | 0.05mm |

| Maximum full plug hole diameter | None | 0.5mm | 0.5mm |

| Solder mask bridge width | 0.075mm (green oil/1OZ) | 0.075mm (green oil/1OZ) | 0.075mm (green oil/1OZ) |

| Molding dimension tolerance | ±0.1mm/limit ±0.05mm | ±0.1mm/limit ±0.05mm | ±0.1mm/limit ±0.05mm |

| Minimum hole to edge molding distance | 0.075-0.15mm | 0.15mm | 0.075-0.15mm |

| Minimum bevel angle accuracy tolerance | None | ±3-5° | ±3-5° |

| Inter-layer alignment | ≤0.075mm (1-6 layers) | ≤0.075mm (1-6 layers) | ≤0.075mm (1-6 layers) |

| Minimum inner layer plug-in hole ring | 0.15mm | 0.15mm | 0.15mm |

| Minimum outer layer plug-in hole ring | 0.15mm | 0.15mm | 0.15mm |

| Surface treatment | OSP, immersion gold, electroplating gold finger, immersion silver, electroplating silver, immersion tin | OSP, tin spraying, immersion gold, nickel palladium gold, electroplating gold finger, immersion silver, electrosilver, immersion tin | OSP, immersion gold, electroplating gold finger, immersion silver, electroplating silver, immersion tin, nickel-palladium-gold |

| Board bending & board warping flatness | Reinforced bonding area Negotiable according to customer requirements | ≤0.5% | ≤0.5% Flatness less than 45u |

Own Factory PCB Production Machines

Fast prototyping Metal Core PCB, Multilayer PCB, Rigid-flex PCB, FR4 PCB, Polyimide PCB and Special PCB. 5000㎡ own factory electronic function testing

100% Electronics Testing

Small Batch To Max Valume

4000㎡ Factory, 8 SMT + 4 DIP + 2 ASSY production lines.

PCBA New Customer Promotion

Our own factories provide competitive prices, respond quickly to changes in customer demand.

PCB assembly services include: SMT Assembly, Through Hole PCB Assembly and Box Build Assembly

Military supply factory quality management, ISO 9001 certification

Systematic PCB material management, Max system tracking + refrigerator storage accessories

PCB Application Of Cooperative Clients

Kingfieldpcb has designed, manufactured and assembled PCB types for customers in the medical industry so far: flexible circuit boards, rigid-flex circuit boards, multi-layer PCBs, etc. They are mostly used in medical testing and monitoring.

Our batch PCBA can reach IPC class 3, of which IPC class 2 accounts for up to 99%. Outstanding factory manufacturing capabilities are very suitable for industrial application PCB standards.

King Field is a leader in PCB for automotive motors, inverters, and seat controllers in China. We can complete design, prototyping, electronic testing, production, and assembly services from 0 to 1.

Among consumer electronics products, our PCBs are mostly used in beauty equipment, LED lighting, digital remote controls, home appliances and other fields.

With 20 years of experience in PCB design, manufacturing and assembly, King Field sticks to its original intention and its "win-win" cooperation concept has been recognized by more than 100 countries and more than 3,000 companies.

Complex PCB Deisgn & Manufacturing

Rigid Flex PCB

Rigid flex PCB has the advantages of both flexible circuit boards and rigid boards, making it the most popular printed circuit board in the market. The more layers are laminated, the more complex and difficult it is to manufacture. At present, we can achieve 100% compliance with 40 layers, which can meet the production standards of most customers.

High Density PCB

HDI (High Density) PCBs have a higher wiring density than common PCBs. Along with thinner spaces, smaller vias, and a higher connection pad density, these boards boast a lot of different advantages to the typical prototype circuit boards.

High Frequency PCB

High Frequency Printed Circuit Boards (HF PCBs) are fabricated with special materials that can transmit high frequency signals above 500MHz with minimal losses. They are used in variety of applications including telecommunications, RF microwave, military and aerospace. When designing a high frequency PCB, a designer must and take into considerations a number of parameters to meet the signal requirements of the particular high frequency application. These parameters include dielectric constant (Dk), dissipation factor (Df), coefficient of thermal expansion (CTE), temperature coefficient of dielectric constant (TCDk) and thermal conductivity.

Ceramic PCB

Ceramic PCB is famous for its special manufacturing materials. Its manufacturing process is complex and varied, including thick film, thin film, DPC (Direct Plate Copper-direct), DBC (Direct Bonding Copper), AMB (Active Metal Brazing), LTCC and HTCC. The size can be very small, and the difficulty of connection and wiring increases accordingly.

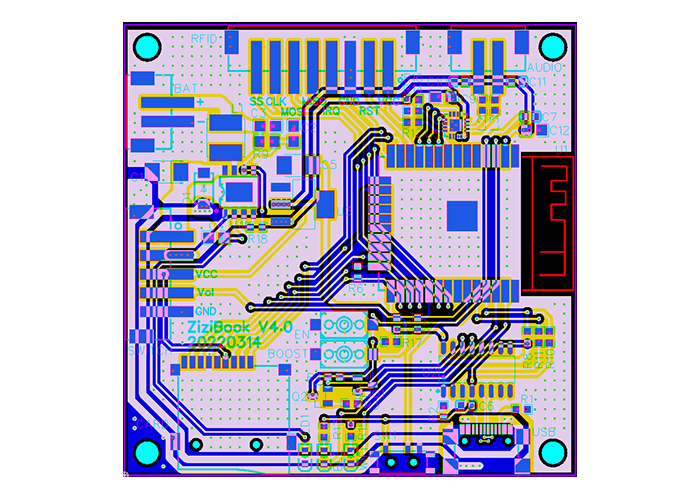

"0-1" PCB Design

King Field can provide “0-1” one-stop PCB manufacturing services. What does “0-1” mean? If you are developing a new project and need a brand new circuit board, we can start PCB design, wiring, material procurement, prototyping, testing, manufacturing and assembly according to the end product. Of course, we also provide design guidance to help you reduce costs and stabilize product performance.

PCB Components Service

Cooperative Brand Logo

Company Certification

With 20 years of PCB service experience, we have been constantly innovating and making breakthroughs, and we have a complete range of relevant certificates, including factory management certification ISO 9001:2015, IATF 16949:2016, safety and environmental protection certificate RoHS, quality certification CE, SGS and design patent certificate, etc. The cooperation concept of “customer first” also helps us to continuously jump over the threshold.

Customer Reviews