KING FIELD ELECTRONIC CO., LTD

PCB/PCBA One-Stop Service Manufacturer

PCB/PCBA One-Stop Service Manufacturer

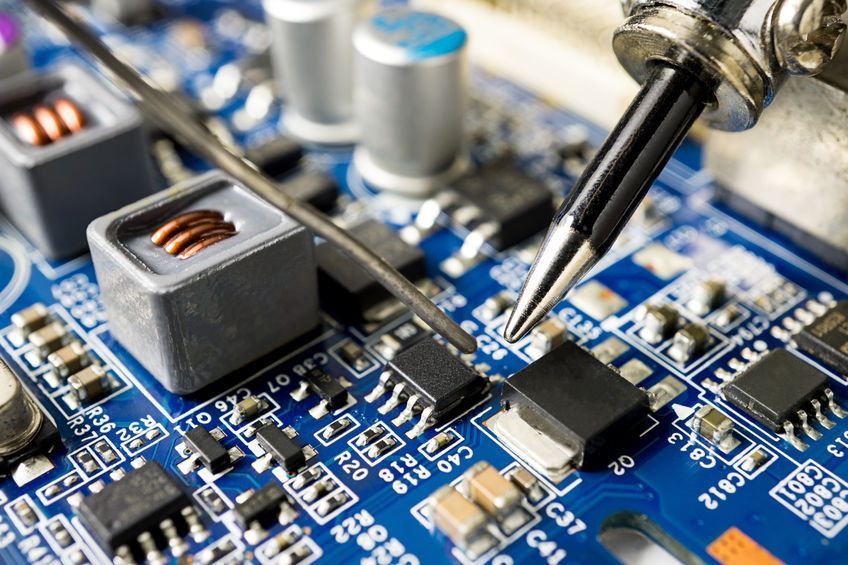

As a leading PCB assembly factory, we are dedicated to providing professional, efficient, and precise PCB assembly services to customers worldwide. Whether it’s Surface Mount Technology (SMT), Through-Hole Assembly (DIP), or finished product assembly, our cutting-edge technology and equipment place us at the forefront of the industry.We leverage advanced production equipment and automated assembly lines to ensure high production efficiency, allowing for quick turnaround times without compromising quality. Each assembly stage is subjected to strict quality control measures, guaranteeing that all products meet rigorous quality standards. Additionally, we offer flexible customization options based on specific client requirements, ensuring that we deliver the best product fit for every unique application.

PCB assembly encompasses the process of mounting electronic components onto a bare board through assembly and soldering techniques, resulting in a fully functional PCBA board. We use surface mount, through hole, and Box Build Assembly to serve full turnkey and consigned PCB assemblies, It ranges from prototype quantities to large production orders.

Our experienced team of PCB assembly has the expertise to assemble PCBs with a level of accuracy and speed. We use the latest tools and technologies to ensure reliable results. With a commitment to quality, reliability, and on-time delivery, we ensure to provide the best possible service.

*We understand all the PCB board assembly requirements vary across different industries whether it is for electronics, medical, telecommunication, or any.

*Whether you require low volume, prototypes, or high-volume PCB assemblies over 10,000 pieces, we work on all types of projects.

*With our circuit board assembly capabilities and the newest technologies, we ensure that our customers will get what they want and when they want.

*All circuit board assemblies are gone through rigorous testing and inspection such as ICT, X-ray, functional testing, AOI and more to ensure the quality.

*Lead free, RoHS compliant material can be available based on customer requirements.

Attaching electronic components directly onto the surface of the PCB and soldering them to the pads.

The following steps are needed in SMT:

Step 1 : A solder paste printer is required to solder paste on components and boards. Use stencil to ensure it is done properly or not.

Step 2 : PCBs are sent to the pick and place machine automatically for mounting components and integrated circuits on the pads with the solder paste effect. After that, the component reels are required for the installation of components onto the PCB boards.

Step 3 : Reflow soldering is done at high temperatures. Circuit boards are placed in an approx. 22-foot-long furnace.

We have extensive experience and expertise in SMT assembly, allowing us to efficiently handle various complex circuit designs. By utilizing advanced SMT equipment, we achieve high-precision placement, ensuring that each component is accurately positioned on the PCB. Our flexible production capabilities support both small-batch and large-scale manufacturing, enabling us to respond quickly to customer demands while maintaining high-quality standards for exceptional product performance and reliability.

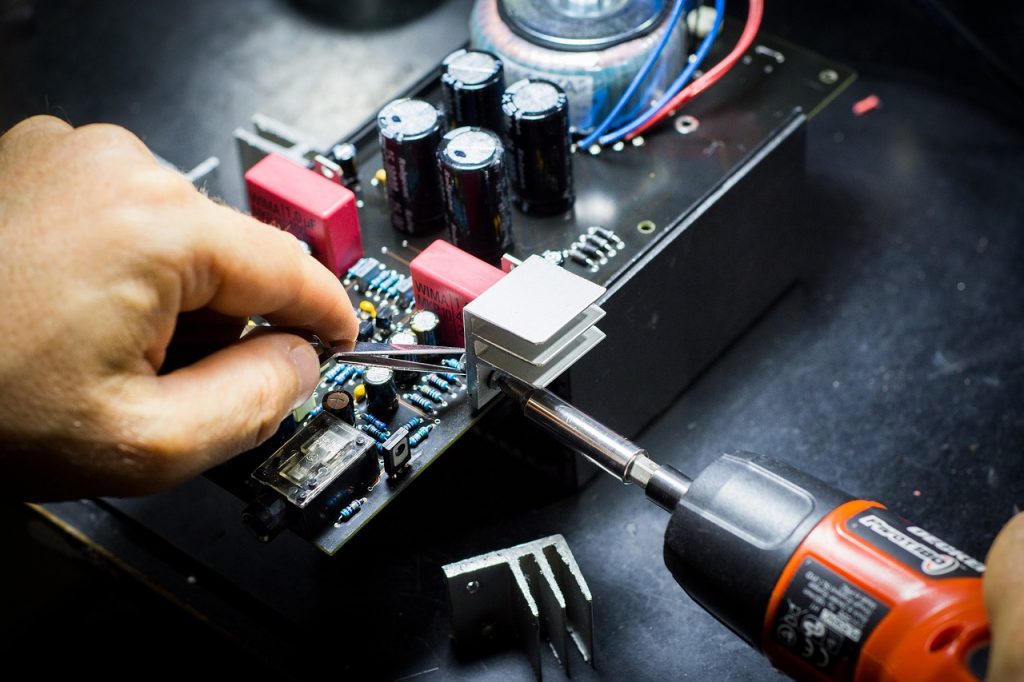

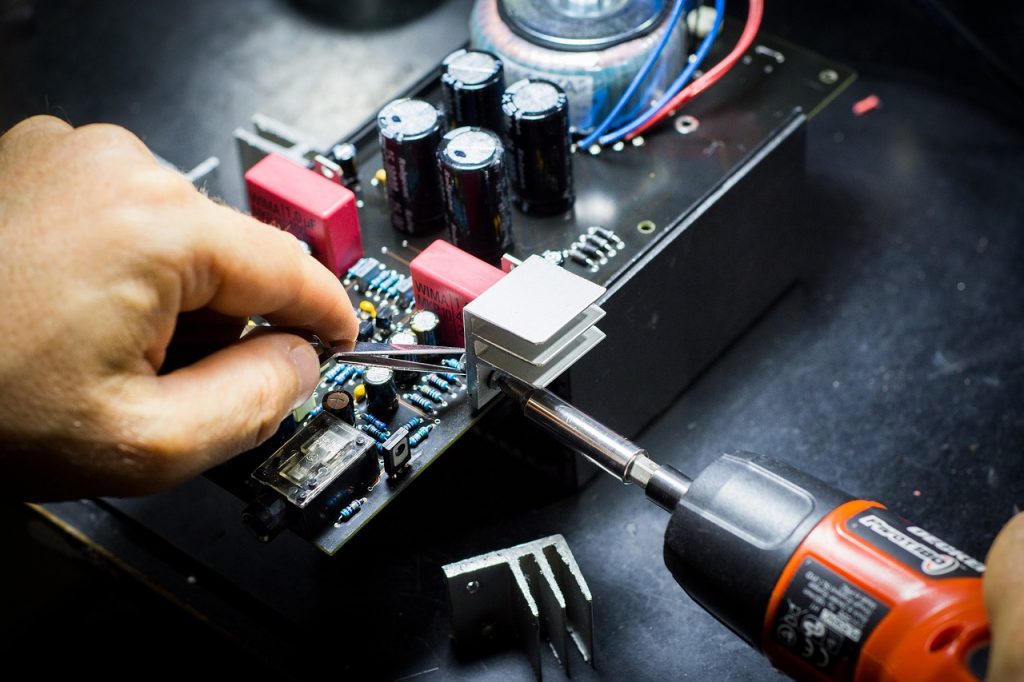

In the field of through-hole assembly, we have a skilled team capable of handling various types of electronic components, including larger and uniquely shaped elements. We implement stringent quality control processes to ensure that each through-hole component undergoes thorough inspection to achieve the highest level of reliability. Additionally, our flexible assembly capabilities allow us to customize solutions based on specific customer requirements, ensuring adaptability and performance for diverse application scenarios.

Combining SMT and Through-Hole Assembly to accommodate different types of components.

The steps usually include the following:

Step 1 : Choose the appropriate components for the PCB assembly, considering the requirements of the design and the functionality of the final product.

Step 2 : Use automated pick-and-place machines or manual placement techniques to mount surface mount components onto the PCB according to the design specifications.

Step 3 : Insert through-hole components into their designated holes on the PCB, ensuring proper alignment and orientation.

Step 4 : Inspect the assembled PCB for any defects or issues, such as solder bridges, component misalignment, or insufficient solder joints.

We offer a one-stop finished product assembly service, managing everything from component assembly to final testing and packaging to ensure products meet customer specifications. Our team pays close attention to detail when integrating various components, implementing rigorous quality control and testing procedures to ensure the finished products meet or exceed performance standards. We are committed to enhancing our customers’ market competitiveness by providing efficient and reliable finished product assembly solutions, allowing them to focus on their core business.

Assembly Types | ● SMT Assembly( with AOI inspection); ● BGA Assembly(with X-Ray inspection); ● Through-hole Assembly; ● SMT & Through-hole Mixed Assembly; ● Kit Assembly |

Quality Inspection | ● AOI Inspection; ● X-Ray Inspection ● Voltage Test; ● Chip Programming; ● ICT Test; Functional Test |

PCB Types | Rigid PCB、Metal core PCB、Flex PCB、Rigid-Flex PCB |

Component Types | ● Passives, smallest size 0201(inch) ● Fine-pitch chips to 0.38mm ● BGA (0.2mm pitch), FPGA, LGA, DFN,QFN with X-Ray testing ● Connectors and terminals |

Components Sourcing | ● Full turnkey (All components sourced by Yingstar); ● Partial turnkey; ● Kitted/Consigned |

Solder Types | Leaded; Lead-Free(Rohs);Water soluble solder paste |

Files Required for Quote and Production | ● Gerber RS-274X, 274D, or PCB Design file ● BOM (Bill of Materials, .xls, xlsx) ● Pick-N-Place file / XY file (for production only) |

Order quantity | ● 5pcs to 100,000pcs; ● From Prototypes to Mass Production |

Assembly Lead Time | From 8 hours to 72 hours when parts are ready |

select-content | Incoming quality control: Check whether the raw materials, such as electronic components, are the same with the BOM list provided by customer, ensure the raw materials meet the customer’s requirement. PCB board testing, solderablity testing, paste fluxtesting. |

In-process quality control | There will be visual for each process. |

AOI and X-ray testing | AOI is commonly used to test for defects in the inner layer prior to lamination. It includes solder amount, component location, defect and polarity, and solder joint defects. X-ray testing focuses on the fine and micro defects after lamination and can test wiring assemblies, semiconductor package, BGA solder defects, solder joint voids. |

ICT test | ICT test is mainly used to test the welding condition of components, on-off of circuit, voltage and current value, fluctuation curve, amplitude and noise. |

FCT test | FCT test needs IC program burning, then connect PCBA board with load, simulate user input and output, detect the function of PCBA board, find the problems in hardware and software, realize the hardware and software connection, ensure the front-end manufacture and welding normal. |

Aging test | The aging test is to sample the PCBA board, simulate the high-frequency and long-time operation of the user, observe whether the PCBA board is invalid, judge the probability of the test failure, so as to feedback the working performance of PCBA board in electronic products. |